Hollow cast ingot inner hole casting device

A hollow ingot and inner hole technology, applied in ingot workshops, foundry workshops, casting equipment, etc., can solve the problems of solid ingot quality, large volume, affecting the pass rate of ingots, unstable casting quality, etc., to improve mechanical strength Performance and uniformity, improvement of microstructure uniformity, and the effect of solving the increase in production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

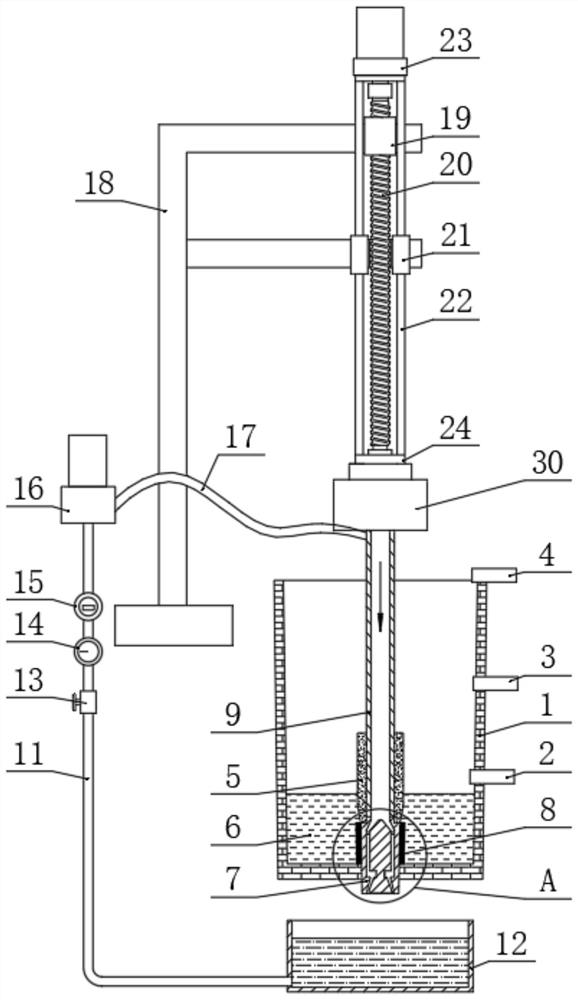

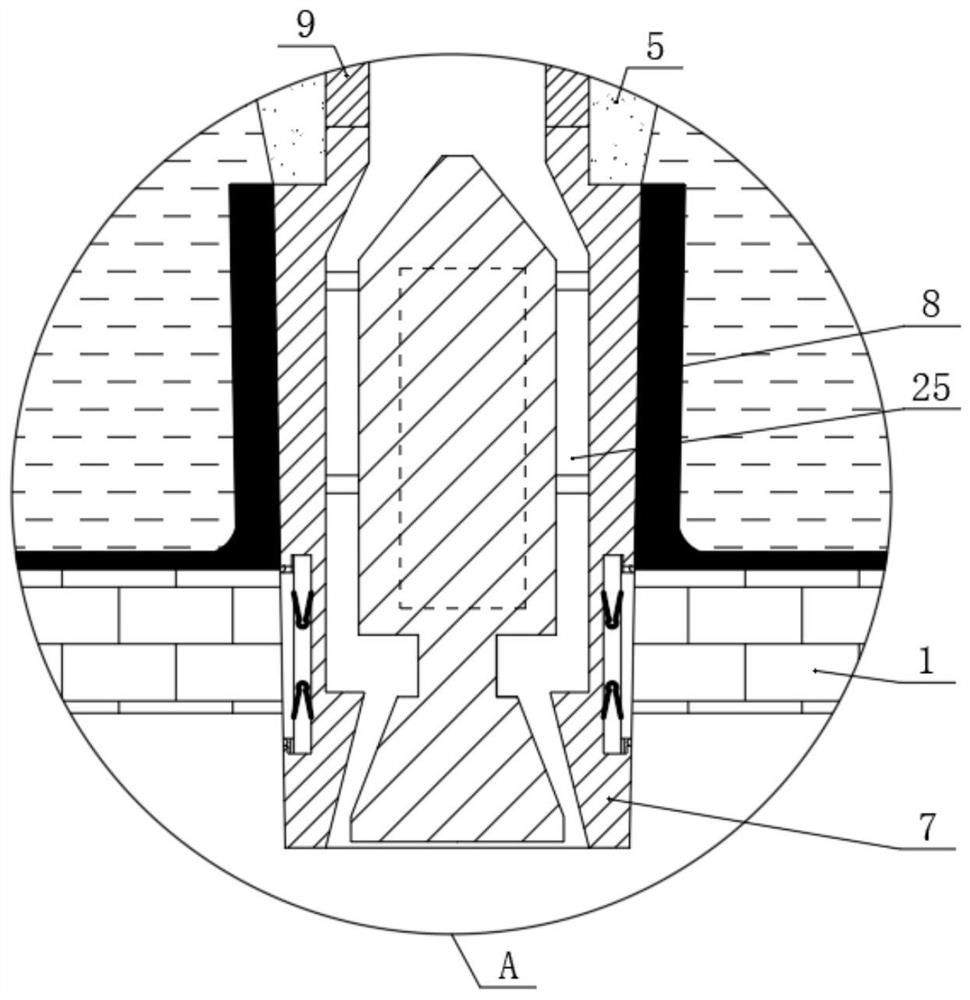

[0030] In this embodiment, for the device for casting the inner hole of the hollow ingot, please refer to figure 1 , comprising an ingot mold 1, a first liquid inlet 2, a second liquid inlet 3 and a third liquid inlet 4 are fluidly communicated on the side wall of the ingot mold 1 from bottom to top along its height direction, and the A cooling and forming mechanism is inserted into the ingot mold 1, a lifting mechanism is arranged above the cooling and forming mechanism, a connecting pipe 9 is arranged on the top of the cooling and forming mechanism, and a connecting seat 30 is arranged on the top of the connecting pipe 9. The top of the connecting seat 30 is fixedly connected with the driving end of the lifting mechanism, the oscillator 10 is arranged in the cooling forming mechanism, the liquid inlet end of the cooling forming mechanism is connected with the cooling mechanism, and the lifting mechanism drives the The cooling forming mechanism moves along the height directio...

Embodiment 2

[0039] see Image 6In this embodiment, an external crystallizer 26 is arranged on the outer wall of the ingot mold 1, and the upper part of the side wall of the external crystallizer 26 is connected with an external crystallizer water inlet 28, and the lower part of the side wall of the external crystallizer 26 is connected with an external crystallizer. The crystallizer water inlet 27, the bottom of the ingot mold 1 is an ingot tray 29 with a central hole, and the edge of the ingot tray 29 is sealed with the inner wall of the ingot mold 1, and the crystallizer 7 is inserted into the central hole of the ingot tray 29 , the metal liquid enters the ingot mold 1 through the first liquid inlet at the top of the ingot mold 1;

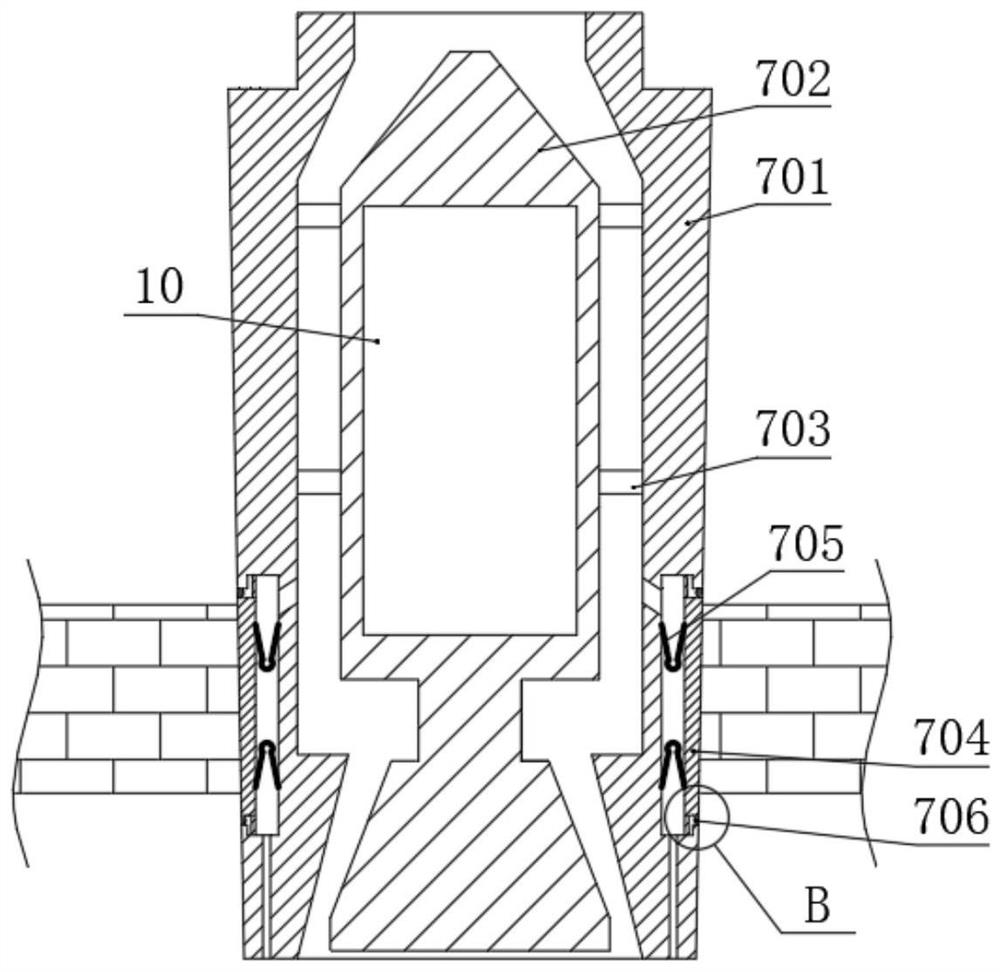

[0040] The top of the crystallizer 7 is fixedly connected with a connecting pipe 9, and the bottom end of the connecting pipe 9 is covered with a refractory material sleeve 5, the bottom of the refractory material sleeve 5 is fixedly connected with the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com