Five-piece material-saving and energy-saving motor end cover casting template

A technology of motor end cover and five pieces in one mold is applied in casting and molding equipment, molds, mold components, etc., and can solve the problems of low process yield, large loss of raw materials and energy consumption, and low production efficiency of single-piece molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

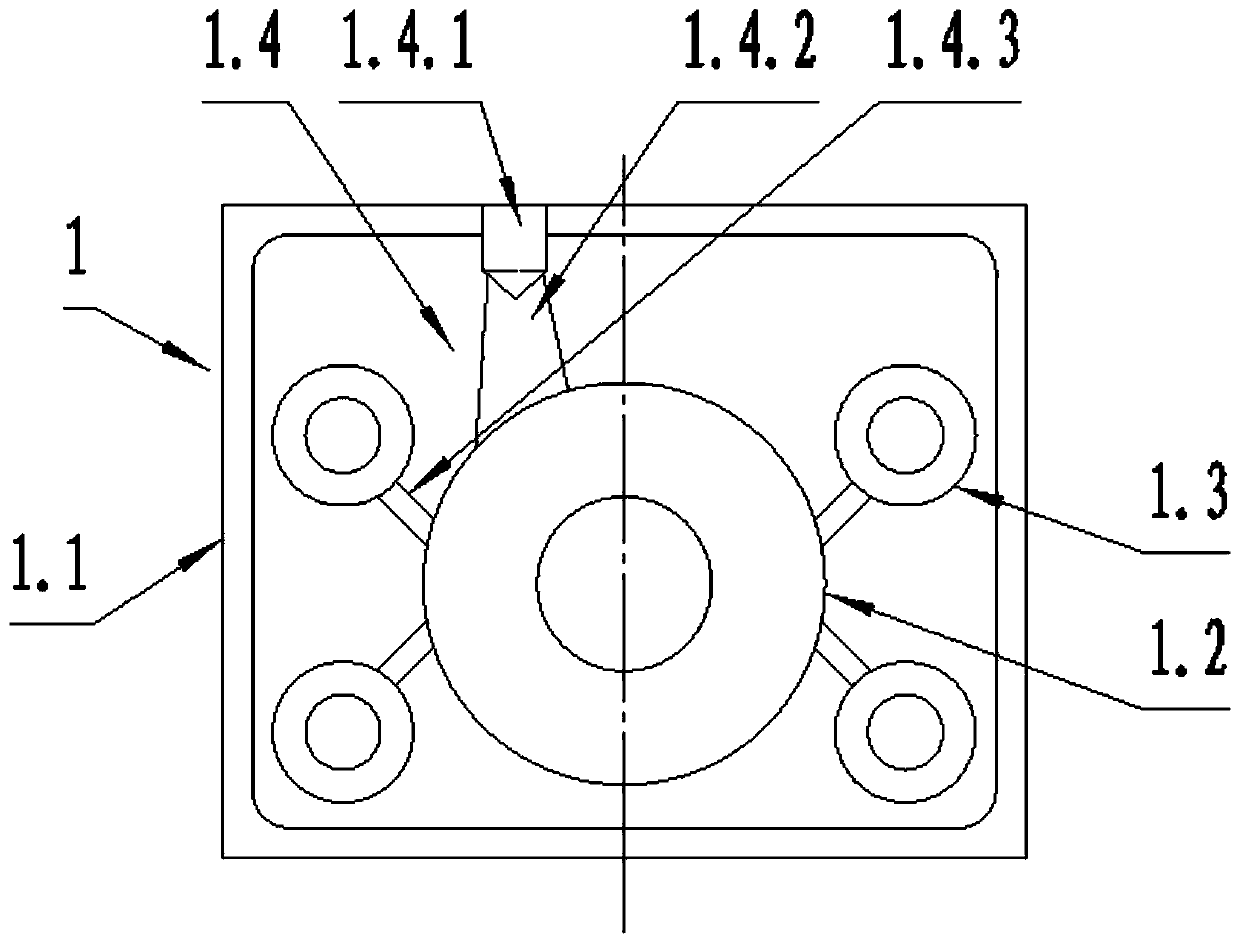

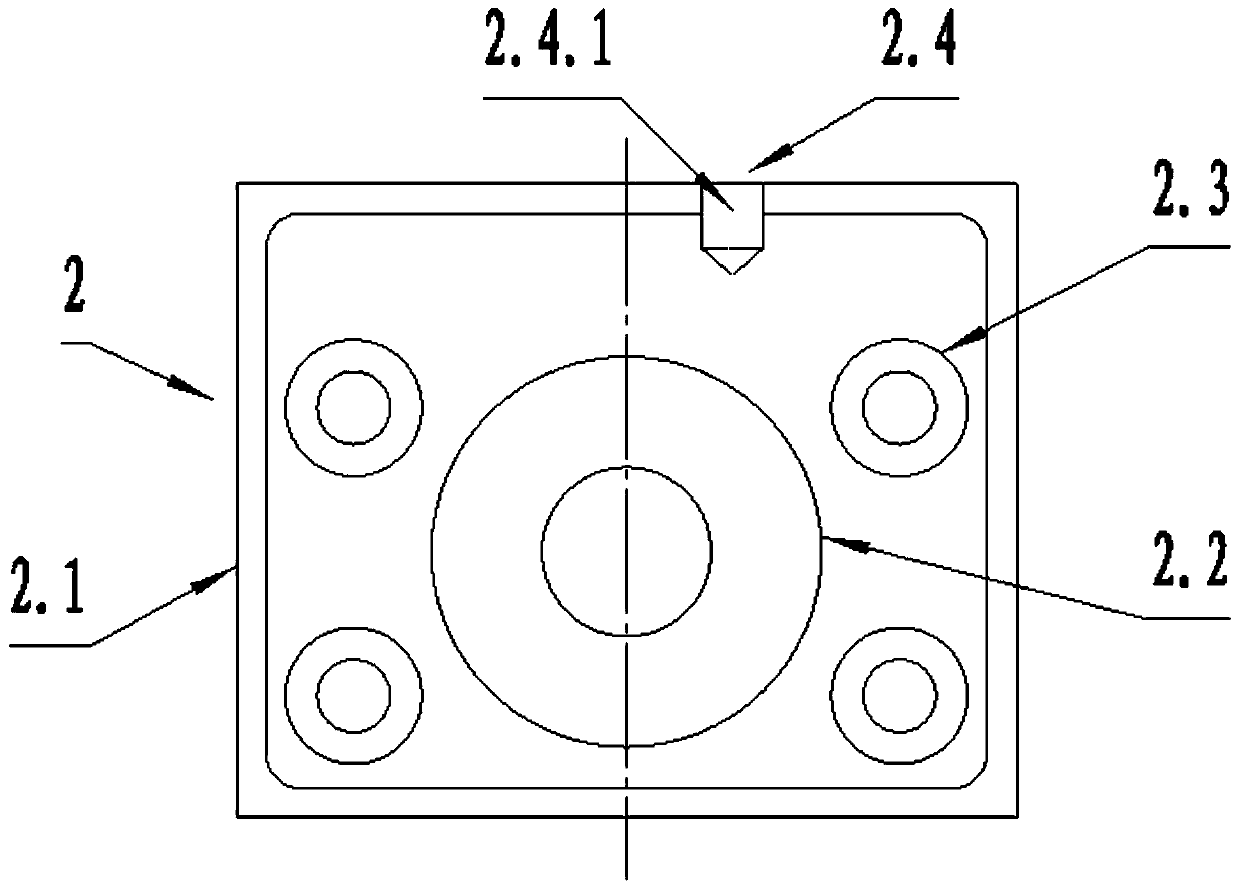

[0025] like Figure 1-2 As shown, a five-piece material-saving and energy-saving motor end cover casting template in this embodiment includes a left template (1) and a right template (2) for vertical parting;

[0026] Described left formwork (1) comprises left formwork bottom plate (1.1), large casting body pattern (1.2) and small casting body pattern (1.3), and left mold pouring pattern (1.4), and described large casting body pattern (1.2) is One, fixed on the middle of the left mold bottom plate (1.1), four small casting body templates (1.3), surrounding the periphery of the large casting body pattern (1.2), two on the left and right, symmetrically fixed at even intervals set on the left mold bottom plate (1.1); the left pouring pattern (1.4) is fixedly set on the left mold bottom plate (1.1);

[0027] Described right formwork (2) comprises right mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com