Welding structure of lithium battery and circuit board and welding method

A welding method and welding structure technology, applied in the direction of circuits, structural parts, battery pack parts, etc., can solve problems such as scrapping and inability to rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

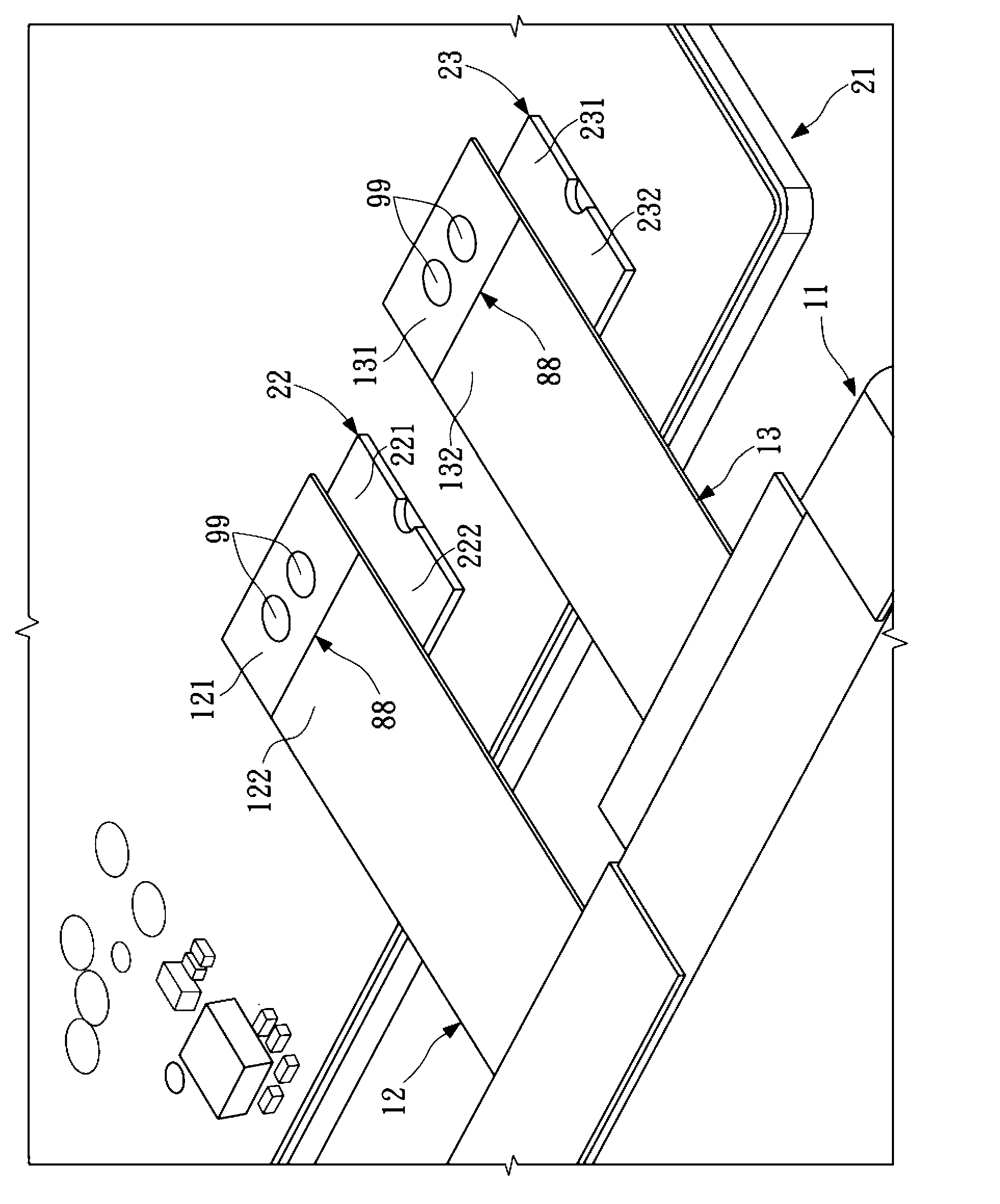

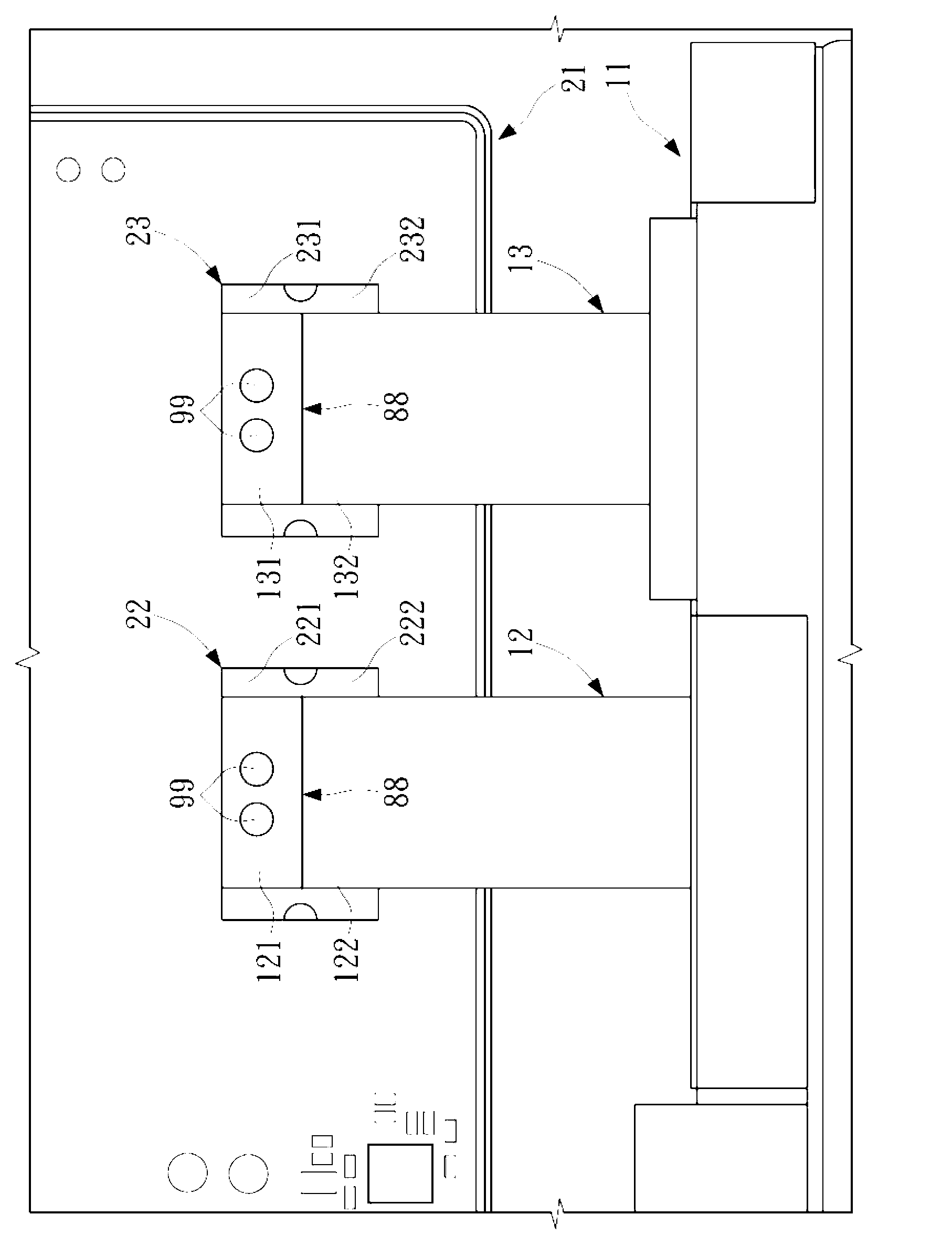

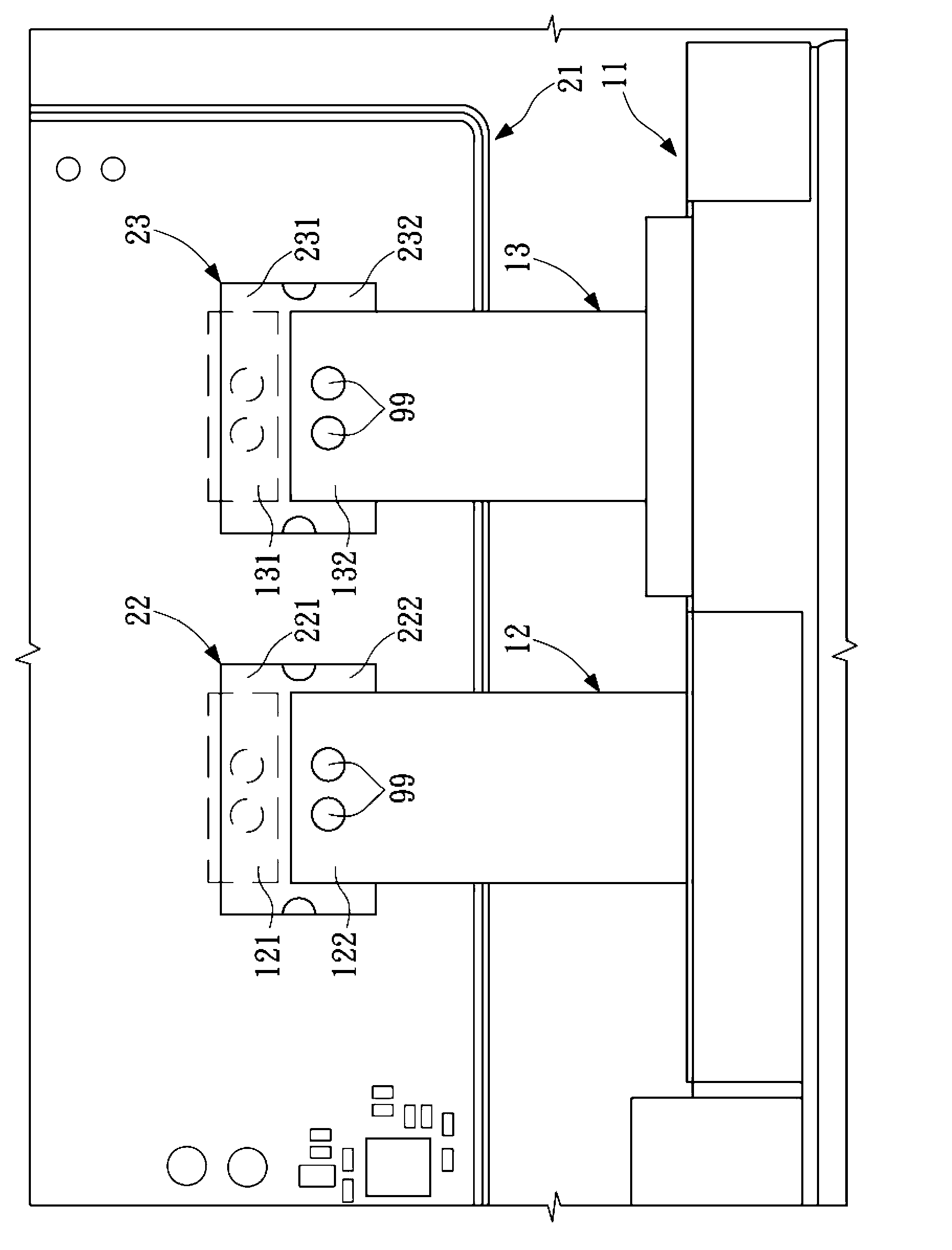

[0060] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0061] Please refer to figure 1 and figure 2 , are schematic diagram (1) and schematic diagram (2) respectively of the first embodiment of the present invention, disclosing a welding structure of lithium battery 11 and circuit board 21 . Wherein, the lithium battery 11 includes a positive electrode plate 12 and a negative electrode plate 13 , the positive electrode plate 12 includes a first positive electrode welding portion 121 and a second positive electrode welding portion 122 , and the second positive electrode welding portion 122 is connected to the first positive electrode welding portion 121 . The circuit board 21 includes a positive electrode welding pad 22 and a negative electrode welding pad 23, the positive electrode welding pad 22 includes a first positive electrode welding area 221 and a second positive electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com