Gas water heater, wind pressure detection method and fan control method

A technology of a gas water heater and a control method, which is applied to the control of fluid heaters, water heaters, fluid heaters, etc., can solve the problems of low sensitivity, delayed wind resistance of gas water heaters, potential safety hazards, etc. Time delay, the effect of preventing the overflow of ignition flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

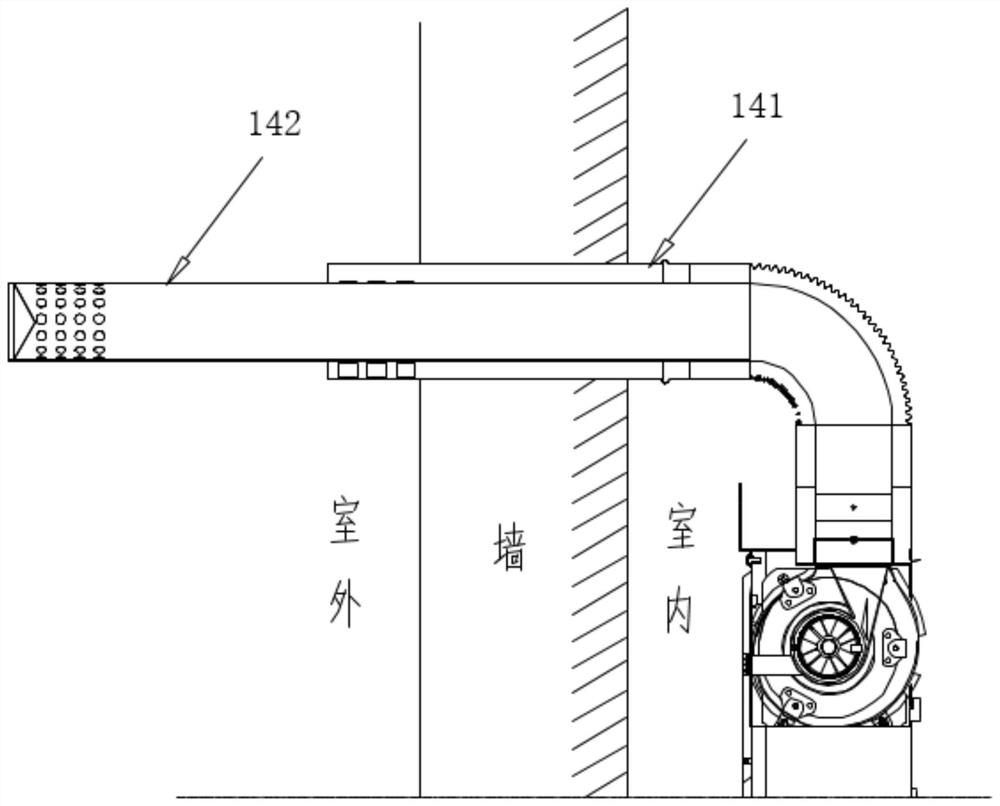

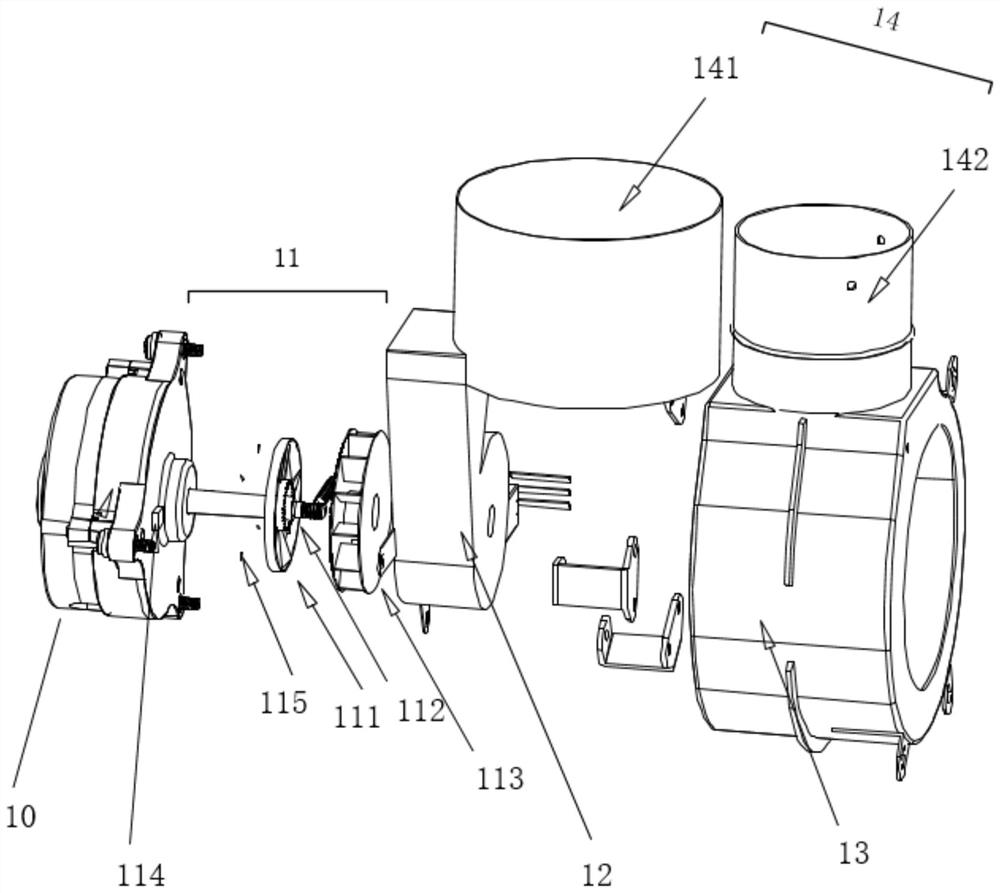

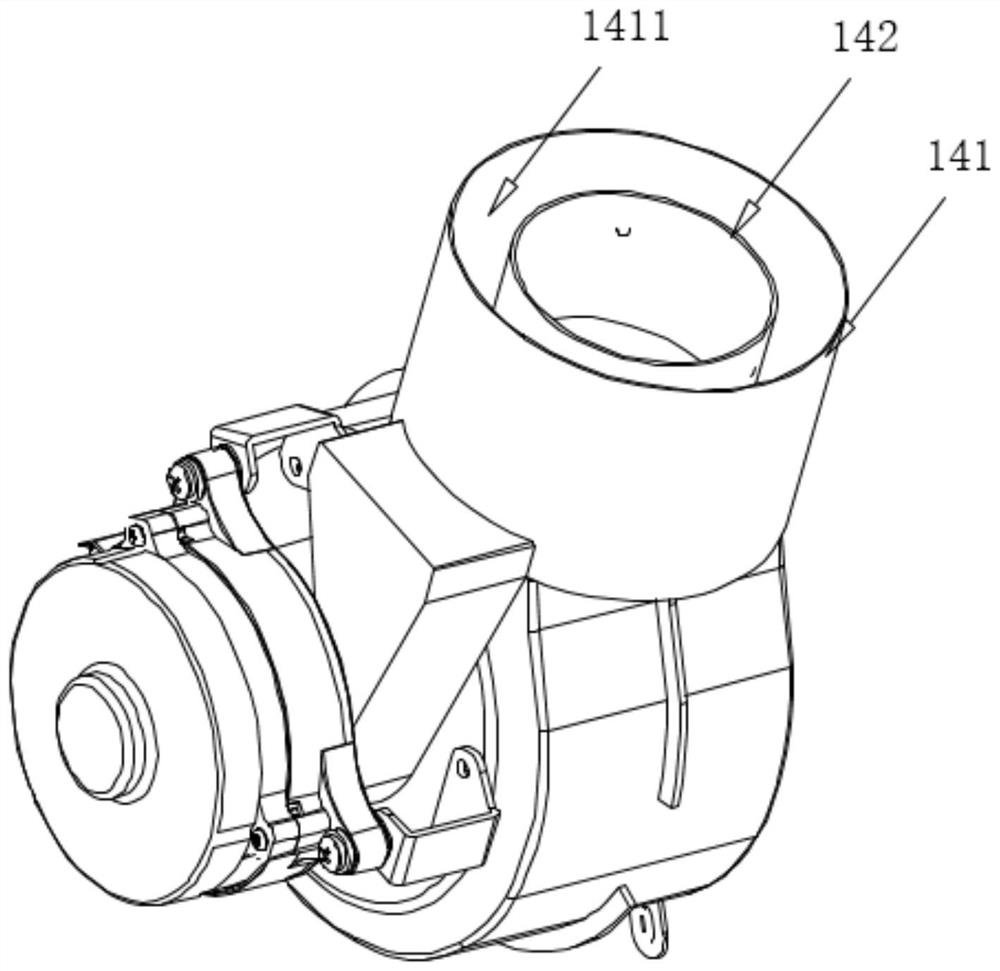

[0057] This embodiment provides a gas water heater, figure 1 , figure 2 and image 3 The plan view, exploded view and side view of the gas water heater in this embodiment are respectively shown. The gas water heater includes a fan motor 10, a wind pressure detection device 11, a double-layer smoke pipe 142 and an outer layer smoke pipe 141. In the layer of smoke pipe 14, the outer layer of smoke pipe 141 is sleeved with the inner layer of smoke pipe 142, wherein the space between the outer layer of smoke pipe 141 and the inner layer of smoke pipe 142 forms the ventilation area 1411 of the outer layer of smoke pipe 141.

[0058] One end of the inner layer smoke pipe 142 is connected to the gas collecting hood, and the other end leads to the outdoor, and the inner layer smoke pipe 142 is specially used to discharge the smoke in the gas collecting hood to the outdoor.

[0059] One end of the outer layer smoke pipe 141 leads to the outside, and the other end leads to the indoor...

Embodiment 2

[0077] This embodiment provides a wind pressure detection method, the wind pressure detection method is applied in the gas water heater as in Embodiment 1, and the wind pressure detection method includes:

[0078] The wind pressure detection device obtains the wind pressure difference between the two ends of the outer smoke pipe, and the wind pressure difference is used to adjust the operation of the fan motor.

[0079] Specifically, as Figure 4 As shown, this embodiment can specifically calculate the wind pressure difference through the following steps:

[0080] Step 201, detecting the rotational speed of the impeller through a rotational speed detection unit;

[0081] Step 202, calculating the air intake volume entering the outer smoke pipe according to the rotational speed;

[0082] Step 203: Calculate the wind pressure difference between the two ends of the outer smoke pipe according to the air intake volume.

[0083] Wherein, step 202 and step 203 may be specifically ...

Embodiment 3

[0086] This embodiment provides a fan control method for a gas-fired water heater, and the fan control method is implemented based on Embodiment 2, such as Figure 5 As shown, the fan control method includes:

[0087] Step 301: Obtain the wind pressure difference between the two ends of the outer layer smoke pipe.

[0088] Step 302: Obtain the current compensation current according to the wind pressure difference and the corresponding relationship between the preset wind pressure difference and the compensation current.

[0089] The corresponding relationship between the wind pressure difference and the compensation current can be pre-calibrated.

[0090] Step 303 , compensating the running current of the fan motor according to the current compensation current to adjust the operation of the fan motor.

[0091] Wherein, steps 301 to 303 may be specifically implemented by the computing unit in Embodiment 1.

[0092] In this embodiment, the corresponding relationship between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com