Method and facility for producing a plastic film

A technology for manufacturing equipment and plastic films, which is applied in applications, flat products, household appliances, etc., and can solve problems such as downtime and long downtime of blown film equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

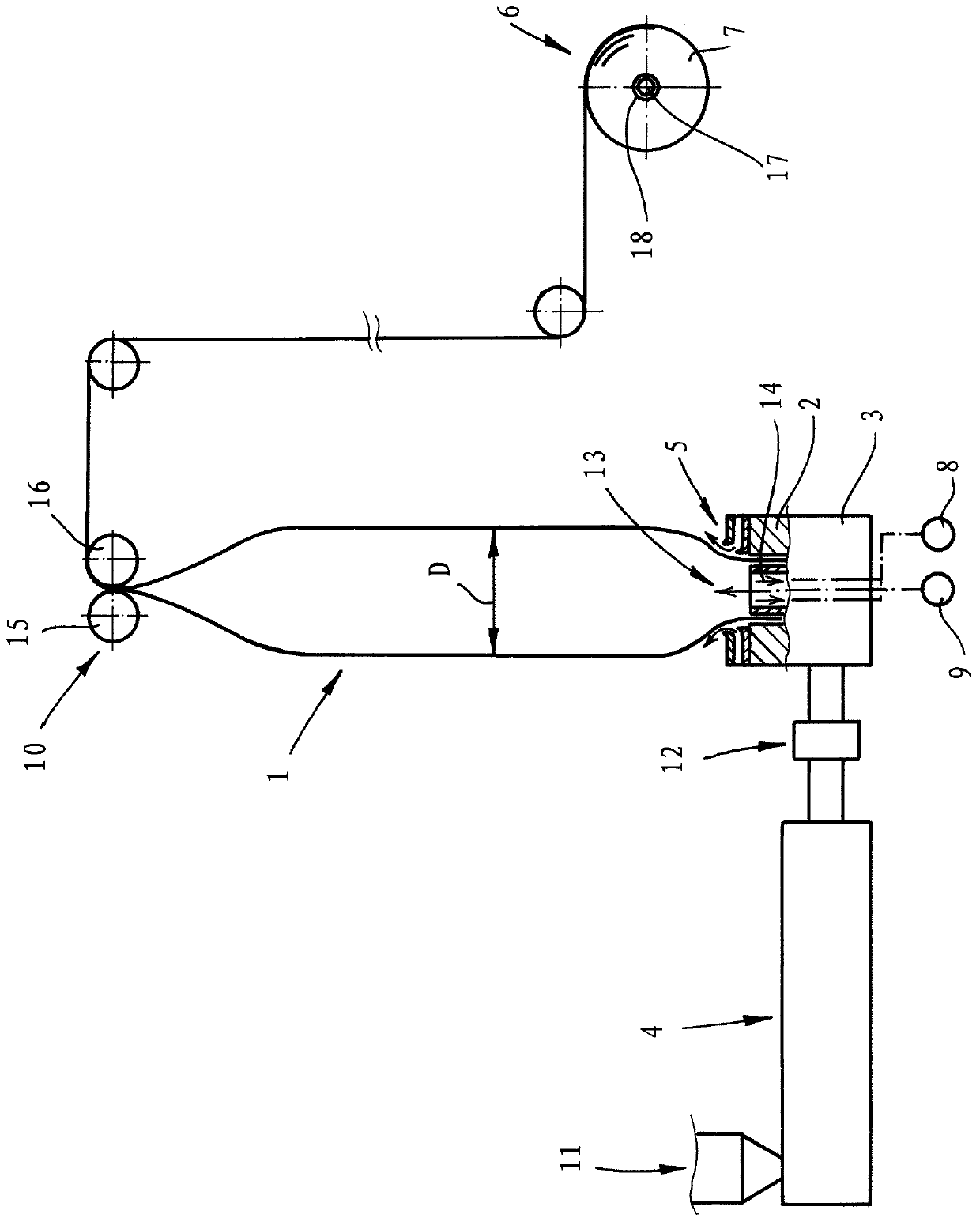

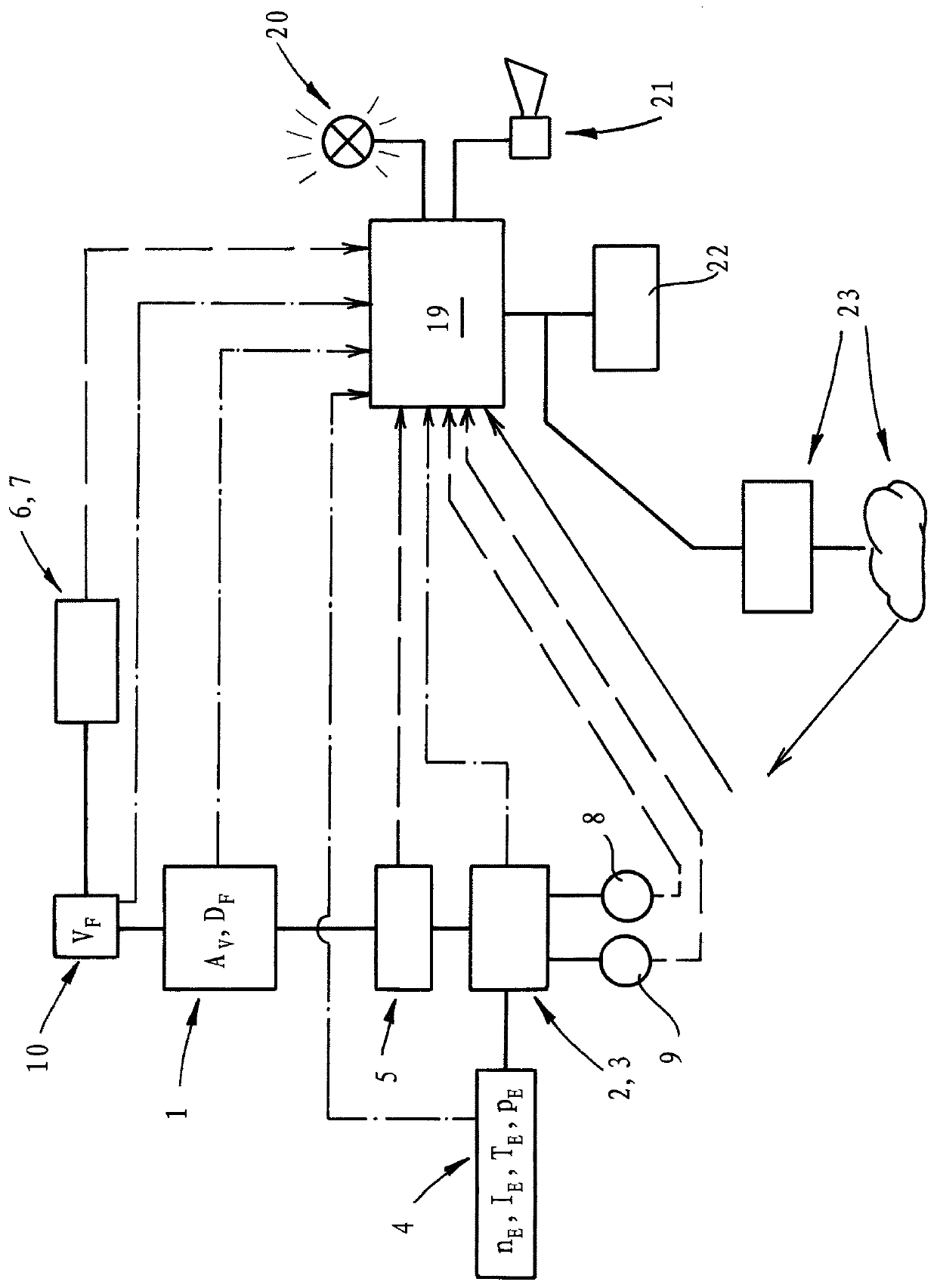

[0035] figure 1 A film production plant for producing a film tube 1 or a film web formed therefrom is shown in the form of a blown film plant according to the invention. In this case, the film tube is extruded from the annular slit nozzle 2 of the spray head 3 . For this purpose, the plastic or plastic melt is fed to the spray head 3 or the annular slot nozzle 2 by means of the extruder 4 . Preferably and in this exemplary embodiment, the extruded film hose 1 is cooled by means of a cooling device 5 , drawn out and flattened by means of a pulling device 10 and wound up into a film roll 7 by means of a winding device 6 Or wound into a film coil.

[0036] Expediently and in this embodiment, the plastic is fed to the extruder 4 via the distribution funnel 11 in the form of plastic pellets. Preferably and in this embodiment, the plastic melt is directed via the cleaning screen 12 to the spray head 3 or the annular slot nozzle 2 by means of the extruder 4 . It is within the sco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com