OLED display panel, production method and electronic equipment containing same

A display panel and manufacturing method technology, applied in chemical instruments and methods, circuits, electrical components, etc., can solve the problems of LCD's inability to emit light, contrast, viewing angle, bendable display and power consumption limitations, and reduce lateral leakage current. Phenomenon, the effect of reducing the probability that holes combine with electrons in the light-emitting layer of the adjacent pixel region to emit light, and improving the injection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as specific limitations on the present invention.

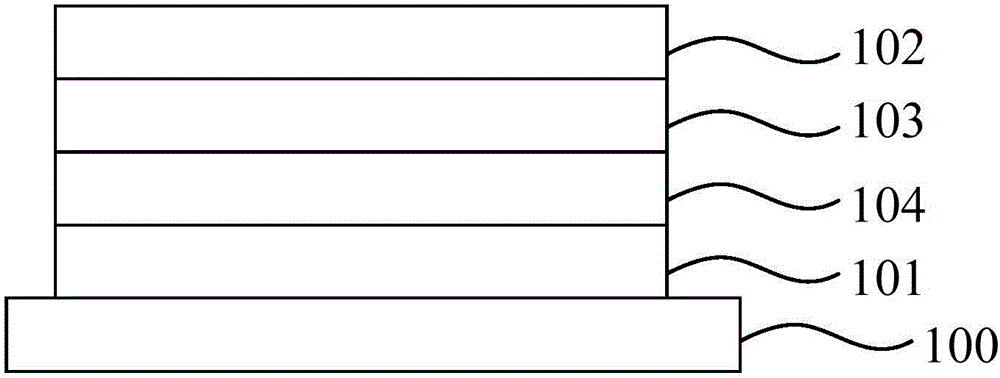

[0027] In a specific embodiment, the present invention provides an OLED display panel, see figure 2 , including a substrate 100 , and oppositely disposed first electrodes 101 and second electrodes 102 disposed on the substrate 100 . Wherein, a light emitting layer 103 and a first auxiliary light emitting layer 104 are disposed between the first electrode 101 and the second electrode 102 , and the first auxiliary light emitting layer 104 is disposed between the light emitting layer 103 and the first electrode 101 . The first auxiliary light emitting layer 104 includes at least a first hole type auxiliary light emitting layer. The first hole-type aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com