TOP-LED packaging device and preparation method thereof

A technology for TOP-LED and packaged devices, which is applied in the field of TOP-LED packaged devices and its preparation, can solve the problems of increasing production costs, increasing inventory, and reducing the concentration of SMD product color areas, so as to improve the bonding strength and improve The effect of safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

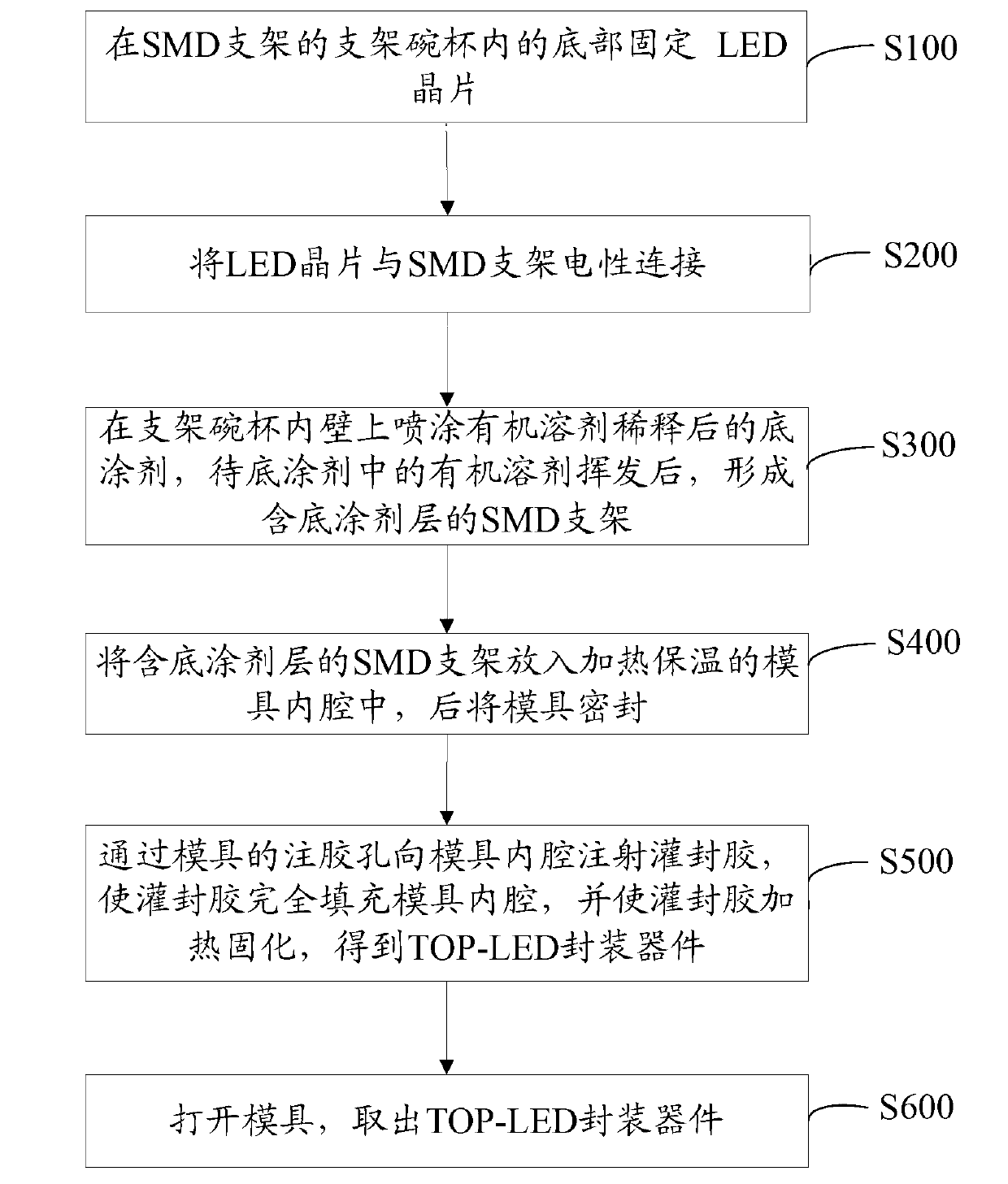

[0041] see figure 2 , the preparation method of the TOP-LED encapsulation device of an embodiment, comprises the following steps:

[0042] Step S100 , fixing the LED chip at the bottom of the holder cup of the SMD holder.

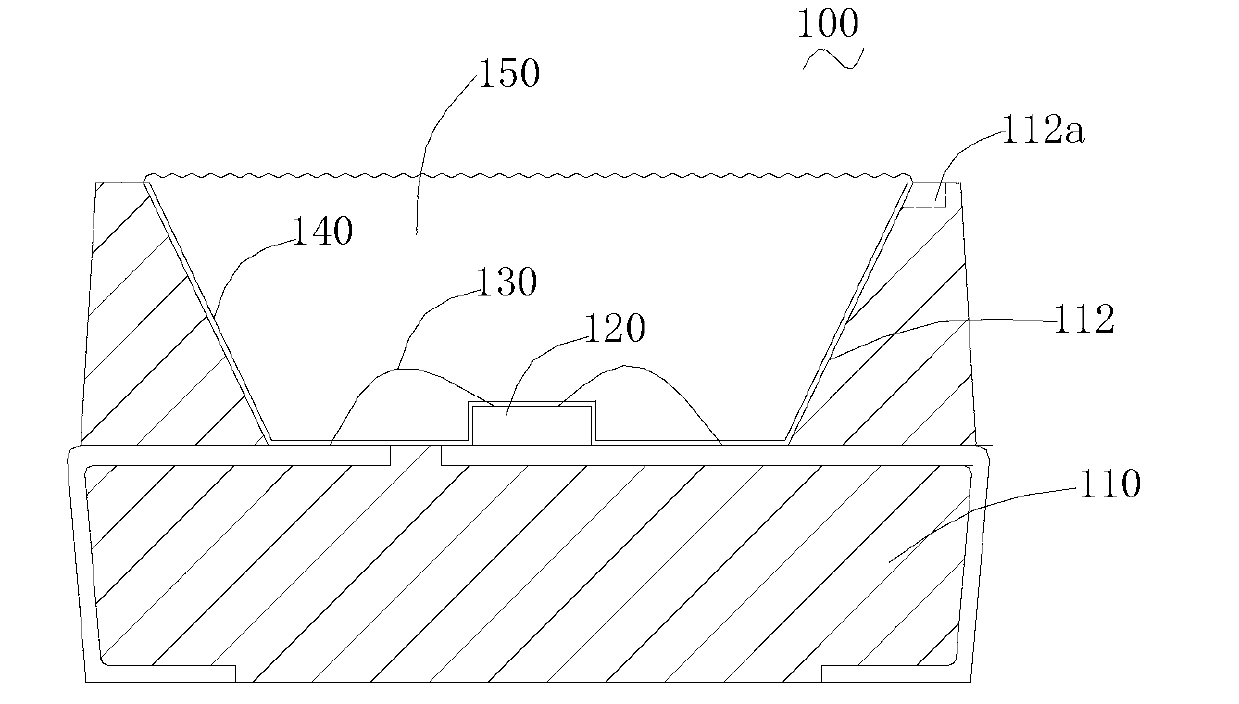

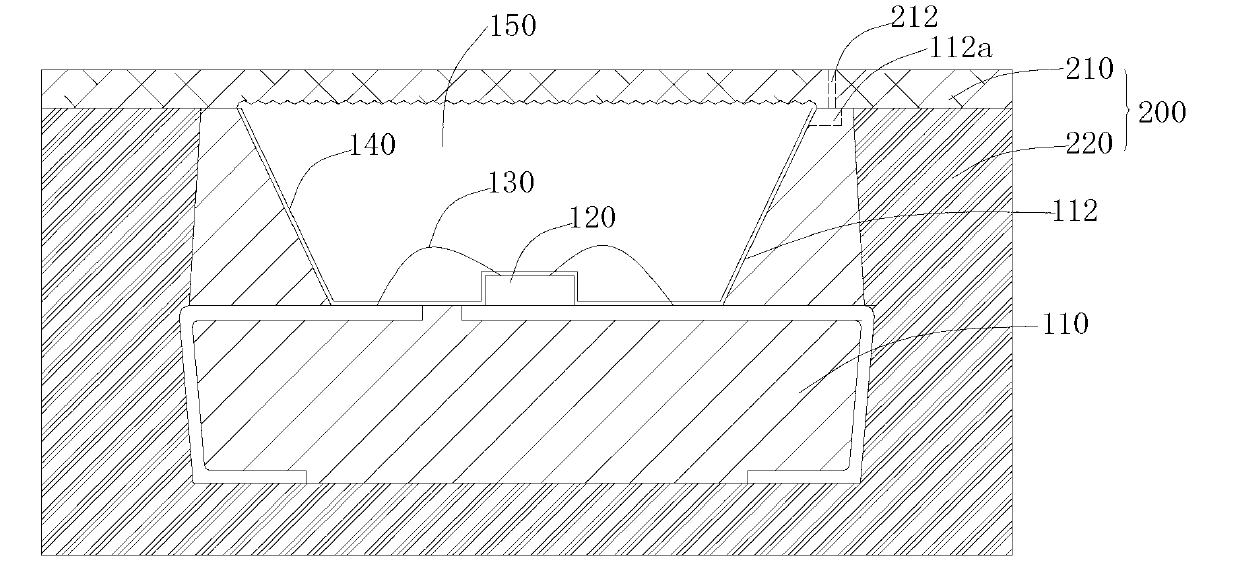

[0043] see image 3 After the SMD bracket 110 is dehumidified, the LED chip 120 is fixed at the bottom of the bracket cup 112 with a crystal-bonding primer.

[0044] Step S200, electrically connecting the LED chip to the SMD bracket.

[0045] The electrodes of the LED chip 120 are connected to the SMD bracket 110 through wires 130 , and a wire bonding machine is used to perform wire bonding to form a wire-bonded SMD bracket.

[0046] Step S300 , spraying a primer diluted with an organic solvent on the inner wall of the bracket bowl, and after the organic solvent in the primer volatilizes, an SMD bracket containing a primer layer is formed.

[0047] The primer is sprayed on the inner wall of the bracket cup 112 , and the primer layer 140 is formed after t...

Embodiment 1

[0063] A method for preparing a TOP-LED packaging device, comprising the following steps:

[0064] 1. Fix the LED chip at the bottom of the bracket cup of the SMD bracket.

[0065] see image 3 , The SMD bracket 110 is a TOP type SMD3528 bracket, and the top of the inner wall of the bracket cup 112 is provided with a glue injection hole 112a.

[0066] 2. Electrically connect the LED chip to the SMD bracket.

[0067] 3. Spray the primer diluted with organic solvent on the inner wall of the bracket bowl, and after the organic solvent in the primer volatilizes, an SMD bracket with a primer layer is formed.

[0068] The material of the primer is a polysiloxane primer, which consists of 26.5 parts of the partially hydrolyzed product of tetraethoxysilane, 27.5 parts of tetrabutyl titanate, 18.5 parts of silicone MQ resin soluble in toluene, 10 1,2-bistriethoxysilylethane mixed in 330 parts hydrocarbon solvent.

[0069] 4. Put the SMD bracket containing the primer layer into the ...

Embodiment 2

[0077] A method for preparing a TOP-LED packaging device, comprising the following steps:

[0078] 1. Fix the LED chip at the bottom of the bracket cup of the SMD bracket.

[0079] see Figure 4 , The SMD bracket 310 is a TOP-SMD3535 ceramic bracket.

[0080] 2. Electrically connect the LED chip to the SMD bracket.

[0081] 3. Spray the primer diluted with organic solvent on the inner wall of the bracket bowl, and after the organic solvent in the primer volatilizes, an SMD bracket with a primer layer is formed.

[0082] The material of the primer is a polysiloxane primer, which is specifically composed of 10 parts of polymethylhydrogensiloxane, 4.95 parts of vinyltrimethoxysilane, 37.8 parts of heptane, converted into a Pt mass fraction of 4×10 -6 Chloroplatinic acid was prepared.

[0083] 4. Put the SMD bracket containing the primer layer into the cavity of the heated and heat-preserved mold, and then seal the mold.

[0084] Wherein, the mold 400 includes an upper mold 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com