Sintering flue gas integrated type oxidization and denitration device and application thereof

An integrated technology of sintering flue gas, applied in the field of environmental engineering, can solve the problems of SCR catalyst life impact, great difference, gypsum rain pollution, etc., to shorten the length of pipeline transportation, occupy a small area, and increase turbulent mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

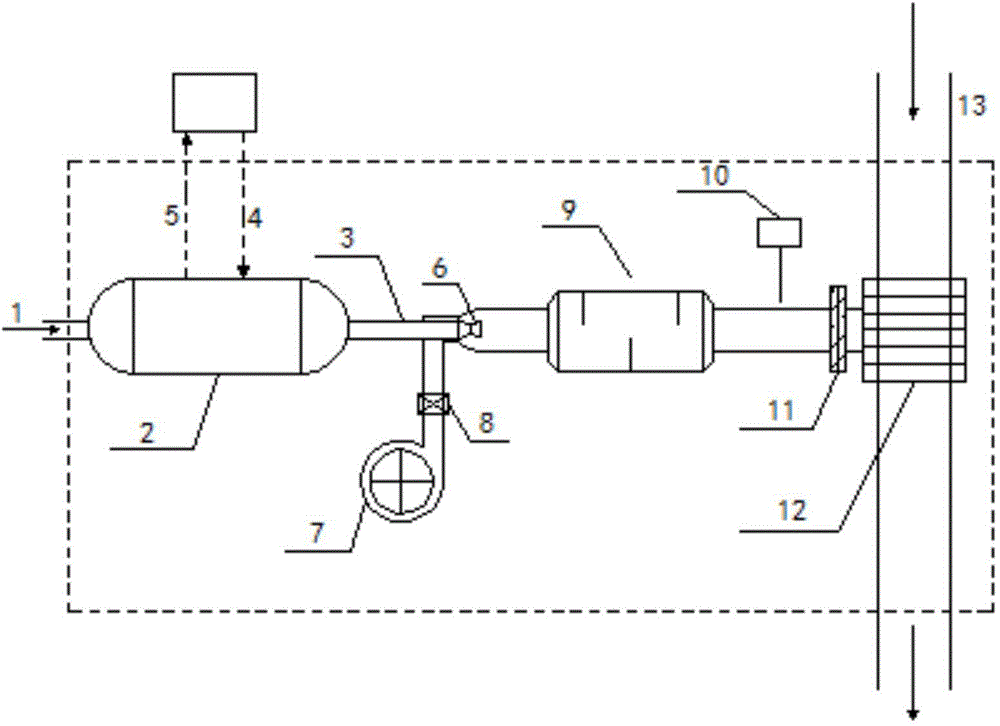

[0051] The sintering flue gas integrated oxidation denitrification device, the ozone generated by the ozone generator is passed through the venturi into the air induction pipeline, and after being merged with the air, it is passed into the diluter, diluted and mixed evenly, and evenly distributed to the sintering waste gas through the ozone distributor Oxidation and denitration in the tunnel.

[0052] The integrated oxidation and denitrification device for sintering flue gas includes a gas source input terminal, an ozone generator, an ozone output terminal, a cooling water inlet, a cooling water outlet, a Venturi, a mixing fan, a one-way regulating valve, an ozone diluter, Flange, ozone concentration detector, ozone distributor, flue;

[0053] Described ozone generator ozone output end connects Venturi;

[0054] The Venturi is inside the induced air pipeline of the induced draft fan;

[0055] The induced draft pipeline of the induced draft fan is connected with the inlet of ...

Embodiment 1

[0066] Sintering flue gas integrated oxidation denitrification device, the ozone generated by the ozone generator is mixed with the air introduced by the induced draft fan after passing through the Venturi, and then enters the diluter after passing through the expansion section pipeline for mixing and dilution. After being detected by the ozone concentration detector, the ozone is distributed The device is sprayed into the flue and oxidized in contact with the flue gas.

[0067] The Venturi is located at the center of the air-inducing pipeline, and the center coincides with the center of the air-inducing pipeline.

[0068] The Venturi constriction angle is 65°, the divergence angle is 30°, and the throat aspect ratio is 1.1.

[0069] The length of the expansion section is 0.5m.

[0070] The number of partitions in the diluter is 1, and the distance between adjacent partitions in the tube is 1m.

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is:

[0073] The Venturi constriction angle is 80°, the divergence angle is 45°, and the throat aspect ratio is 1.1.

[0074] The length of the expansion section is 1.5m.

[0075] There are 4 partitions in the diluter, and the distance between adjacent partitions in the pipe is 1.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com