Submerge liquid supplying recovery controlling device for photoetching machine

A technology of liquid supply and control device, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc. It can solve the problems of affecting the stable operation of the exposure system, difficult coordination of pressure, and negative exposure quality, so as to achieve timely and effective contamination and temperature rise, reduce the infiltration of boundary bubbles, and eliminate the effects of flow field interference and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

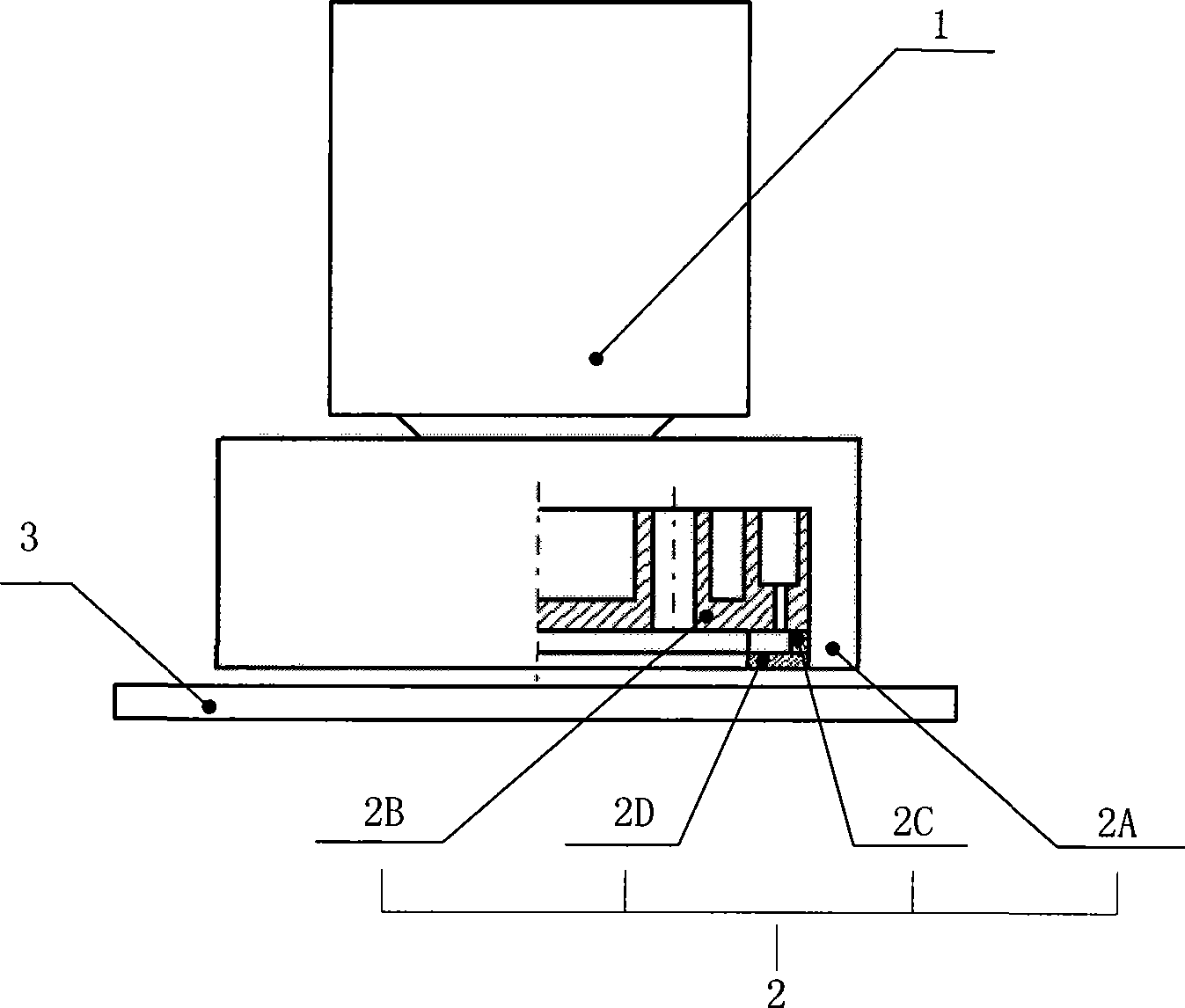

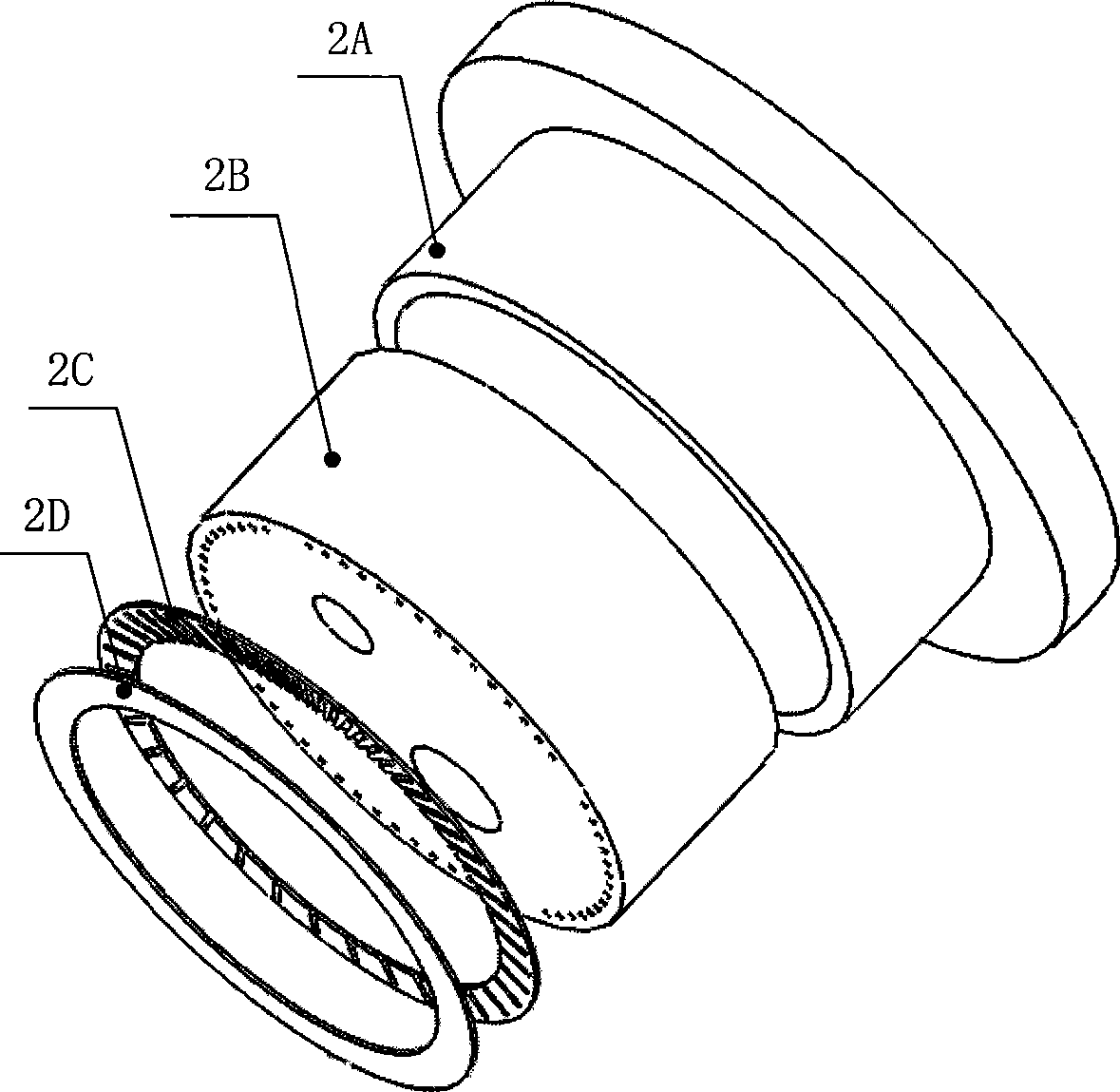

[0035] Such as figure 1 , figure 2 As shown, the present invention is a liquid supply and recovery control device 2 arranged between the projection lens group 1 and the substrate 3 . The liquid supply and recovery control device 2 includes a liquid injection cover 2A, a liquid injection tray 2B, a flow control ring 2C and a retaining ring 2D; wherein:

[0036] 1) Liquid injection cover 2A: from the center to the outside, there is an external connection channel 6B of the recovery chamber offset from the center, and two symmetrically distributed liquid injection chambers external connection channel 6A;

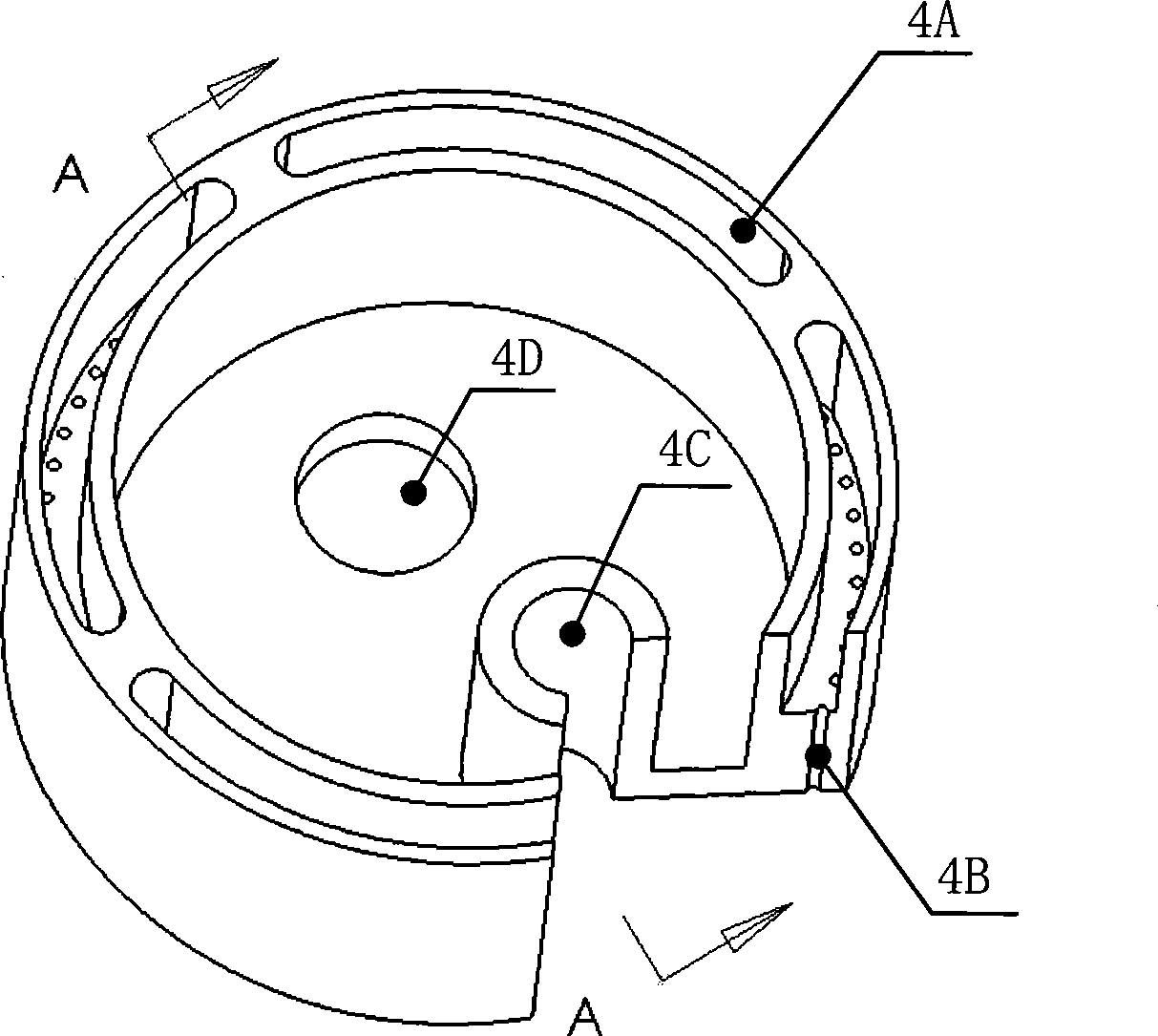

[0037] 2) Liquid injection plate 2B: the objective lens hole 4D offset from the center outwards, the recovery chamber 4C and four liquid injection chambers 4A uniformly arranged in a ring along the circumferential direction, and the four liquid injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com