Injection molding machine microinjection device capable of realizing high-speed and high-precision injection

An injection molding machine and high-precision technology, which is applied in the field of micro-injection devices, can solve the problems of increasing the possibility of material stagnation, affecting the flow of molten material, and low injection pressure, so as to improve injection accuracy and injection speed, eliminate the influence of deformation, and improve plastic injection. The effect of optimizing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

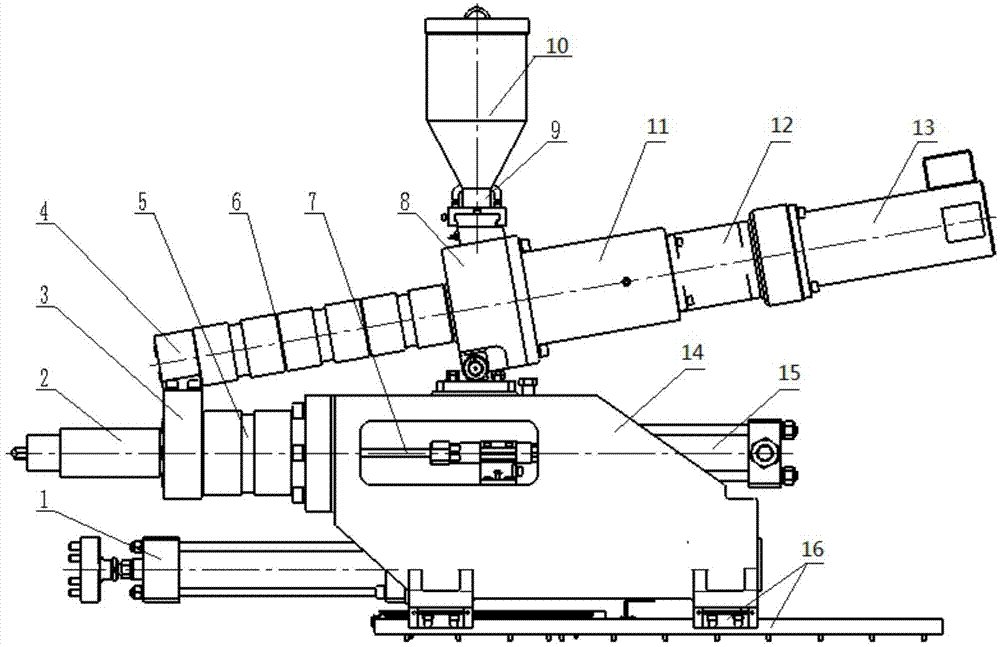

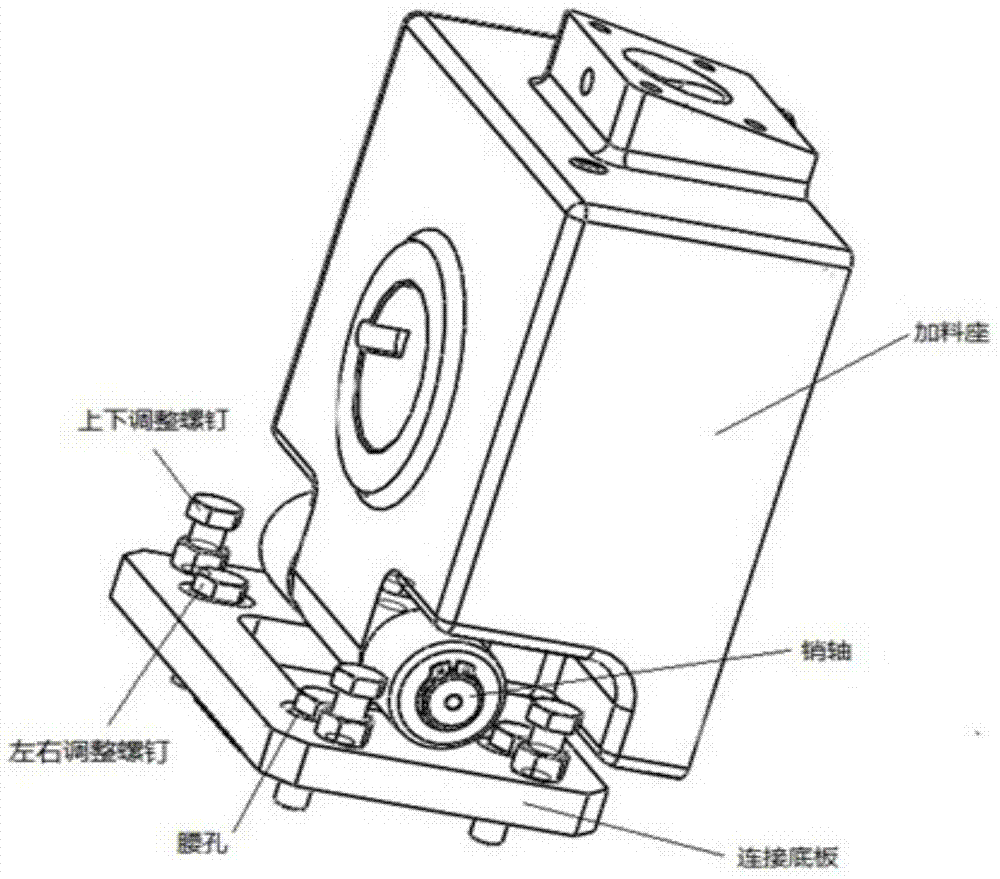

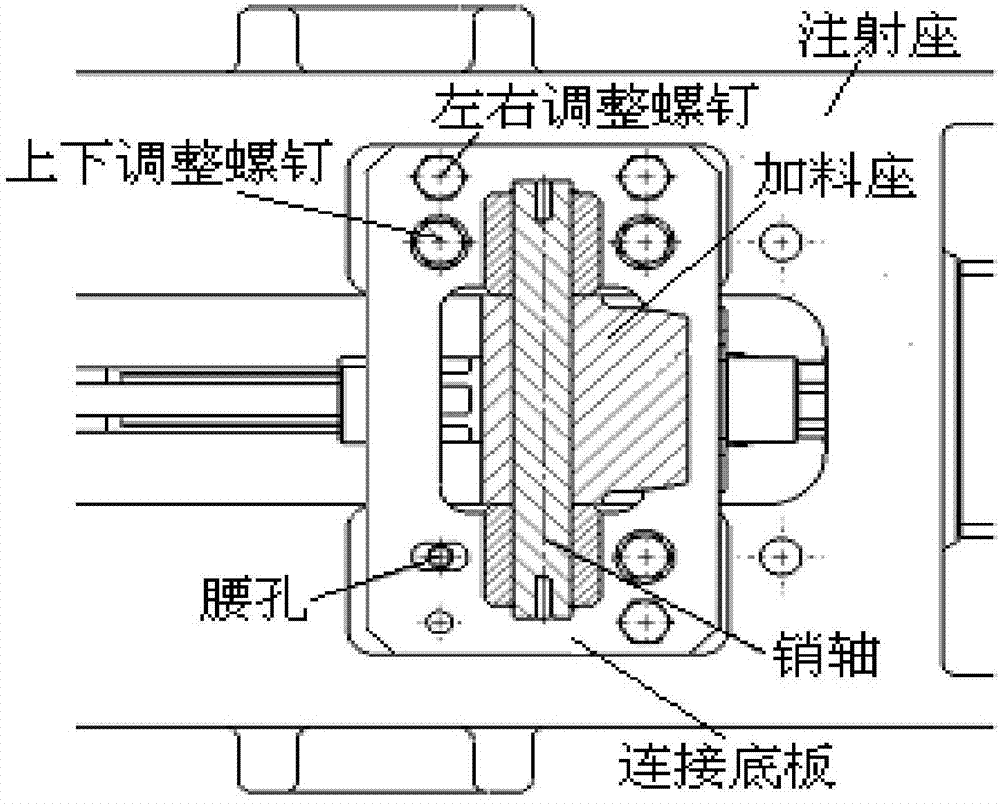

[0036] Such as figure 1 As shown in the injection device of the injection molding machine, the device of the present invention includes an injection platform mobile cylinder 1, an injection barrel precursor 2, an injection unit connector 3, a plasticizing unit connector 4, an injection barrel 5, a plasticizing barrel 6, a column Plug 7, feeding seat 8, hopper assembly 9, feeding barrel 10, transmission box 11, reducer 12, plasticizing motor 13, injection seat 14, hydraulic cylinder 15, injection platform moving linear slide rail slider pair 16; this device can Divided into five parts, namely plasticizing unit, injection unit, feeding unit, injection unit moving unit and other units (such as sensors, linear slide rails and various cooling water pipes); plasticizing unit includes plasticizing unit connector 4, plasticizing unit Plasticizing barrel 6, feeding seat 8, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com