Low-modulus polyurethane sealant with high elasticity recovery rate and preparation method thereof

A polyurethane sealant, high-elasticity technology, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of poor sealing performance and low elastic recovery performance at concrete joints, Achieve the effect of avoiding phase separation, reducing damping, and improving interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0058] Preparation of hydroxyl-terminated polydimethylsiloxane: Mix 350 parts of dimethyldimethoxysilane and 104 parts of deionized water, add hydrochloric acid solution dropwise to pH 3.2, and stir at room temperature for 10 minutes. 2 parts by mass percent concentration of 35% NaH 2 PO 4 / Na 2 HPO 4 The aqueous solution was slowly dropped into the mixed solution, and stirred at room temperature for 10 min. Distill under reduced pressure, filter, and dry to obtain hydroxyl-terminated polydimethylsiloxane PDMS-1.

[0059] Preparation of hydroxyl-terminated polydimethylsiloxane: Mix 390 parts of dimethyldimethoxysilane and 120 parts of deionized water, add hydrochloric acid solution dropwise to pH 3.9, and stir at room temperature for 20 minutes. 1 part of NaH with a mass percent concentration of 35% 2 PO 4 / Na 2 HPO 4 The aqueous solution was slowly dropped into the mixed solution, and stirred at room temperature for 50 min. Distill under reduced pressure, filter, and...

Embodiment 1

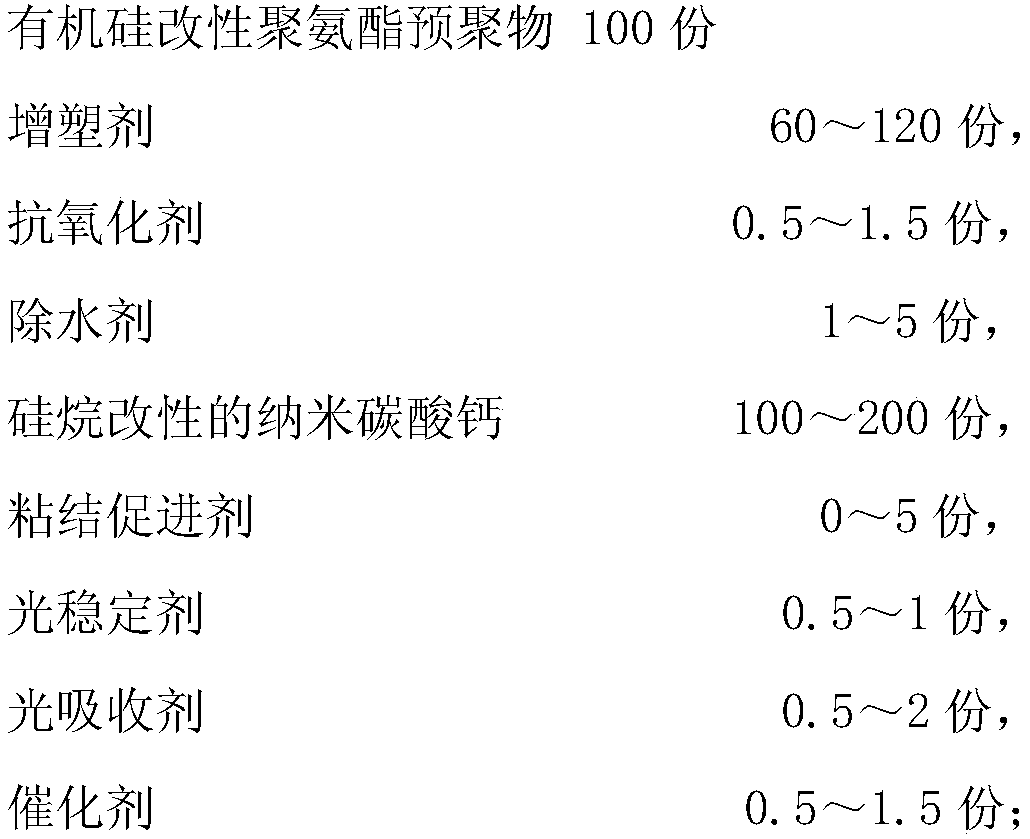

[0066] Preparation of silicone-modified polyurethane sealant with low modulus and high elastic recovery:

[0067] Take 100 parts of SPU-1, add it to a 5L planetary mixer, add 80 parts of dioctyl phthalate, 100 parts of silane-modified nano calcium carbonate NanoCaCO 3 -1, under the conditions of planetary revolution speed 70rpm and dispersion speed 15m / s, high-speed stirring for 1.2h, then add 1 part of vinylsilane, 0.5 part of 3,5-di-tert-butyl-4-hydroxyphenylpropionate isooctyl, 1 part of 3-aminopropylmethylsiloxane, 0.5 part of bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate), 1 part of 2-(2' -Hydroxy-3',5'-di-tert-butylphenyl)benzotriazole, 0.5 parts of dibutyltin dilaurate, continue to vacuumize and stir (vacuum degree<200mbar, planetary revolution line speed 45rpm, dispersion line speed 15m / s) 1.5h, discharge.

Embodiment 2

[0069] Preparation of silicone-modified polyurethane sealant with low modulus and high elastic recovery:

[0070] Take 100 parts of SPU-2, add it to a 5L planetary mixer, add 100 parts of dinonyl phthalate, 150 parts of silane-modified nano calcium carbonate NanoCaCO 3 -2. Stir at high speed for 1.5h under the conditions of planetary revolution speed 80rpm and dispersion speed 12m / s, then add 2 parts of vinylsilane and 1.0 part of 3,5-di-tert-butyl-4-hydroxyphenylpropionate isooctyl, 2 parts of 3-n-butylaminopropyltrimethoxysilane, 1 part of bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate, 2 parts of 2-(2 '-Hydroxy-3', 5'-di-tert-butylphenyl)benzotriazole, 1 part of stannous octoate, continue vacuum stirring (vacuum degree <200mbar, planetary revolution line speed 50rpm, dispersion line speed 12m / s ) 2h, discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com