Preparation method of water-soluble polymer dispersion

A technology of water-soluble polymer and dispersion liquid, which is applied in the field of preparation of water-soluble polymer dispersion liquid, can solve the problems of great influence on the solubility of polyelectrolyte, reduction of flocculation effect and other application properties, and reduction of product dissolution rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

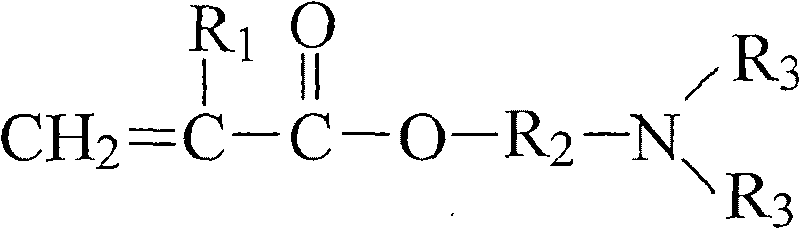

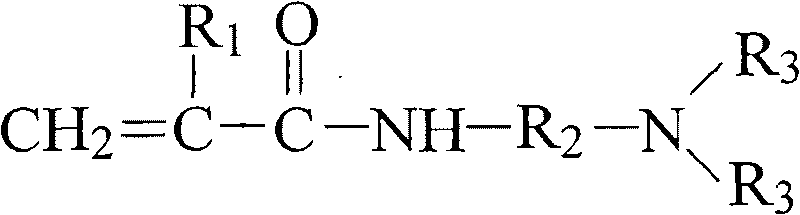

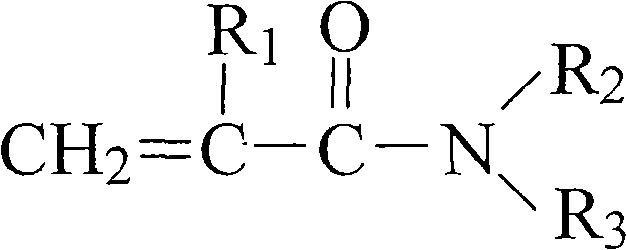

Method used

Image

Examples

Embodiment 1

[0055] Example 1: In this example, a relatively high molecular weight polymer dispersant is prepared by polymerization of monomers.

[0056] 560 grams of 50% by weight of trimethyl(meth)acrylamidopropylammonium chloride monomer solution, 7 grams of 2% by weight of EDTA disodium salt solution, and 124.6 grams of water were added to 1000 milliliters of four In the reactor, the four ports of the reactor are mechanical stirring, nitrogen inlet, thermometer, and feeding port. After the reaction system was preheated to 50 degrees Celsius and replaced with nitrogen to remove oxygen for 30 minutes, 8.4 ml of 10% by weight AIBA solution was added by injection. After reacting for 6 hours, the temperature of the system was raised to 90°C. The reaction was continued for 2 hours to stop the reaction, and the system was cooled to room temperature to obtain a polytrimethyl(meth)acrylamidopropyl ammonium chloride dispersant product. The determined molecular weight of the product is 117,000....

Embodiment 2

[0057] Example 2: In this example, a relatively low molecular weight polymer dispersant is prepared by polymerization of monomers.

[0058] Add 7 grams of 2% by weight EDTA disodium salt solution and 342 grams of water into a 1000 ml four-port reactor. The four ports of the reactor are mechanical stirring, nitrogen inlet, thermometer, and feeding port. After the reaction system was preheated to 50 degrees Celsius and replaced with nitrogen to remove oxygen for 30 minutes, 28 ml of 30% by weight APS solution was added by injection. Then, 323 grams of 65% by weight diallyldimethylammonium chloride monomer solution was added dropwise into the reactor, and the addition of the monomer was controlled to end within 4 hours. After reacting for 6 hours, the temperature of the system was raised to 90°C. The reaction was continued for 2 hours to stop the reaction, and the system was cooled to room temperature to obtain a polydiallyldimethylammonium chloride dispersant product. The dete...

Embodiment 3

[0060] With 70 grams of solid dispersant calcium carbonate (heavy calcium carbonate, fineness is 2500 orders), 0.378 grams of ammonium persulfate, 280 grams of 45% by weight polydiallyl dimethyl ammonium chloride dispersant aqueous solution (by the embodiment 1 method preparation), 157 grams of 40% by weight of acrylamide aqueous solution, 78 grams of 80% by weight of acryloyloxyethyltrimethylammonium chloride aqueous solution, 104 grams of deionized water and 7 grams of 2% by weight of ethylenediaminetetra Aqueous solution of disodium acetate salt was sequentially added into a 1000 ml four-port reactor, and the four ports of the reactor were mechanical stirring, nitrogen gas inlet, thermometer, and feeding port. After the reaction system was preheated to 30 degrees Celsius and replaced with nitrogen to remove oxygen for 30 minutes, 1.57 ml of 10% by weight sodium bisulfite was added by injection. The temperature of the system rises rapidly after a few minutes, and the viscosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com