Rubber backing plate of passenger dedicated line

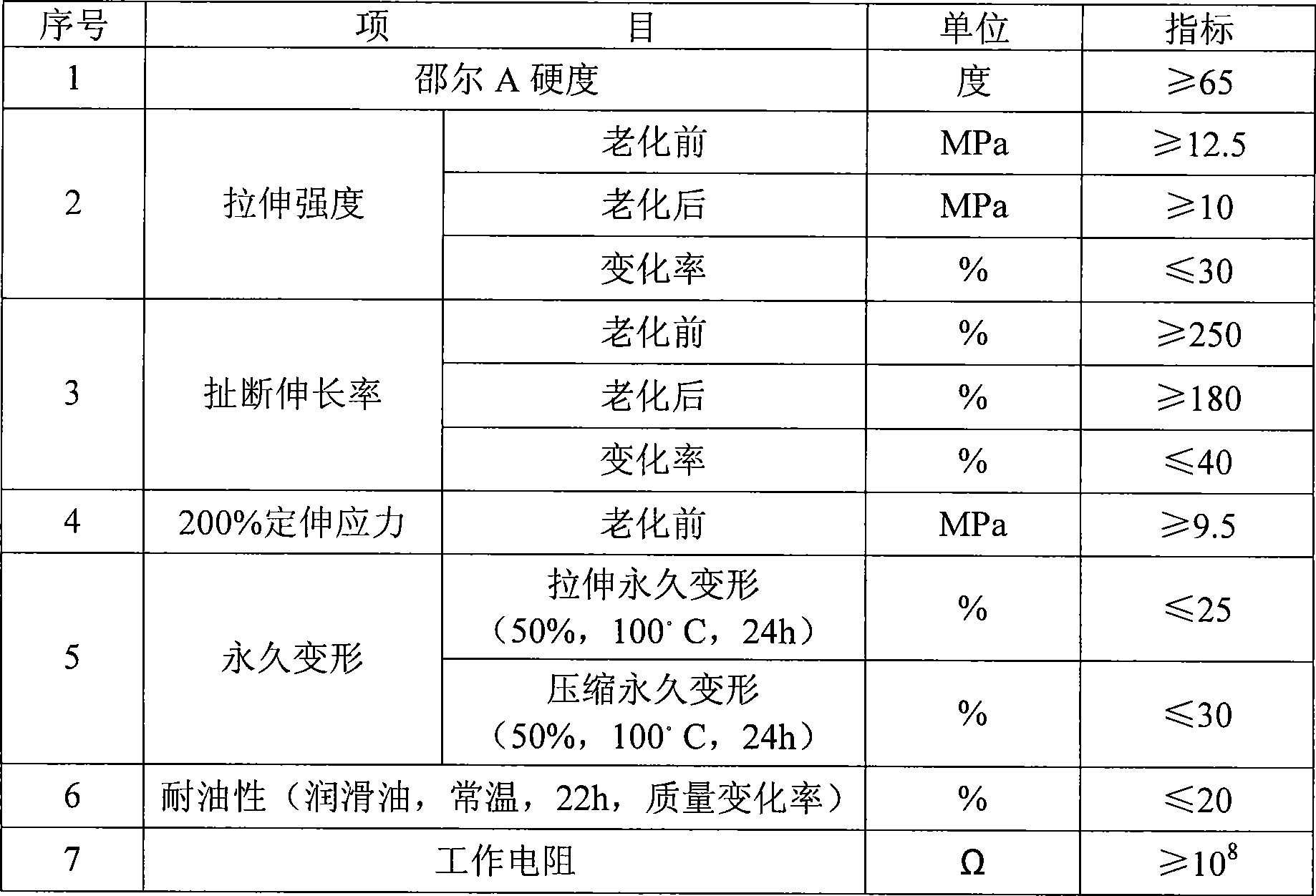

A technology for rubber pads and passenger dedicated lines, which is used in tracks, buildings, fixed rails, etc., can solve the problems of lack of dynamic and static stiffness ratio, inability to meet the technical requirements of rubber pads for passenger dedicated lines, and low aging resistance requirements. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Styrene butadiene rubber 100; Zinc oxide 4; Stearic acid 1.5; Accelerator TMTD 1.2; Accelerator CZ 1.2; Accelerator DTDM 0.5; Coupling agent Si69 1.5; Semi-reinforcing carbon black 30; Nano-kaolin 70; Nano-calcium carbonate 20 Antiaging agent 4010NA 1.5; Antiaging agent RD 2; Microcrystalline wax 1; Sulfur 1; Total 235.4.

[0038] The production method is as follows:

[0039] (1), mastication: 100 parts of styrene-butadiene rubber is masticated in an open mill, then divided into blocks according to requirements, and then wound into rolls;

[0040] (2) Mixing: The order of feeding during mixing is:

[0041] First put the above rolls into the internal mixer and knead for 1 to 2 minutes;

[0042] Then put 1 / 2 of the coarse material in the internal mixer, and the mixing time is 1 to 2 minutes;

[0043] Add the remaining 1 / 2 coarse material, and mix for 1 to 2 minutes;

[0044] The coarse material comprises: 30 parts of semi-reinforcing carbon black; 70 parts of nano-kao...

Embodiment 2

[0056] Styrene butadiene rubber 100; zinc oxide 5; stearic acid 0.5; accelerator TMTD 0.8; accelerator CZ 0.7; accelerator DTDM 0.7 coupling agent Si69 1.0; semi-reinforcing carbon black 40; nano kaolin 50; nano calcium carbonate 15; Antiaging agent 4010NA 1.0; Antiaging agent RD 1.0; Microcrystalline wax 0.5; Sulfur 1.2; Total 236.5. Production technology and technical performance are with embodiment one.

Embodiment 3

[0058] Styrene butadiene rubber 100; Zinc oxide 6; Stearic acid 1.5; Accelerator TMTD 1.4; Accelerator CZ 0.5; Accelerator DTDM 0.9; Coupling agent Si69 2.0; Semi-reinforcing carbon black 50; Antiaging agent 4010NA 1.2; Antiaging agent RD 1.5; Microcrystalline wax 0.8; Sulfur 0.6; Total 236.1. Production technology and performance are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com