Water-based environment-friendly adhesive suitable for adhesion between ground decoration layer and cushion layer

A ground decoration layer and adhesive technology, applied in the directions of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of environmental impact, cumbersome production process, complex production process, etc., and achieve good initial viscosity and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

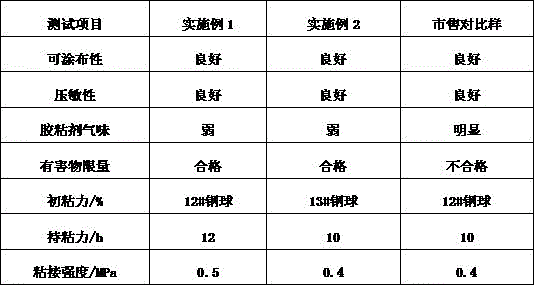

Examples

Embodiment 1

[0020] 1. Formula (unit: Kg):

[0021] Styrene modified acrylic resin emulsion 35

[0022] Terpene Resin Emulsion 20

[0023] Paraben plasticizer 2

[0024] 400 mesh heavy calcium 30

[0025] Wetting agent 1

[0026] Defoamer 1

[0027] Preservatives 1

[0028] pH regulator 0.5

[0029] Thickener 1

[0030] water 8

[0031] 2. Preparation:

[0032] According to the above formula, pour water, heavy calcium, wetting agent, half of the defoamer, and preservative into the mixer in advance, and disperse at a high speed at a speed higher than or equal to 1000r / min, and then add styrene-modified acrylic resin successively The emulsion and the terpene resin emulsion are stirred and mixed at a low speed at a speed lower than or equal to 500r / min until they are completely mixed to form a uniform slurry, then add a polyester plasticizer, and finally add the remaining defoamer, pH regulator, Thickening agent finally obtains a white paste mixture, which is the water-based environ...

Embodiment 2

[0034] 1. Formula (unit: Kg):

[0035] Polyurethane Acrylic Emulsion 55

[0036] Rosin resin emulsion 35

[0037] Polyester plasticizer 8

[0038] Defoamer 0.5

[0039] Preservatives 1

[0040] pH regulator 0.5

[0041] Thickener 1

[0042] 2. Preparation:

[0043] According to the above formula, add polyurethane acrylic resin emulsion and rosin resin emulsion into the mixer successively, stir and mix at a low speed at a speed lower than or equal to 500r / min, until completely mixed to form a uniform slurry, add polyester plasticizer , and finally add defoamer, preservative, pH regulator, thickener, and finally obtain a white paste mixture, that is, the water-based environmentally friendly adhesive of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com