OCA optical cement for bonding frame of cell phone

A mobile phone frame and optical glue technology, which is applied in the field of OCA optical glue, can solve the problems of ideal bonding performance, poor light transmission performance, and high price, and achieve low cost, low holding force, and good light transmission performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

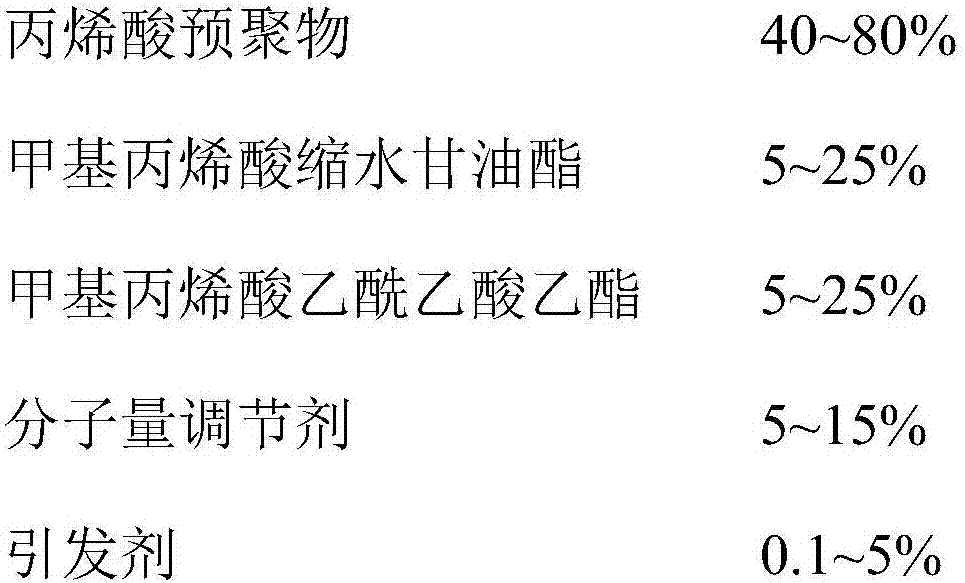

[0014]

[0015] Put the above components into the stirring tank according to the mass percentage, mix and stir evenly, let it stand for defoaming naturally to make glue, then apply the glue on both sides of the PET release film, and then attach the silicon release film on both sides Curing by UV;

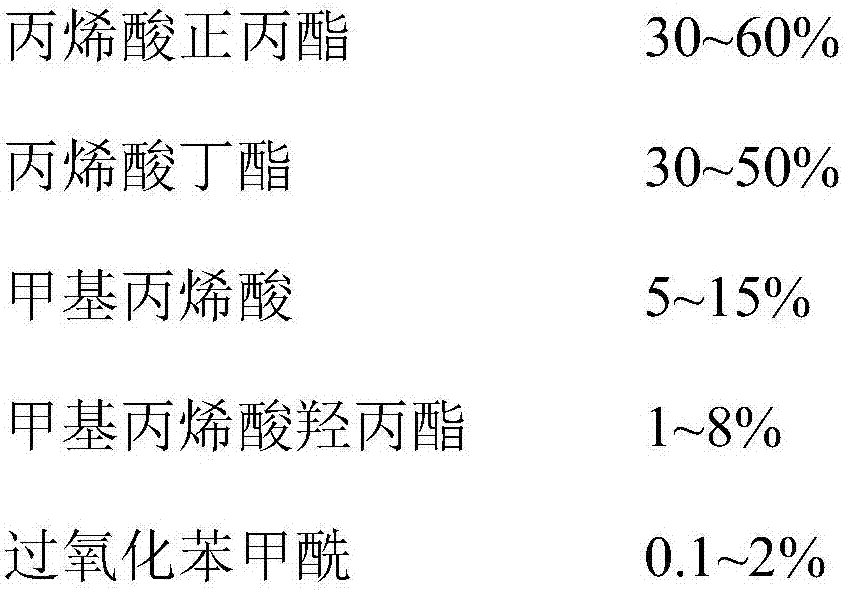

[0016] Wherein, the acrylic acid prepolymer is made by reacting the following substances in mass percent:

[0017]

[0018] After the weighing is completed, add n-propyl acrylate, methacrylic acid, and hydroxypropyl methacrylate into the reaction kettle in sequence, and add butyl acrylate dissolved in benzoyl peroxide dropwise to the reaction kettle while raising the temperature of the materials in the reaction kettle. In the kettle, the temperature of the reaction kettle was raised to 80-90°C and kept at a temperature of 10 hours, then cooled to normal temperature.

Embodiment 2

[0020]

[0021] Put the above components into the stirring tank according to the mass percentage, mix and stir evenly, let it stand for defoaming naturally to make glue, then apply the glue on both sides of the PET release film, and then attach the silicon release film on both sides Curing by UV;

[0022] Wherein, the acrylic acid prepolymer is made by reacting the following substances in mass percent:

[0023]

[0024] After the weighing is completed, add n-propyl acrylate, methacrylic acid, and hydroxypropyl methacrylate into the reaction kettle in sequence, and add butyl acrylate dissolved in benzoyl peroxide dropwise to the reaction kettle while raising the temperature of the materials in the reaction kettle. In the kettle, the temperature of the reaction kettle was raised to 80-90°C and kept at a temperature of 10 hours, then cooled to normal temperature.

Embodiment 3

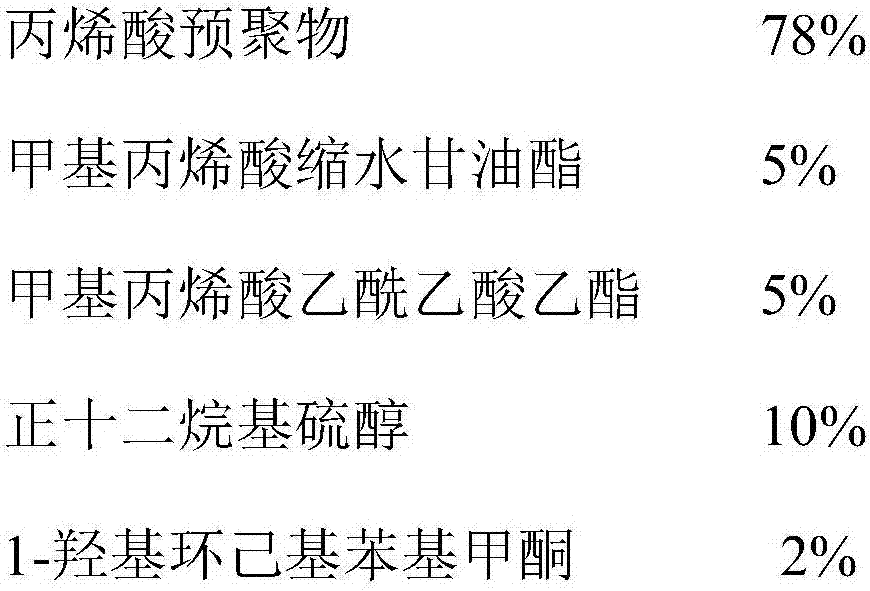

[0026]

[0027] Put the above components into the stirring tank according to the mass percentage, mix and stir evenly, let it stand for defoaming naturally to make glue, then apply the glue on both sides of the PET release film, and then attach the silicon release film on both sides Curing by UV;

[0028] Wherein, the acrylic acid prepolymer is made by reacting the following substances in mass percent:

[0029]

[0030]

[0031] After the weighing is completed, add n-propyl acrylate, methacrylic acid, and hydroxypropyl methacrylate into the reaction kettle in sequence, and add butyl acrylate dissolved in benzoyl peroxide dropwise to the reaction kettle while raising the temperature of the materials in the reaction kettle. In the kettle, the temperature of the reaction kettle was raised to 80-90°C and kept at a temperature of 10 hours, then cooled to normal temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com