Mineral slurry conveying high-abrasion-resistance anticorrosive composite pipe for wet desulphurization and preparation

A wet desulfurization and corrosion-resistant technology, applied in the field of transportation pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

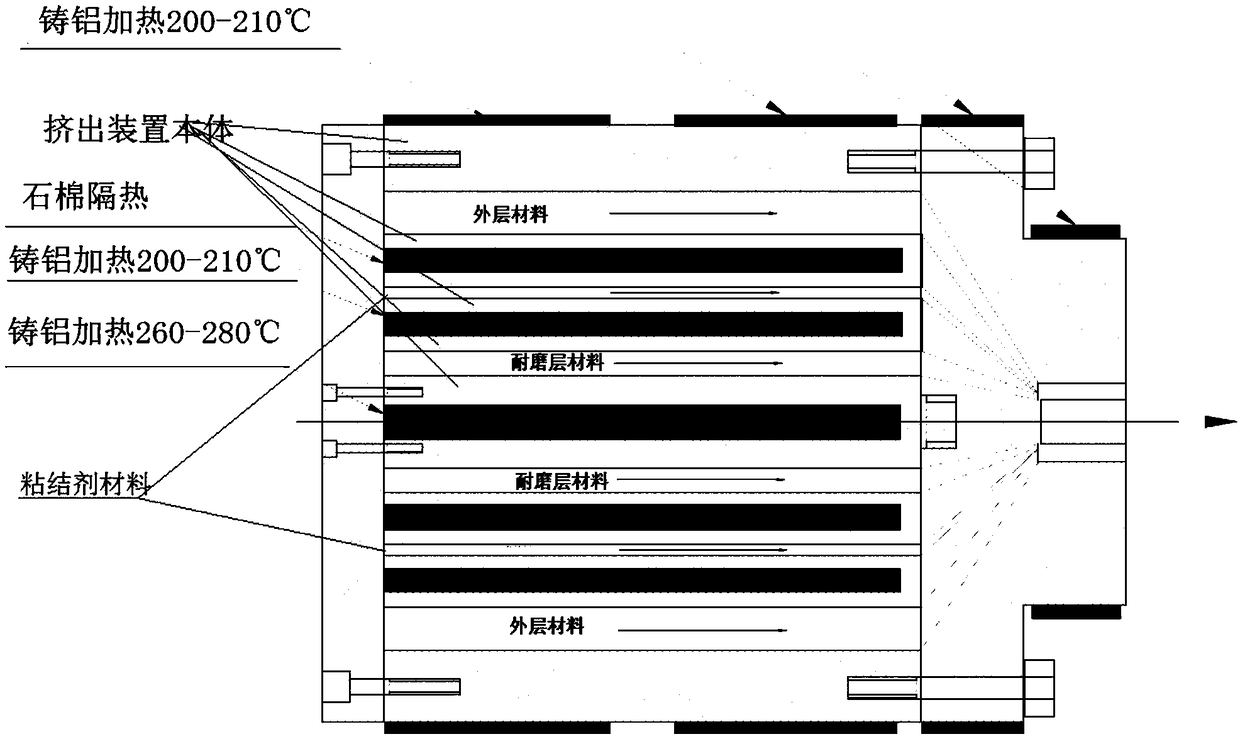

Method used

Image

Examples

Embodiment 1

[0038] 1. The high-strength adhesive A is a hot-melt adhesive with a copolymer as the matrix material corresponding to the inner layer (1) and the high-impact layer (3) and simultaneously producing a good bonding effect.

[0039] High-strength adhesive B is a technology that has been published in a Chinese patent application, and the application number is 201511000579.2. Its composition of raw material mass parts: PPR50-80; POE (ethylene-octene copolymer) 10-30; epoxy resin 1-5; dicumyl peroxide (DCP) 0.08-0.25; maleic anhydride 1-3 ; Oligomeric silsesquioxane (POSS) 0.5-2; Petroleum resin 3-8; Other additives 5-10.

[0040] Preparation includes the following steps:

[0041] (1) Dehumidification and drying of raw materials

[0042] When producing the special hot-melt adhesive of the present invention, it is necessary to ensure that the raw materials are dry; for PPR, POE (ethylene-octene copolymer), epoxy resin, petroleum resin, vacuum dehumidification is adopted, the temper...

Embodiment 2

[0082] Same as Example 1, except that the inner layer (1) of the high wear-resistant and corrosion-resistant material is made of high wear-resistant ultra-high molecular weight polyethylene UHMWPE, and the high-strength adhesive layer A (2) is made of HDPE as the base material Graft copolymer hot melt adhesive, airtight anti-leakage high-impact layer (3) adopts polybutene PB to form a composite inner core pipe together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com