Photovoltaic cell module packaging adhesive film, and preparation method and application thereof

A photovoltaic cell and encapsulation adhesive film technology, which is applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of material light transmittance decrease, yellowing, and affect the long-term service life of solar cell components, and achieve high ion barrier capacity, The effect of long-term stable operation and excellent water vapor barrier ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

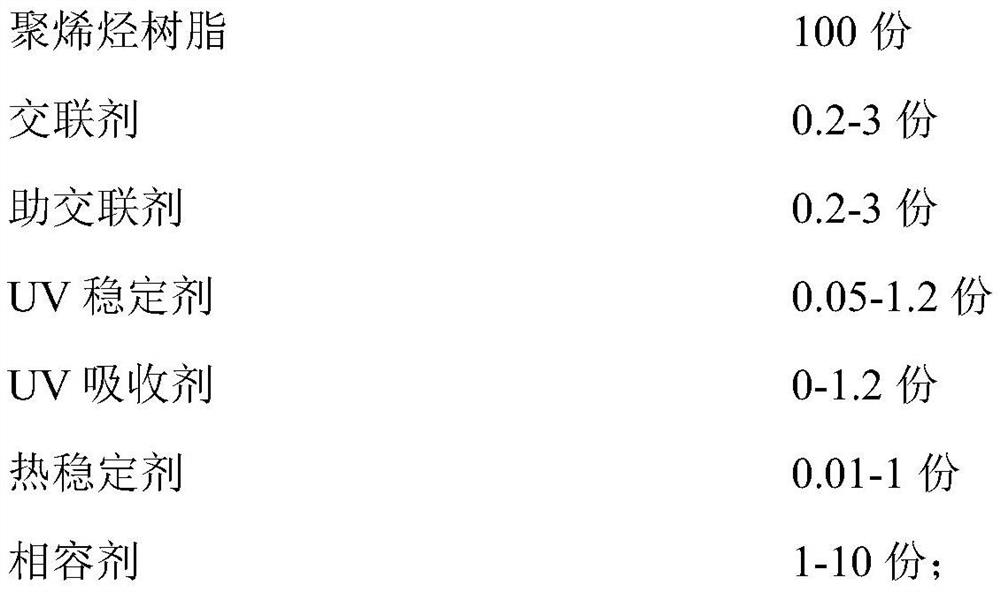

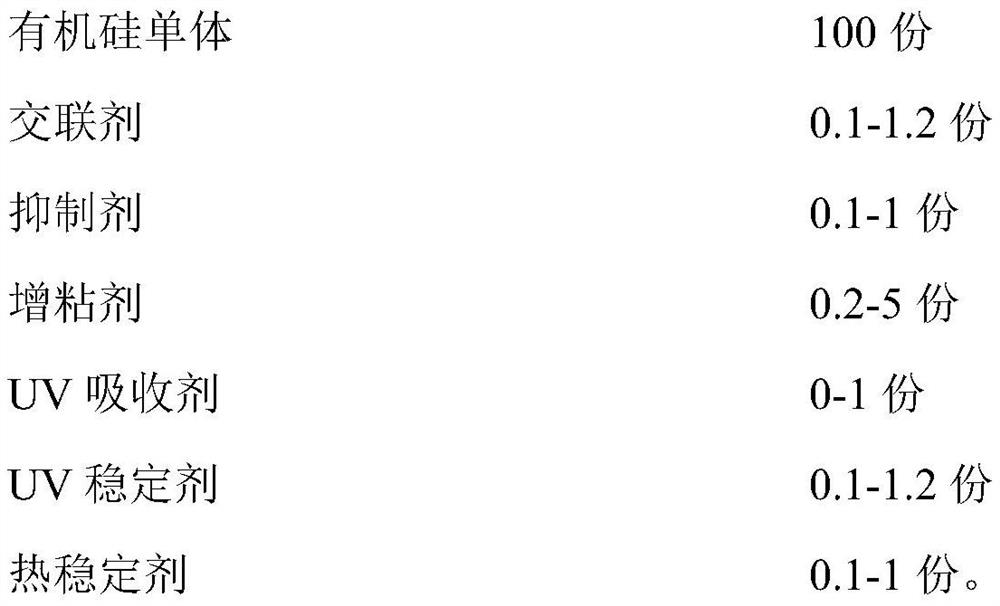

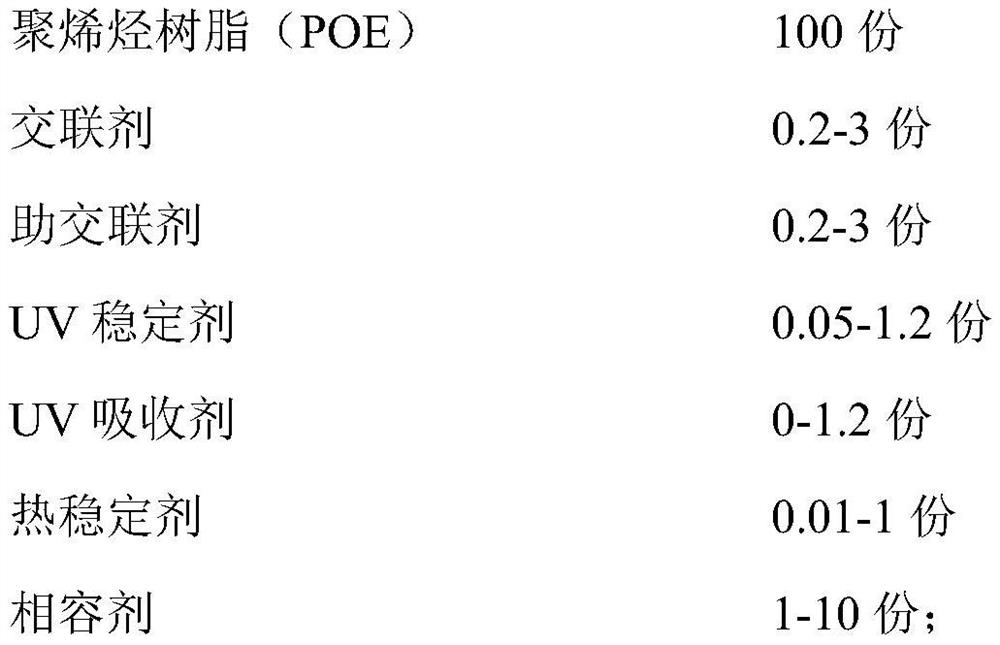

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment provides a photovoltaic cell assembly packaging film comprising a polyolefin film layer, preparation method includes the following steps:

[0056] Step S1, the polyolefin film according to the ratio of raw materials were weighed layer 100 parts POE, 0.2 parts of 2,4-dichlorobenzoyl peroxide (crosslinking agent), 0.2 parts of 3 (ethoxy) trimethylol propane triacrylate (crosslinking aid), 0.1 parts of cyanuric chloride polymer (UV stabilizers), 0.3 parts of 2- (2-hydroxy-5-methylphenyl) benzotriazole (UV absorber ), 0.15 parts of 2,6-di-t-butyl-4-methylphenol (heat stabilizer), 0.15 parts of tris (2,4-di-t-butylphenyl) phosphite (a thermal stabilizer), 10 parts of POE organosiloxane graft (compatibilizing agent), mixing kettle with stirring mixture was added, a temperature controlled mixing vessel 30 ℃ ~ 55 ℃, when the aid is sufficiently liquid to be absorbed POE particles, the end of the mixing, to obtain a first mixture;

[0057] Step S2, casting the...

Embodiment 2

[0060] The present embodiment provides a photovoltaic cell assembly of composite packaging film, a composite film of a polyolefin layer and a silicone rubber layer located on the upper and lower surface of the polyolefin film layer is formed. The preparation method includes the following steps:

[0061] Step S1, the polyolefin film according to the ratio of raw materials were weighed layer 100 parts POE, 2.8 parts of 1,1-bis (tert-butylperoxy) -3,3,5-trimethylcyclohexane (a crosslinking agent), 3 parts of trimethylolpropane trimethacrylate (co-crosslinking agent), 0.05 parts of 2,2,6,6-tetramethyl-4-piperidyl stearate (UV stabilizers), 0.01 part of tetrakis [β- (3,5- di-tert-butyl-4-hydroxyphenyl) propionate] (thermal stabilizer), 1 part of organosiloxane graft POE (compatibilizing agent), mixture was added stirring and mixing feed kettle; controlled mixing pot temperature 30 ℃ ~ 55 ℃, when the aid is sufficiently liquid to be absorbed POE particles, the end of the mixing, to obta...

Embodiment 3

[0068] The present embodiment provides a photovoltaic cell assembly of composite packaging film, a composite of a silicone rubber layer on a polyolefin film layer and a surface layer formed by a polyolefin film. The preparation method includes the following steps:

[0069] Step S1, the polyolefin film according to the ratio of raw materials were weighed layer 100 parts POE, 1.6 parts of peroxide, 3,3,5-trimethyl hexanoate (crosslinking agent), 1.2 parts of 3,5 tri-2-propenyl-1,3,5-triazine -2,4,6 (1H, 3H, 5H) - trione (co-crosslinking agent), 0.9 parts of bis (1-octyloxy -2, 2,6,6-tetramethyl-4-piperidyl) sebacate (UV stabilizer), 1 part of 2- (2-hydroxy-3,5-di-t-butylphenyl) -5-chloro Generation benzotriazole (UV absorber), 0.8 parts of sebacic acid (2,2,6,6-tetramethyl-4-piperidyl) ester (thermal stabilizer), 3 parts of POE grafted ethylene methyl silane (compatibility agent), mixing kettle with stirring mixture was added, a temperature controlled mixing vessel 30 ℃ ~ 55 ℃, when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com