EVA/EVM blending type thermoplastic vulcanizate and preparation method therefor

A thermoplastic vulcanizate and blending technology, which is used in the preparation and performance research of thermoplastic vulcanizates, in the field of thermoplastic vulcanizate preparation, can solve the problems of low hardness, UV aging resistance, poor UV aging resistance, etc. The effect of anti-UV aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

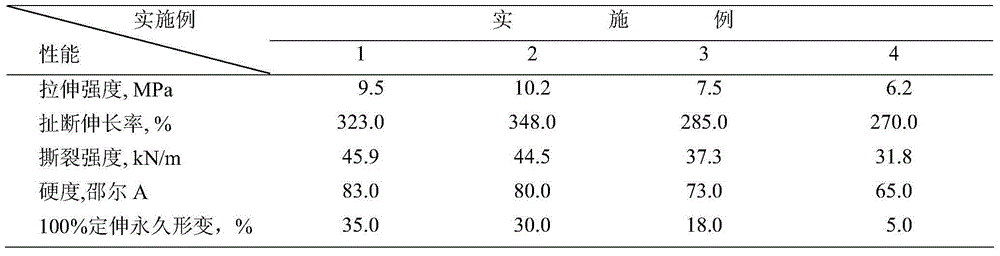

Embodiment 1

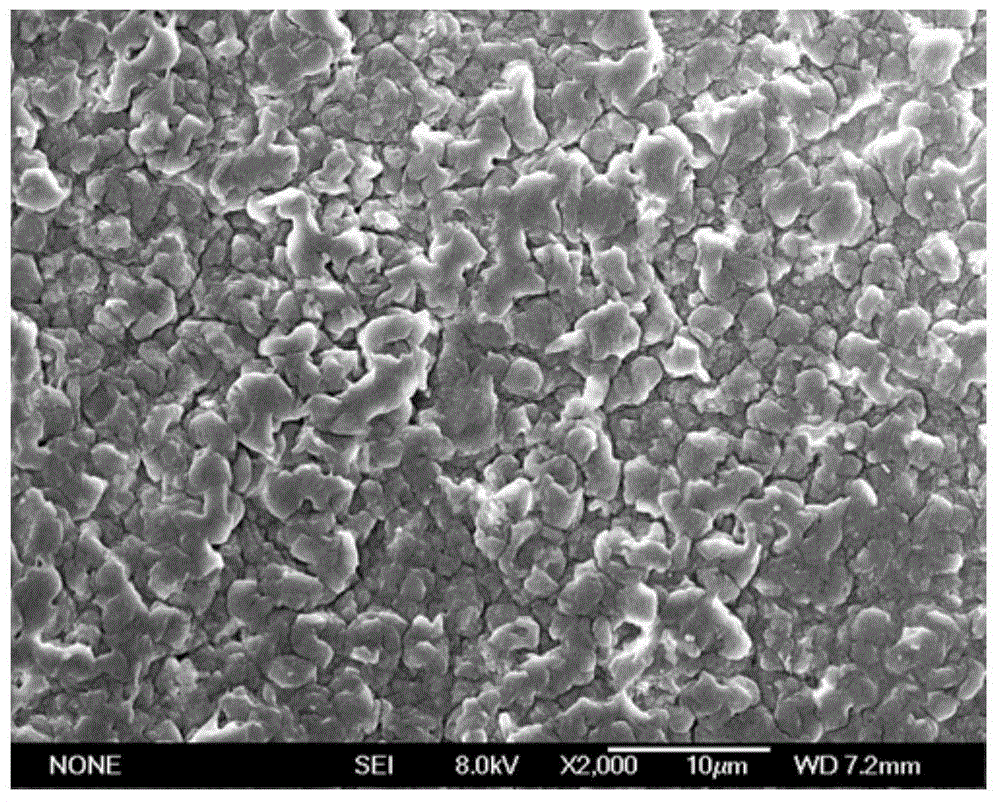

[0018] Example 1: Preparation of EVA / EVM blended thermoplastic vulcanizate

[0019] (1) 50.0 grams of EVM (vinyl acetate mass content is 50%) rubber particles are added into an open mill at 30° C. with a roller spacing of 1.0 mm, then 1.0 grams of DCP and 1.5 grams of TAIC are added, and mixed for 3 minutes to obtain EVM rubber compound;

[0020] (2) 50 grams of EVA (vinyl acetate mass content is 15%) resin is melted and plasticized on a two-roll mill at 165°C; EVM compound rubber is added to the mill afterwards, and is mixed with the EVA melt of melting at temperature Dynamic vulcanization under the action of field and shear force field for 8 minutes;

[0021] (3) After the dynamic vulcanization is over, quickly remove the sheet from the mill and cool it down, then put the sample into a stainless steel mold with a polytetrafluoroethylene isolation film, preheat it at 165°C for 5 minutes with a flat vulcanizer, and then Molded under a pressure of 10MPa for 8 minutes, and the...

Embodiment 2

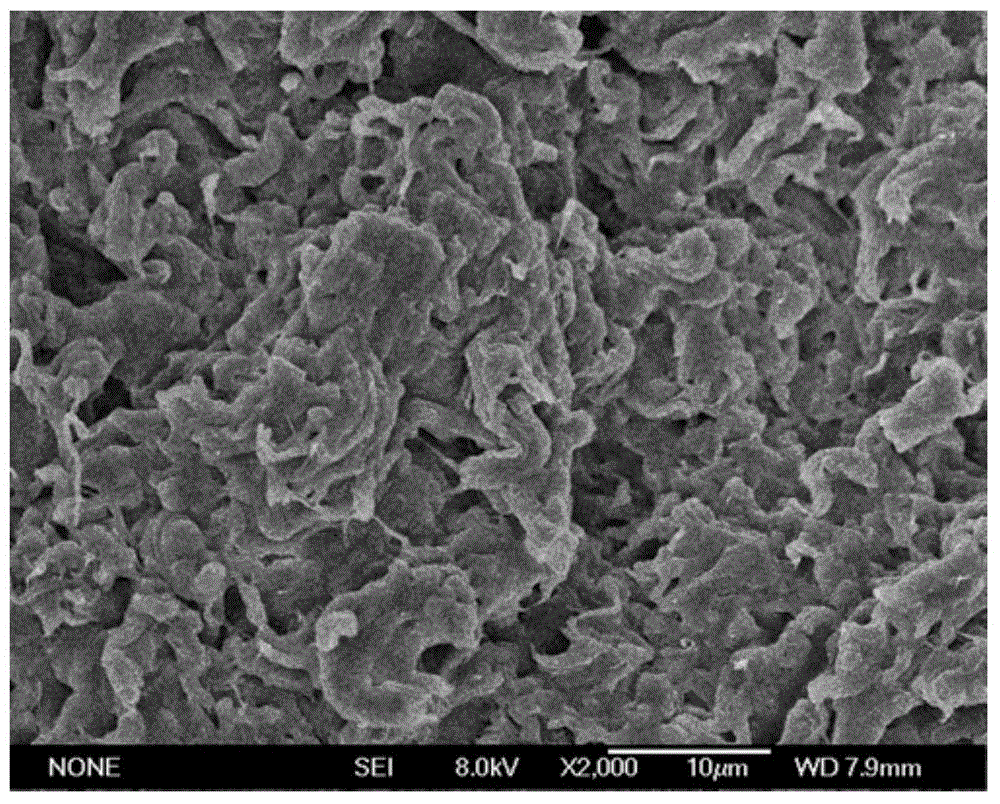

[0024] Example 2: Preparation of EVA / EVM blended thermoplastic vulcanizate

[0025]EVM (mass content of vinyl acetate is 50%), DCP, TAIC and EVA (mass content of vinyl acetate is 20%) are 60 grams, 1.2 grams, 1.8 grams and 40 grams respectively. The rest is the same as implementation 1.

Embodiment 3

[0026] Example 3: Preparation of EVA / EVM blended thermoplastic vulcanizate

[0027] EVM (vinyl acetate mass content is 60%), DCP, TAIC and EVA (vinyl acetate mass content is 15%) are 70 grams, 1.4 grams, 2.1 grams and 30 grams respectively. The rest is the same as implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com