High-wear-resistance vacuum coating hydroxyl acrylic coating as well as preparation method and application thereof

A technology of coating hydroxy acrylic acid and vacuum coating, applied in the field of coatings, can solve the problems of easy paint chipping, poor bending resistance, easy cracking and peeling paint, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

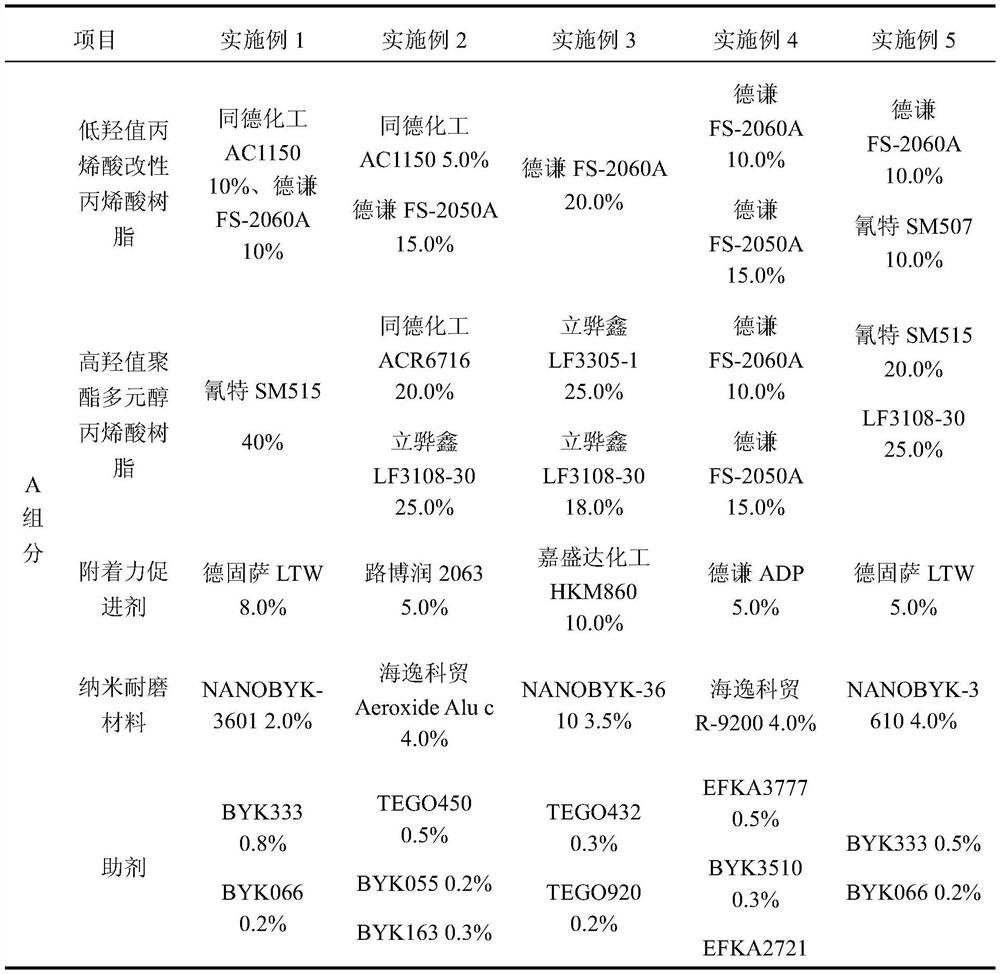

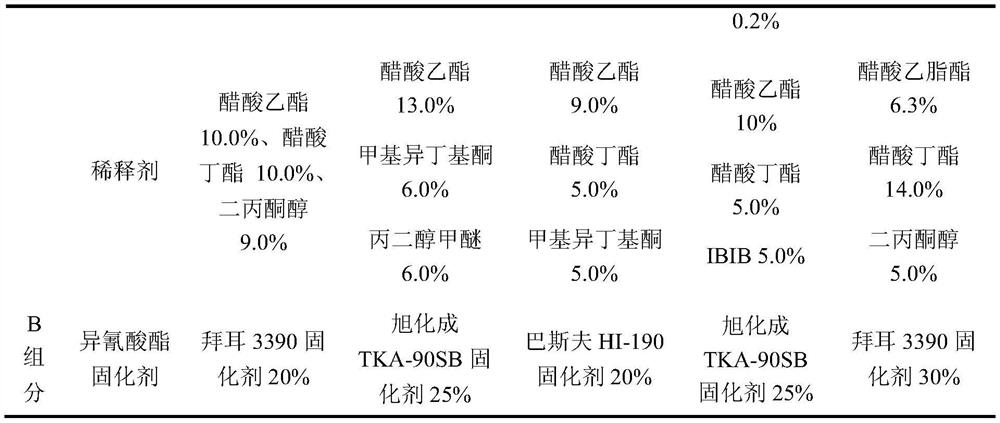

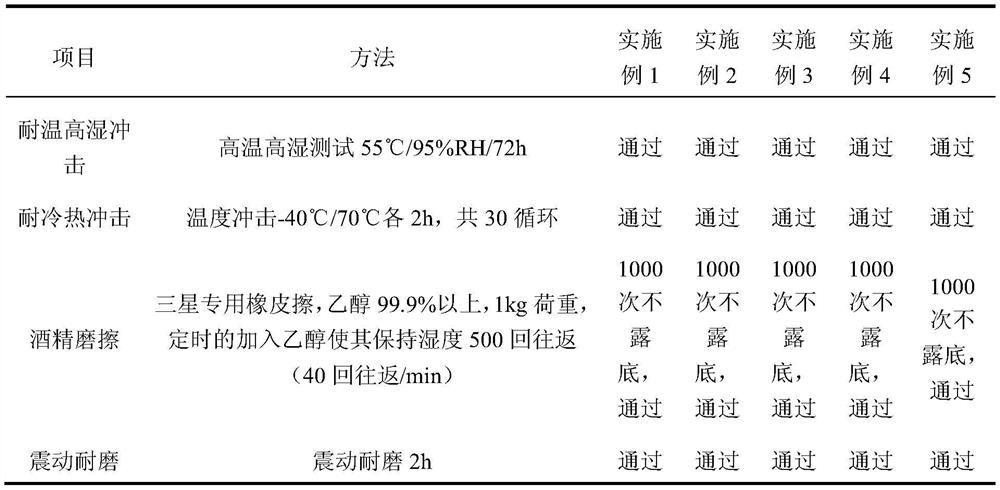

Examples

preparation example Construction

[0035] According to another aspect of the present invention, there is also provided a preparation method of the above-mentioned high wear-resistant vacuum-coated hydroxyacrylic paint, comprising the following steps:

[0036] (1) Preheating the low hydroxyl value acrylic modified acrylic resin and the high hydroxyl value polyester polyol acrylic resin, placing it in the reaction kettle after preheating and adding part of the diluent to fully stir evenly;

[0037] (2) add adhesion promoter in the reactor again, heat and stir evenly;

[0038] (3) adding nano wear-resistant material, auxiliary agent and remaining diluent to the reaction kettle, stirring evenly, filtering to obtain A component;

[0039] (4) Mix the A component and the B component uniformly to obtain a high wear-resistant vacuum coating hydroxy acrylic paint.

[0040] The preparation method of the high-wear-resisting vacuum-coated hydroxy acrylic coating of the present invention is based on the fact that the low-hy...

Embodiment 1

[0054] High Abrasion Resistant Vacuum Coated Hydroxy Acrylic Paint:

[0055] Including component A and component B, component A includes the following mass percentages: Tongde Chemical AC1150 10%, Deqian FS-2060A 10%, Cytec SM515 40.0t%, Degusa LTW 8.0%, NANOBYK-3601 2.0% , BYK333 0.8%, BYK0660.2%, ethyl acetate 10.0%, butyl acetate 10.0%, diacetone alcohol 9.0%, B component uses Bayer 3390 curing agent, the mass ratio of A component to B component is 100: 20.

[0056] The preparation method of high wear-resisting vacuum coating hydroxy acrylic coating comprises the following steps:

[0057] (1) Put Tongde Chemical AC1150, Deqian FS-2060A and Cytec SM515 at 50℃, preheat for 15min, put them in the reaction kettle after preheating and add 1 / 2 of ethyl acetate, butyl acetate and diacetone The alcohol is fully stirred, the stirring speed is 1000 rpm, and the stirring time is 40 minutes;

[0058] (2) add Degussa LTW to the reactor again, be heated to 50 ℃, the rotating speed of ...

Embodiment 2

[0062] The composition ratio of each component of the highly wear-resistant vacuum-coated hydroxyacrylic coating is shown in Table 1, and its preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com