Uvioresistant epoxy composition and its preparing method and use

An epoxy composition, anti-ultraviolet technology, applied in electrical components, circuits, electrical solid devices, etc., can solve the problems of resin stability, low transmittance in the short wavelength field, resin discoloration, etc., which are unfavorable for sealing semiconductors, and achieve improvement LED luminous intensity is uneven, excellent anti-ultraviolet aging performance, the effect of preventing ultraviolet leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

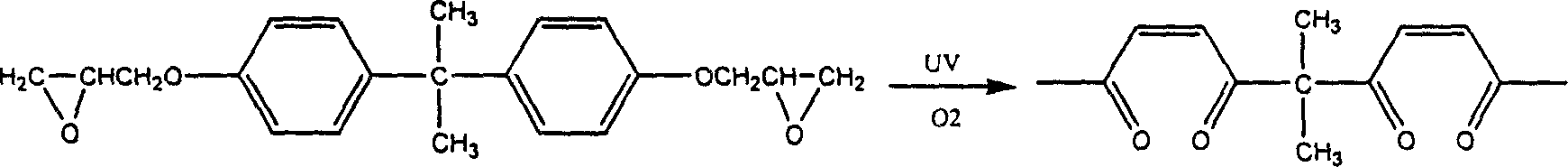

Method used

Image

Examples

Embodiment 1

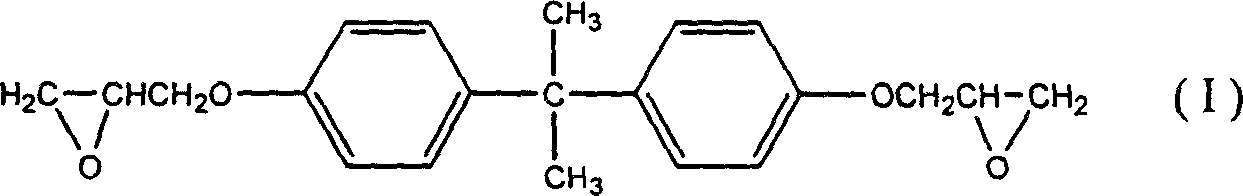

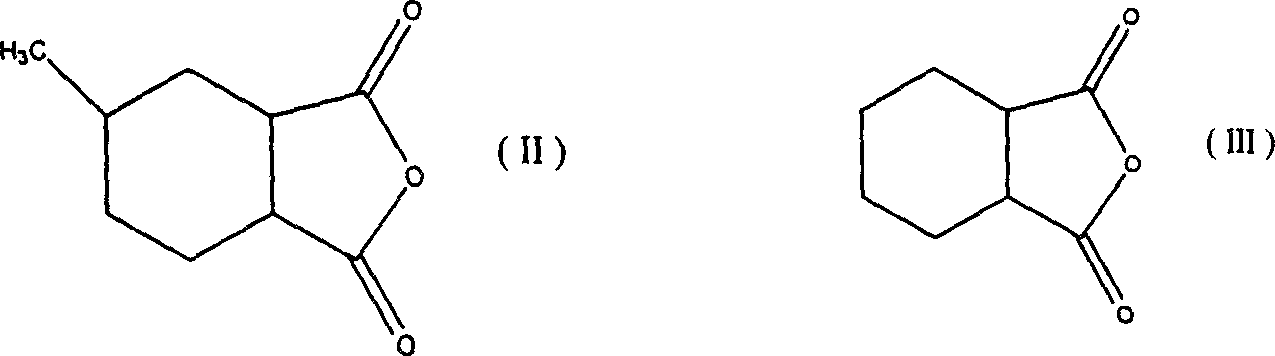

[0034] In a 200ml Erlenmeyer flask, add 50 parts by weight of hexahydrophthalic anhydride (curing agent), 0.15 parts by weight of tetraethylammonium bromide (curing accelerator), 1 part by weight of 2,2 methylene-bis(4 -methyl-6-tert-butylphenol) (antioxidant), 0.001 parts by weight of 2,4-dihydroxybenzophenone (ultraviolet absorber), 0.001 parts by weight of BaTiO 2 (absorbent and scattering agent), heated to 80° C. under magnetic stirring, and cooled to room temperature after the mixture was completely dissolved. Add 100 parts by weight of bisphenol A epoxy resin DGEBA and stir evenly to obtain the UV-resistant epoxy composition I of the present invention.

Embodiment 2~10

[0038] According to the method of Example 1, anti-ultraviolet epoxy compositions II to X with different compositions were prepared, and their compositions and contents are listed in Table 1.

[0039] Reality

Embodiment 11

[0041] With embodiment 1~10 and comparative example 1 # Prepared anti-ultraviolet epoxy composition I~X and I # After vacuum defoaming, solidify in an oven at 130°C for 2 hours, and take out the sample after cooling in the oven. Then reheat to 130°C for 2h to remove residual stress and volatile components. Then the samples were tested for photoaging properties, mechanical properties, and thermal properties, and the obtained data are listed in Table 2.

[0042] 1. Photoaging performance: The fluorescent lamp Q-UV Tester with a wavelength of 340nm was used to irradiate for 1000h, and the transmittance of the sample was measured with an Agilengt 8453UV-visible Spectroscopy System UV-visible spectrophotometer before and after irradiation.

[0043]2. Mechanical properties: The flexural strength test of the samples was measured on the RGT-20A testing machine of the Cryogenic Materials Laboratory of the Institute of Physics and Chemistry, Chinese Academy of Sciences according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com