Patents

Literature

39results about How to "Suitable for industrial manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrode for Alkali Fuel Cell and Method for Making a Fuel Cell Including at Least One Step of Making Such an Electrode

InactiveUS20090042092A1Improve efficiencyEasy to implementFinal product manufacturePrimary cellsNano sizeElectron

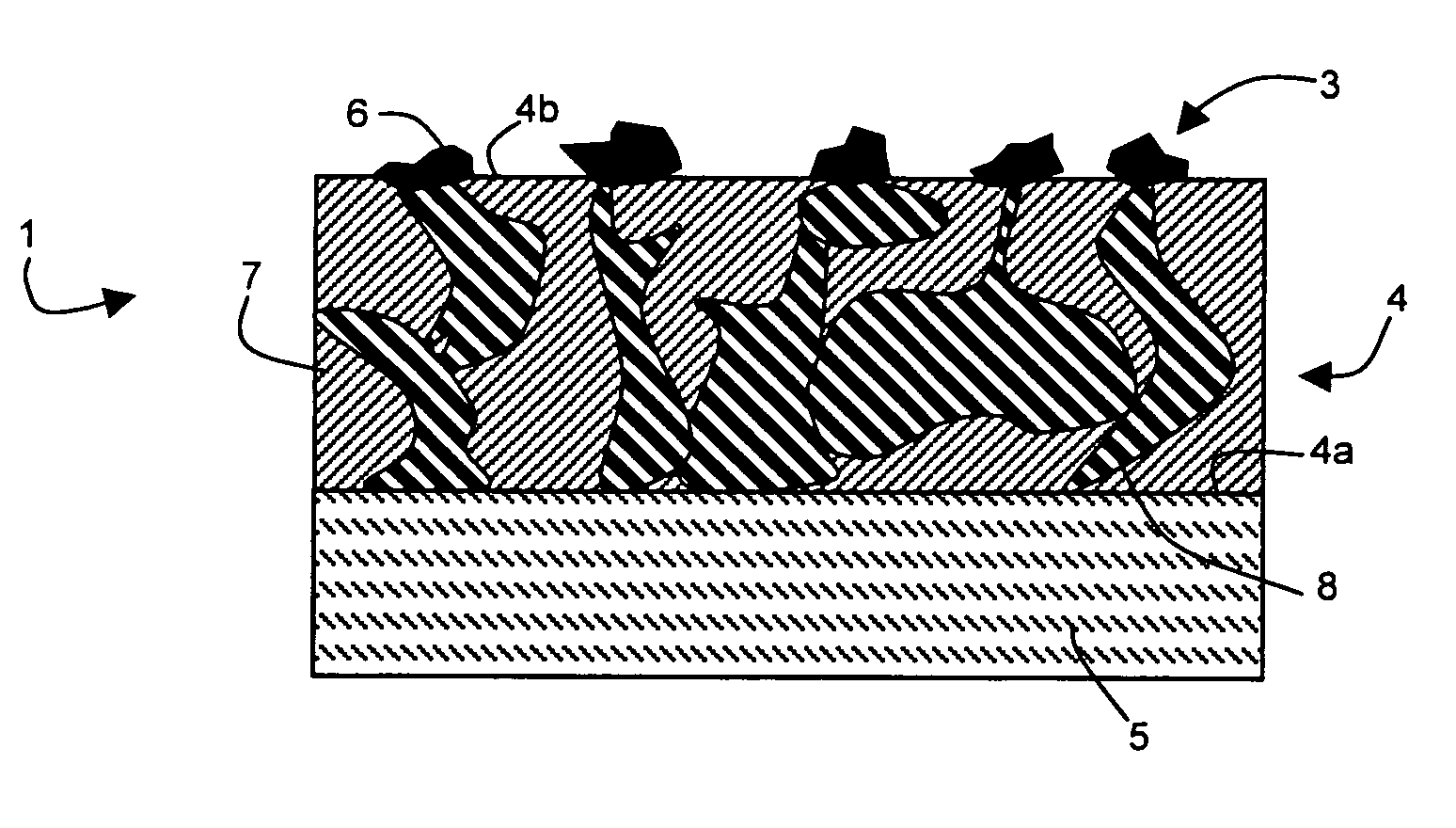

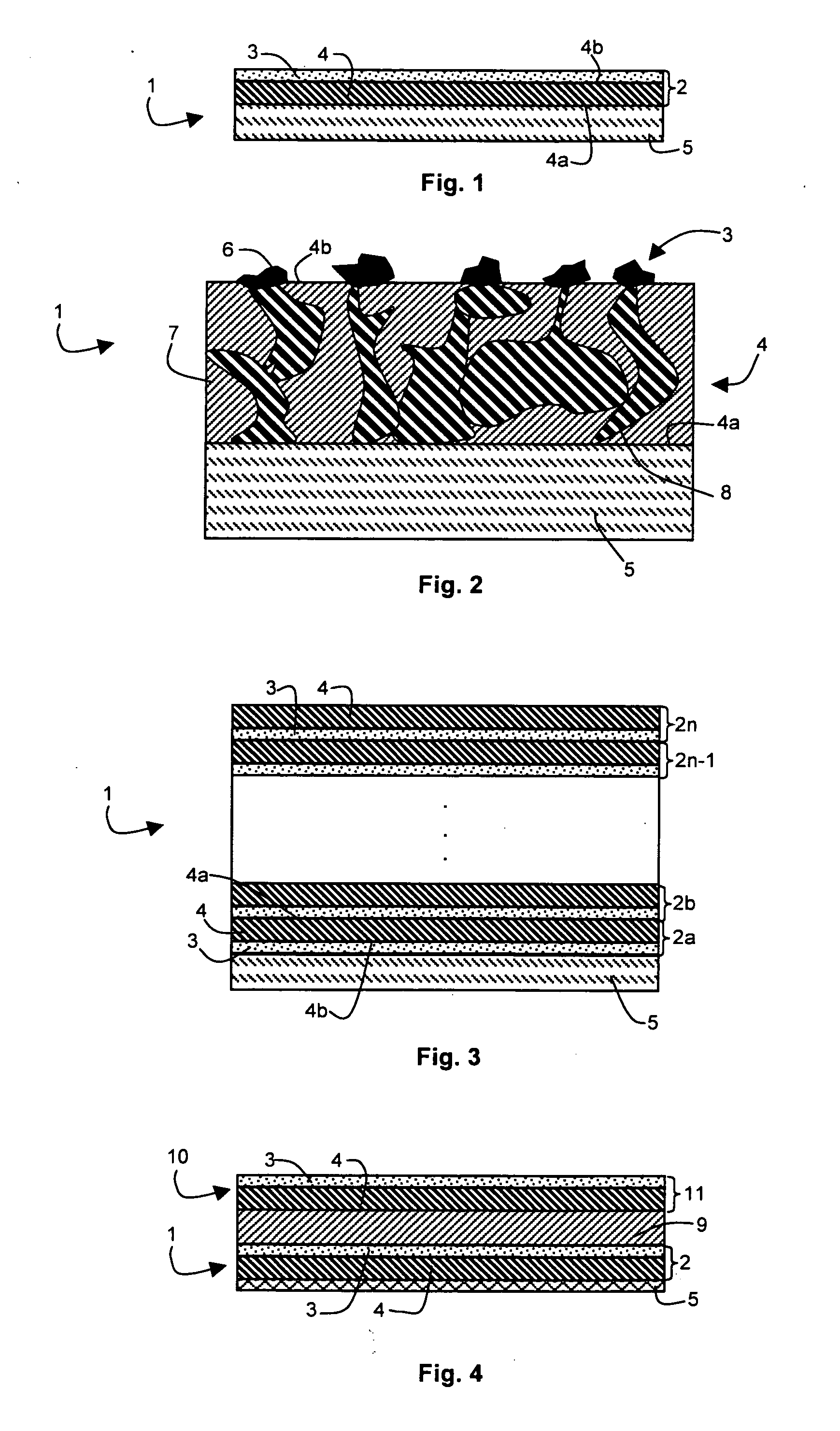

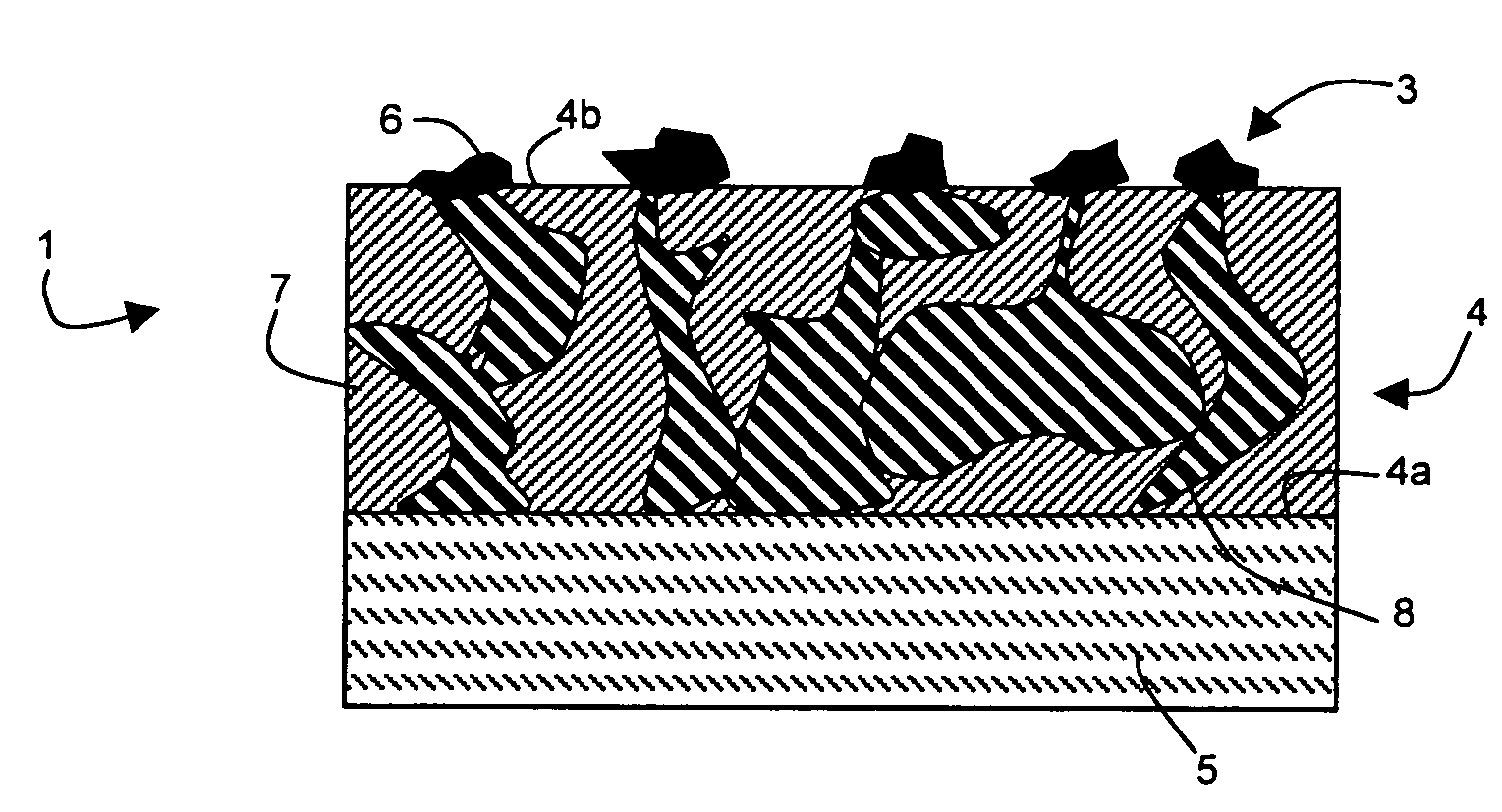

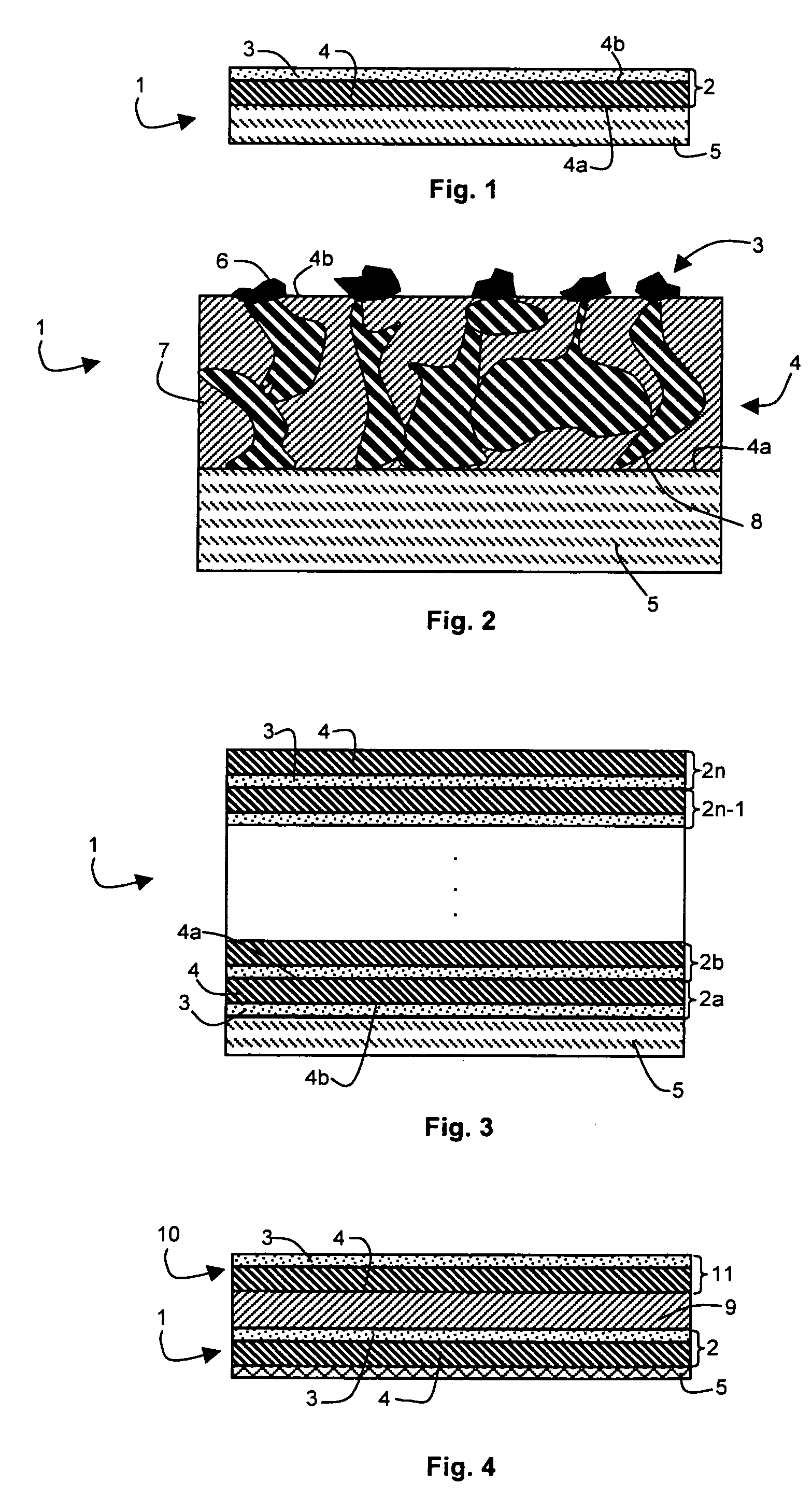

An electrode for an alkali fuel cell comprises an active layer formed by a bilayer or by a stack of a plurality of bilayers. Each bilayer is composed of a catalytic layer comprising catalyst particles of nanometric size and of a porous layer comprising two opposite faces one of which is in contact with the catalytic layer. The porous layer is made from a porous composite material comprising a hydroxide ion conducting polymer matrix in which a metallic lattice is formed constituting a plurality of electronically conducting paths connecting the two opposite faces of the porous layer. Advantageously, fabrication of such an electrode is obtained by successively performing vacuum deposition of the catalyst particles and vacuum co-deposition of the hydroxide ion conducting polymer and of the metal on a free surface of a support.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

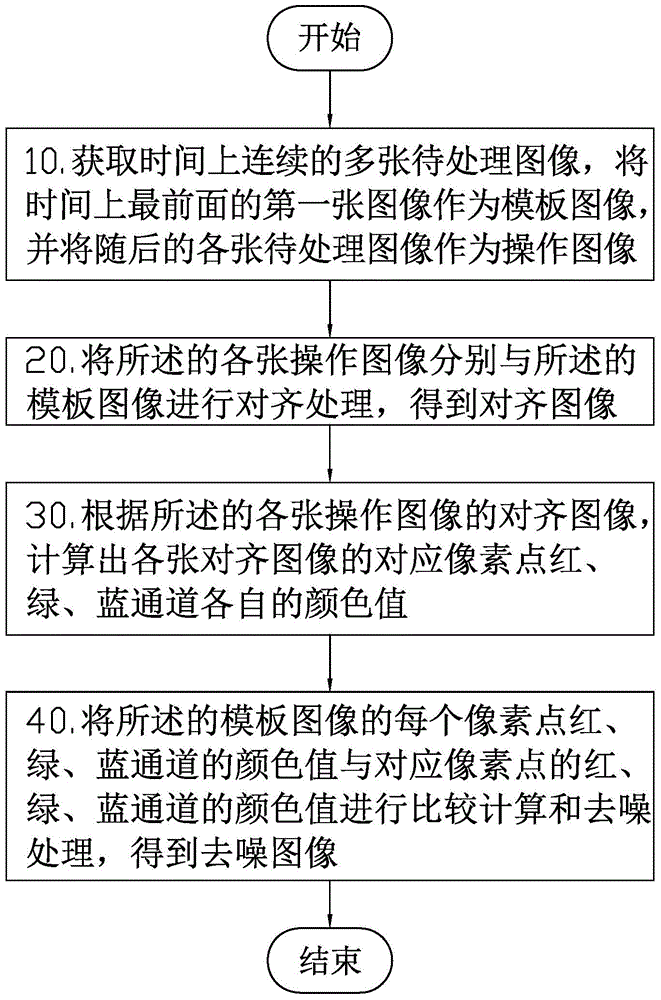

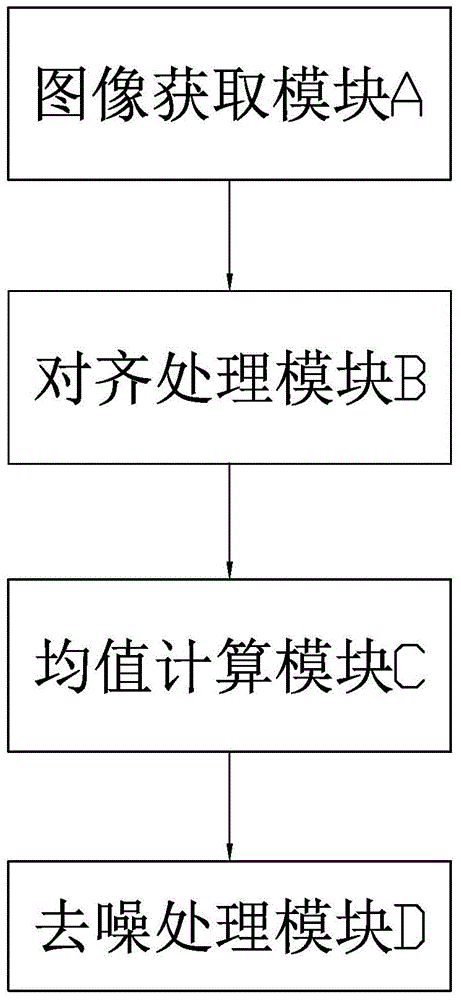

Alignment-based image denoising method and system

The invention discloses an alignment-based image denoising method and system. The method includes the following steps that: a plurality of images to be processed which are continuous in the aspect of time are obtained, and the first foremost image in the aspect of time is adopted as a template image, and the subsequent images to be processed are adopted as operation images; alignment processing is performed on the operation images and the template image, so that alignment images can be obtained; respective color values of red, green and blue channels of corresponding pixels of the alignment images are calculated; and finally, comparative calculation and denoising processing are performed on the red, green and blue channels of each pixel of the template image and the red, green and blue channels of the corresponding pixels of the alignment images, so that de-noised images can be obtained. The algorithm is simple and convenient to use, and has high time and space efficiency, and can be better applied to production and popularization, and is very suitable for industrial manufacturing.

Owner:XIAMEN MEITUZHIJIA TECH

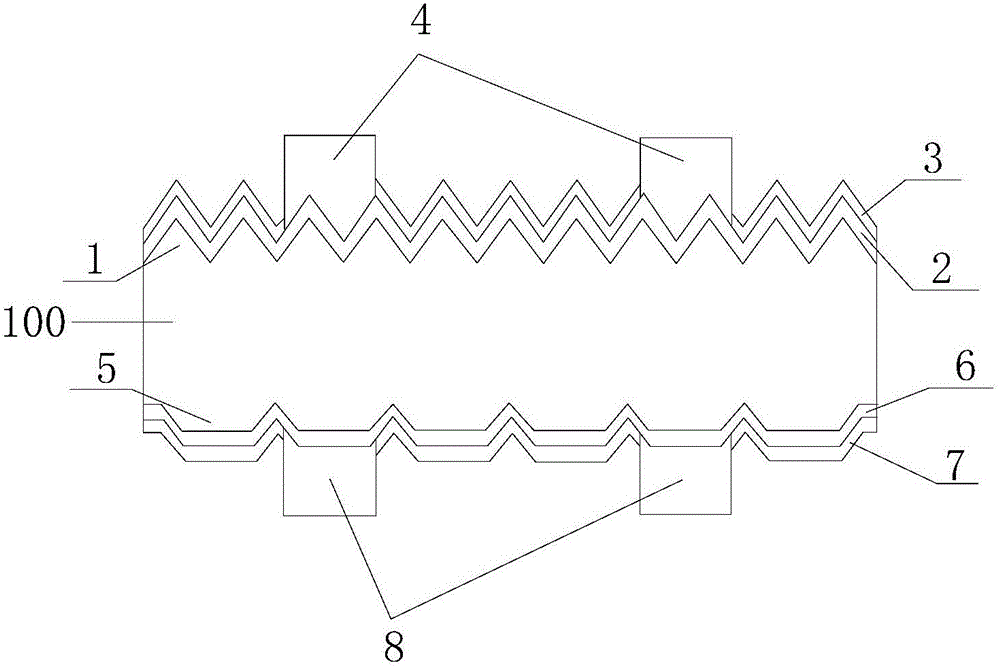

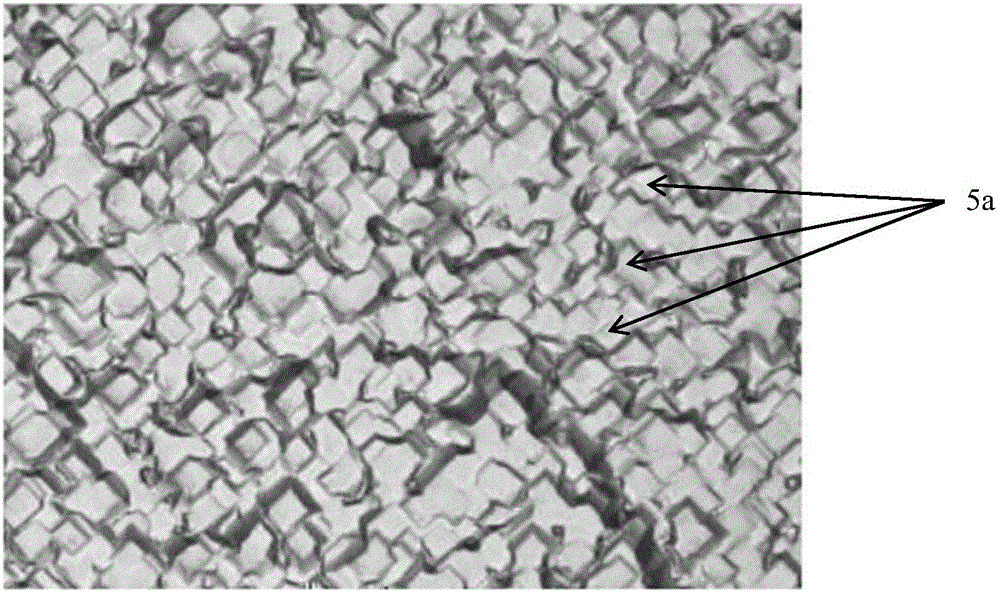

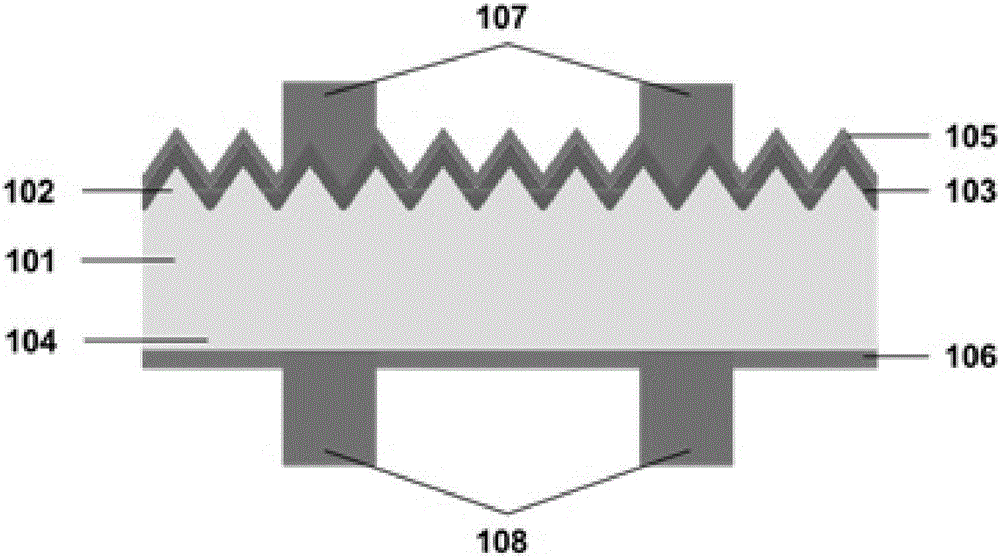

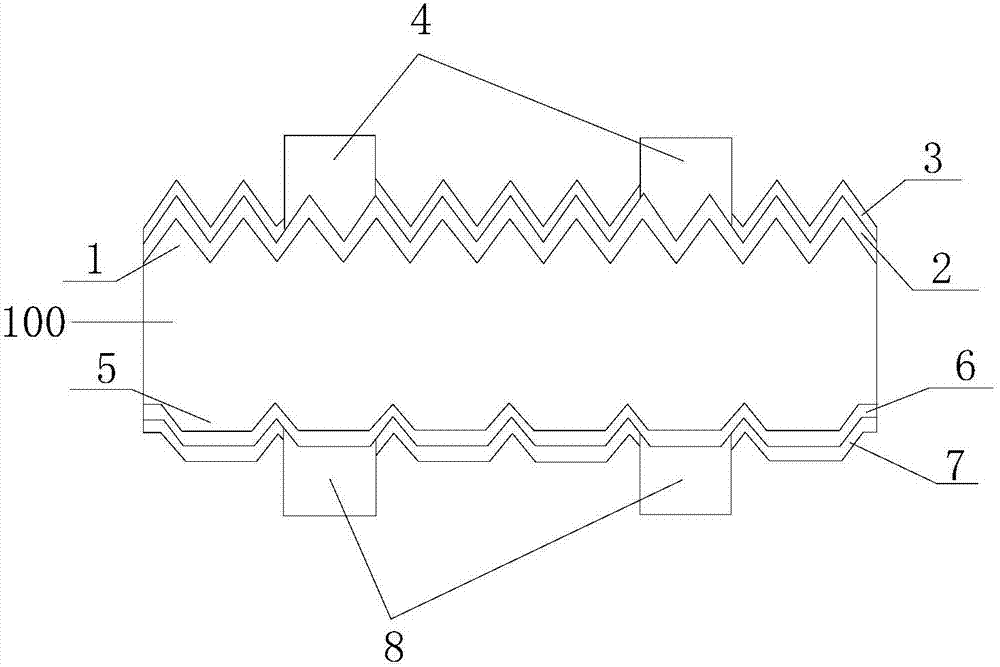

Mono-crystalline silicon double-sided solar cell and preparation method thereof

ActiveCN105826411ASmall surface areaIncrease reflectionFinal product manufacturePhotovoltaic energy generationBack surface fieldCrystalline silicon

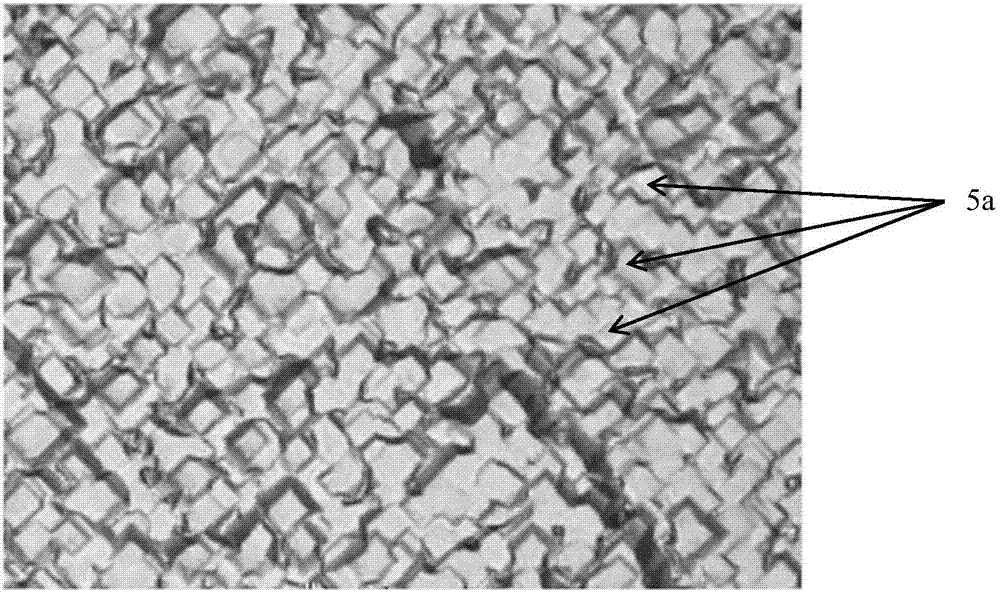

The invention discloses a mono-crystalline silicon double-sided solar cell. A front texturing morphology structure (1), a front PN emitter junction (2), a front passivated anti-reflection medium layer (3) and a front electrode (4) are sequentially formed on the front of a mono-crystalline silicon substrate (100). A back texturing morphology structure (5), a back surface field (6), a back passivated anti-reflection medium layer (7) and a back electrode (8) are sequentially formed on the back of the mono-crystalline silicon substrate. The solar cell is characterized in that the back texturing morphology structure (5) is a platform type texture surface, and platform structures (5a) are distributed on the mono-crystalline silicon substrate in a scattered, or tiled, or partially scattered, partially tiled, partially connected and partially overlapped way. The invention further discloses a preparation method of the mono-crystalline silicon double-sided solar cell. The minority carrier surface recombination and optical absorption characteristics of the double-sided solar cell are optimized, and the efficiency of quantum conversion is improved.

Owner:TRINA SOLAR CO LTD

Poly(p-phenylene benzobisoxazole) composite fiber containing nano-TiO2 preparation method

InactiveCN101613892AExcellent UV aging resistanceSuitable for industrial manufacturingSpinning head liquid feederWet spinning methodsChemistryMechanical property

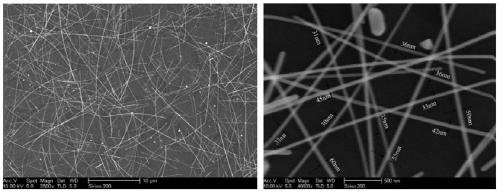

The invention relates to a poly(p-phenylene benzobisoxazole) (PBO) composite fiber containing nano-TiO2 preparation method, comprising the following steps: dissolving 4,6-diaminoresorcinol hydrochloride and terephthalic acid and a certain number of phosphorus pentoxide in equal molar ratio in polyphosphoric acid, removing hydrogen chloride gas, heating and polymerizing to obtain poly(p-phenylene benzobisoxazole), then adding poly(p-phenylene benzobisoxazole) and phosphoric acid solution containing nano-TiO2 in a double-screw extruder and obtaining PBO composite fiber containing nano-TiO2 by dry-jet wet spinning; the invention uses nano-TiO2 particles with ultraviolet shielding property and utilizes the strong shearing and high effective blending of the double-screw extruder to prepare the composite fiber; compared with pure PBO fiber, the ultraviolet aging resistance property is effectively improved while the mechanical properties are not reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

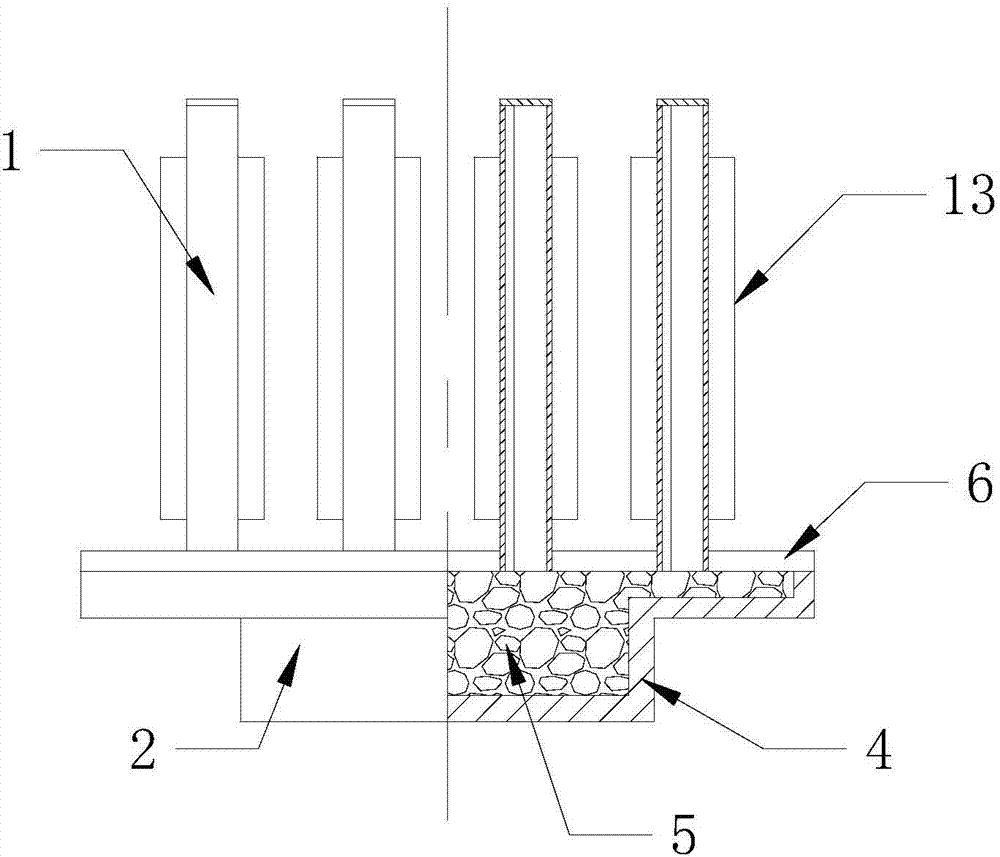

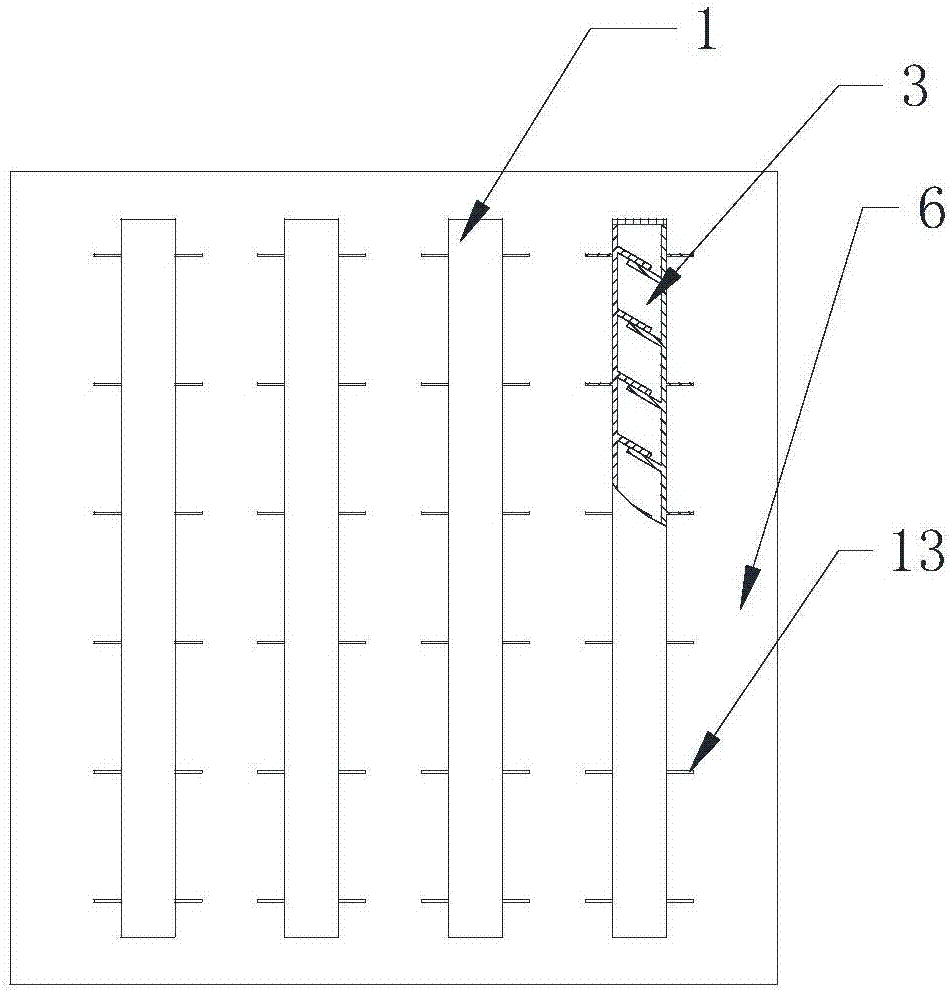

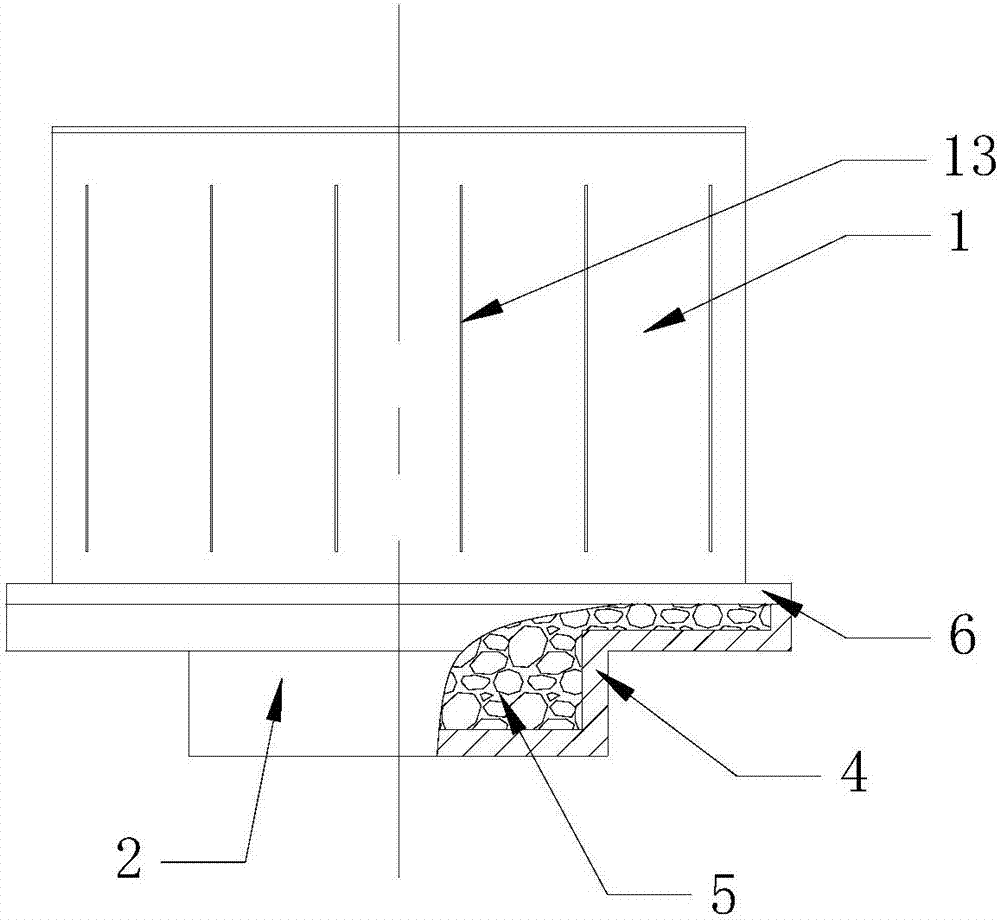

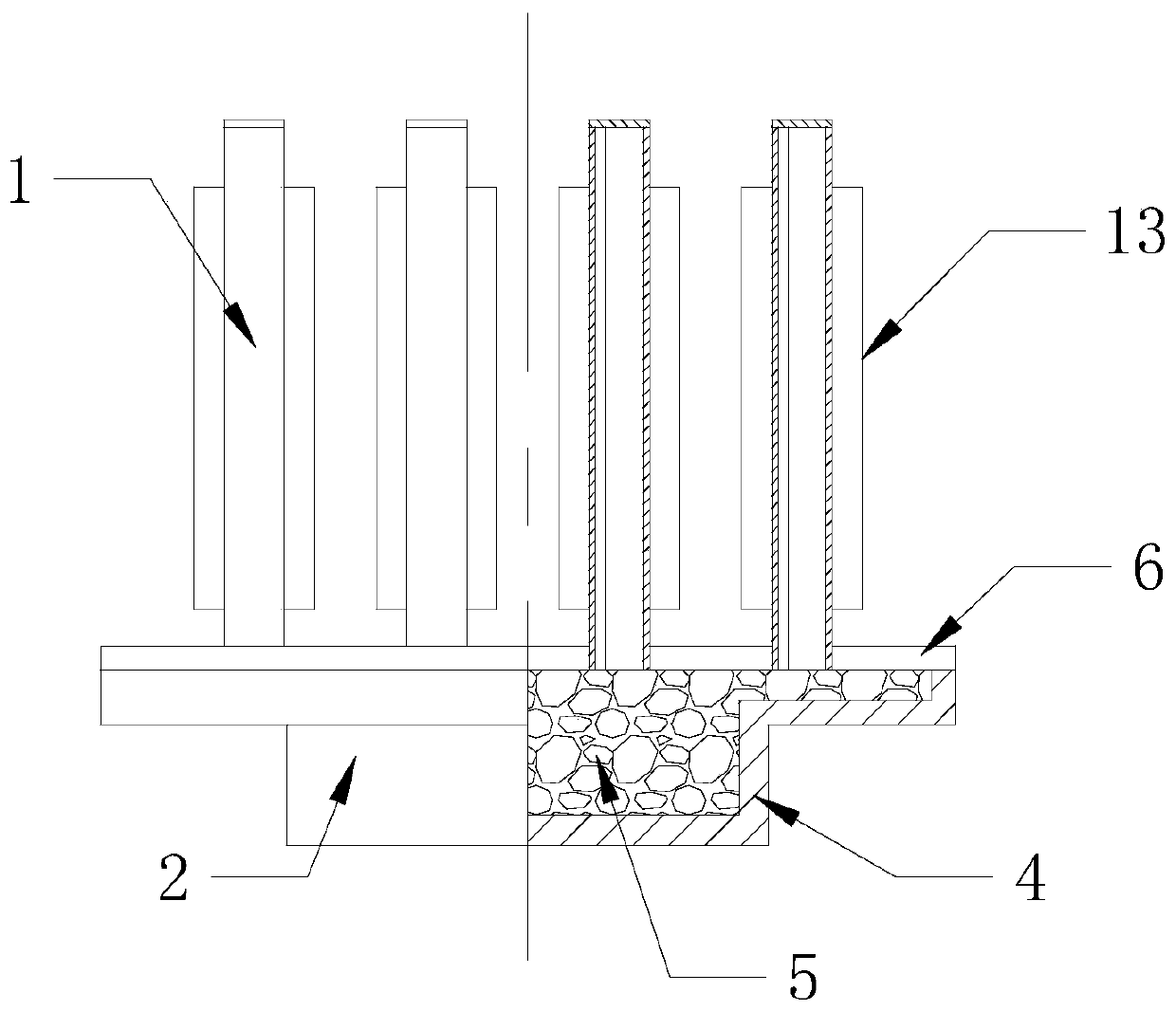

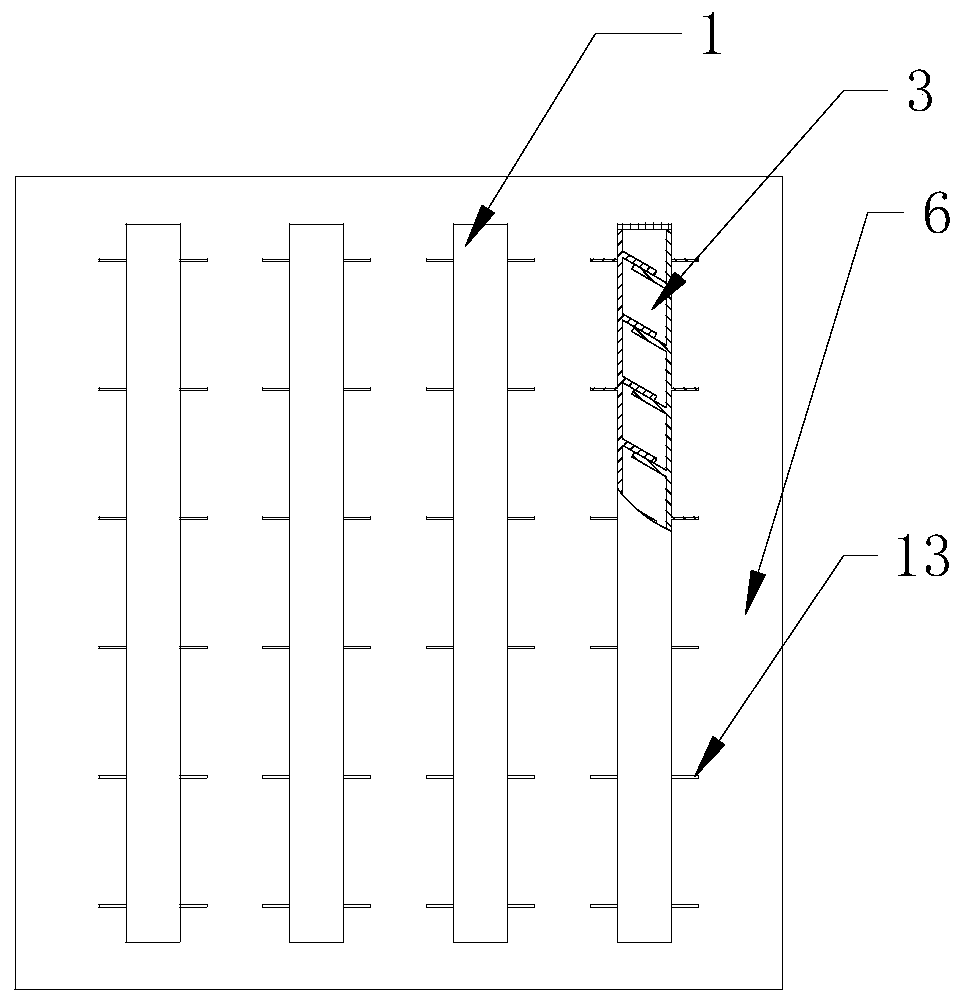

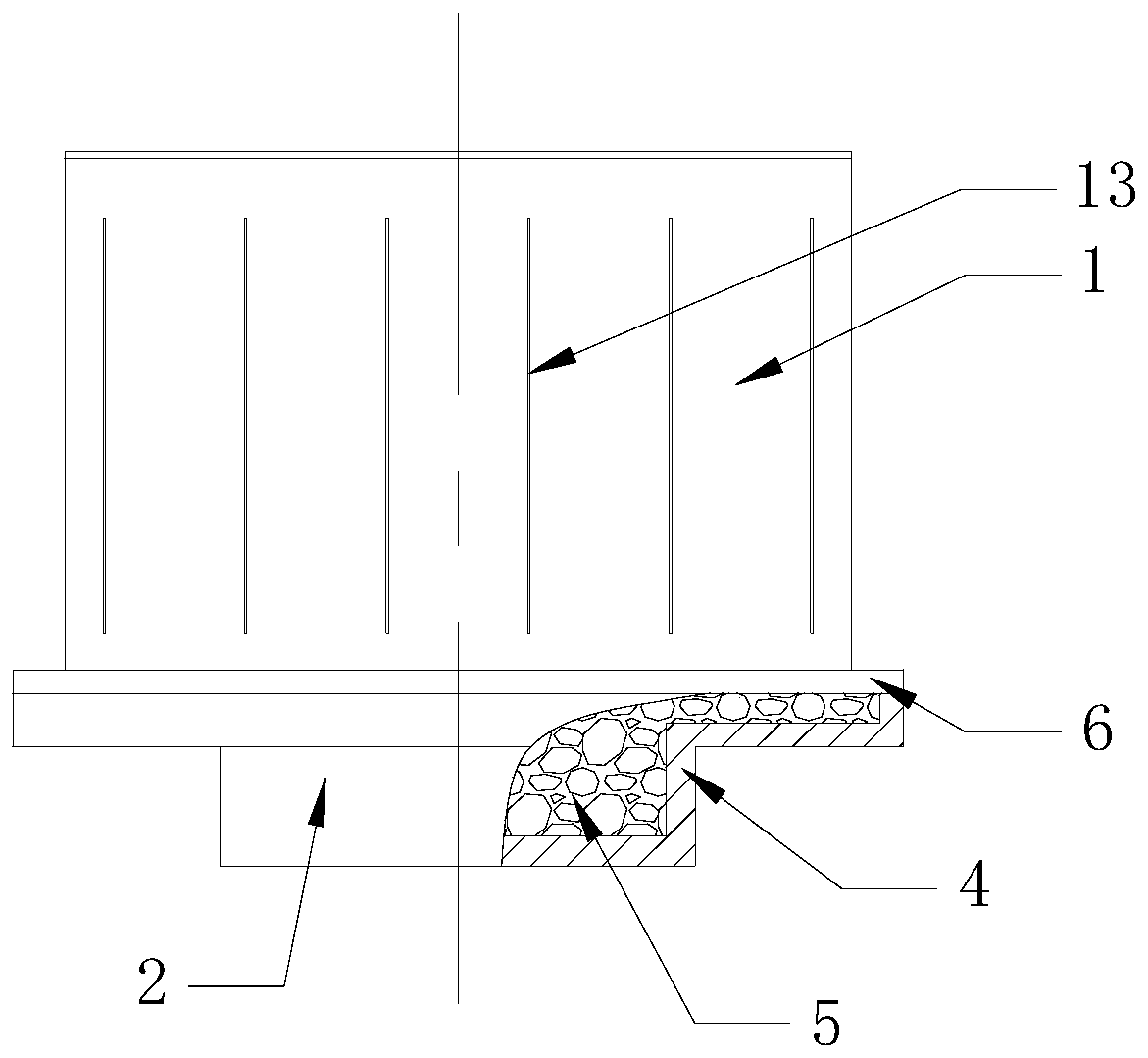

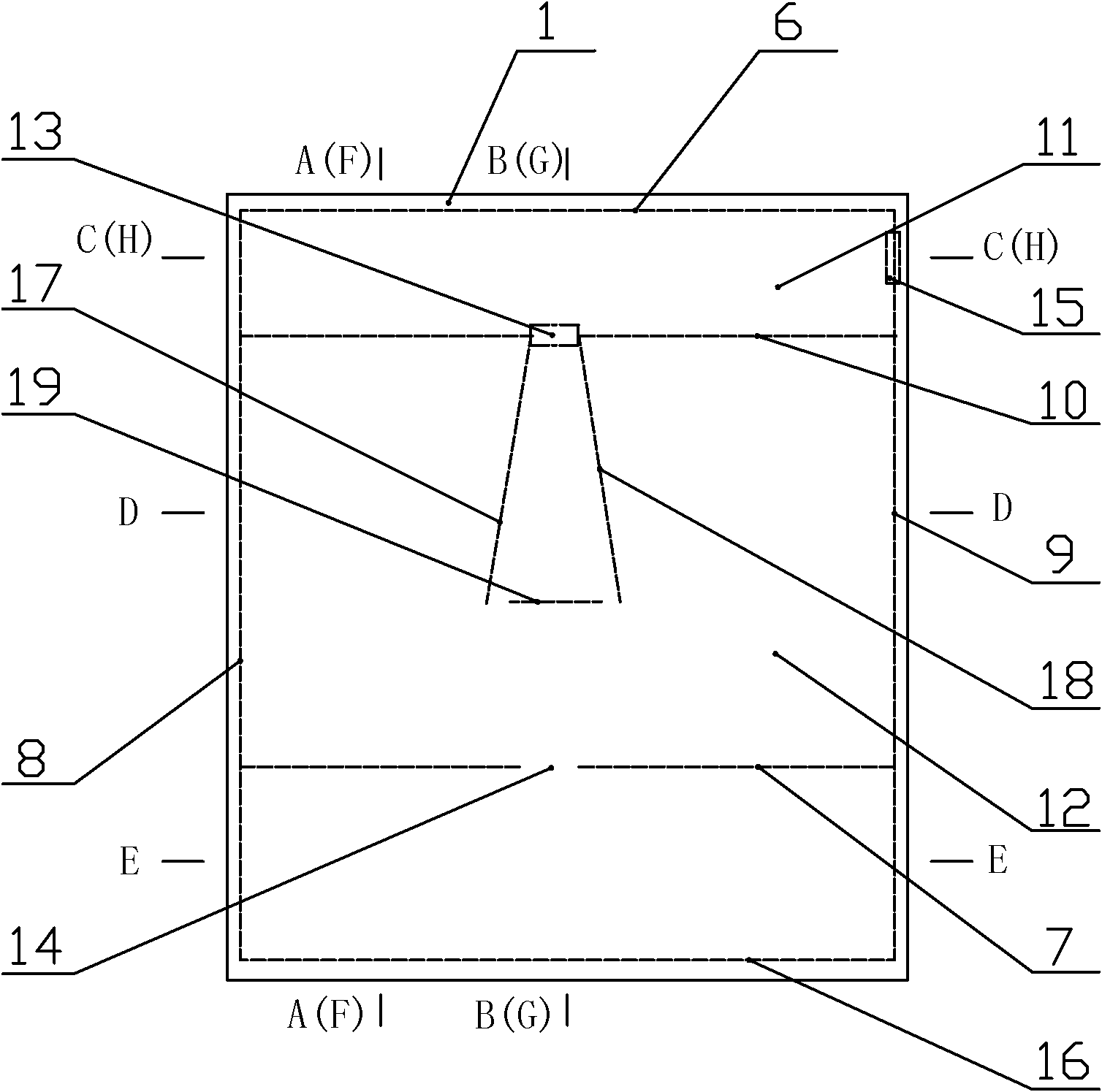

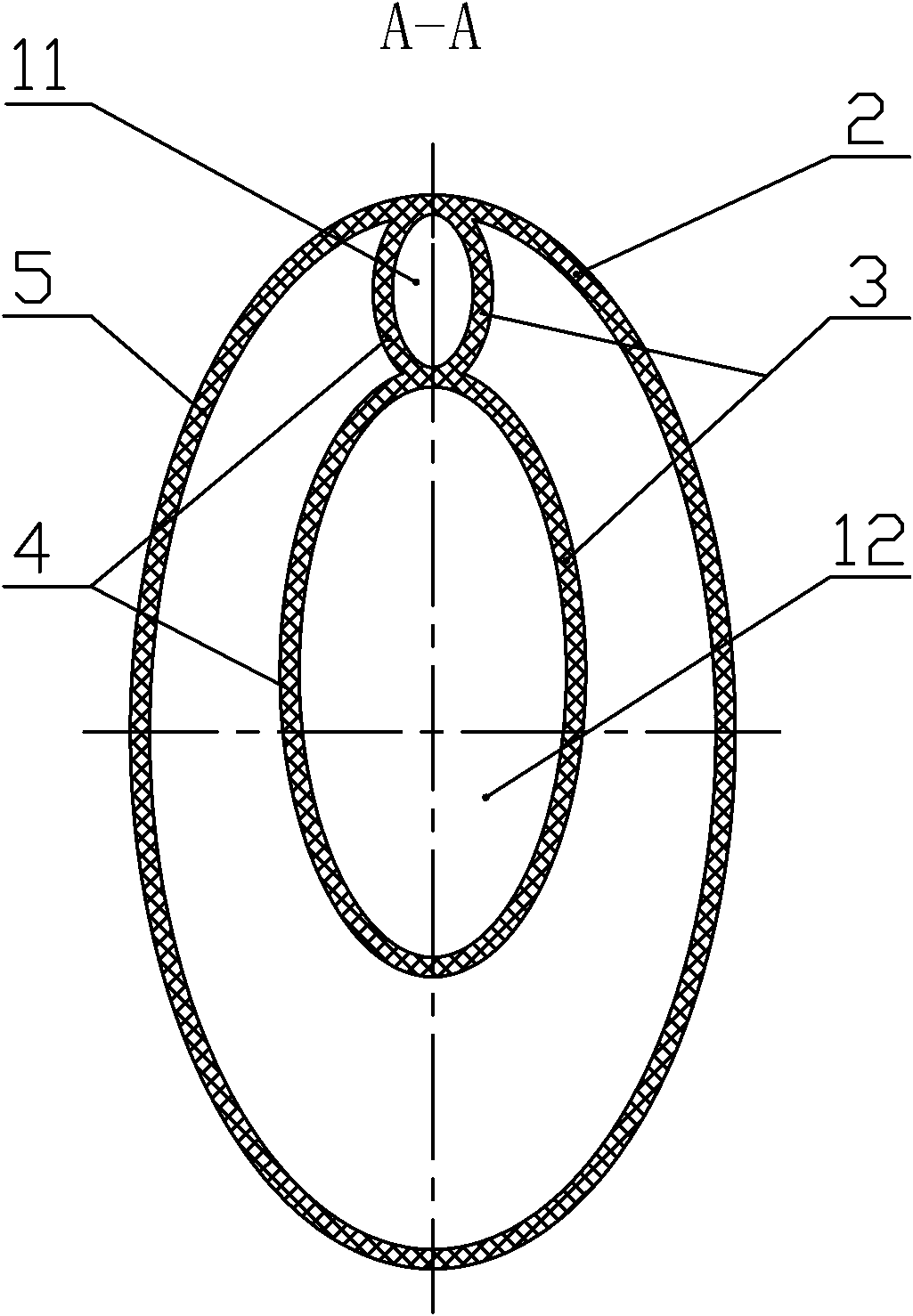

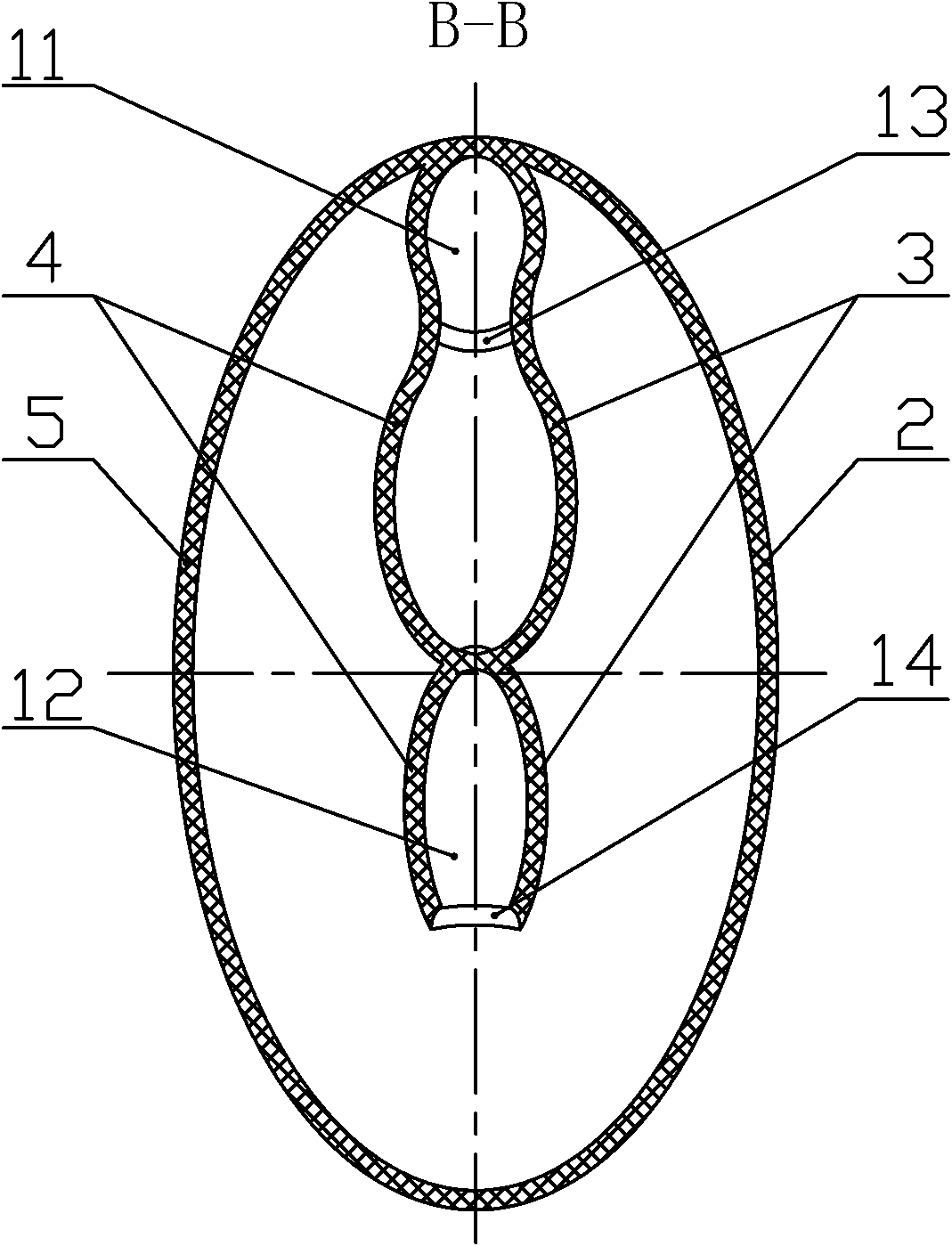

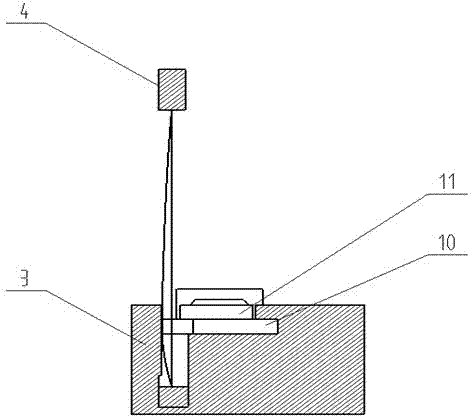

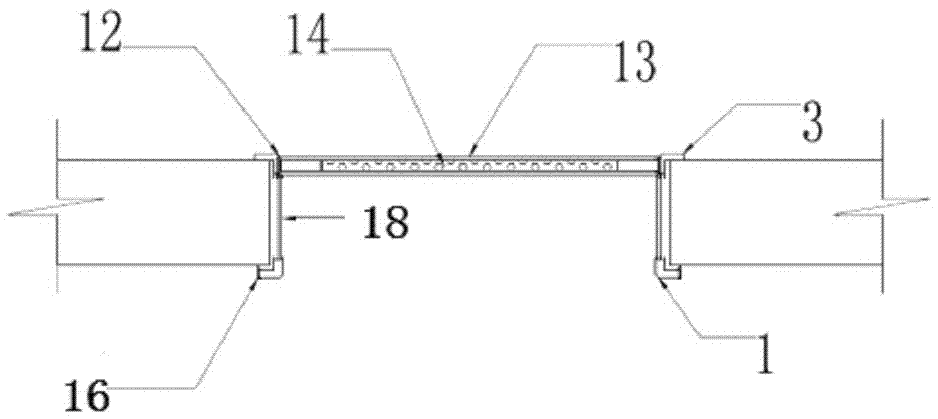

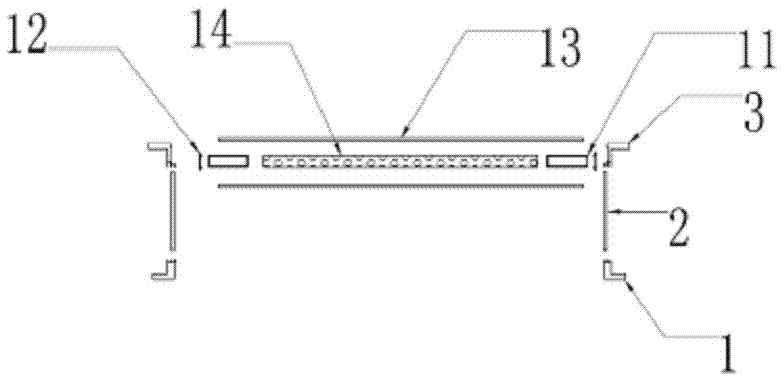

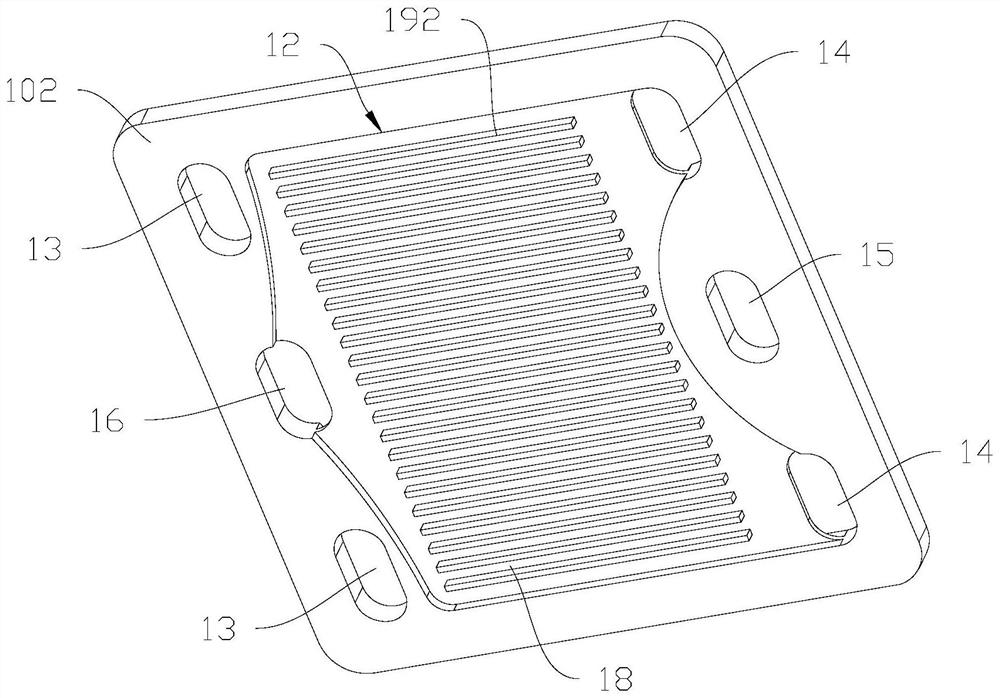

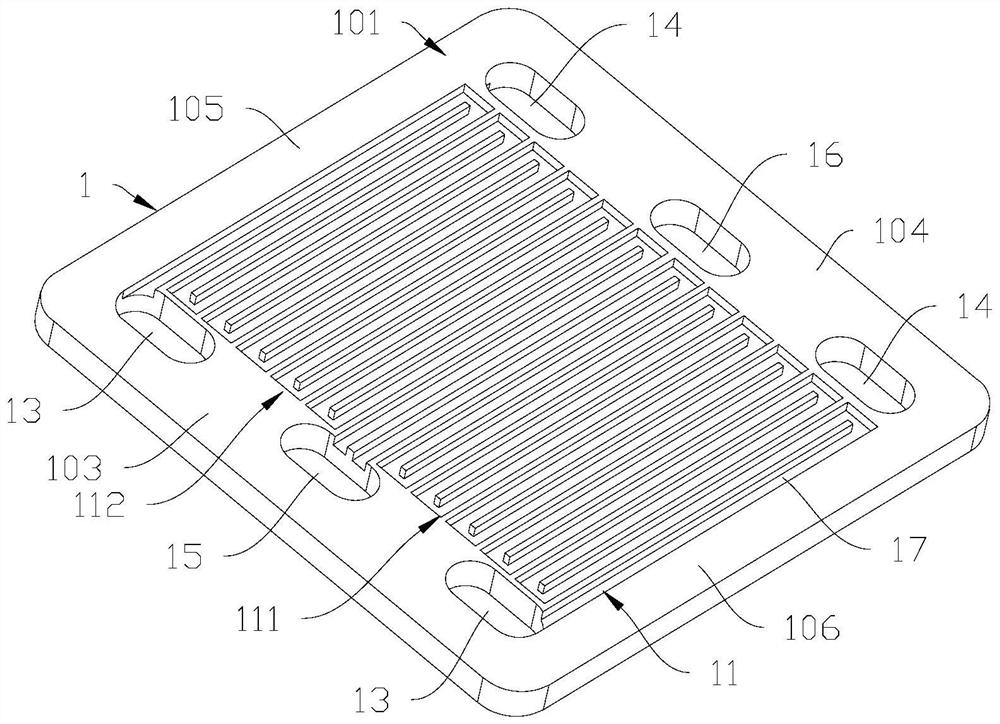

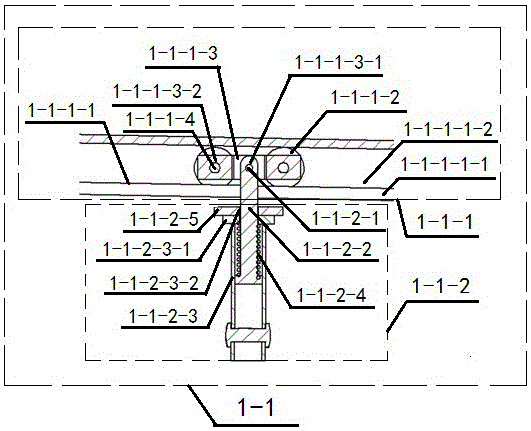

Heat pipe radiator with variable-section hot end and multiple pulsation cold ends

The invention provides a heat pipe radiator with a variable-section hot end and multiple pulsation cold ends. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends comprises the pulsation cold ends and the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is characterized in that each pulsation cold end is a heat dissipating plate internally provided with multiple pulsation channels, the hot end is a hollow cavity, the cavity is filled with a working medium and a capillary liquid absorbing core, an upper cover plate of the hot end hollow cavity is provided with multiple cold end connectors, each cold end connector is provided with one pulsation cold end, and the pulsation channels of the pulsation cold ends communicate with the hollow cavity of the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is simple in structure, easy to manufacture and capable of being transversely and vertically used, the variable-section structure is adopted, so that the pressure bearing capacity of heat pipes can be improved, especially the heat dissipating area of the cold ends is increased, the two thermal processes of evaporation and condensation adopt a pulsation heat transferring mode and a porous medium heat transferring mode correspondingly, the heat transferring performance and the medium transferring performance are effectively improved, backflow is uniform, the temperature uniformity is good, and the heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is suitable for industrial manufacturing.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

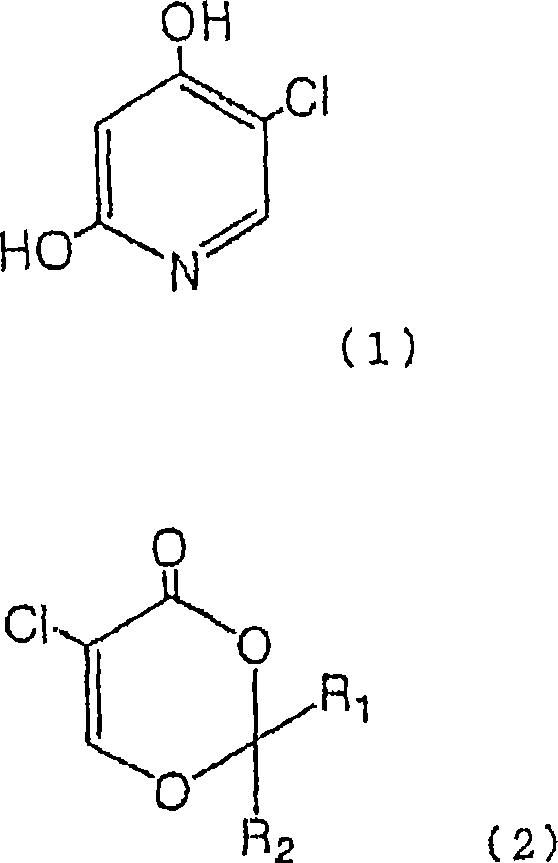

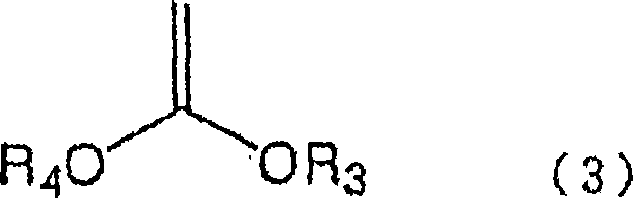

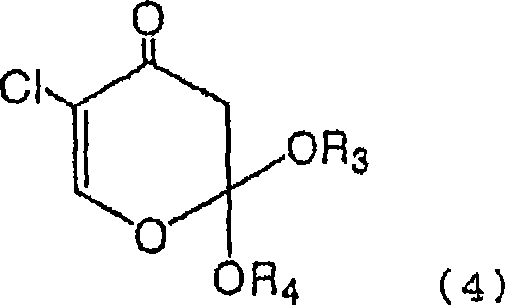

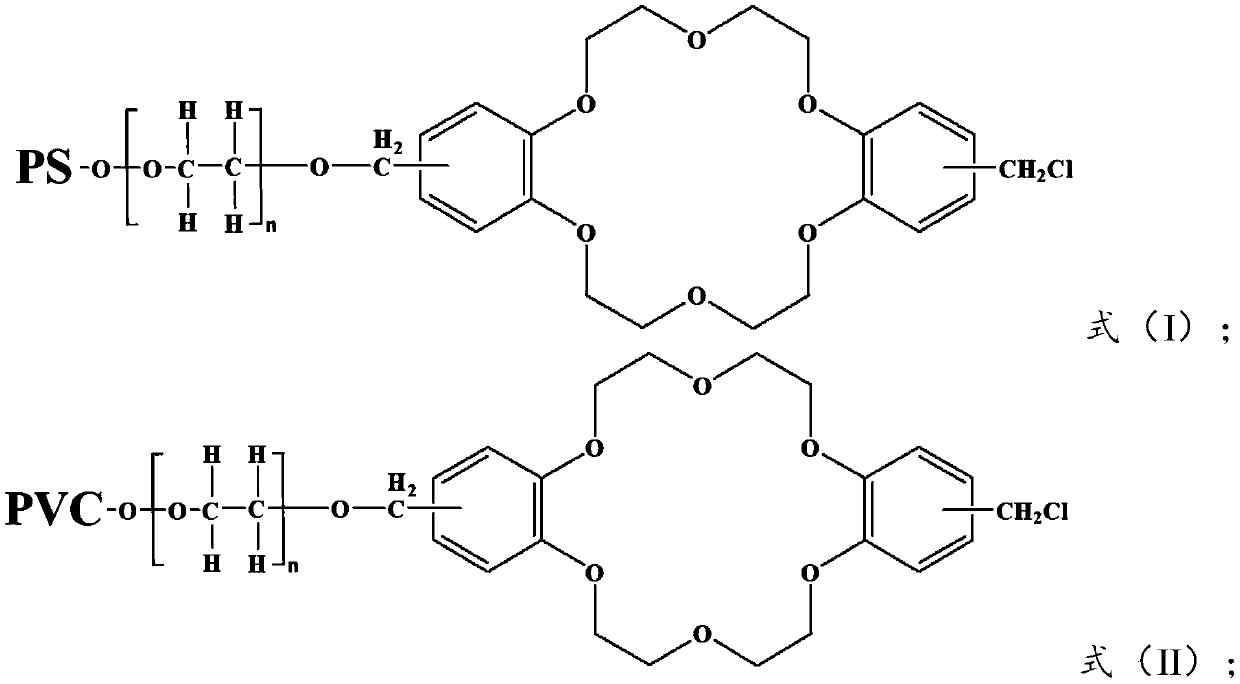

Process for production of 5-chloro-2,4-dihydroxypyridine

InactiveCN101107230ASuitable for industrial manufacturingGroup 4/14 element organic compoundsSilyleneToxic industrial waste

A process for producing 5-chloro-2,4-dihydroxypyridine of Formula (1) comprising the steps of reacting a 5-chloro-1,3-dioxin-4-on derivative (2) represented by Formula (2) with a ketene acetal derivative (3) represented by Formula (3) to give a pyrone derivative (4) represented by Formula (4), treating the pyrone derivative (4) with an acid, and reacting the resulting product with ammonia: [Chemical formula 4] (1); [Chemical formula 1] (2) wherein R1 and R2 are as defined in the description; [Chemical formula 2] (3) wherein R3 and R4 independently represent a straight-chain or branched alkyl group having 1 to 6 carbon atoms or a silyl group substituted by a straight-chain or branched alkyl group having 1 to 6 carbon atoms; and [Chemical formula 3] (4) wherein R3 and R4 are as defined above. This process can produce 5-chloro-2,4-dihydroxypyridine which is an inhibitor of a biodegradation enzyme against an anti-malignant tumor agent 5-fluorouracil under mild conditions in a short process and generates less industrial waste, and therefore is industrially advantageous.

Owner:TAIHO PHARMA CO LTD

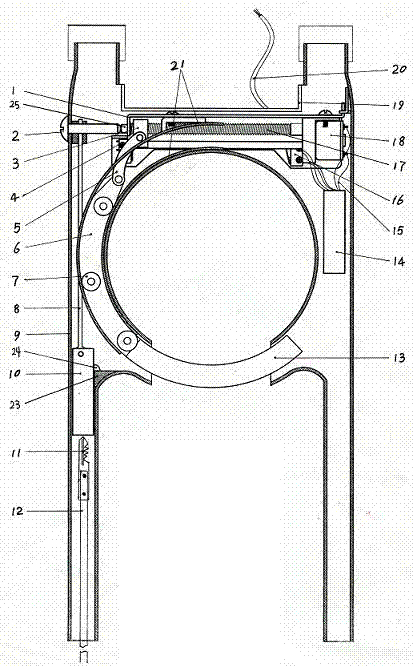

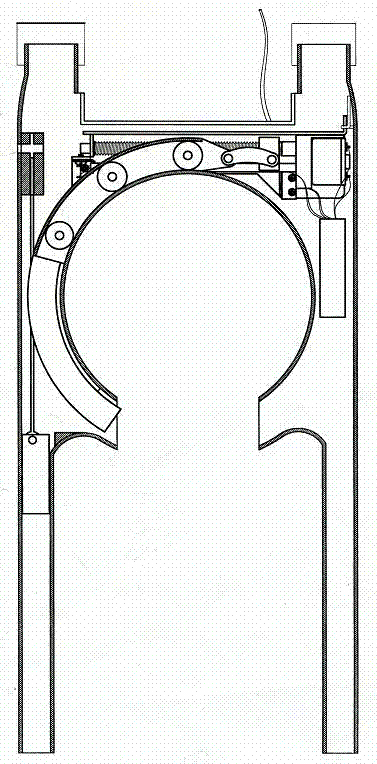

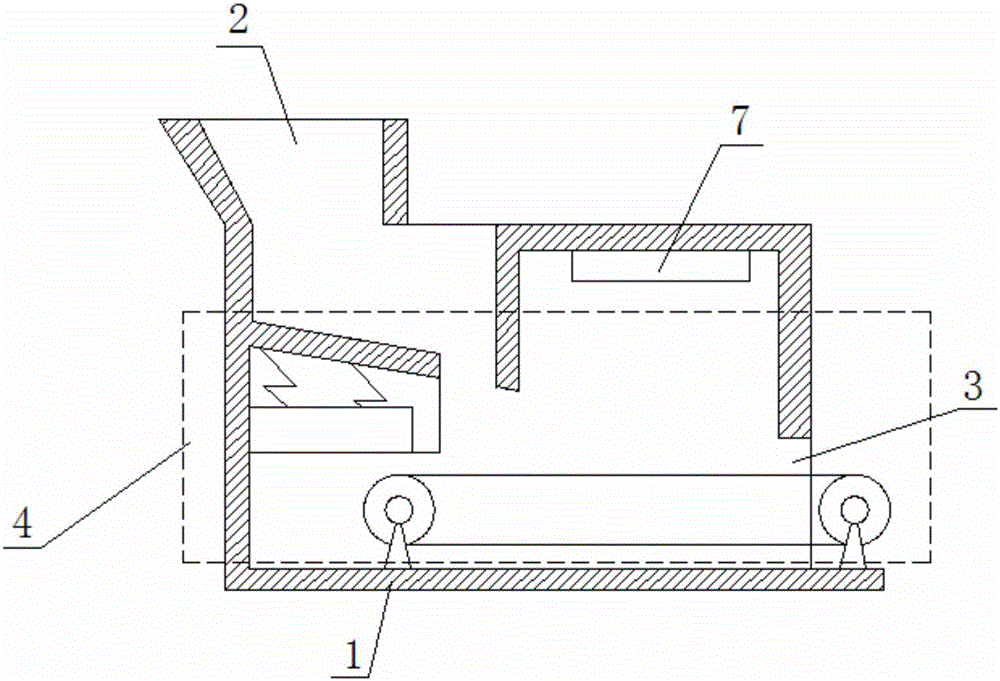

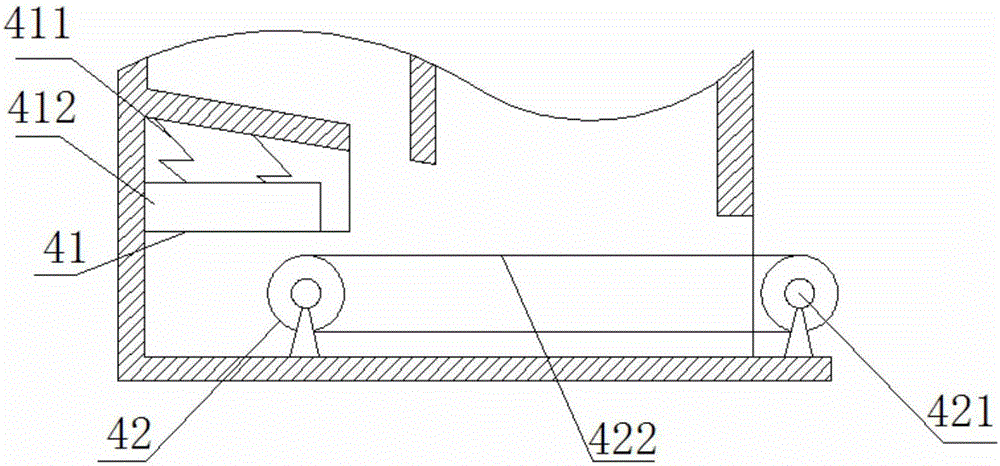

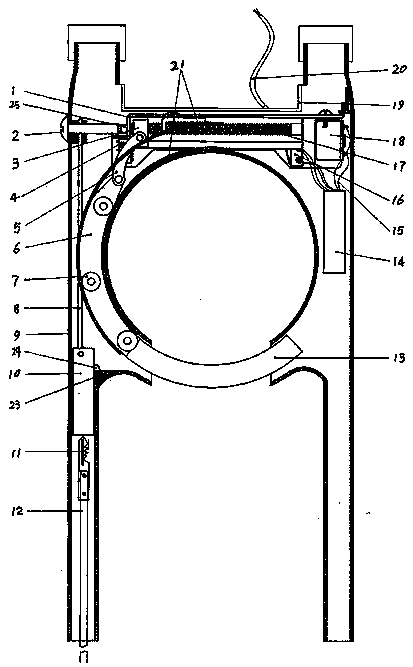

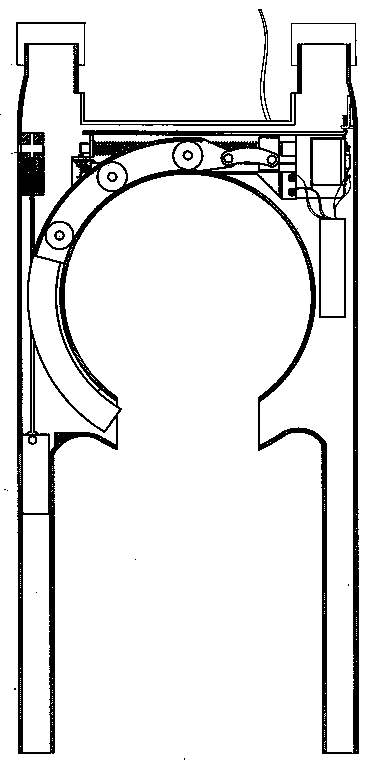

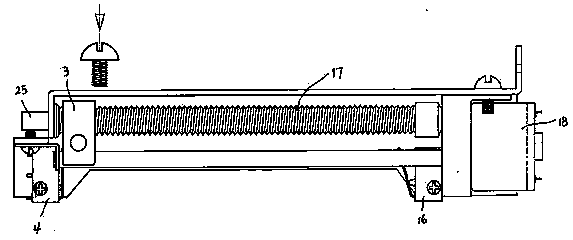

Motorcycle rear fork anti-theft lock

InactiveCN102963461AImprove your own anti-theft functionEliminate technology lockpickingAnti-theft cycle devicesNon-mechanical controlsMotor driveMotor shaft

The invention discloses a motorcycle rear fork anti-theft lock. A motor driving mechanism is arranged in a motorcycle rear fork anti-theft lock shell; one end of a lead screw is connected with a motor shaft; the other end of the lead screw is rotationally arranged on a shaft sleeve; a driving block is rotationally connected to the lead screw driven by using a direct-current motor; a lock rod is in sliding fit with a slip way; a connecting rod is hinged between the driving block and the lock rod; the left and the right sides of the lead screw are provided with locking and opening limiting switches respectively; the upper end of a pull rod which is fixedly connected to a mechanical lock core opened by using an external extending key extends into a hole in an emergency screw rod; and the inner end of the emergency screw rod is rotationally connected to the shaft sleeve from outside to inside. Due to the adoption of the motorcycle rear fork anti-theft lock, technical unlocking and violent unlocking can be prevented; and the motorcycle rear fork anti-theft lock has the characteristics of reasonable structure, easiness and convenience in operating and high anti-theft performance.

Owner:张永建

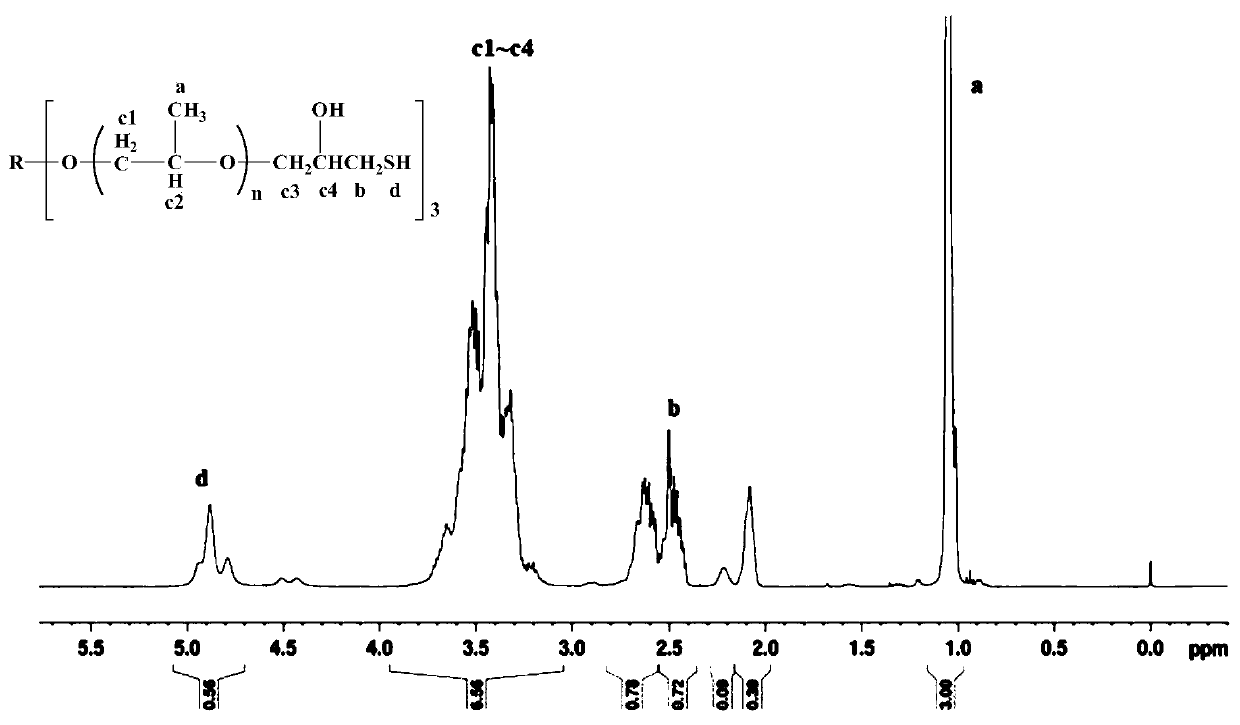

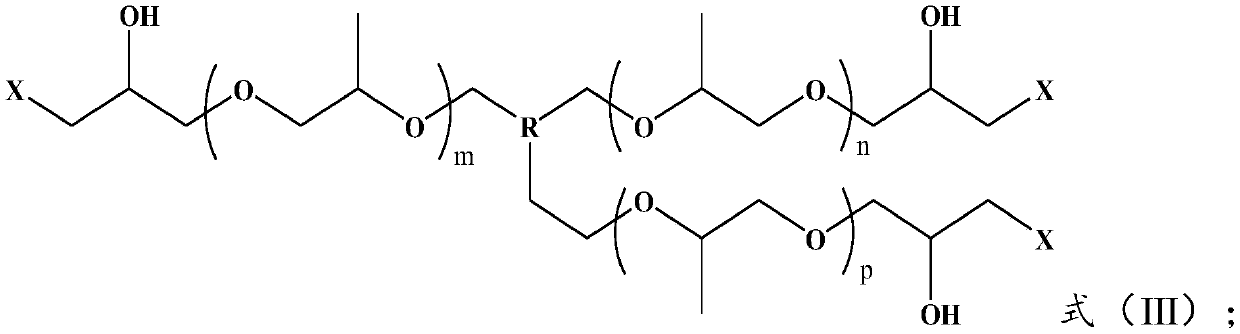

Method for preparing high-quality polythiol curing agent for epoxy resin

The invention provides a method for preparing a high-quality polythiol curing agent for an epoxy resin. The method comprises the following steps: a) enabling NaSH, a catalyst, halogenated polyether polyhydric alcohol and water to react in the presence of H2S, and further separating the catalyst so as to obtain a crude product, wherein the catalyst is a three-phase transfer catalyst; and b) performing water washing and drying on the crude product obtained in the step a) in sequence, so as to obtain the high-quality polythiol curing agent for the epoxy resin. Compared with the prior art, the method adopts a specific type of catalysts, the high-quality polythiol curing agent for the epoxy resin is synthesized by using a specific preparation process through solvent-free method three-phase transfer catalysis, the prepared product is colorless and transparent and low in halogen residue, and in addition, the catalyst is easy to recycle, low in separation cost, recyclable and very good in industrial application prospects. Testing results show that the chromaticity of the high-quality polythiol curing agent which is prepared by using the preparation method provided by the invention and is adopted for the epoxy resin is 16-21, and the halogen content is within 176ppm.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Preparation method of corrosion-resistant conveyor belt

InactiveCN104693661AImprove heat resistanceGood acid and alkali resistanceRubber materialPolymer science

The invention discloses a preparation method of a corrosion-resistant conveyor belt. The preparation method is characterized in comprising following steps: (1) reaction kettle pretreatment; (2) preparation of modified rubber; (3) rubber material mixing; and (4) milling and sulfuration. A fluorine-containing rubber used for preparing the conveyor belt is prepared via the preparation method; molecular weight distribution is ideal; plasticity is excellent; acid and alkali resistance is excellent; sulfuration speed and fluidity are increased effectively; the obtained conveyor belt possesses excellent heat resistance, wear resistance, and acid and alkali resistance, and is especially suitable for industrial production.

Owner:QINGDAO ALLPOLY CONVEYOR BELT

A hot-end variable cross-section multi-pulse cold-end heat pipe radiator

ActiveCN106885485BIncrease the installation locationGuaranteed evaporation effectIndirect heat exchangersPorous mediumEvaporation

The invention provides a heat pipe radiator with a variable-section hot end and multiple pulsation cold ends. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends comprises the pulsation cold ends and the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is characterized in that each pulsation cold end is a heat dissipating plate internally provided with multiple pulsation channels, the hot end is a hollow cavity, the cavity is filled with a working medium and a capillary liquid absorbing core, an upper cover plate of the hot end hollow cavity is provided with multiple cold end connectors, each cold end connector is provided with one pulsation cold end, and the pulsation channels of the pulsation cold ends communicate with the hollow cavity of the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is simple in structure, easy to manufacture and capable of being transversely and vertically used, the variable-section structure is adopted, so that the pressure bearing capacity of heat pipes can be improved, especially the heat dissipating area of the cold ends is increased, the two thermal processes of evaporation and condensation adopt a pulsation heat transferring mode and a porous medium heat transferring mode correspondingly, the heat transferring performance and the medium transferring performance are effectively improved, backflow is uniform, the temperature uniformity is good, and the heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is suitable for industrial manufacturing.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Air sac with air leakage prevention self-locking one-way valves

The invention relates to an air sac with air leakage prevention self-locking one-way valves. The air sac comprises an air sac body and the one-way valves, wherein the air sac body is formed by a rectangular first film layer, a rectangular second film layer, a rectangular third film layer and a rectangular fourth film layer in turn from top to bottom through heat sealing; a second one-way valve which is arranged in a first cavity formed by the second film layer and the third film layer, and a first one-way valve on a fifth heat sealing line are used for inflating the air sac; meanwhile, the second film layer and the third film layer which are provided with the one-way valves are integrally covered and inflated by the first film layer and the fourth film layer, and the one-way valves which are arranged between the second film layer and the third film layer are pressed through air pressure in the first film layer and the fourth film layer, so that the one-way valves are prevented from leaking air after the second film layer and the third film layer are inflated. The air sac has a simple and reasonable structure and good sealing effect; and the air tightness of the air sac can be effectively improved, the effective utilization time of the inflated air sac is prolonged, the defect that the one-way valves of the conventional air sac have poor air tightness is overcome, and the air sac is suitable for industrial manufacturing.

Owner:熊平 +2

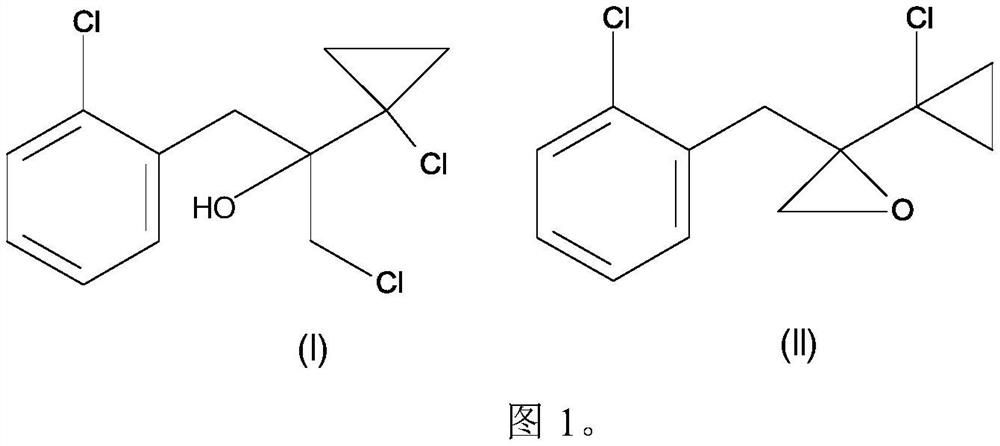

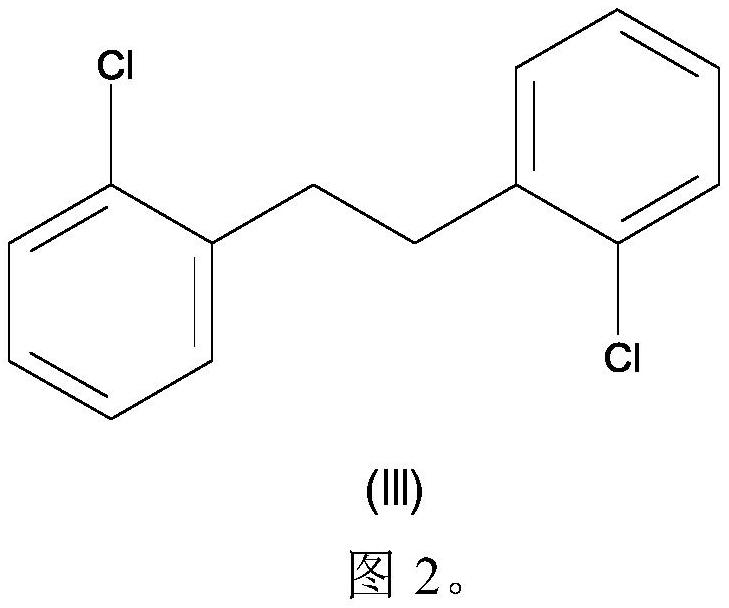

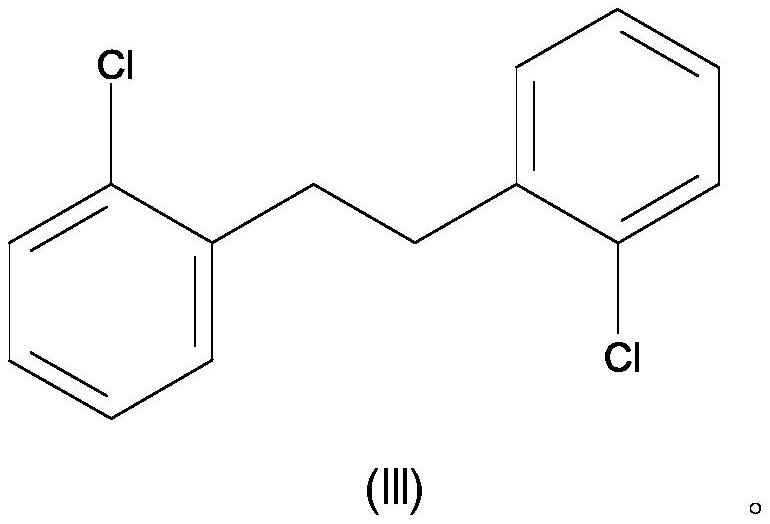

Improved process for preparation of intermediates

PendingCN112399967AReduce formationSuitable for industrial manufacturingBiocideOrganic compound preparationChlorobenzeneEthylene oxide

Disclosed herein is a process for preparation of 1-chloro-2-(1-chlorocyclopropyl)-3-(2-chlorophenyl)propane-2-ol (compound of formula (I)) 5 and 2-(1-chlorocyclopropyl)-2-[(2-chlorophenyl)methyl]oxirane (compound of formula (II)).

Owner:UNITED PHOSPHORUS LTD

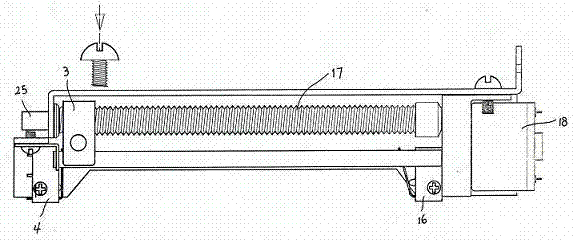

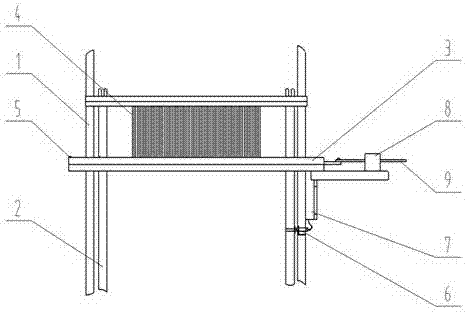

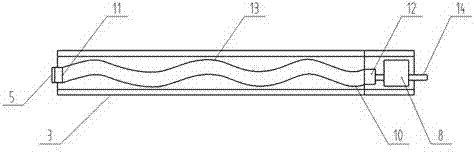

Automatic weft-direction wave-shaped fabric production mechanism of sample weaving machine

ActiveCN103938344ATo achieve the purpose of trial weaving corrugated fabricRealize latitudinal curveSmallware loomsMotor driveWave shape

The invention discloses an automatic weft-direction wave-shaped fabric production mechanism of a sample weaving machine. The automatic weft-direction wave-shaped fabric production mechanism comprises a sample weaving machine body and is characterized in that the automatic weft-direction wave-shaped fabric production mechanism further comprises a PLC, a sliding module and a stepping motor driven by the PLC, and the sliding module is fixedly connected with a threaded rod of the stepping motor, is horizontally installed on a going part and is perpendicular to a deformation reed. The automatic weft-direction wave-shaped fabric production mechanism has the advantages that the sliding module is in the shape of a strip integrally formed, an arc rail is arranged on the side, making contact with the deformation reed, of the sliding block and is used for changing the shape of the deformation reed, a baffle is arranged at the front end of a wave-shaped rail, the baffle is connected with a threaded rod at the front end of the arc rail, therefore, the contact area between the rail and the deformation reed 4 is increased and the service life of equipment is prolonged; the sliding module and the threaded rod of the stepping motor are fixedly connected through a round pin, and sliding blocks in different shapes can be flexibly replaced according to use requirements; the PLC controls rotation of the stepping motor according to signals emitted by a position sensor A and a position sensor B, and automation is realized.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

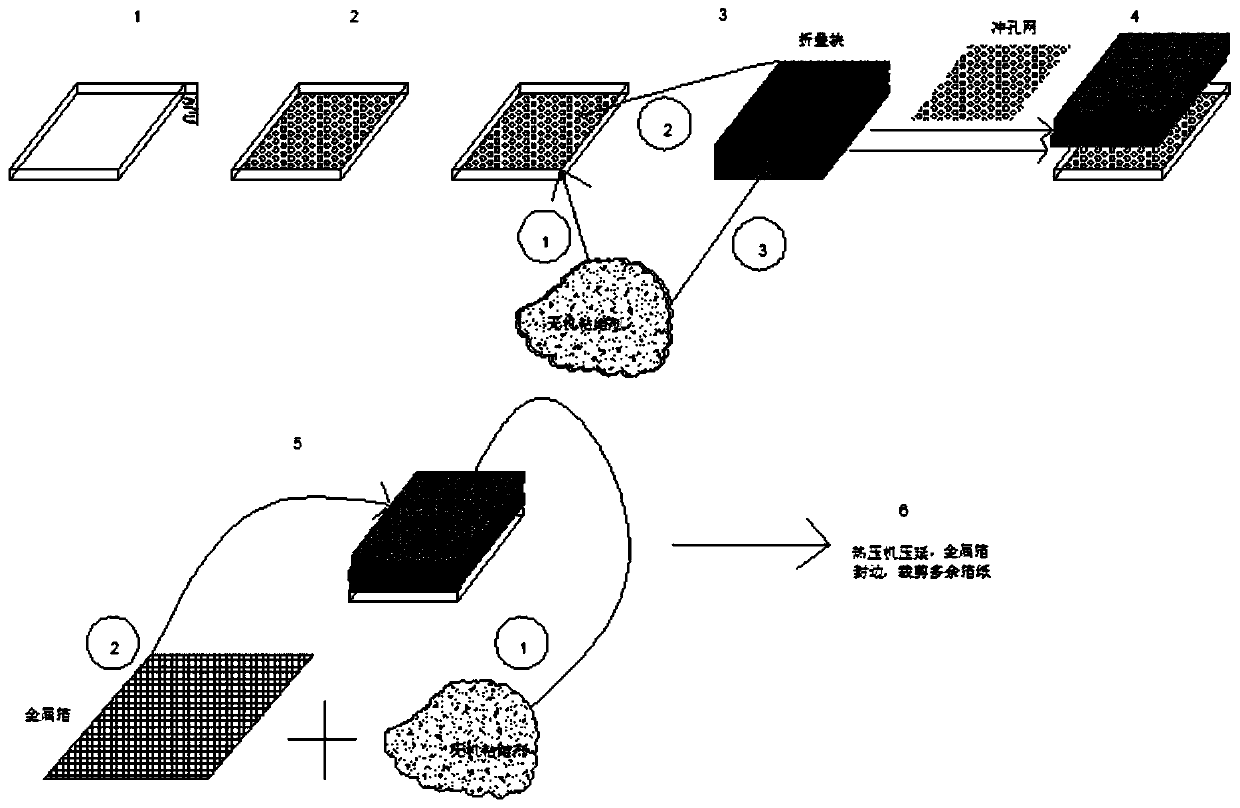

Composite fireproof plate and preparation method thereof

The invention provides a composite fireproof plate and a preparation method thereof. The preparation method comprises the following steps that a), a plurality of stainless steel nails are fixed in a metal plate groove, are coated with an inorganic binding agent, and then are pressed into ceramic fiber blanket folding blocks, so that the stainless steel nails penetrate through the folding blocks; after the inorganic binding agent is coated on the surfaces of the folding blocks, a punching hole mesh and a metal foil are sequentially bound, hot pressing is carried out to the height of the frame in the metal plate groove to obtain the composite fireproof plate; and the compression rate of the ceramic fiber blanket folding blocks is 30%-60%. Compared with the prior art, the preparation method of the composite fireproof plate adopts specific process steps and conditions, and through pressing into the ceramic fiber blanket folding blocks, the obtained composite fireproof plate is excellent infire resistance and low in volume weight; meanwhile, the bearing capacity of the product is improved through the specific fixing mode under the action of the metal plate groove, the stainless steel nails and the punching hole mesh; and raw materials does not contain organic, toxic and harmful components, the environmental protection property is good, and wide application prospect is achieved.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

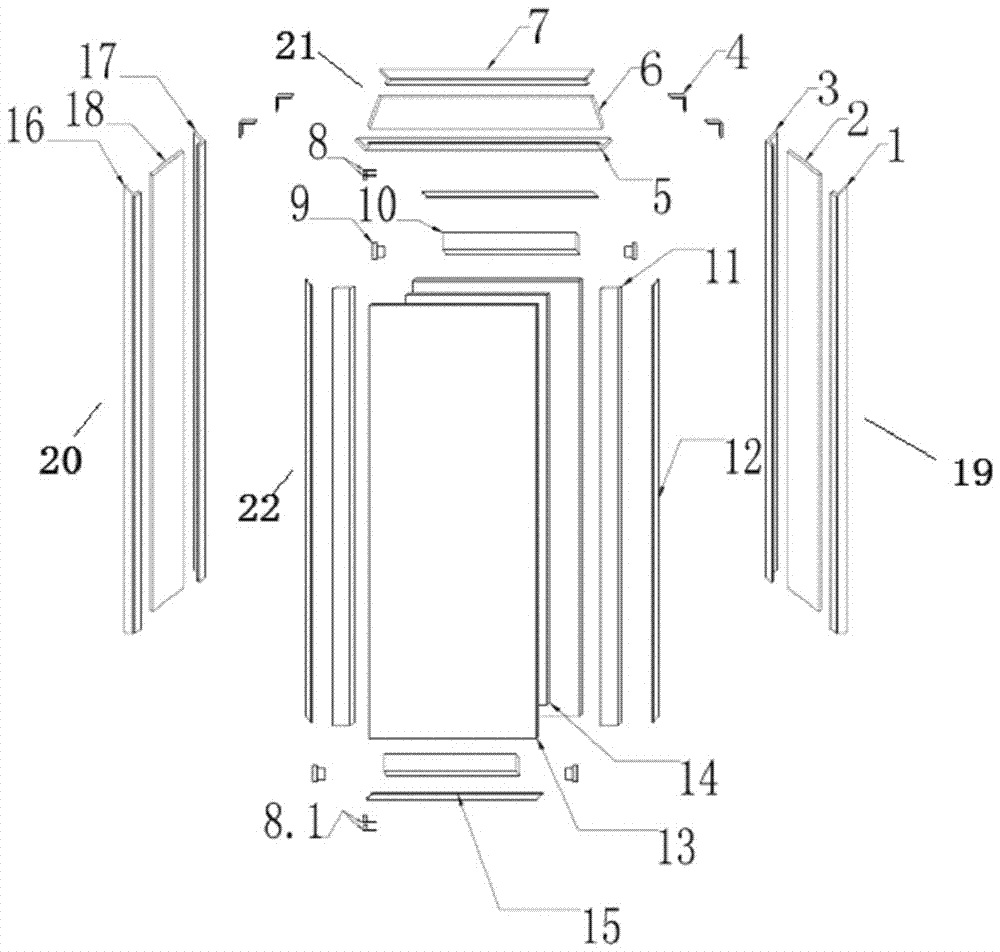

Novel whole set structure of door plate, door sleeve and hinges

InactiveCN107060594ASimple preparation processAvoid wastingWindow/door framesHingesEngineeringUltimate tensile strength

Owner:蒋倩倩

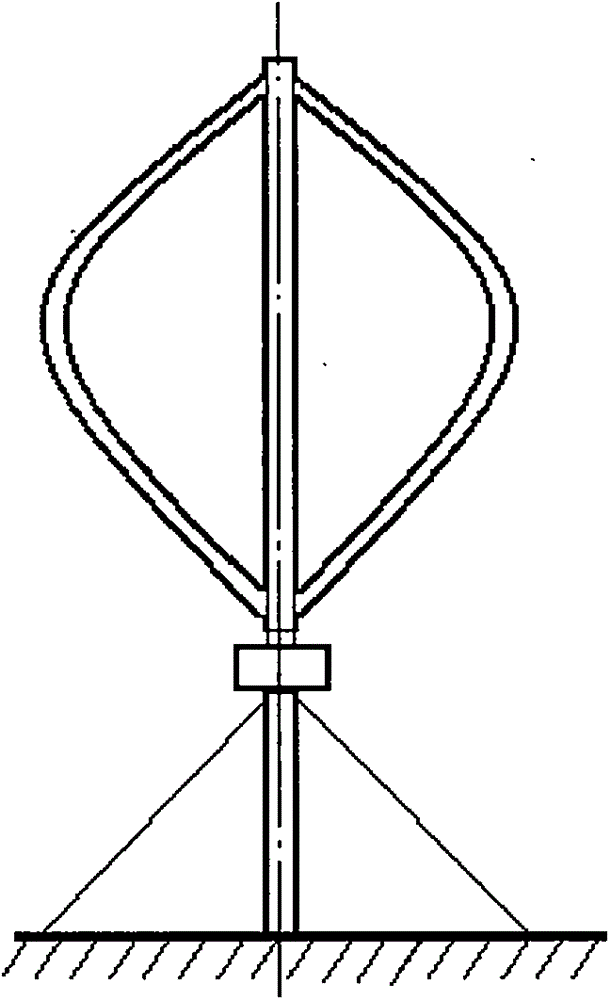

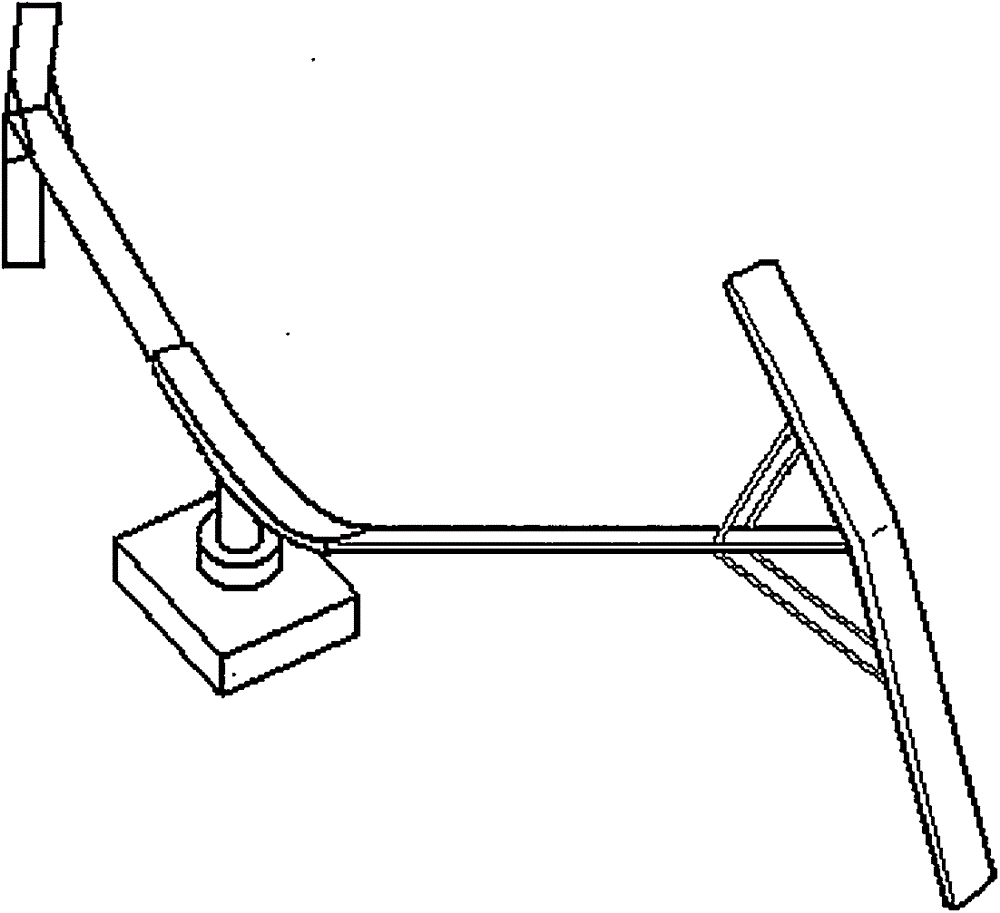

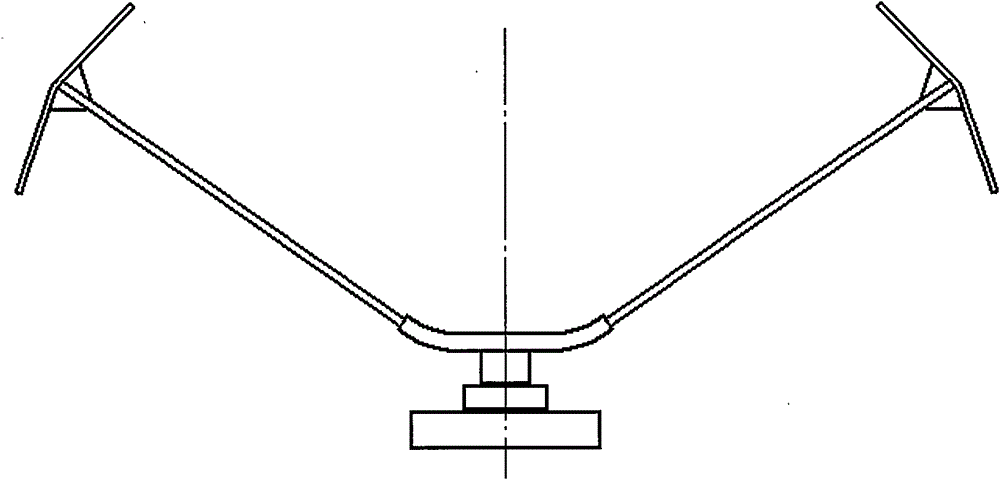

Vertical axis wind turbine with double-arm double-triangular-structure fan blades

InactiveCN104791189ALarge starting torqueLarge driving torqueRenewable energy generationMachines/enginesTriangle fanEngineering

The invention discloses the technology of ultra-large type vertical axis wind turbine units. A turbine is an ultra-large type unit of 10MW level or the level of power above 10MW. From the perspective of structural mechanics, two-blade single arm Aerogenerator X design of the Arup company in the England is changed into double-triangle connecting design of two-blade double arms, blade stress and deformation generated by blade gravity and wind thrust can be overcome, the special high rigid structure is achieved, the structural strength is improved sufficiently to increase cut-out wind speed, and the generating capacity is increased; secondarily, through the increased complementary capacity of a Savonius turbine, starting torque can be increased, and the driving torque is made to be more stable, so that the unit output power is further increased. The wind turbine becomes the vertical axis wind turbine unit integrated with the latest technology at home and abroad, the maximum output power and the quite high industrialization implementation degree, and the double-arm double-triangle fan blade structure is also suitable for kW level wind driven generators.

Owner:SHANGHAI WIND NEW ENERGY TECH

Molding material of conveying belts

InactiveCN106366367AReasonable choiceIngenious ratio designMixing operation control apparatusCement mixing apparatusSilane couplingIsoprene

The invention relates to the technical field of cement production, and especially relates to a molding material of conveying belts. The molding material is prepared from the following raw materials in parts by weight: 10 parts of isoprene rubber, 10 parts of ethylene-propylene rubber, 10 parts of acrylic resin, 10 parts of styrene-butadiene rubber, 3 parts of silane coupling agent, 3 parts of curing agent, 2 parts of anti-aging agent, 1 part of accelerating agent, 10 parts of isopropanol, 15 parts of deionized water and 5 parts of total anthraquinone in rhubarb. The molding material of the conveying belts has reasonable selection of rubber raw materials and a skillful proportion design and can realize that the prepared molding material of the conveying belts has properties convenient for milling and open milling, the raw materials are cheap and easily available, and the acid and alkali resistance and wear-resisting property of the subsequently prepared conveying belts are notably upgraded.

Owner:合肥海宝节能科技有限公司

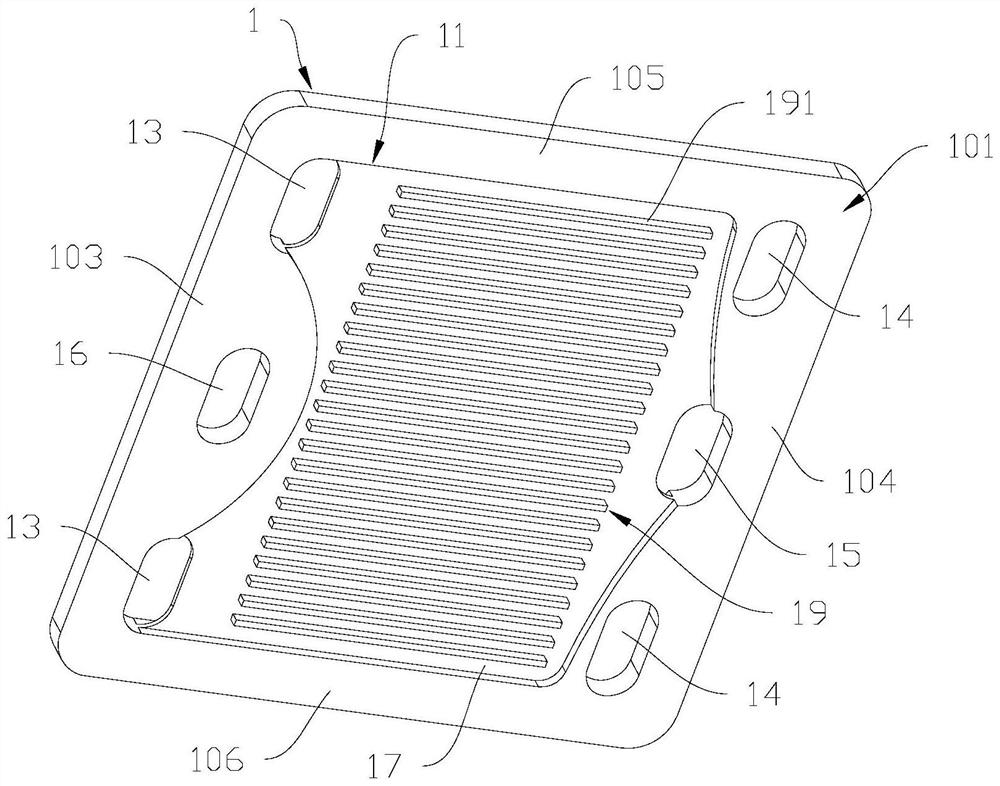

Preparation method of solid oxide fuel cell/electrolytic cell connector

ActiveCN113328113AReasonable structureInhibit oxidationCellsFinal product manufactureElectrolytic cellSolid oxide fuel cell

The invention discloses a preparation method of a solid oxide fuel cell / electrolytic cell connector, and belongs to the technical field of fuel cells / electrolytic cells. The method comprises the following steps: designing and modeling a solid oxide fuel cell / electrolytic cell connector; carrying out position placement, format conversion, defect repair and slicing processing on the model of the connector body; preparing the connector body by adopting an additive manufacturing method; carrying out post-treatment on the connector body; and preparing the protective coating by adopting a spraying or coating method. And the connector body is prepared by adopting an additive manufacturing method, so that refined preparation of a complex structure of the connector body can be realized. Controllable preparation of the high-quality connector can be achieved, the consistency of the connector is remarkably improved, the stability of a fuel cell / electrolytic cell stack is improved, and the service life of the fuel cell / electrolytic cell stack is prolonged. Meanwhile, the preparation method disclosed by the invention is short in period and low in cost, and has stronger practical significance on popularization and application of the fuel cell / electrolytic tank.

Owner:GUANGDONG INST OF NEW MATERIALS

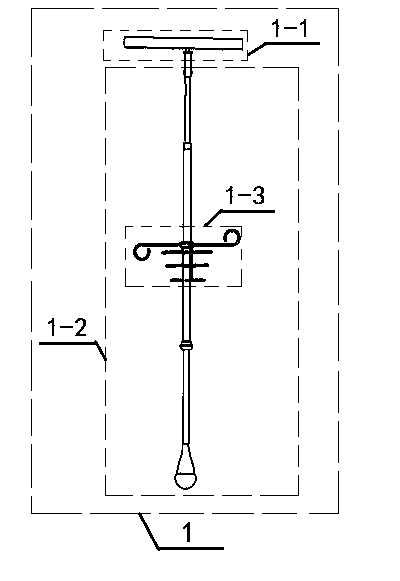

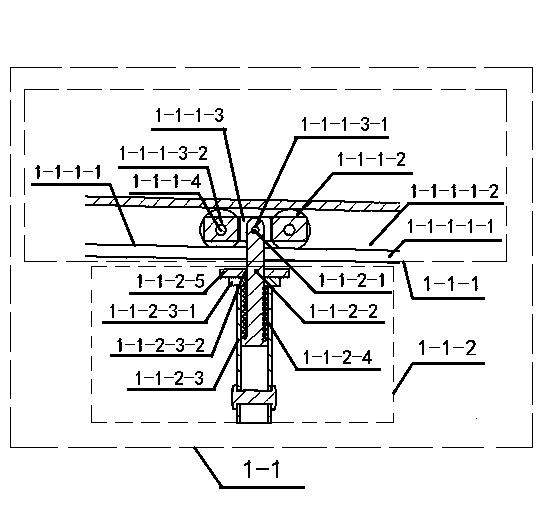

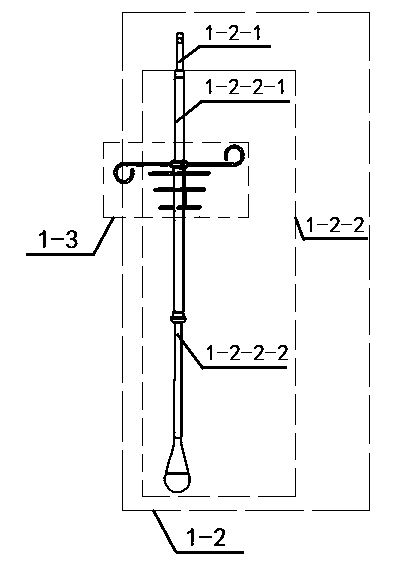

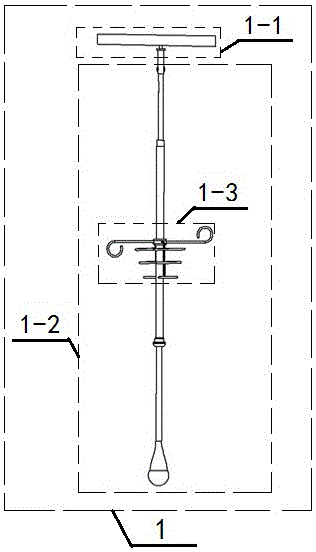

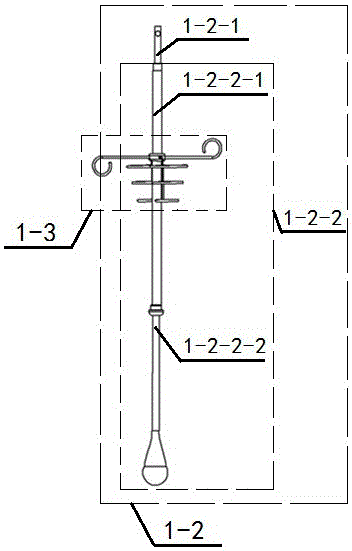

Novel hanging type infusion stand

The invention provides a novel hanging type infusion stand, in particular to a novel hanging type infusion stand which is medical, slidable and telescopic and is provided with a slide locking function. A power source data line is inlaid in a hollow tubular hanging rod, medical instruments such as an infusion monitor and an infusion pump can be assembled outside the hanging rod, and infusion height and ground clearance can be optionally adjusted by telescopic length of the hanging rod. The novel hanging type infusion stand with a double-spring structure is simple in structure and ingenious in design, the advantage of the hanging type infusion stand that space is saved is kept while the problem about mounting of electricity-dependent medical instruments is solved. Medical environment is effectively improved, and enormous economic and social benefits are achieved.

Owner:ZHENGZHOU HAONENG TECH

Double-sided crystal silicon solar cell and making method thereof

InactiveCN106328724ASmall surface areaReduce compoundingFinal product manufacturePhotovoltaic energy generationSilicon solar cellMedia layer

The invention discloses a double-sided crystal silicon solar cell. A front flock structure, a front pn emitter junction, a front passivated anti-reflection medium layer and front electrodes are sequentially arranged on the front face of a silicon substrate, and a back planar structure, a back passivated anti-reflection medium layer and back electrodes are sequentially arranged on the back face of the silicon substrate; the double-sided crystal silicon solar cell is characterized in that the back planar structure is a planar silicon substrate which is directly formed on the silicon substrate through a polishing technology; no doped layers are formed on the surface of the back planar structure. The invention further discloses a making method of the double-sided crystal silicon solar cell. The back planar structure is arranged on the double-sided crystal silicon solar cell, so that surface recombination and optical absorption features of minority carriers of the double-sided solar cell are optimized, and quantum conversion efficiency is improved; the making method is simple in technology, low in cost and suitable for large-scale industrial production.

Owner:TRINASOLAR CO LTD

Plastic deformed checking air valves for sewer pipe

InactiveCN100368638CStrong defecation abilityEasy to installWater closetsDomestic plumbingSewageEngineering

Owner:赵钦

A new type of hanging infusion stand

The invention provides a novel hanging type infusion stand, in particular to a novel hanging type infusion stand which is medical, slidable and telescopic and is provided with a slide locking function. A power source data line is inlaid in a hollow tubular hanging rod, medical instruments such as an infusion monitor and an infusion pump can be assembled outside the hanging rod, and infusion height and ground clearance can be optionally adjusted by telescopic length of the hanging rod. The novel hanging type infusion stand with a double-spring structure is simple in structure and ingenious in design, the advantage of the hanging type infusion stand that space is saved is kept while the problem about mounting of electricity-dependent medical instruments is solved. Medical environment is effectively improved, and enormous economic and social benefits are achieved.

Owner:ZHENGZHOU HAONENG TECH

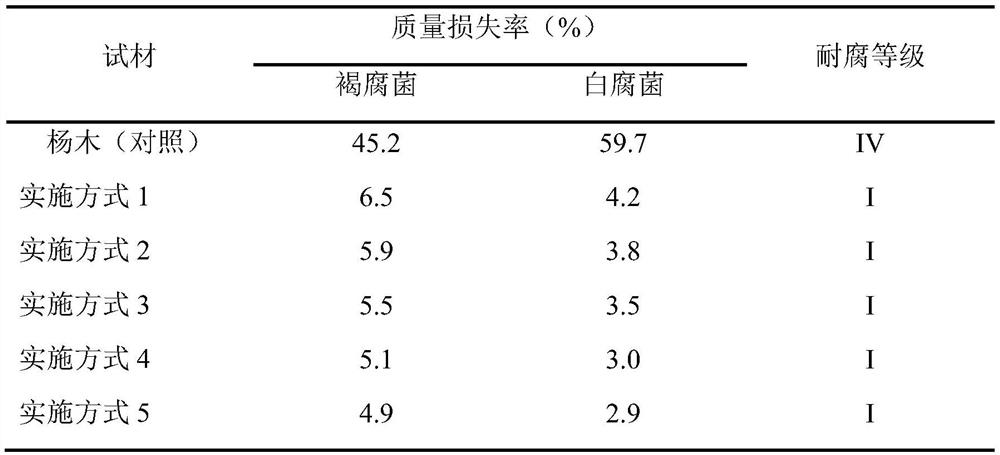

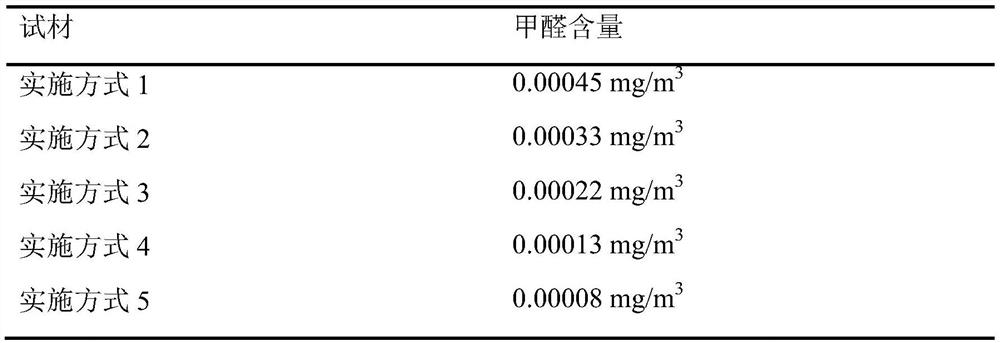

Formaldehyde-removing, corrosion-preventing and environment-friendly agriculture and forestry residue fiberboard and preparation method thereof

InactiveCN112248179AImprove adsorption capacitySuitable for industrial manufacturingDomestic articlesFlat articlesFiberChitosan nanoparticles

The invention belongs to a biomass composite decorative material, and particularly relates to a formaldehyde-removing, corrosion-preventing and environment-friendly agriculture and forestry residue fiberboard and a preparation method thereof. Specifically, agriculture and forestry residue fibers are used as the main raw material, a soybean protein adhesive without formaldehyde, chitosan nanoparticles and modified chitosan nanoparticles are added, and the antibacterial property of the chitosan nanoparticles and the formaldehyde absorption property of the modified chitosan nanoparticles are utilized to prepare the environment-friendly agriculture and forestry residue fiberboard with formaldehyde-removing and corrosion-preventing functions. The formaldehyde-removing, corrosion-preventing andenvironment-friendly agriculture and forestry residue fiberboard is suitable for industrial manufacturing, low in production cost, environmentally friendly and capable of purifying formaldehyde, preventing corrosion and the like, products of the fiberboard can be used as furniture, indoor decoration, floor base materials and the like, and conditions are created for healthy development of the fiberboard industry and widening of the application range.

Owner:BEIHUA UNIV

Motorcycle rear fork anti-theft lock

InactiveCN102963461BImprove your own anti-theft functionDifficult to destroyBicycle locksAnti-theft cycle devicesMotor driveEngineering

The invention discloses a motorcycle rear fork anti-theft lock. A motor driving mechanism is arranged in a motorcycle rear fork anti-theft lock shell; one end of a lead screw is connected with a motor shaft; the other end of the lead screw is rotationally arranged on a shaft sleeve; a driving block is rotationally connected to the lead screw driven by using a direct-current motor; a lock rod is in sliding fit with a slip way; a connecting rod is hinged between the driving block and the lock rod; the left and the right sides of the lead screw are provided with locking and opening limiting switches respectively; the upper end of a pull rod which is fixedly connected to a mechanical lock core opened by using an external extending key extends into a hole in an emergency screw rod; and the inner end of the emergency screw rod is rotationally connected to the shaft sleeve from outside to inside. Due to the adoption of the motorcycle rear fork anti-theft lock, technical unlocking and violent unlocking can be prevented; and the motorcycle rear fork anti-theft lock has the characteristics of reasonable structure, easiness and convenience in operating and high anti-theft performance.

Owner:张永建

Monocrystalline silicon double-sided solar cell and preparation method thereof

ActiveCN105826411BSmall surface areaIncrease reflectionFinal product manufacturePhotovoltaic energy generationBack surface fieldCrystalline silicon

The invention discloses a mono-crystalline silicon double-sided solar cell. A front texturing morphology structure (1), a front PN emitter junction (2), a front passivated anti-reflection medium layer (3) and a front electrode (4) are sequentially formed on the front of a mono-crystalline silicon substrate (100). A back texturing morphology structure (5), a back surface field (6), a back passivated anti-reflection medium layer (7) and a back electrode (8) are sequentially formed on the back of the mono-crystalline silicon substrate. The solar cell is characterized in that the back texturing morphology structure (5) is a platform type texture surface, and platform structures (5a) are distributed on the mono-crystalline silicon substrate in a scattered, or tiled, or partially scattered, partially tiled, partially connected and partially overlapped way. The invention further discloses a preparation method of the mono-crystalline silicon double-sided solar cell. The minority carrier surface recombination and optical absorption characteristics of the double-sided solar cell are optimized, and the efficiency of quantum conversion is improved.

Owner:TRINA SOLAR CO LTD

Electrode for alkali fuel cell and method for making a fuel cell including at least one step of making such an electrode

InactiveUS8017283B2Improve efficiencyEasy to implementFinal product manufacturePrimary cellsNano sizeElectron

An electrode for an alkali fuel cell comprises an active layer formed by a bilayer or by a stack of a plurality of bilayers. Each bilayer is composed of a catalytic layer comprising catalyst particles of nanometric size and of a porous layer comprising two opposite faces one of which is in contact with the catalytic layer. The porous layer is made from a porous composite material comprising a hydroxide ion conducting polymer matrix in which a metallic lattice is formed constituting a plurality of electronically conducting paths connecting the two opposite faces of the porous layer. Advantageously, fabrication of such an electrode is obtained by successively performing vacuum deposition of the catalyst particles and vacuum co-deposition of the hydroxide ion conducting polymer and of the metal on a free surface of a support.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

Preparation method of poly(p-phenylene benzobisoxazole) composite fiber containing nano-TiO2

InactiveCN101613892BSuitable for industrial manufacturingGood anti-ultraviolet aging performanceSpinning head liquid feederMonocomponent synthetic polymer artificial filamentFiberPhosphoric acid

Owner:EAST CHINA UNIV OF SCI & TECH

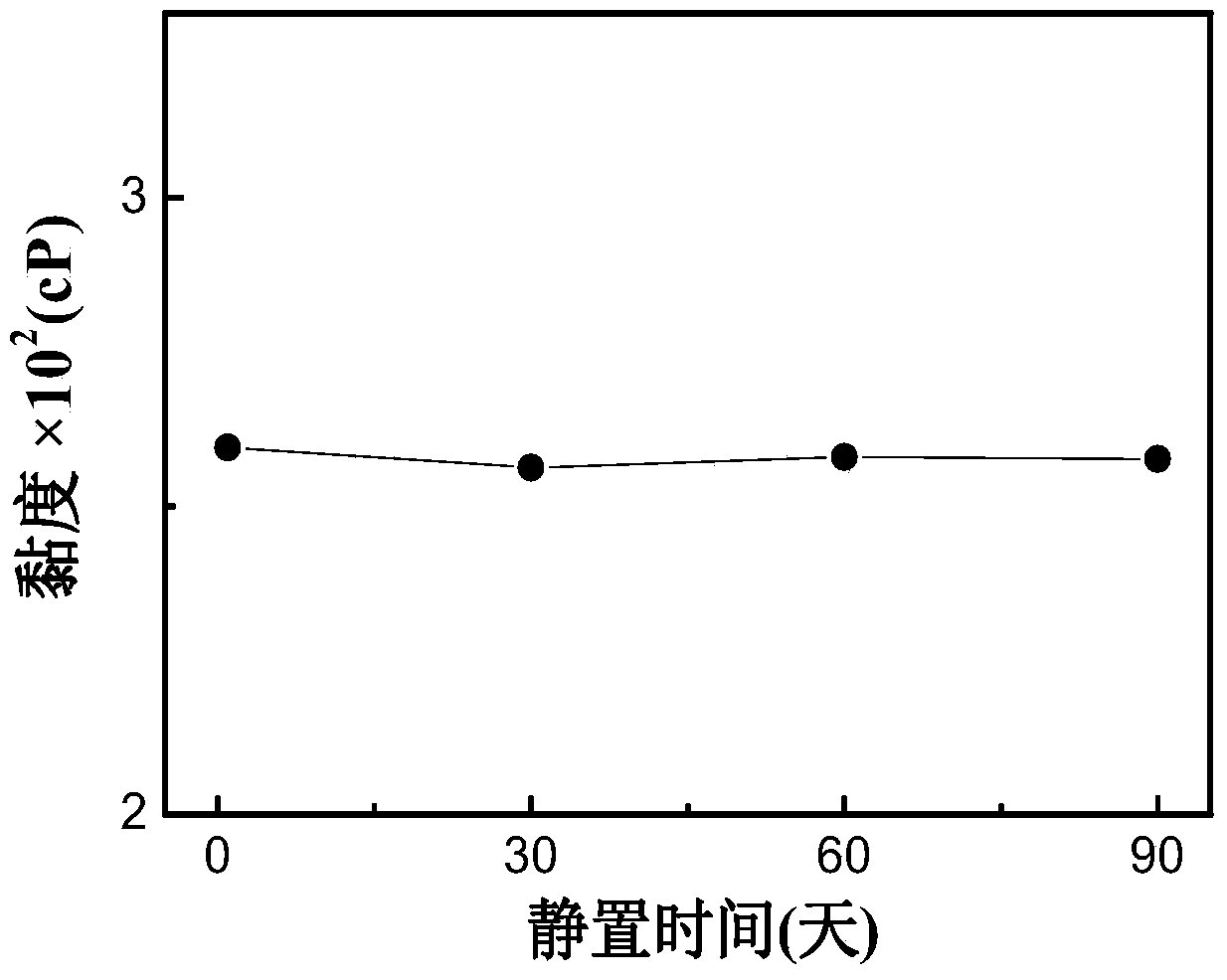

Preparation method and application method of high-concentration silver nanowire stable ink for storage

ActiveCN105176198BEasy to useSuitable for industrial manufacturingInksHigh concentrationOrganic solvent

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

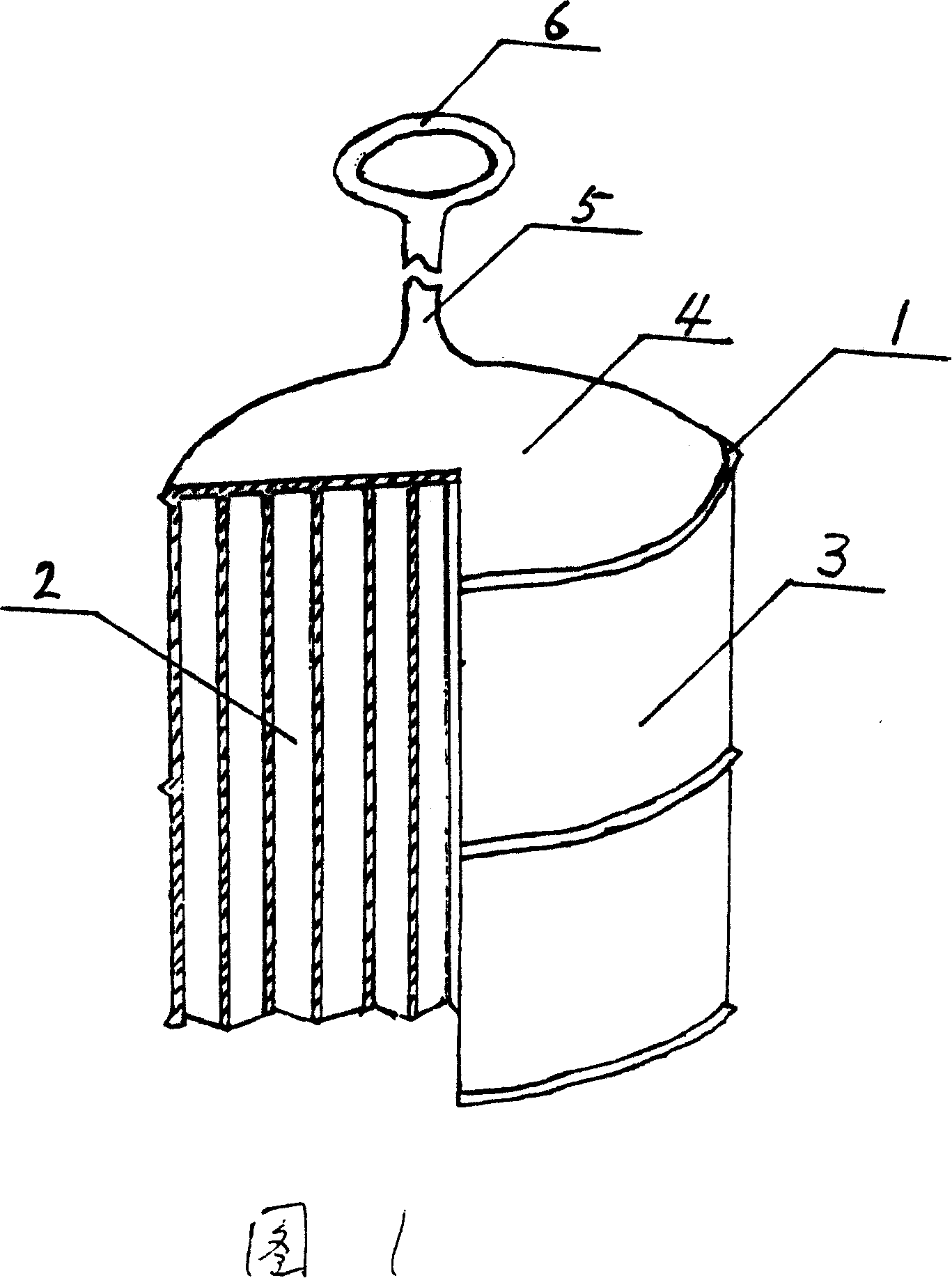

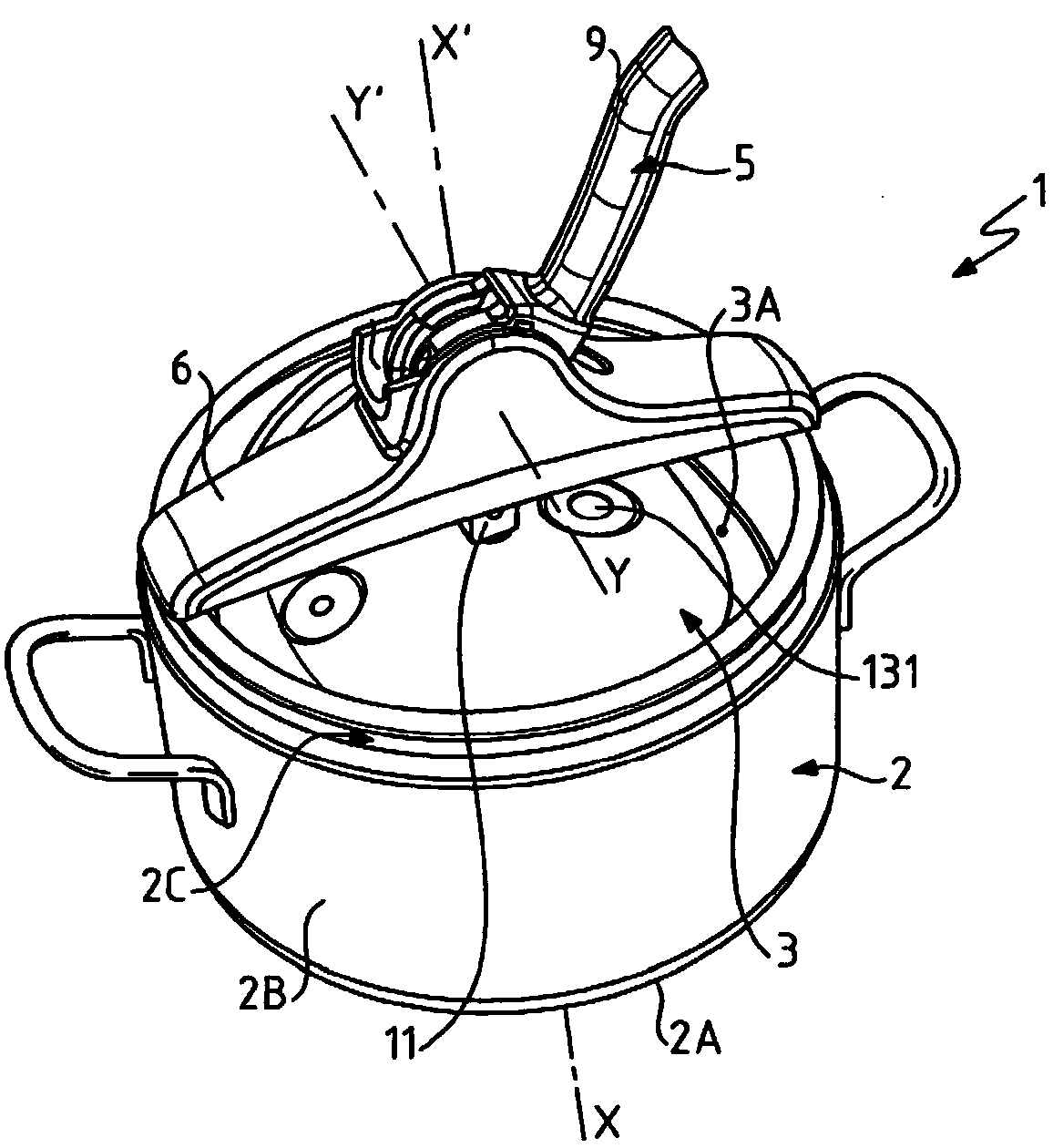

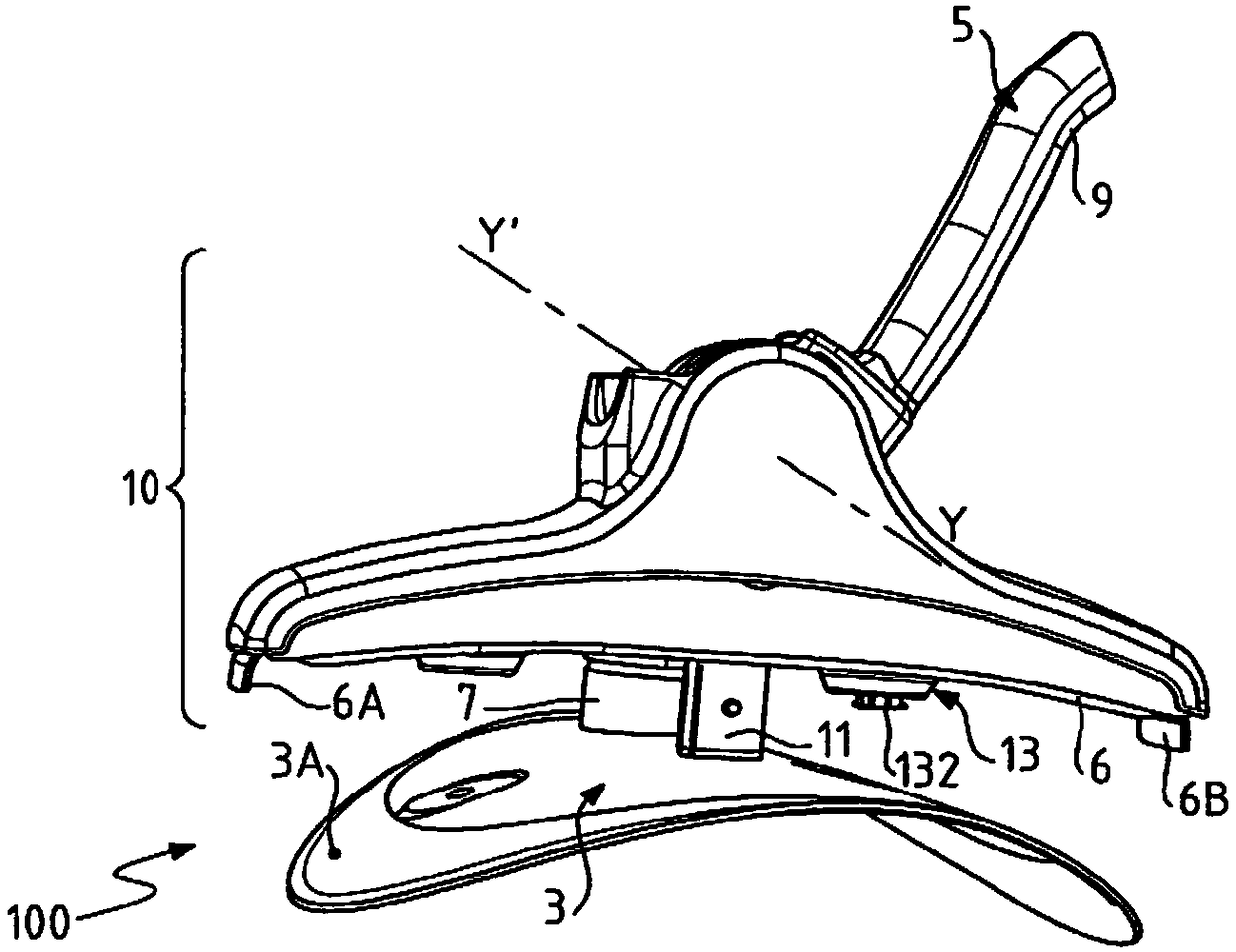

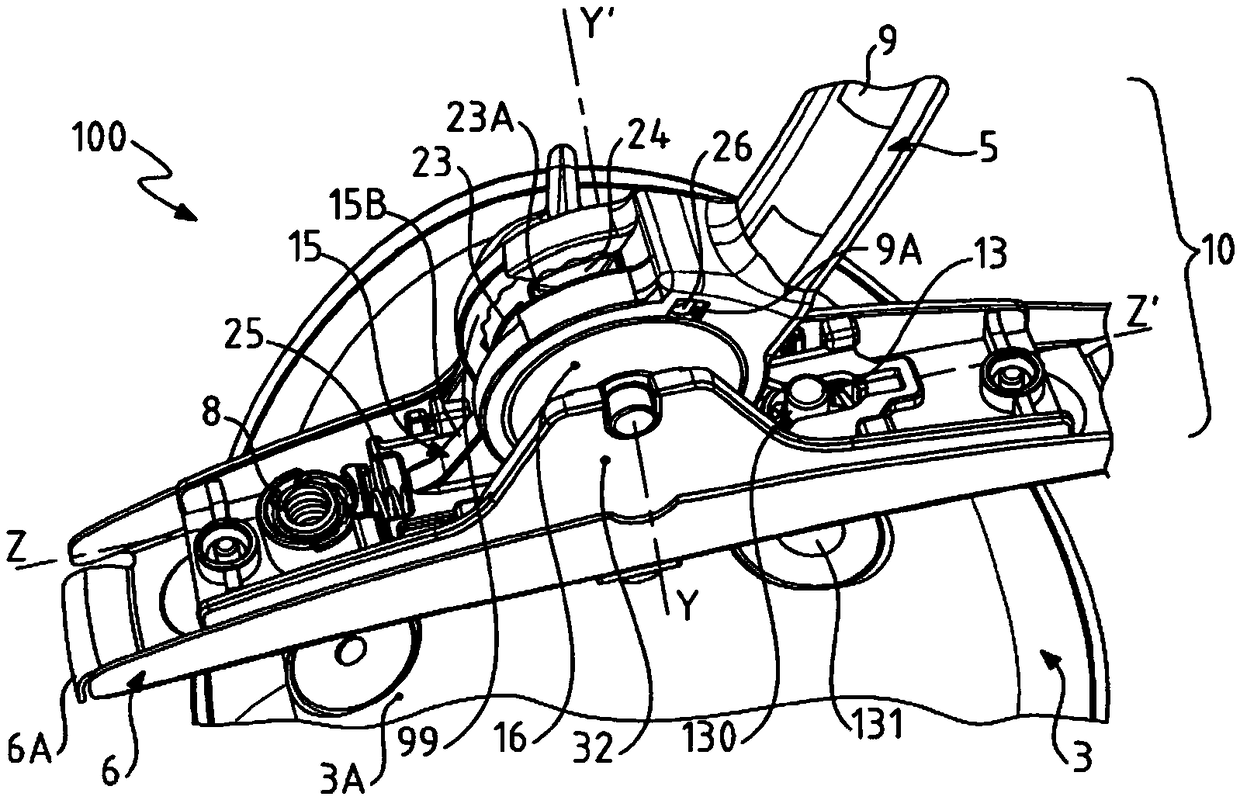

Pressure cooking appliance with improved control ergonomics

The invention concerns a pressure cooking appliance (1) with a fitting lid, comprising at least: a pan (2) and a lid (3), a manual control member (5) for controlling the movement of the lid (3), a movable lock (15) capable of occupying a locked position preventing the lid (3) from assuming the open position of same, and an unlocked position allowing the lid to assume the open position of same, anopening safety means (13) that can be automatically activated / deactivated, characterised in that the manual control member (5) is connected to the lock (15) by a transmission device designed to move the lock (15) out of the locked position of same in response to the movement of the manual control member (5) in the opening direction while the opening safety means (13) is deactivated.

Owner:LAGOSTINA

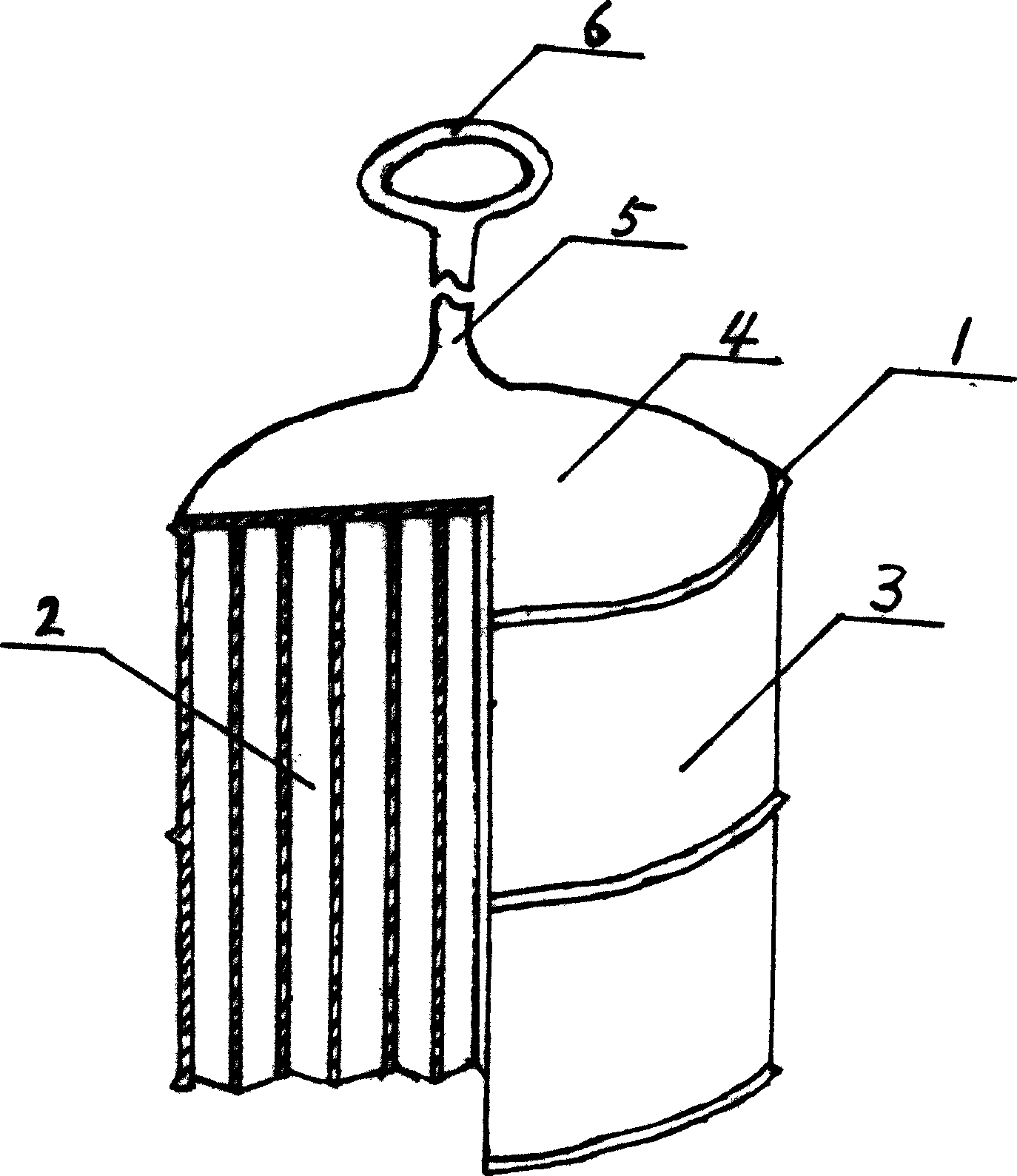

Plastic deformed checking air valves for sewer pipe

InactiveCN1644814AStrong defecation abilityEasy to installWater closetsDomestic plumbingSewageElastic plastic

A deformable plastic check valve for sewer pipe is prepared from the elastic plastics resisting to ageing, acid and alkali, and has the elastic lower mouth with honeycomb structure, closed top end with a pull-up ring, and reinforcing rings on its external circumference. When water is flushed down, it isdeformed from draining the water and then elastically restored to its original shape. Its advantage is high sealing performance.

Owner:赵钦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com