Molding material of conveying belts

A technology for forming materials and conveyor belts, applied in cement mixing devices, clay preparation devices, mixing operation control devices, etc., can solve problems such as polluting the environment, damaging the health of operators, and easily causing dust, etc., and achieves good corrosion resistance such as acid and alkali , Low manufacturing cost, easy mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

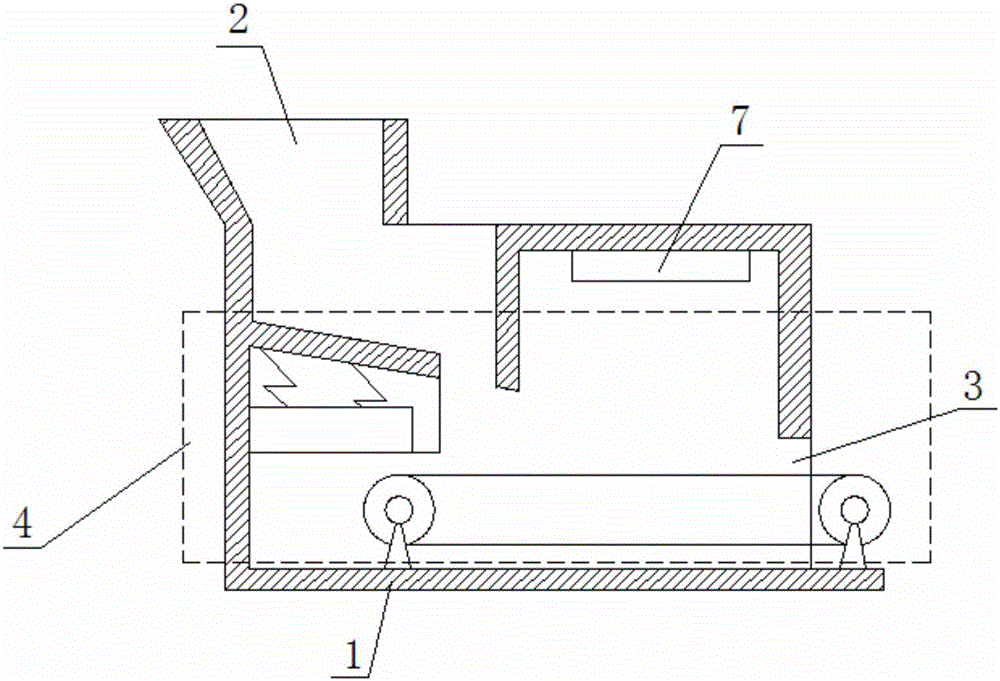

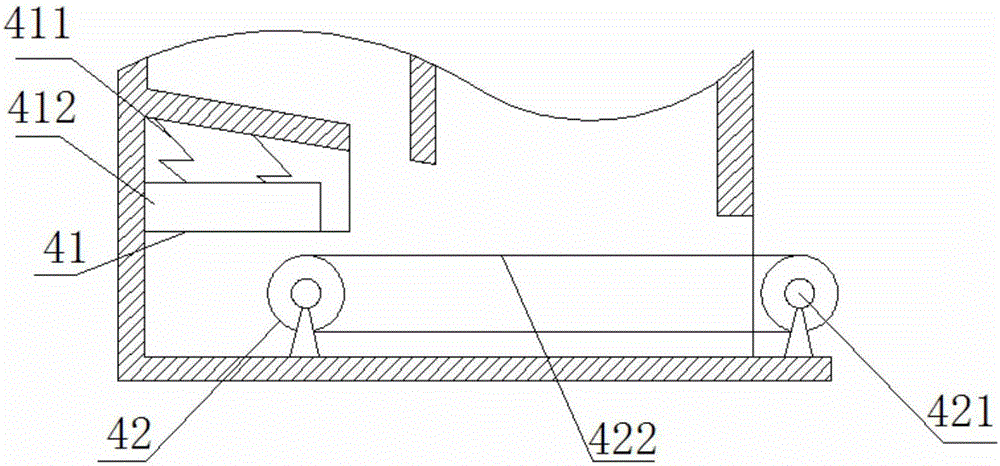

[0028] Such as Figure 1 to Figure 2 As shown, the present invention provides a foam cement production and feeding device, comprising: a box body 1, a feed port 2 arranged at the top of the box body 1, a discharge port 3 arranged at the side of the box body 1, and a The conveying mechanism 4 in the box body 1. Concretely, conveying mechanism 4 comprises the vibration mechanism 41 that is positioned at feed inlet 2 below and the pulley mechanism 42 that is positioned at vibration mechanism 41 one side below; The wheel mechanism 42 includes two pulleys 421 and a conveyor belt 422 connected between the two pulleys 421 . The inside of the casing 1 is provided with a vacuum cleaner 7 above the pulley mechanism 42, which can be used to absorb the dust of the raw material on the pulley mechanism 42.

[0029] The raw material is sent into the vibration mechanism 41 through the feed port 2, and the vibration mechanism 41 sends the raw material to the conveyor belt 422 of the pulley m...

Embodiment 2

[0031] Conveyor belt molding material is made of the following raw materials in parts by weight:

[0032] 10 parts of isoprene rubber, 10 parts of ethylene propylene rubber, 10 parts of acrylic resin, 10 parts of styrene-butadiene rubber, 3 parts of silane coupling agent, 3 parts of vulcanizing agent, 2 parts of anti-aging agent, 1 part of accelerator, 10 parts of isopropanol , 15 parts of deionized water, 5 parts of rhubarb total anthraquinones.

[0033] The preparation method of the conveyor belt molding material has the following steps:

[0034] ①. Add 3 parts of silane coupling agent, 10 parts of isopropanol, 15 parts of deionized water, and 5 parts of rhubarb total anthraquinone into the reaction kettle, stir and mix to obtain a premixed solution;

[0035] ②. Add 10 parts of isoprene rubber, 10 parts of ethylene-propylene rubber, 10 parts of acrylic resin, and 10 parts of styrene-butadiene rubber to the above premix in sequence, then add 3 parts of vulcanizing agent, 2 p...

Embodiment 3

[0037] The conveying mechanism used for the feeding device for foamed cement production includes a vibrating mechanism and a pulley mechanism positioned below one side of the vibrating mechanism; the vibrating mechanism includes a vibrator and a driver located below the vibrator; the pulley The mechanism includes two pulleys and a conveyor belt connected between the two pulleys; the conveyor belt is made of conveyor belt molding material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com