Formaldehyde-removing, corrosion-preventing and environment-friendly agriculture and forestry residue fiberboard and preparation method thereof

A technology of residue and fiberboard, applied in the field of biomass composite decoration materials, can solve the problems of formaldehyde pollution, limited application, easy corruption of soybean protein adhesive, etc., achieve low production cost and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

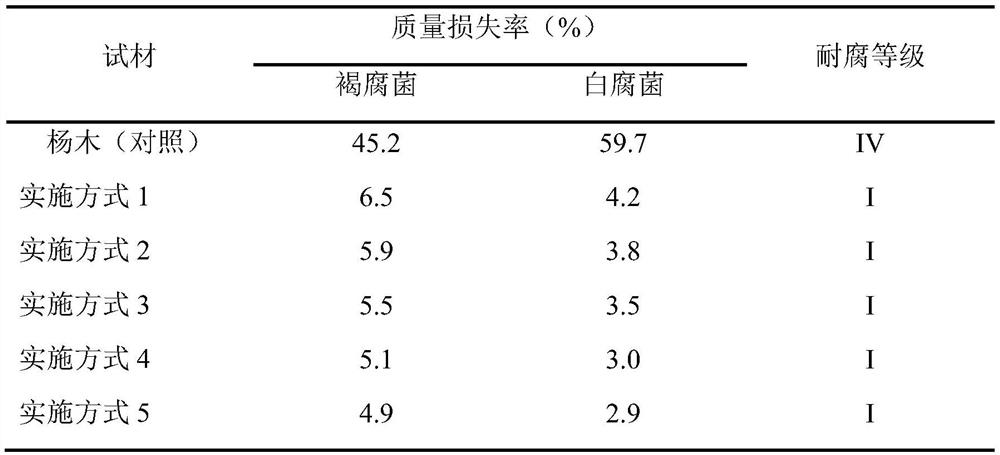

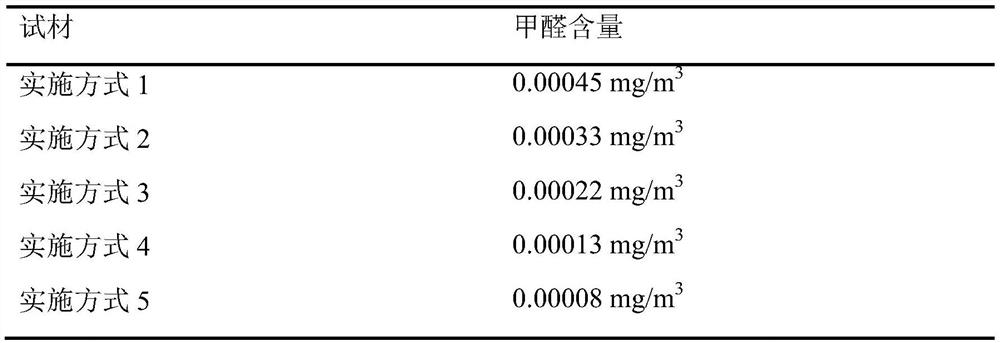

Examples

Embodiment 1

[0036] 1) Preparation of agricultural and forestry residues: purchase 50g of branches produced in the process of forest tending and 50g of straw produced in agricultural production according to the process requirements.

[0037]2) Preparation of chitosan nanoparticles: 1 g of chitosan was dissolved in 200 mL of 1% acetic acid solution, and magnetically stirred for 3 hours under a nitrogen atmosphere until a transparent chitosan solution was obtained. At room temperature, the pH value of the chitosan solution was adjusted to 4 with 1 M hydrochloric acid solution, and magnetically stirred at 500 rpm at 70° C. for 7 hours. Dissolve 0.2g of citric acid in 10mL of distilled water, adjust the pH value of the citric acid solution to 4 with a concentration of 1M sodium hydroxide solution, and add the citric acid solution drop by drop to the chitosan solution with a pH value of 4 , the resulting product was centrifuged at 4000 rpm for 40 minutes, and freeze-dried at -50° C. for 36 hour...

Embodiment 2

[0047] 1) Preparation of agricultural and forestry residues: purchase 50g of branches produced in the process of forest tending and 50g of straw produced in agricultural production according to the process requirements.

[0048] 2) Preparation of chitosan nanoparticles: 2 g of chitosan was dissolved in 400 mL of 1% acetic acid solution, and magnetically stirred for 3 hours under a nitrogen atmosphere until a transparent chitosan solution was obtained. At room temperature, the pH value of the chitosan solution was adjusted to 4 with 1 M hydrochloric acid solution, and magnetically stirred at 500 rpm at 70° C. for 7 hours. Dissolve 0.4g citric acid in 20mL distilled water, adjust the pH value of the citric acid solution to 4 with a concentration of 1M sodium hydroxide solution, and add the citric acid solution drop by drop to the chitosan solution with a pH value of 4 , the resulting product was centrifuged at 4000 rpm for 40 minutes, and freeze-dried at -50° C. for 36 hours to ...

Embodiment 3

[0058] 1) Preparation of agricultural and forestry residues: purchase 50g of branches produced in the process of forest tending and 50g of straw produced in agricultural production according to the process requirements.

[0059] 2) Preparation of chitosan nanoparticles: 3 g of chitosan was dissolved in 600 mL of 1% acetic acid solution, and magnetically stirred for 3 hours under a nitrogen atmosphere until a transparent chitosan solution was obtained. At room temperature, the pH value of the chitosan solution was adjusted to 4 with 1 M hydrochloric acid solution, and magnetically stirred at 500 rpm at 70° C. for 7 hours. Dissolve 0.6g of citric acid in 30mL of distilled water, adjust the pH of the citric acid solution to 4 with a concentration of 1M sodium hydroxide solution, and add the citric acid solution drop by drop to the chitosan solution with a pH of 4 , the resulting product was centrifuged at 4000rpm for 40min, and freeze-dried at -50°C for 36 hours to obtain chitosa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com