Composite fireproof plate and preparation method thereof

A fireproof board and metal plate technology, applied in fire prevention, chemical instruments and methods, building components, etc., can solve the problems of poor environmental protection, inconvenient use and limited application of composite fireproof boards, and achieve good environmental protection, low bulk density and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

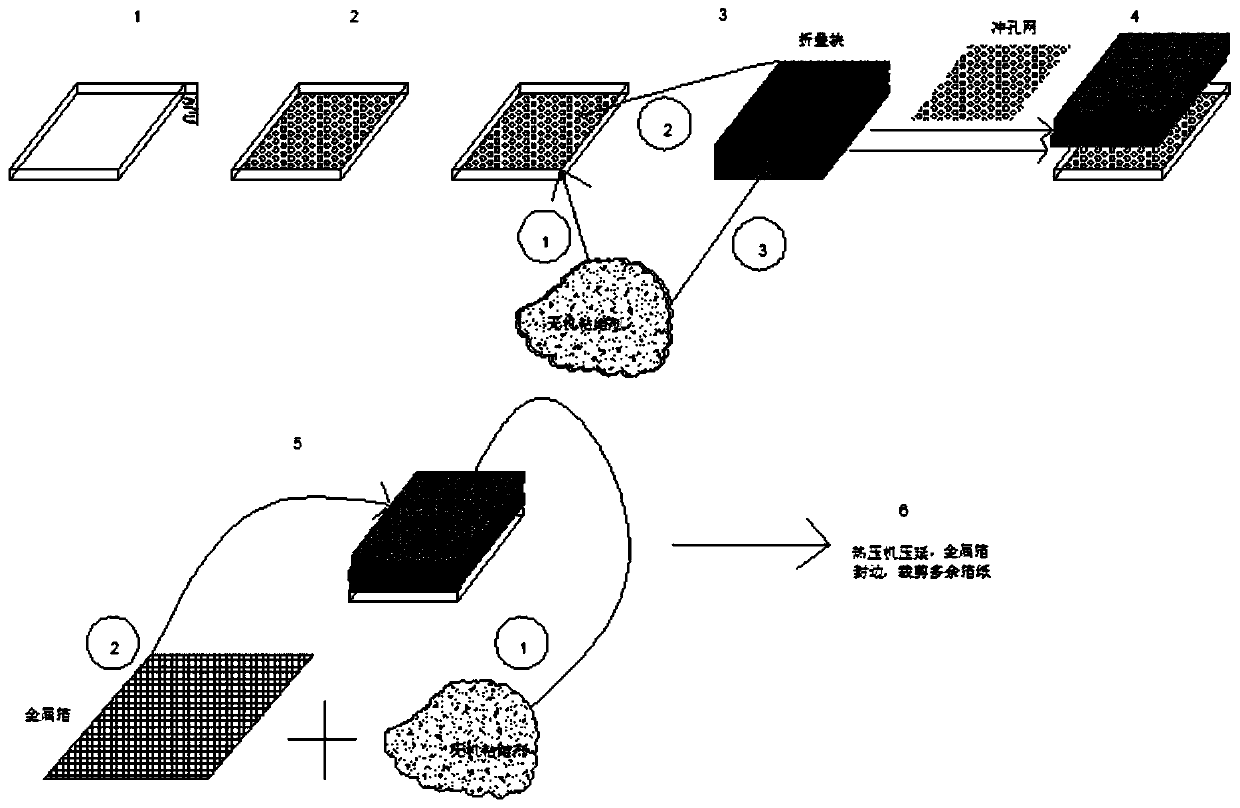

[0021] The invention provides a method for preparing a composite fireproof board, comprising the following steps:

[0022] a) Fix a number of stainless steel nails in the groove of the metal plate and apply an inorganic binder, then press into the ceramic fiber blanket folding block, so that the stainless steel nails penetrate the folding block; then coat the surface of the folding block with an inorganic adhesive, and then Bond the punching mesh and metal foil, hot press to the height of the inner frame of the metal plate groove, and obtain a composite fireproof board;

[0023] The compression rate of the ceramic fiber blanket folding block is 30%-60%.

[0024] In the present invention, several stainless steel nails are firstly fixed in metal plate grooves and coated with an inorganic adhesive. In the present invention, the plate material of the metal plate tank is preferably galvanized plate, stainless steel plate or aluminum plate, more preferably galvanized plate; its edg...

Embodiment 1

[0044] Weld the flat head of a stainless steel nail with a length of 9.5mm into the galvanized sheet groove (the edge forms an inner frame with a height of 10mm), and arrange the corresponding points of the mesh center of the punching net as fixed points at equal intervals, see figure 1 Process 2: Apply 136g of inorganic adhesive on the galvanized sheet tank and on the flat plate, with a thickness of 0.2mm, press into a 20mm thick standard ceramic fiber blanket folding block, so that the stainless steel nails penetrate the folding block, and then apply 523g of inorganic adhesive The bonding agent is applied on the surface of the folding block with a thickness of 0.8mm, see figure 1 Process 3; then bond the perforated net to the folded block to ensure that the stainless steel nails can pass through the perforated net, while the inorganic binder is extruded from the round hole and distributed on the surface of the perforated net, see figure 1 Process 4; then bond the aluminum fo...

Embodiment 2

[0046] Weld a section of the flat head of a stainless steel nail with a length of 19.5mm into the galvanized sheet groove (the edge forms an inner frame with a height of 20mm), and arrange the corresponding points of the mesh center of the punching net as fixed points at equal intervals, see figure 1 Process 2: Apply 136g of inorganic binder around the galvanized sheet tank and on the flat plate, with a thickness of 0.2mm, press into a 30mm thick zirconium-containing ceramic fiber blowing blanket folding block, so that the stainless steel nails penetrate the folding block, and then apply 523g of inorganic adhesive Adhesive is applied on the surface of the folded block with a thickness of 0.8mm, see figure 1 Process 3; then bond the perforated net to the folded block to ensure that the stainless steel nails can pass through the perforated net, while the inorganic binder is extruded from the round hole and distributed on the surface of the perforated net, see figure 1 Process 4;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com