Preparation method of solid oxide fuel cell/electrolytic cell connector

A solid oxide and fuel cell technology, applied in fuel cells, electrolytic components, electrolytic processes, etc., can solve problems such as increasing battery internal resistance, SOFC performance degradation, etc., to improve bonding strength, life and stability, technology Mature and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the solid oxide fuel cell / electrolyzer connector provided by the application may comprise the following steps:

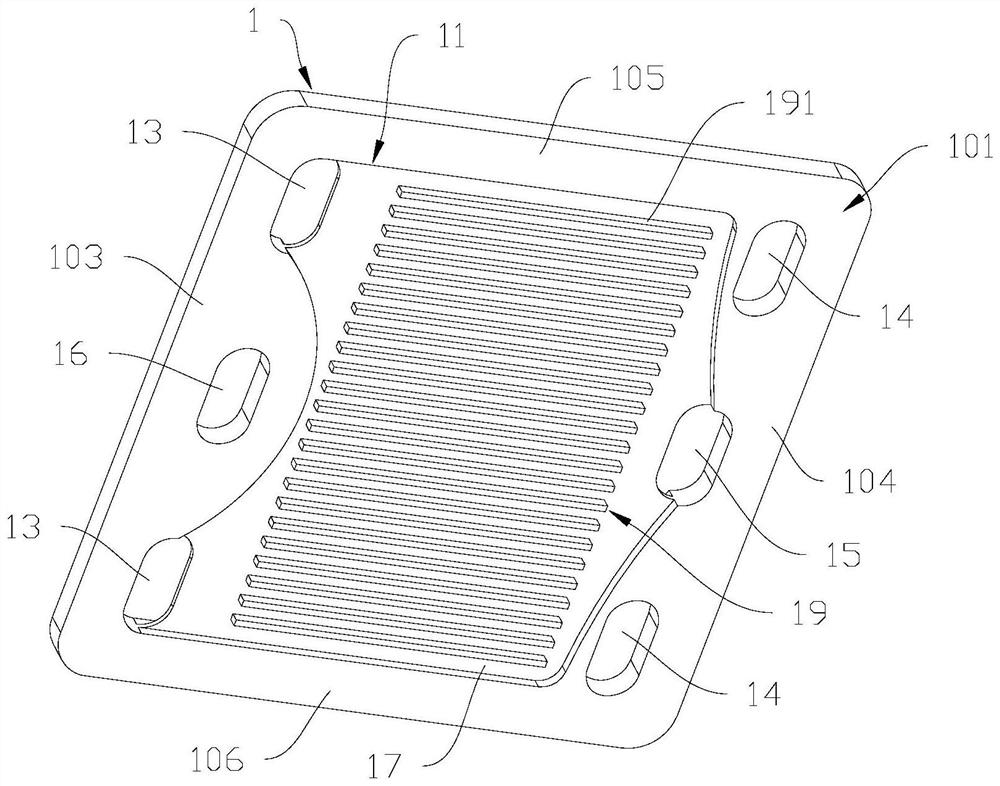

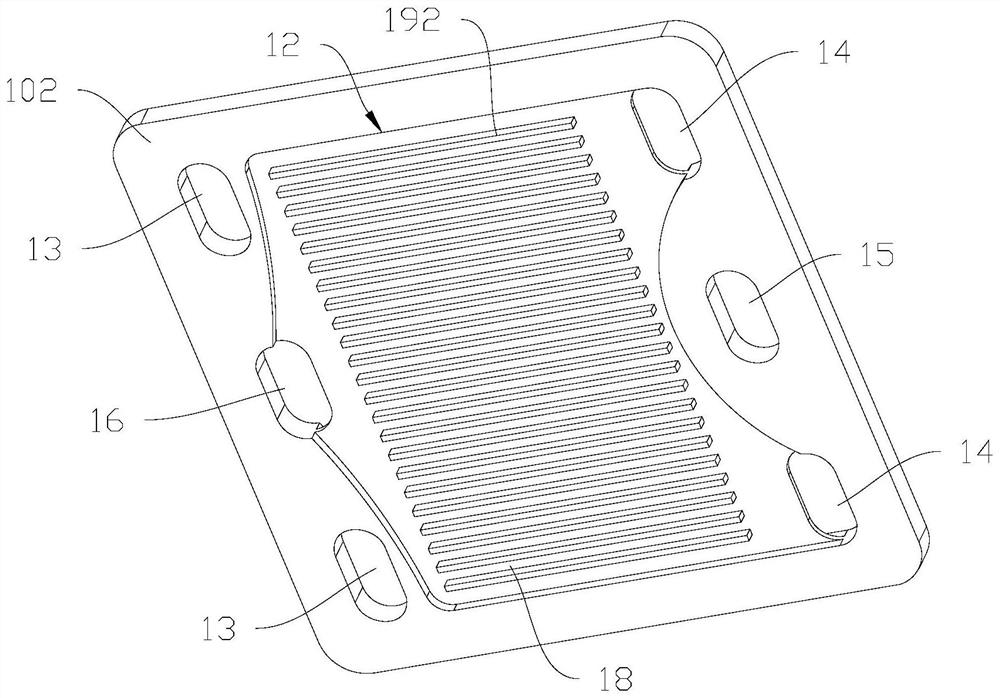

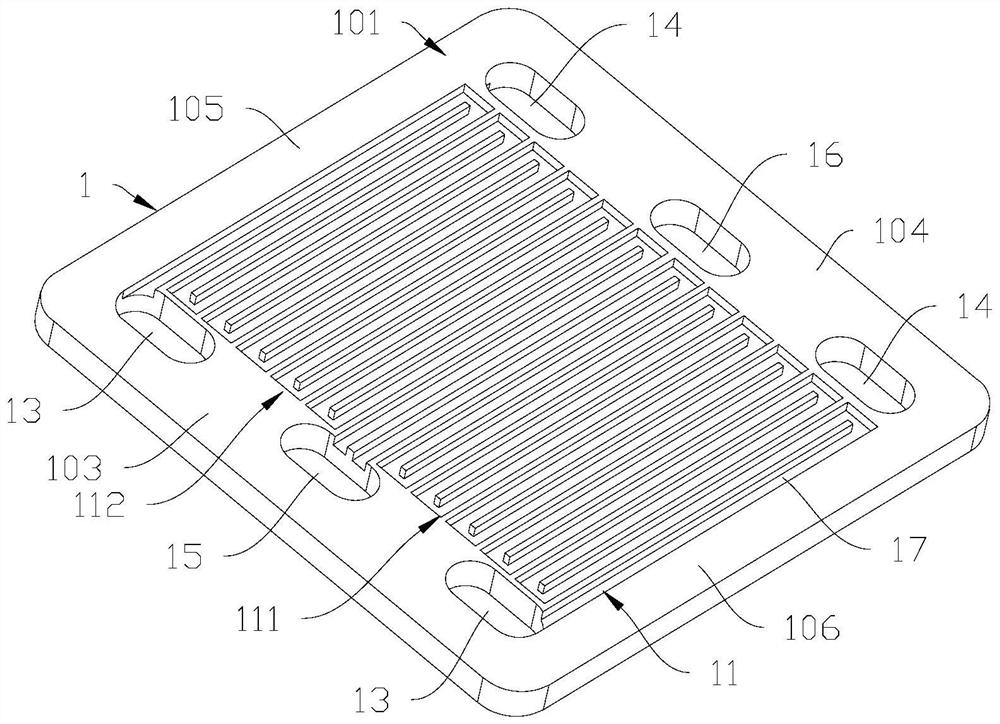

[0047] Step 1: Design and model the structure-function integration of the solid oxide fuel cell / electrolyzer junction. please combine Figure 1 to Figure 7 , the solid oxide fuel cell / electrolytic cell connector includes a connector body 1 and a protective coating 2 on the surface of the connector body.

[0048] The connector body 1 has a first surface 101 and a second surface 102 opposite to each other.

[0049] The connecting body body 1 is provided with at least four through holes all passing through the first surface 101 and the second surface 102 . The first surface 101 has an opposite first side 103 and a second side 104, and the second surface also has an opposite first side 103 and a second side 104, that is, the first side 103 of the first surface and the second side of the second surface. One side 103 is in the same dire...

Embodiment 1

[0086] This embodiment provides a solid oxide fuel cell / electrolytic cell connecting body, which adopts the selective laser melting technology (SLM) and the plasma spraying technology to realize the manufacture of the SOFC connecting body.

[0087] The specific manufacturing process of the SOFC connector is as follows:

[0088] (1) Integrative design of structure and function, rationally plan the structure, material and thickness of the metal part (ie, the connector body 1) and the coating 2 part. Specifically: the material of the connector body 1 is 430 stainless steel powder with a thickness of 3 mm, and the material of the coating 2 (protective coating) is (Mn, Co) 3 o 4 , with a thickness of 30 μm.

[0089] (2) Three-dimensional modeling, the specific design structure is as follows figure 1 , figure 2 and Figure 5 shown.

[0090] The shape of the connector body 1 is a cube, and the front and back sides of the cube are respectively a first surface 101 and a second s...

Embodiment 2

[0100] This embodiment provides a solid oxide fuel cell / electrolytic cell connecting body, which adopts the method of manufacturing the SOFC connecting body by using the selected area electron beam melting technology (SLM) and the plasma spraying technology.

[0101] The manufacturing process of the SOFC connector is as follows:

[0102] (1) Integrative design of structure and function, rationally plan the structure, material and thickness of the metal part (ie, the connector body 1) and the coating 2 part. Specifically: the material of the connector body 1 is Crofer22, the thickness is 4mm, and the material of the coating 2 (protective coating) is (Mn, Co) 3 o 4 , with a thickness of 50 μm.

[0103] (2) Three-dimensional modeling, the specific design structure is as follows Figure 3 to Figure 5 shown.

[0104] The difference between this structure and Embodiment 1 is that starting from the end of the first side 103 close to the fourth side 106, clockwise, the first air i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com