Method for preparing high-quality polythiol curing agent for epoxy resin

A high-quality technology for epoxy resin, applied in the direction of chemical recycling, etc., can solve the problems of large industrial-scale production and application limitations, high production and separation costs, not meeting green environmental protection, etc., and achieves good industrial application prospects and halogen residues. Low, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

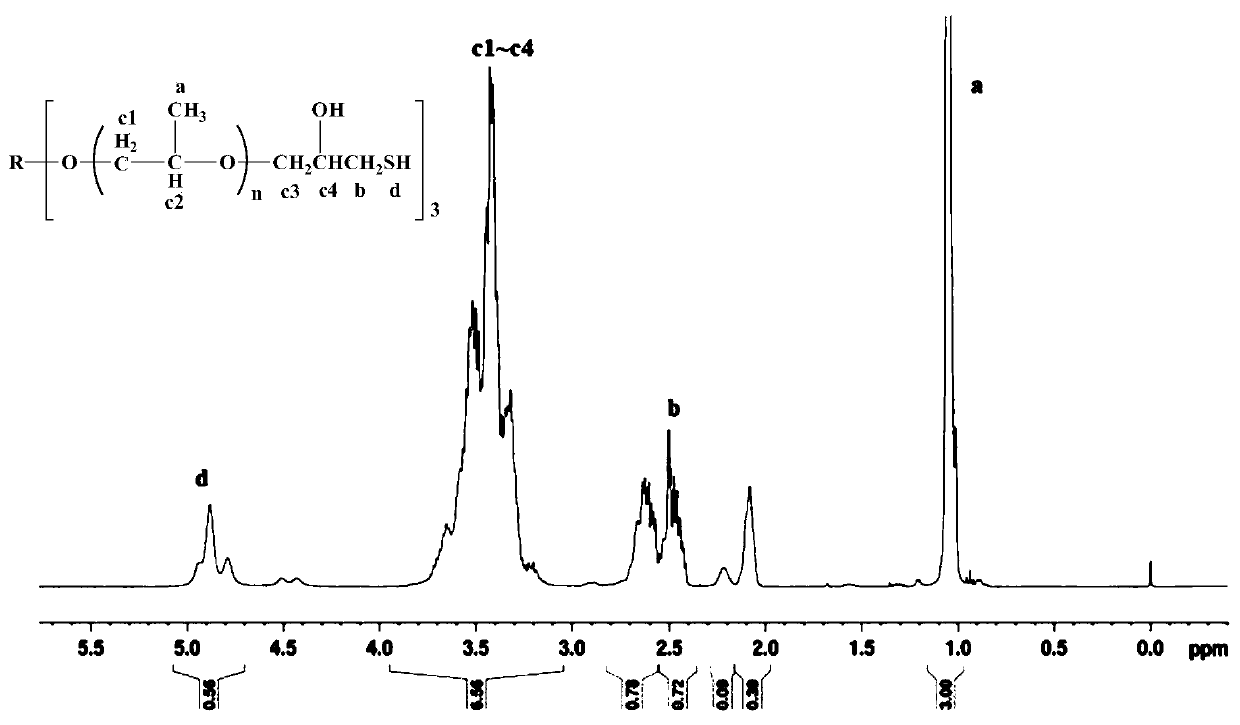

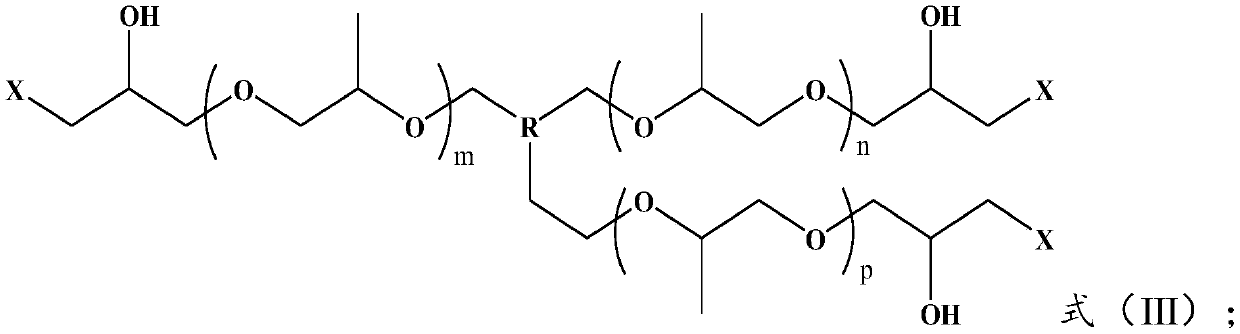

[0030] The invention provides a kind of preparation method of high-quality polythiol curing agent for epoxy resin, comprising the following steps:

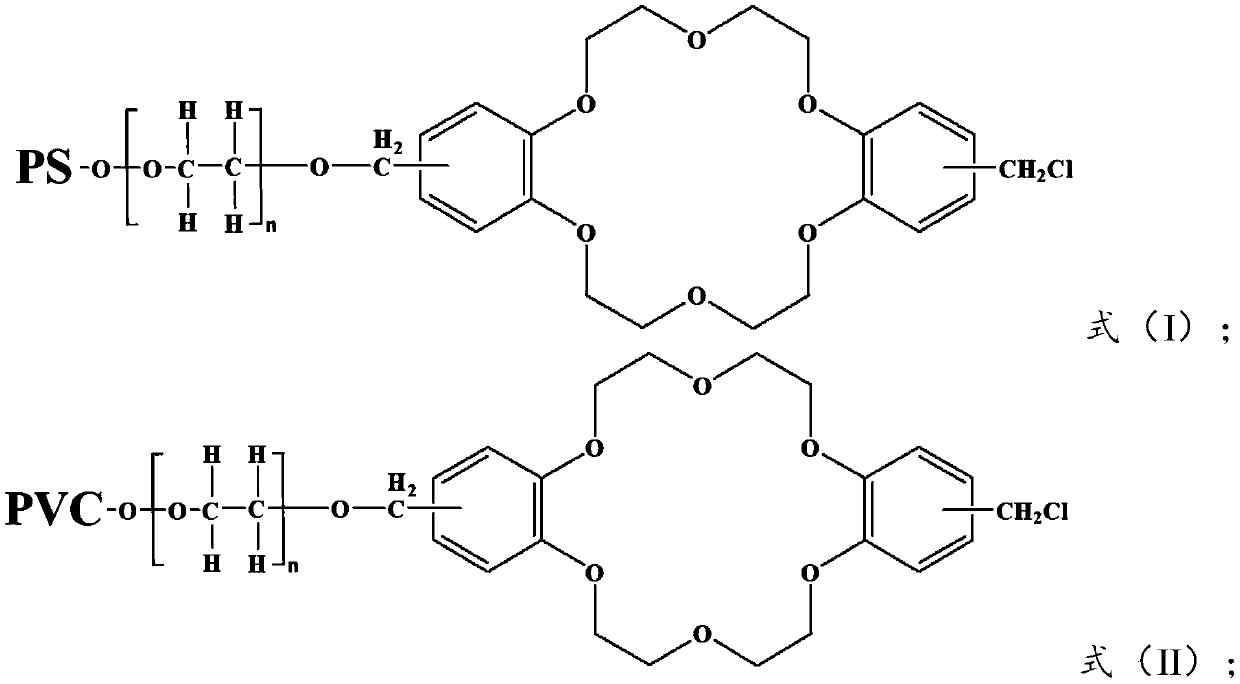

[0031] a) NaSH, catalyst, halogenated polyether polyol and water in H 2 React in the presence of S, and then separate the catalyst to obtain a crude product; the catalyst is a three-phase transfer catalyst;

[0032] b) washing and drying the crude product obtained in step a) successively to obtain a high-quality polythiol curing agent for epoxy resin.

[0033] The present invention at first NaSH, catalyzer, halogenated polyether polyalcohol and water in H 2 The reaction is carried out in the presence of S, and the catalyst is separated to obtain a crude product. The present invention has no special limitation on the source of the NaSH, and commercially available products or self-made products (mainly prepared by injecting hydrogen sulfide into an alkaline solution) well known to those skilled in the art can be used. In the pres...

Embodiment 1

[0065] (1) Adding 198.3g mass fraction in the reactor is 32% NaSH aqueous solution and 8.8g three-phase phase transfer catalyst PS-PEG-DBC-1, then add 177.7g chlorinated polyether and 132g deionized water, react After the kettle is closed, check the airtightness, and then inject H into the kettle. 2 S gas keeps the inside of the kettle at normal pressure, heats the reaction system to 90°C through an oil bath, and then keeps it warm for 6 hours, then opens the vent valve of the reactor and uses N 2 After replacement and filtration of the catalyst, the product was left to stand and separated to obtain the crude product A.

[0066] (2) Add the crude product A into 180g deionized water to wash once, adjust the pH of the organic phase to 5-7 with hydrochloric acid, let it stand for stratification after stabilization, and take out the lower layer material to be the crude product B; Add 180g of deionized water, mix well and let it stand for 12 hours, then cut out the product and rem...

Embodiment 2

[0071] Adopt the preparation method that embodiment 1 provides to obtain high-quality polythiol curing agent for epoxy resin; Phase transfer catalyst PS-PEG-DBC-1.

[0072]The product obtained by the preparation method provided in Example 2 of the present invention is colorless and transparent, with a chromaticity (Hazen) of 18 when tested by a Hunter chromaticity meter, and a halogen content (residual chlorine) of 173 ppm when tested by a coulometric chlorine meter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com