Air sac with air leakage prevention self-locking one-way valves

A one-way valve and airbag technology, applied in the direction of liquid-filled cushions, etc., can solve the problem that the tongue cannot be completely pressed against the inner surface of the co-extruded film or cast film, and it is easy to generate gaps or wrinkles, which affects the normal use of the airbag. and other problems, to achieve the effect of prolonging the effective utilization time, overcoming the poor air tightness, and having a simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

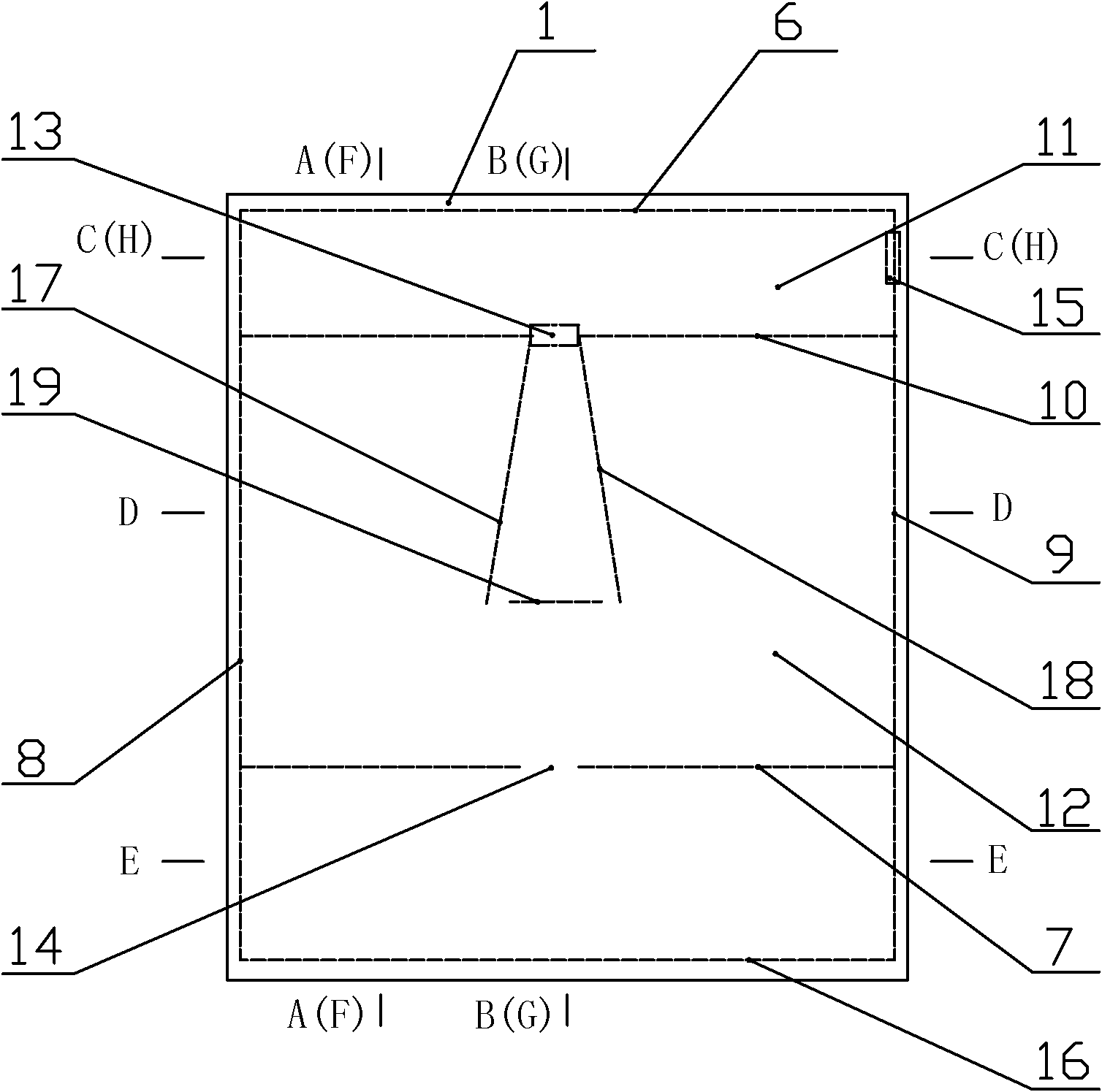

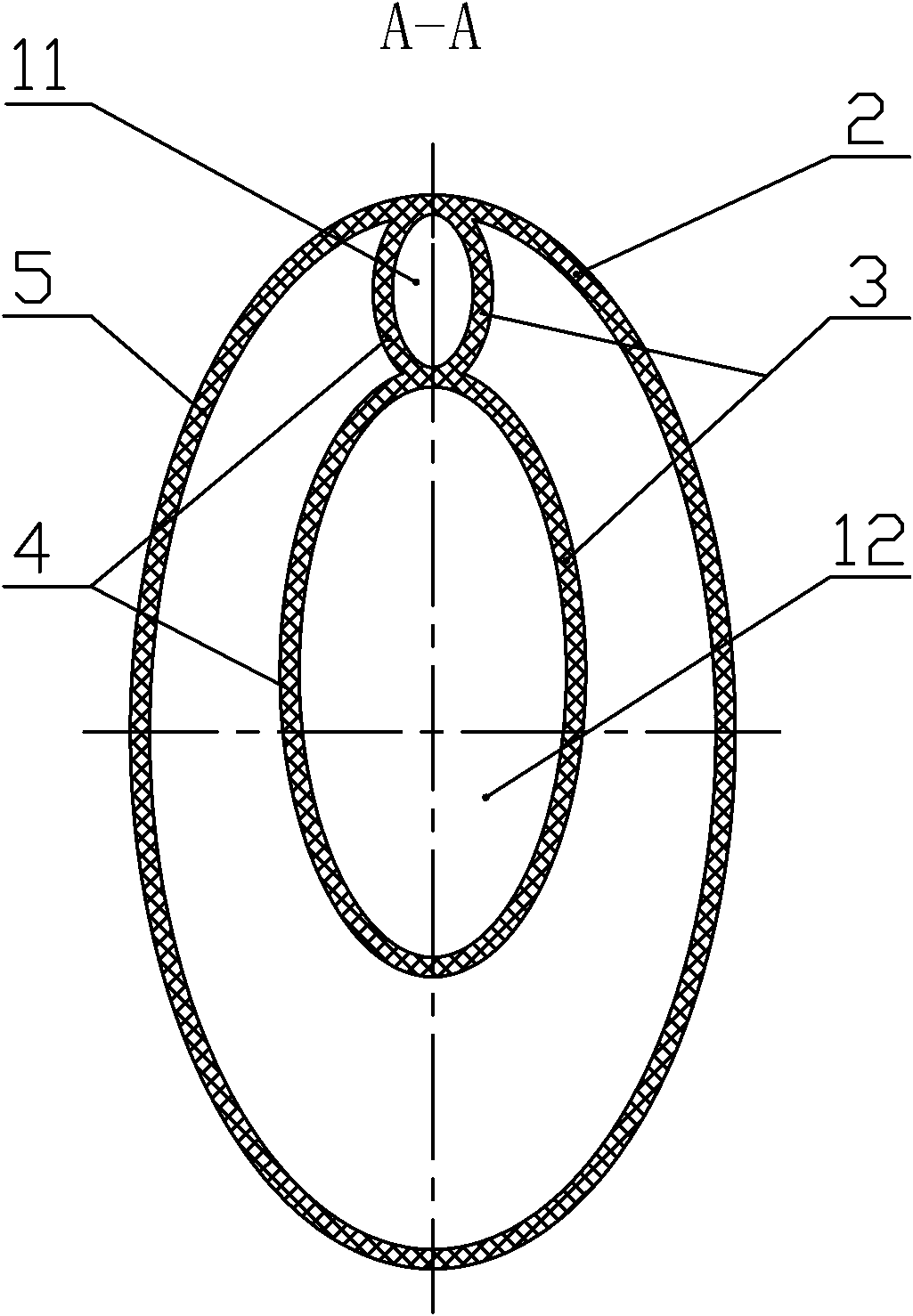

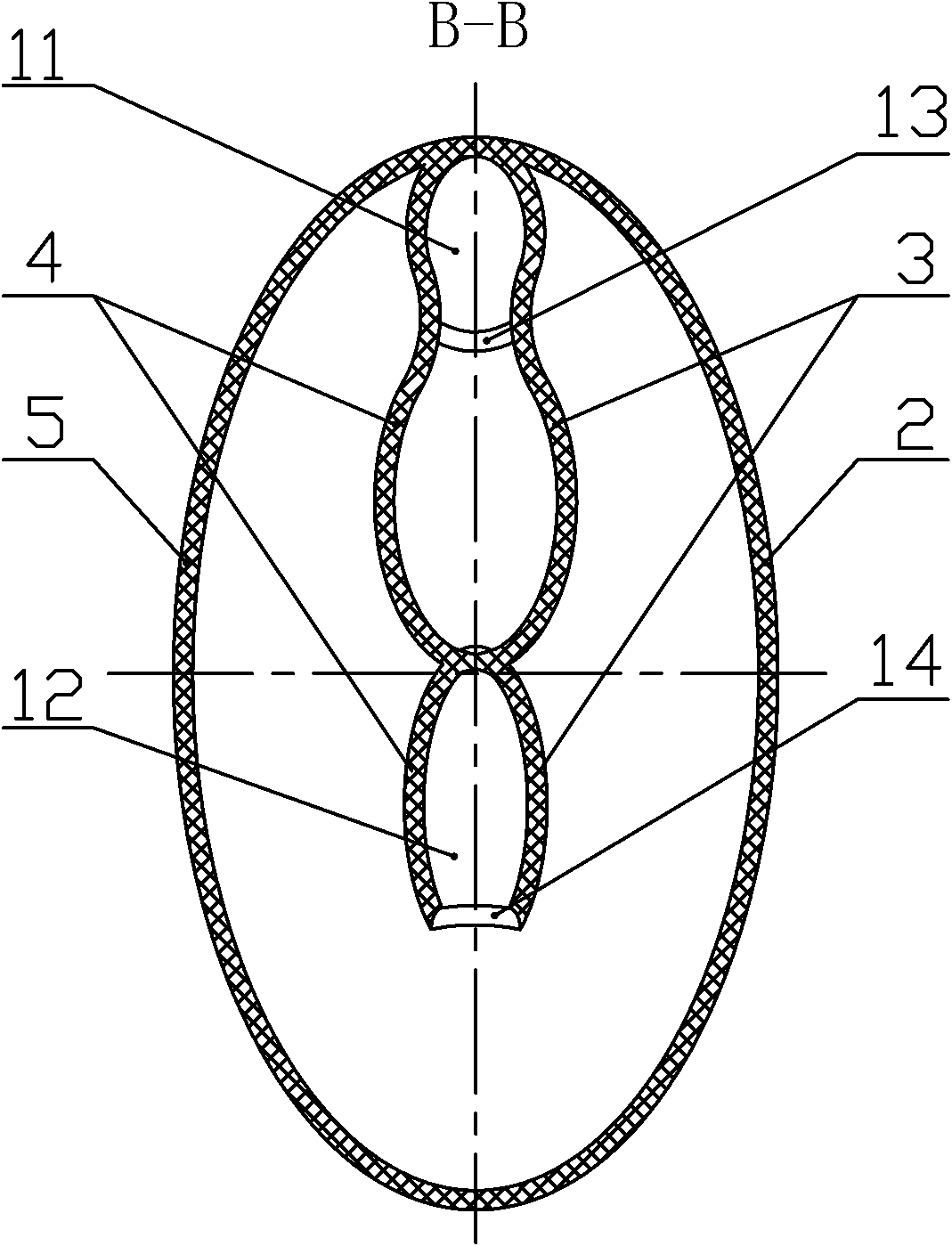

[0026] See attached figure 1 , 2, 3, 4, 5, 6, a kind of airbag of the present invention has anti-leakage self-locking one-way valve, comprises airbag body 1, one-way valve, and described one-way valve is provided with on one side of monolithic tongue The high temperature resistant ink with a width of 6-15mm or the heat-resistant ink with a width of 6-15mm is arranged between the double-piece tongues and co-extruded film or cast film is heat-bonded to form; the airbag body 1 is composed of rectangular The first film layer 2, the second film layer 3, the third film layer 4, and the fourth film layer 5 are thermally sealed, and the shape and size of the first film layer 2 and the fourth film layer 5 are exactly the same; The dimensions in the width direction of the second membrane layer 3 and the third membrane layer 4 are the same as those of the first membrane layer 2 and the fourth membrane layer 5, and the dimensions in the length direction of the second membrane layer 3 and ...

Embodiment 2

[0029] See attached Figure 10 The structure of this embodiment is basically the same as that of Embodiment 1, except that the airbag body 1 is composed of multiple airbags arranged side by side, and the first check valve 15 in the first chamber 11 constitutes an inflation channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com