Anti-ultraviolet copolyester and preparation method thereof

A copolyester, anti-ultraviolet technology, applied in the field of copolyester preparation, can solve the problem of the outward migration of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

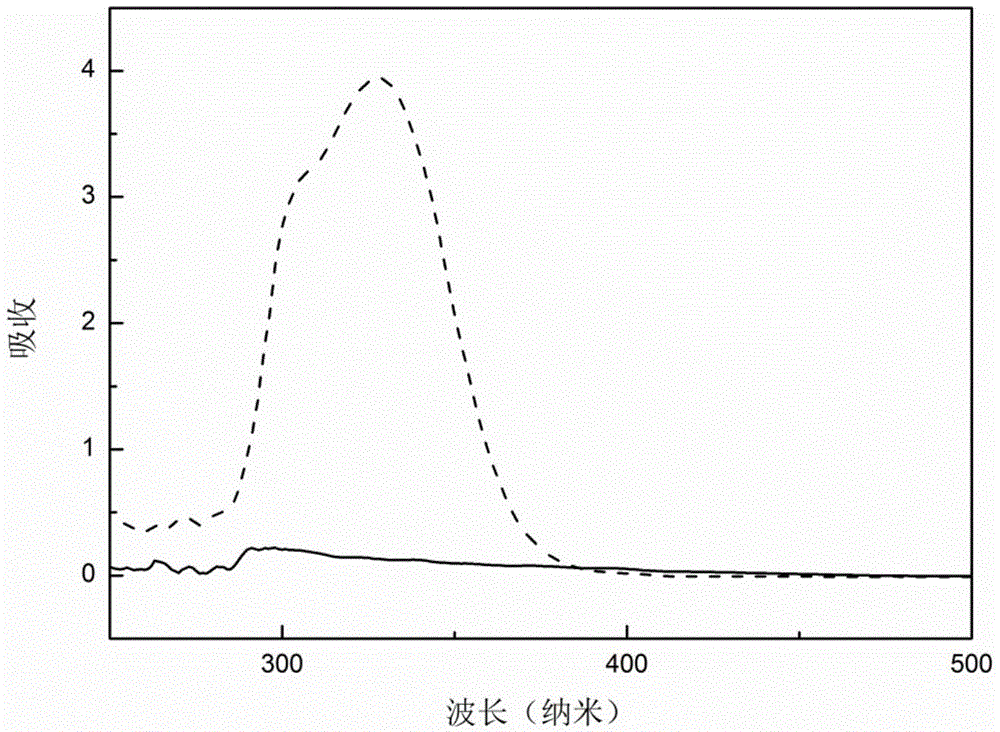

[0028] In this example, polybutylene succinate containing 1% 2-hydroxy-4-(2,3-epoxypropoxy)benzophenone was prepared by bulk melt polycondensation method.

[0029]Add 1.0 moles of succinic acid, 1.2 moles of 1,4-butanediol, 0.012 moles of 2-hydroxy-4-(2,3-epoxypropoxy)benzophenone, and 0.0005% catalyst tetrabutyl titanate In the three-necked flask, under the protection of nitrogen atmosphere, put it in an oil bath and heat it up, react at 120°C for 0.5 hours, at 160°C for 1 hour, and at 220°C for 3 hours, until no liquid flows out, and the mixture in the reaction system becomes clear; Lower the temperature, add 1% catalyst tetrabutyl titanate and 0.01% stabilizer trimethyl phosphate under the protection of nitrogen atmosphere, stir quickly to make the catalyst uniformly dispersed; then vacuumize to 50Pa, react at 240°C for 5 hours to polymer Climb the pole; discharge to obtain the product. The number average molecular weight is 42766 g / mol. It is made into a thin film with a...

Embodiment 2

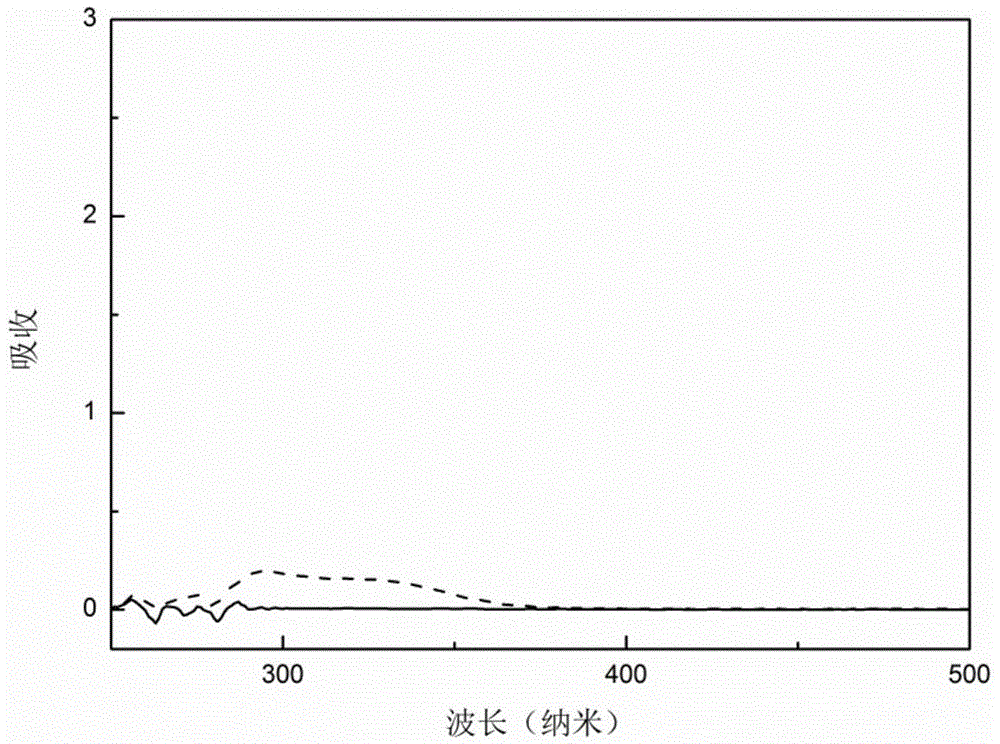

[0031] In this example, polytrimethylene isophthalate containing 0.1% 2,2'-dihydroxy-4-(2,3-epoxypropoxy)benzophenone was prepared by bulk melt polycondensation method.

[0032] 1.0 moles of isophthalic acid, 1.2 moles of 1,3-propanediol, 0.0012 moles of 2,2'-dihydroxy-4-(2,3-epoxypropoxy)benzophenone, 1% catalyst hafnium acetylacetonate Put it into a three-necked flask, under the protection of nitrogen atmosphere, put it in an oil bath and heat it up, react at 120°C for 0.5 hours, at 160°C for 1.5 hours, and at 220°C for 2 hours until no liquid flows out, and the mixture in the reaction system becomes clear; Cool down, add 1% catalyst hafnium acetylacetonate and 0.001% stabilizer bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite under the protection of nitrogen atmosphere, stir quickly to make the catalyst evenly dispersed; then vacuum to 50Pa, react at 250°C for 2 hours until the polymer climbs the pole; the product is obtained by discharging. The number average mole...

Embodiment 3

[0034] In this example, polybutylene adipate containing 1% 2-(5-(2,3-epoxypropoxy)-2-hydroxyphenyl)benzotriazole was prepared by bulk melt polycondensation method.

[0035] 1.0 moles of adipic acid, 1.1 moles of 1,4-butanediol, 0.012 moles of 2-(5-(2,3-epoxypropoxy)-2-hydroxyphenyl)benzotriazole, 2% catalyst Ethyl orthosilicate was added to a three-necked flask, and under the protection of nitrogen atmosphere, it was placed in an oil bath and heated to program temperature rise, reacted at 120°C for 1 hour, at 170°C for 2 hours, and at 230°C for 5 hours until no liquid flowed out, and the reaction system The mixture becomes clear in the middle; cool down, add 0.001% catalyst ethyl orthosilicate and 0.01% stabilizer triphenyl phosphite under the protection of nitrogen atmosphere, stir quickly to make the catalyst evenly dispersed; then vacuumize to 50Pa, at 220℃ React for 4.5 hours until the polymer climbs the pole; discharge to obtain the product. The number average molecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com