Patents

Literature

163results about "Rare earth metal carbonates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare earth compositions and structures for removing phosphates from water

InactiveUS20070149405A1Easy to makeEasy to solveHeavy metal active ingredientsBiocidePhosphateRare earth

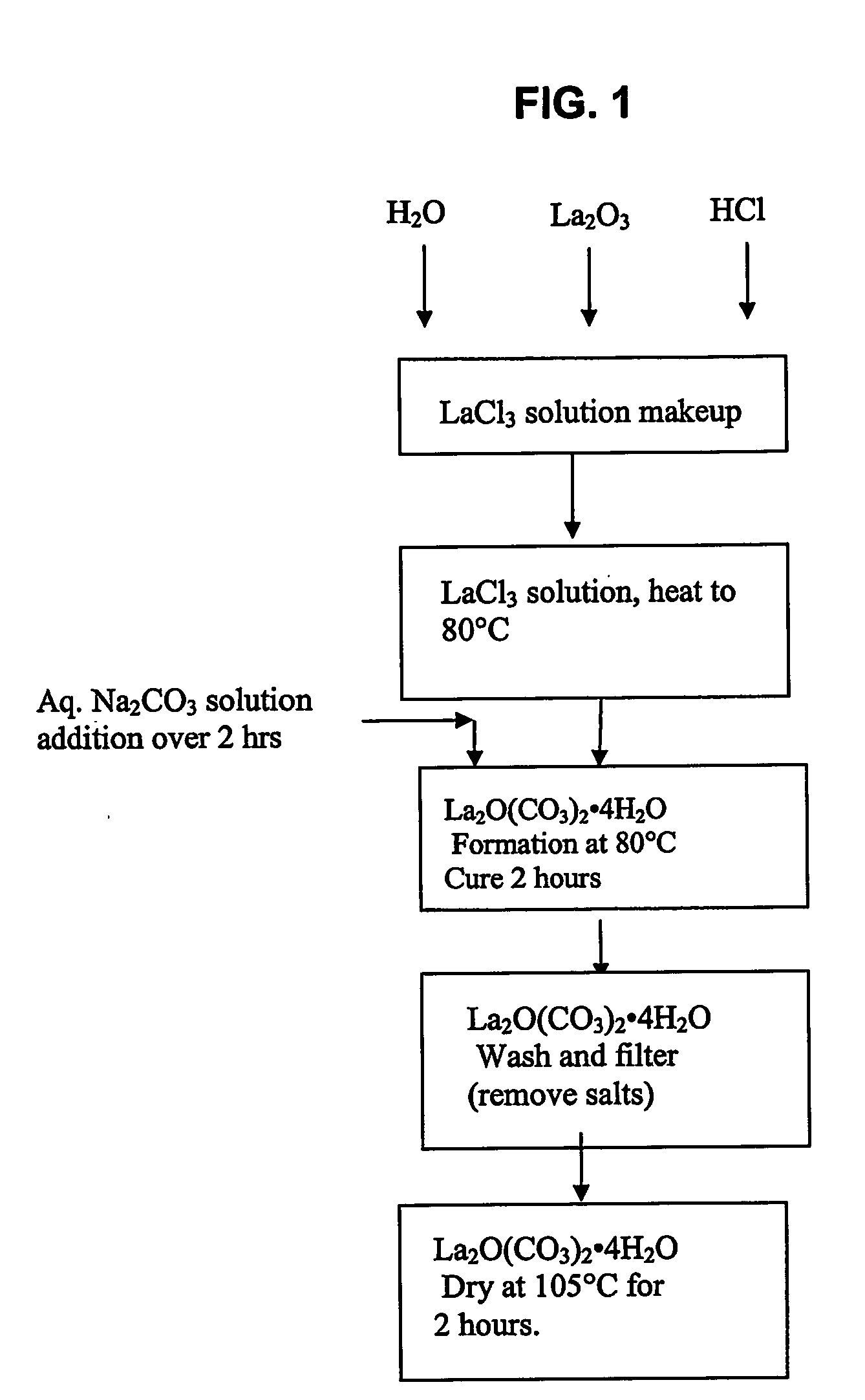

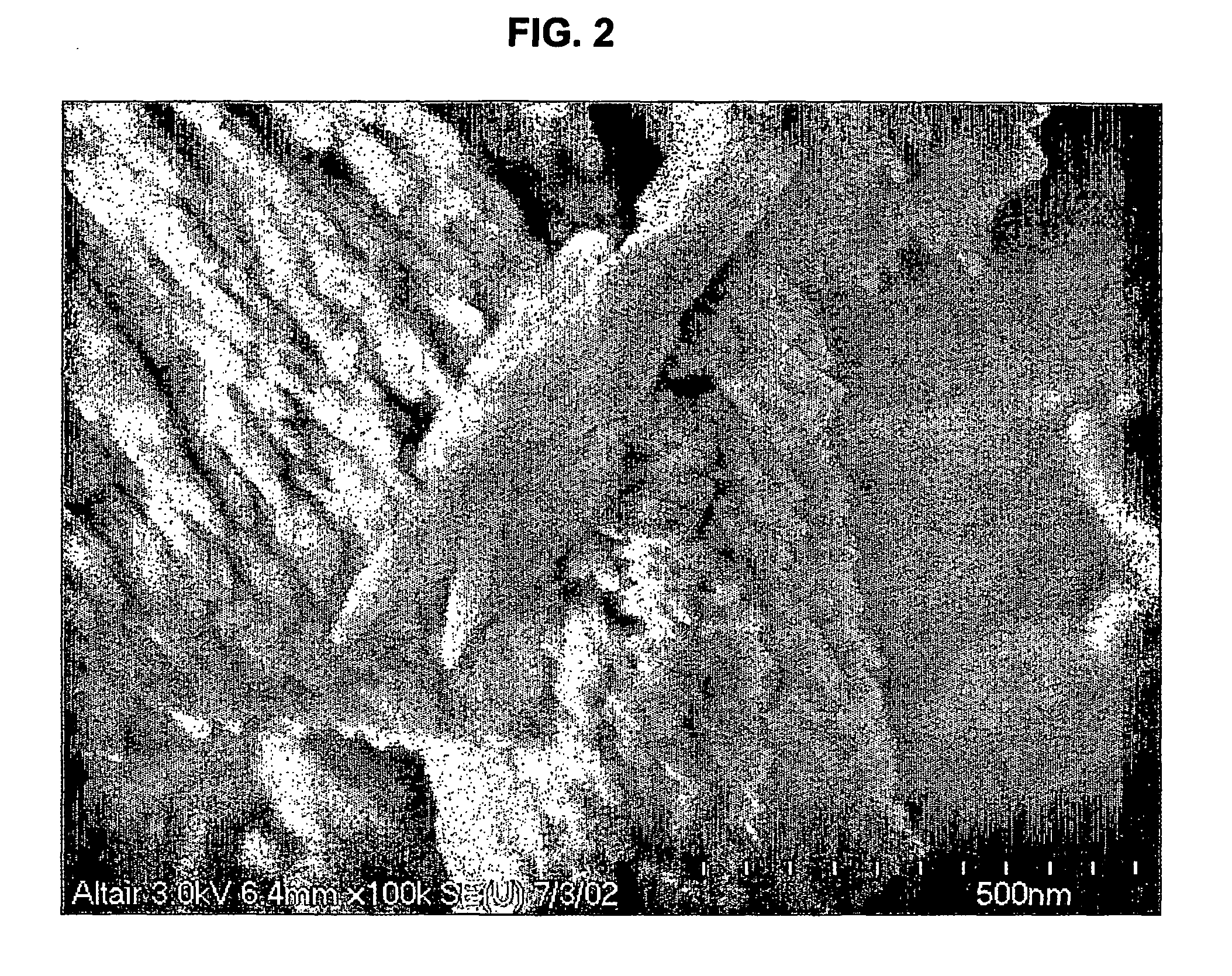

A rare-earth compound selected from the group consisting of rare earth anhydrous oxycarbonate and rare earth hydrated oxycarbonate, with a surface area of at least 10 m2 / g, suitable for the removal of phosphate from water.

Owner:SPECTRUM PHARMA INC

Process For Metal Recovery From Catalyst Waste

InactiveUS20120156116A1Lanthanum oxide/hydroxidesGroup 3/13 element organic compoundsPregnant leach solutionRare earth

A method for recovering rare earth metals from zeolite-containing waste FCC catalysts comprises an acid leaching step to remove the rare earth metals from the catalyst to form a leachate containing dissolved rare earth metals and separating the rare earth metals from the leachate such as by precipitation.

Owner:BASF CORP

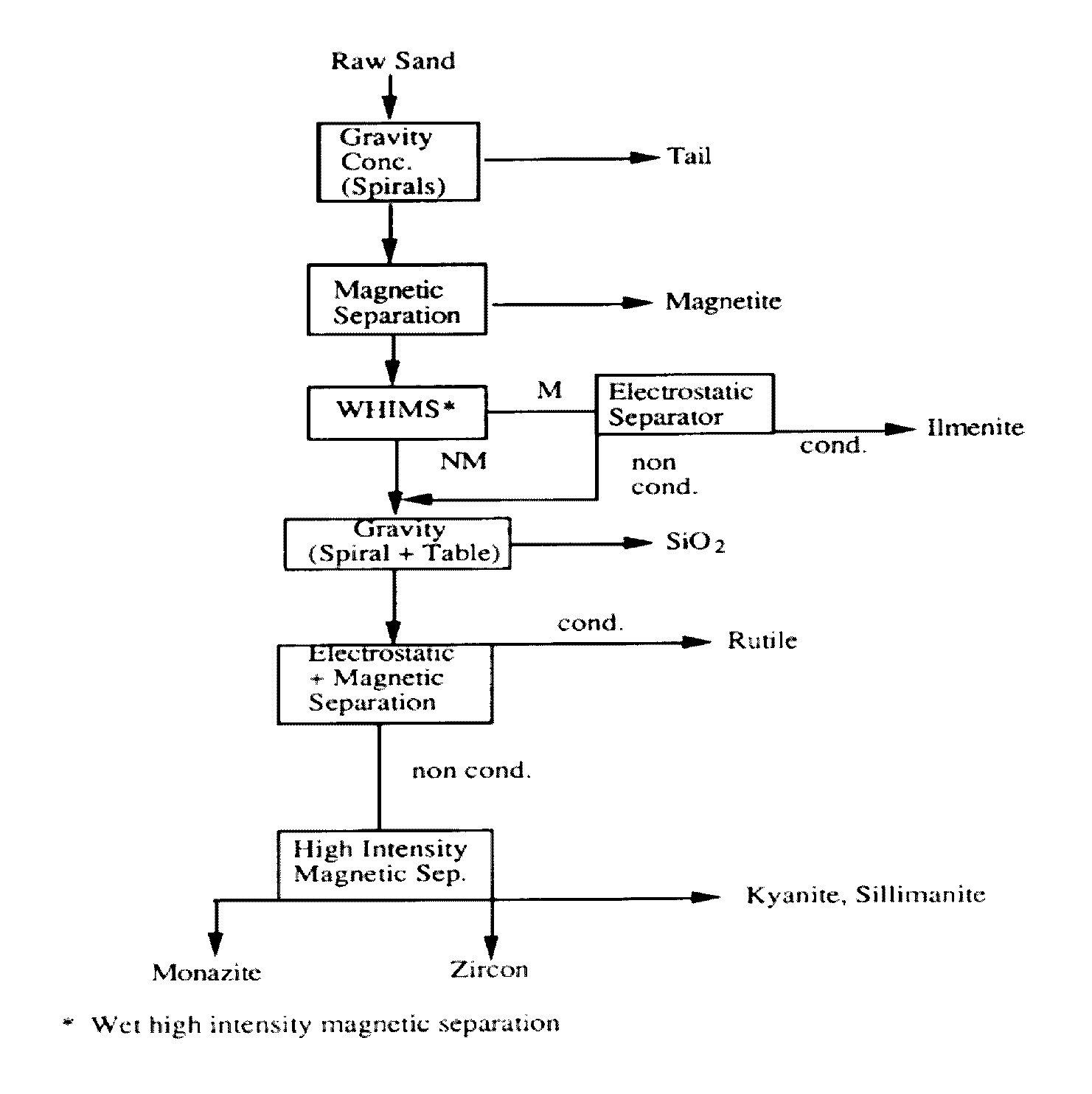

Beneficiation of rare earth elements bearing ancylite

ActiveUS20170028410A1Small sizeHigh gradient magnetic separatorsFlotationStrontium carbonateRare-earth element

Disclosed herein are methods and systems for recovery of ancylite, a rare earth mineral comprising strontium carbonate, from rare earth ore. In many embodiments, the disclosed methods and systems provide for recovery of greater than 50% of the ancylite from an ancylite containing ore. In many embodiments, the ore is subjected to flotation in the presence of an acid, for example a hydroxamic acid, such as octanohydroxamic acid. The ore may also be subjected to magnetic separation, for example wet high intensity magnetic separation.

Owner:COLORADO SCHOOL OF MINES

Security pigments and the process of making thereof

InactiveUS20080274028A1Low costVerify authenticityMaterial nanotechnologyPigmenting treatmentRare earthPigment

Disclosed are methods for using color inconstancy pigments and / or dyes, such as rare earth doped color inconstancy pigments, in security applications including semi-overt and covert security application.

Owner:SUN CHEM CORP

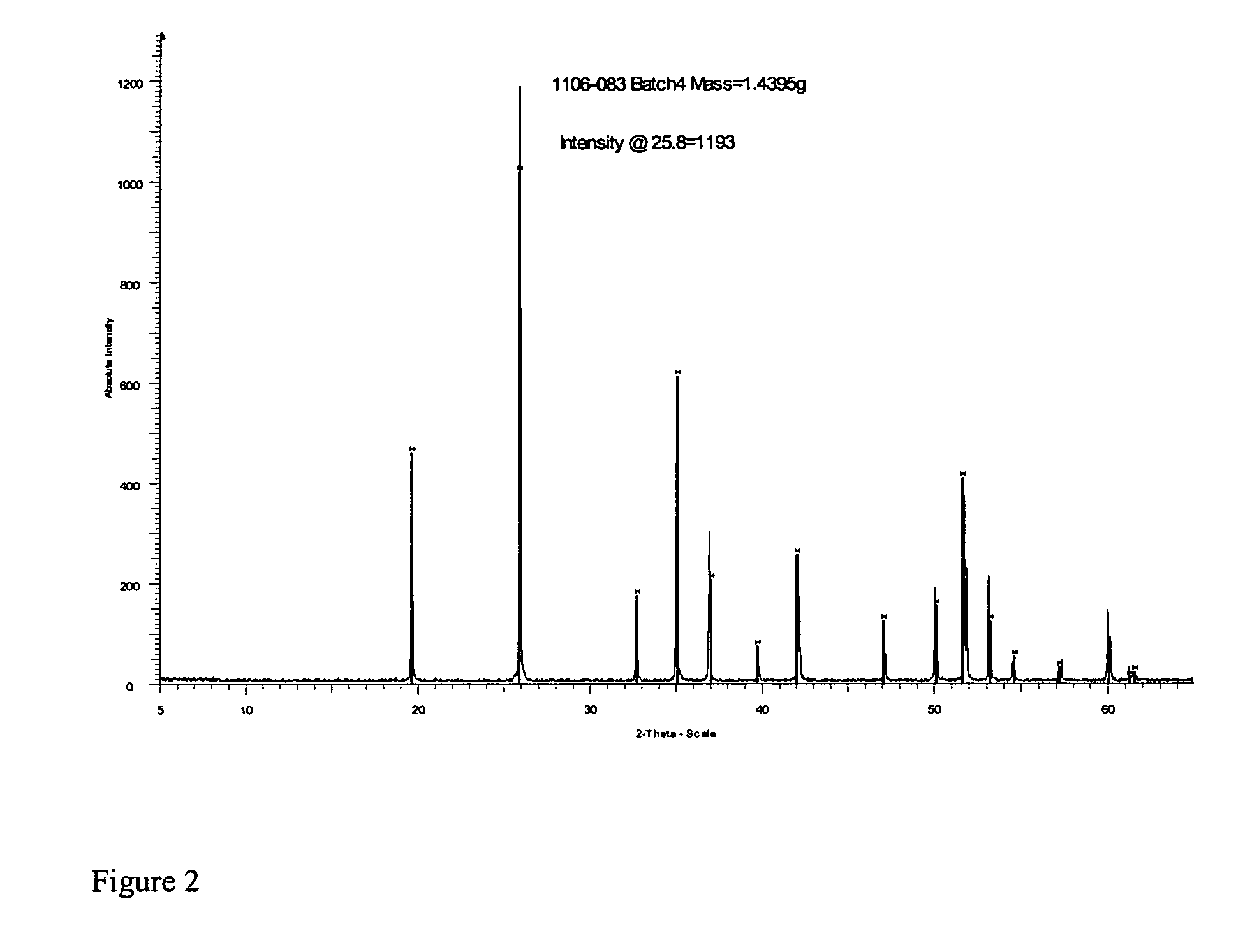

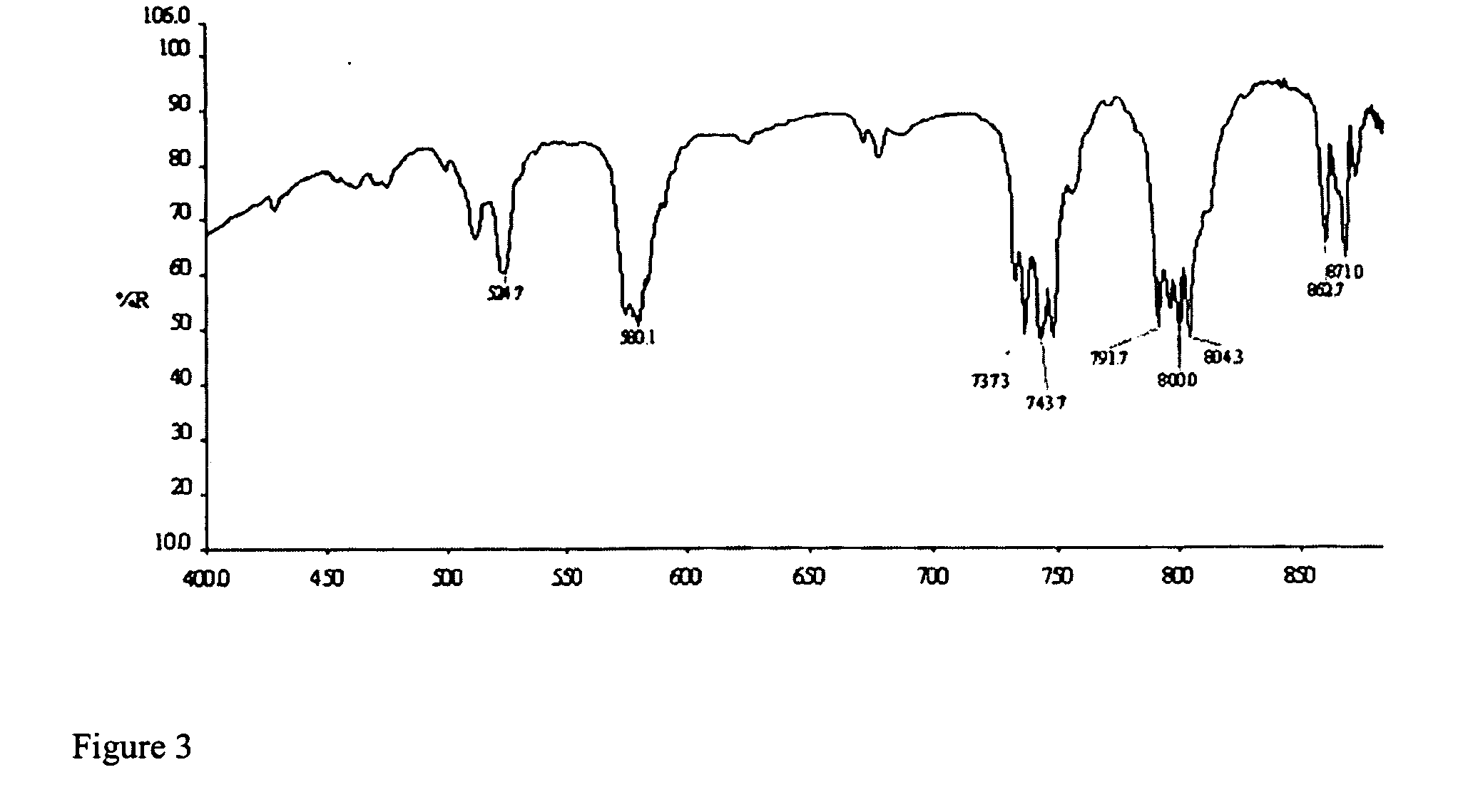

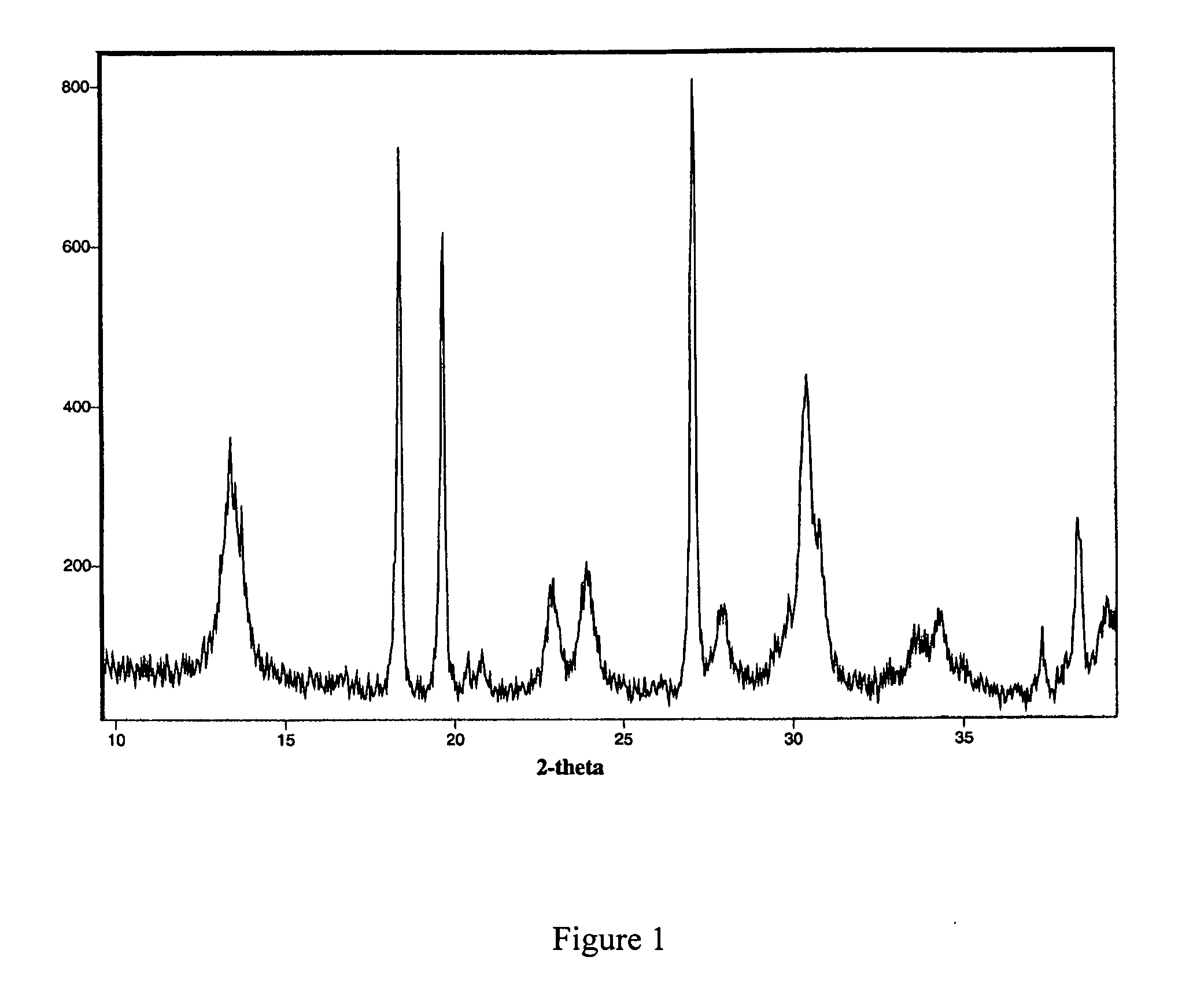

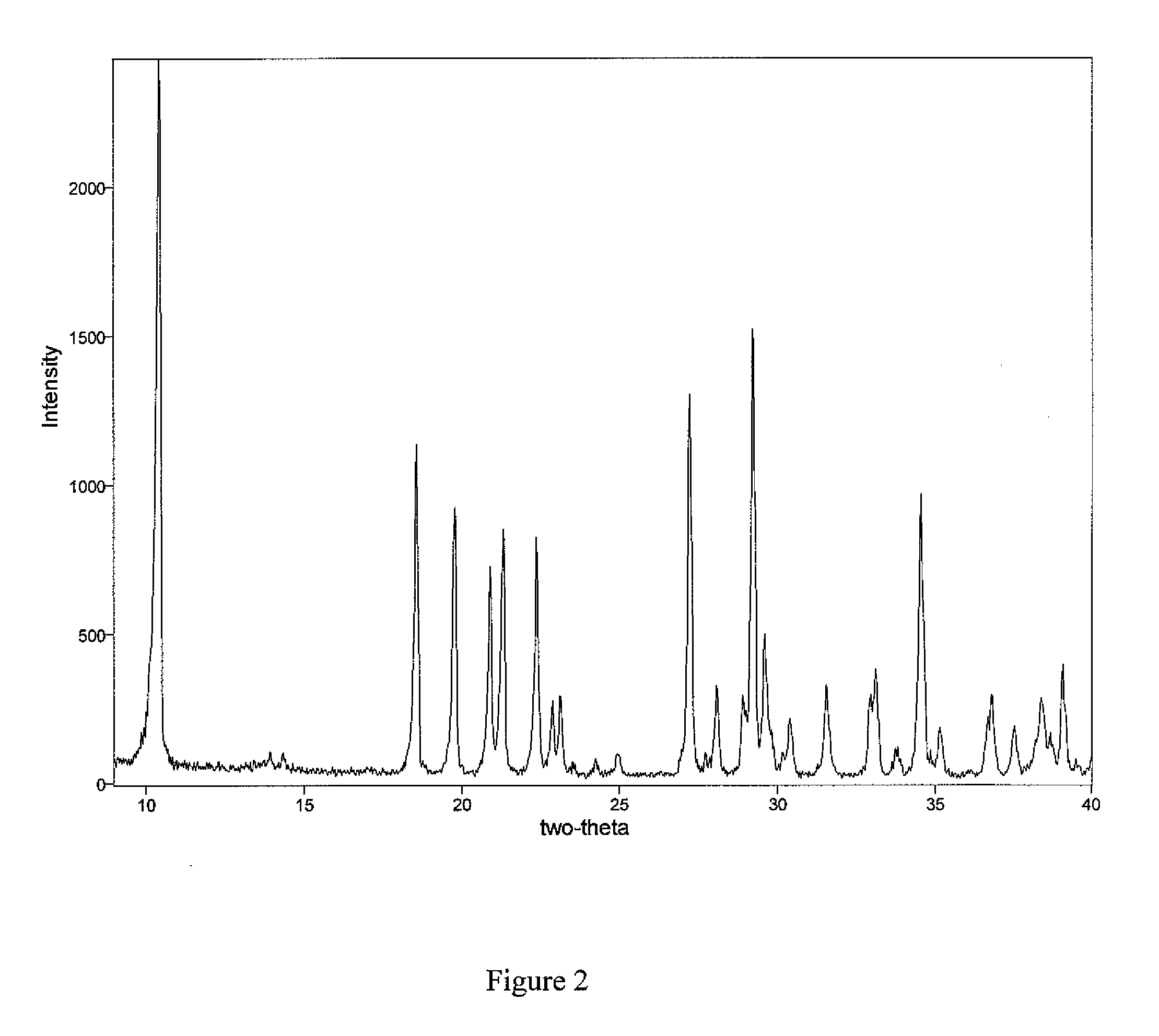

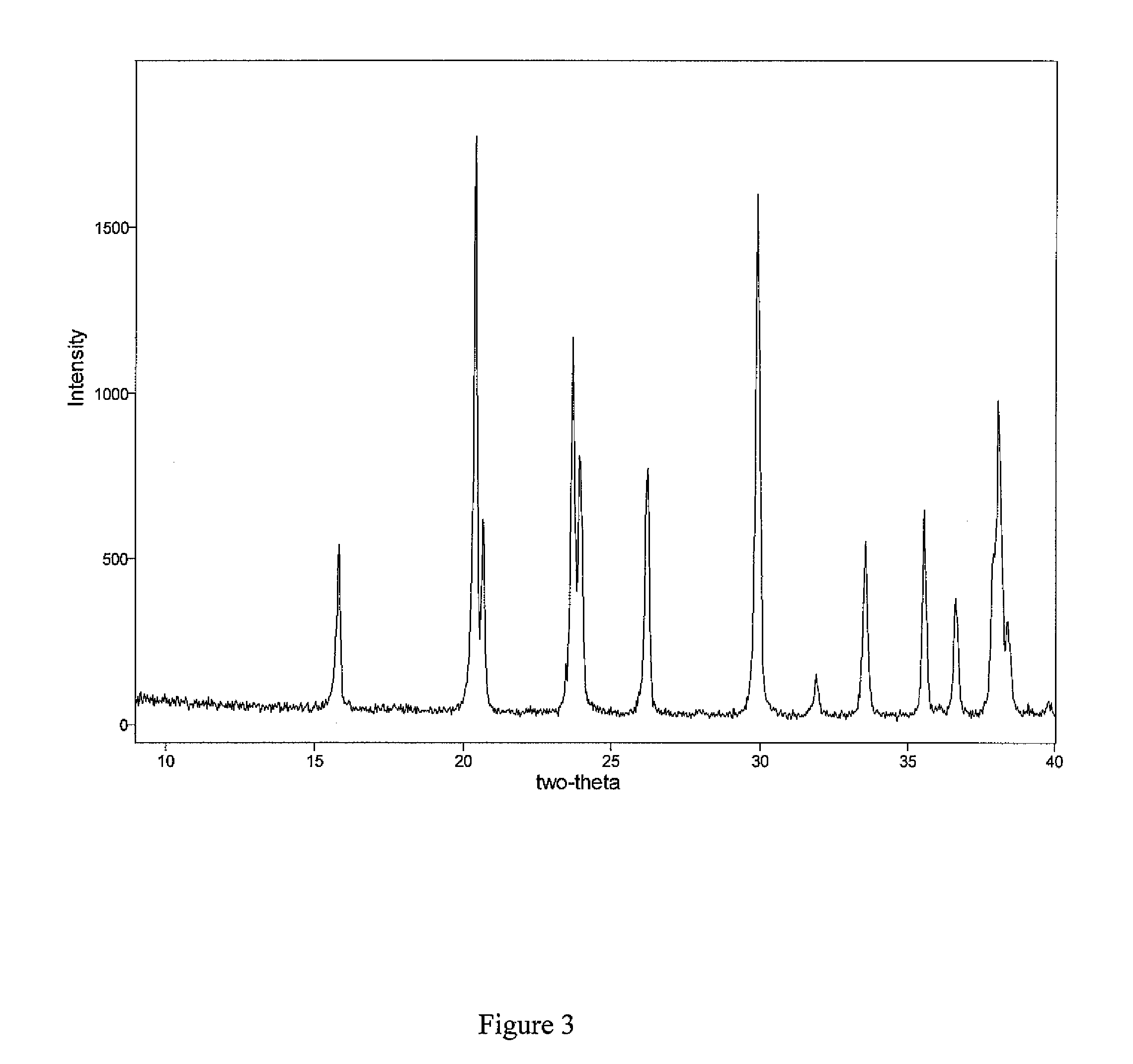

Assay for lanthanum hydroxycarbonate

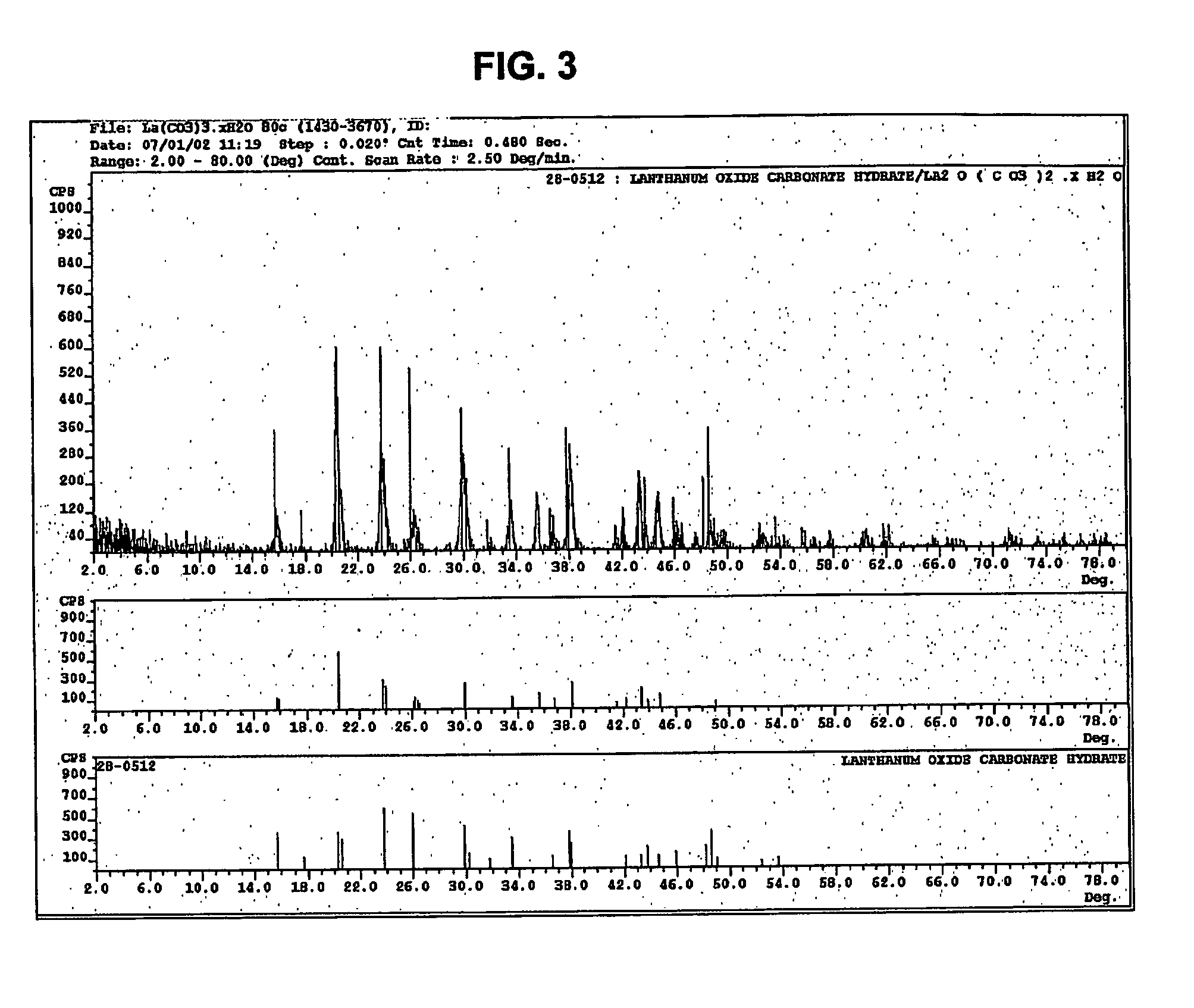

An assay for analytically determining the amount of an impurity in a solid sample is provided. This X-ray diffraction method preferably uses the Rietveld refinement.

Owner:SHIRE INT LICENSING

Cerium salt, producing method thereof, cerium oxide and cerium based polishing slurry

ActiveUS20110006251A1Reduce scratchesScratch can be reducedPigmenting treatmentOther chemical processesCeriumDissolution

A cerium salt wherein, when 20 g of the cerium salt is dissolved in a mixed liquid of 12.5 g of 6N nitric acid and 12.5 g of a 30% hydrogen peroxide aqueous solution, a concentration of an insoluble component present in the solution is 5 ppm or less by mass ratio to the cerium salt before dissolution and cerium oxide produced by processing the cerium salt at high temperatures. Scratch on a surface to be polished can be reduced when a cerium based polishing slurry containing the cerium oxide particles is used, since an amount of impurities in cerium oxide particles and cerium salt particles, raw material thereof, is reduced for high purification.

Owner:RESONAC CORPORATION

Method of recovering rare-earth elements

ActiveUS20150086449A1Reduce profitabilityImprove leaching efficiencyLanthanide oxides/hydroxidesSolid waste disposalRare-earth elementSlurry

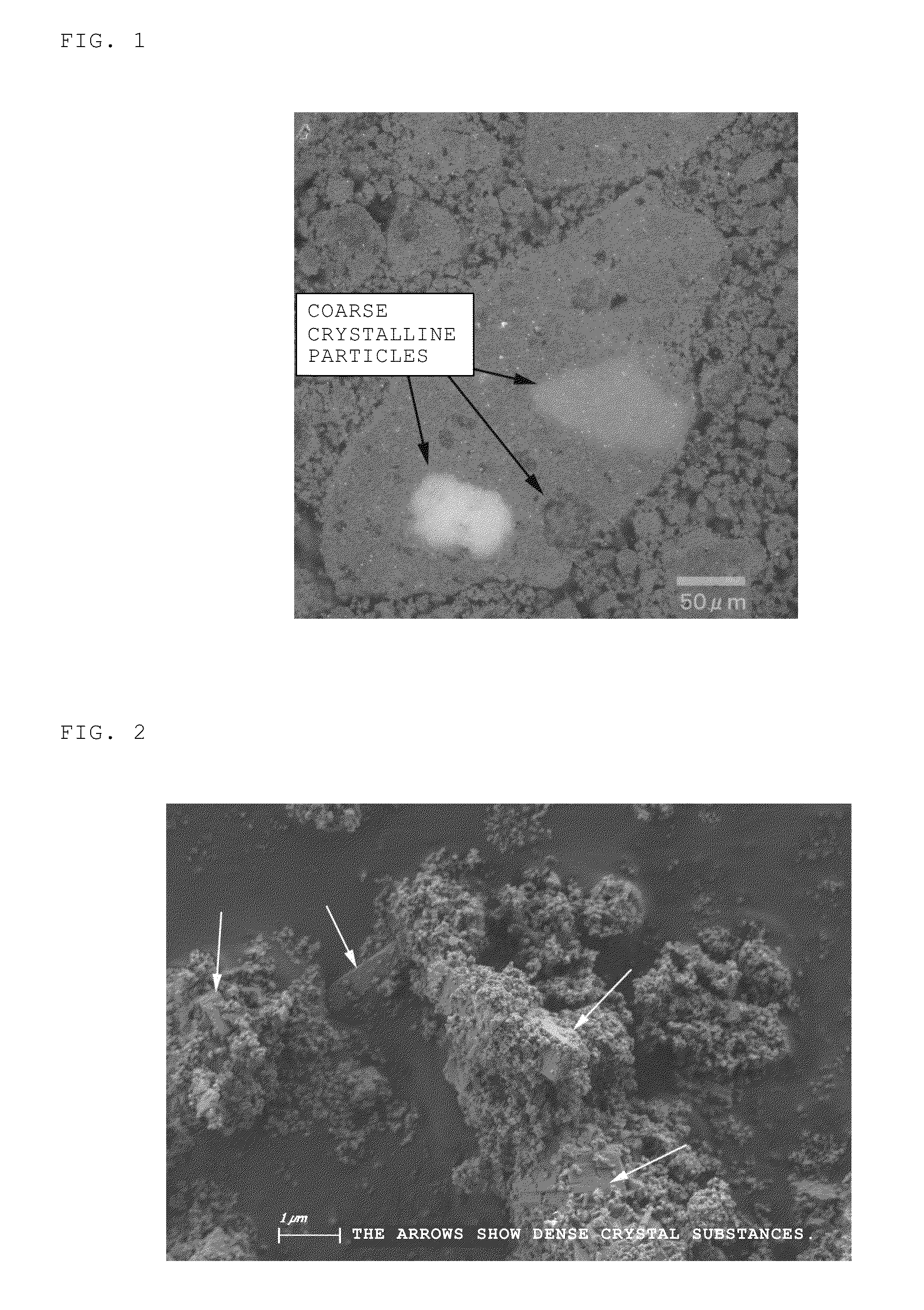

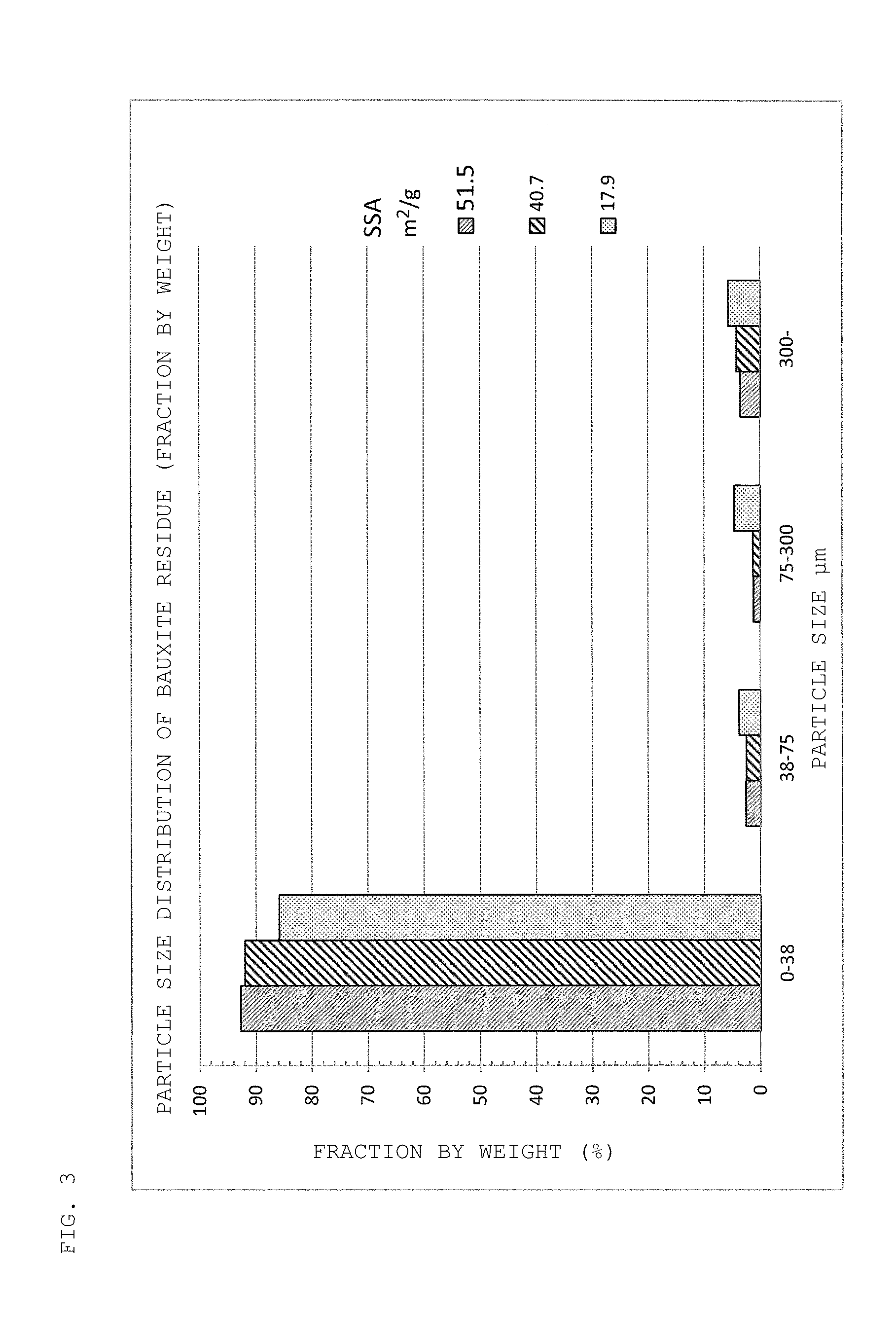

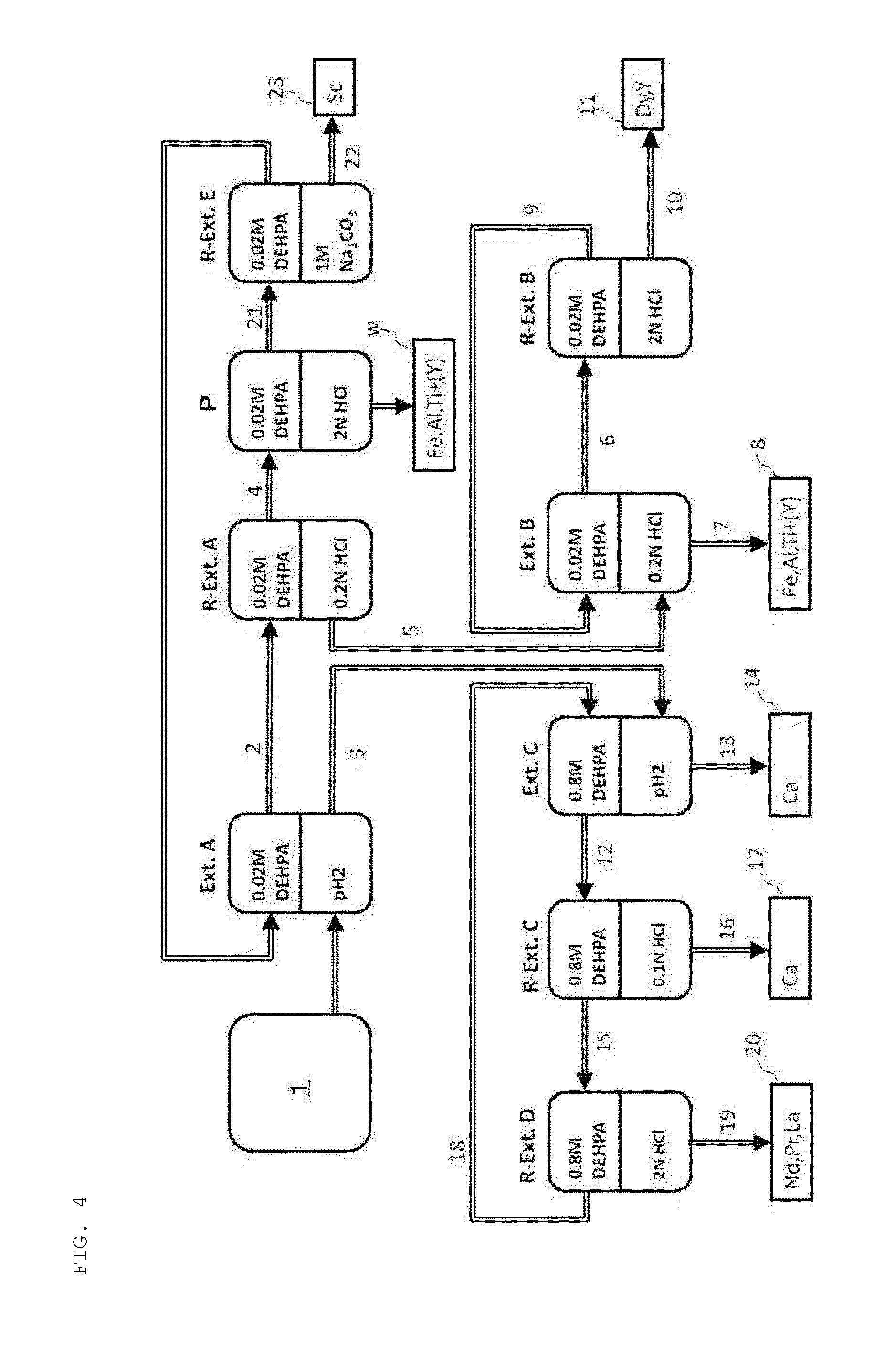

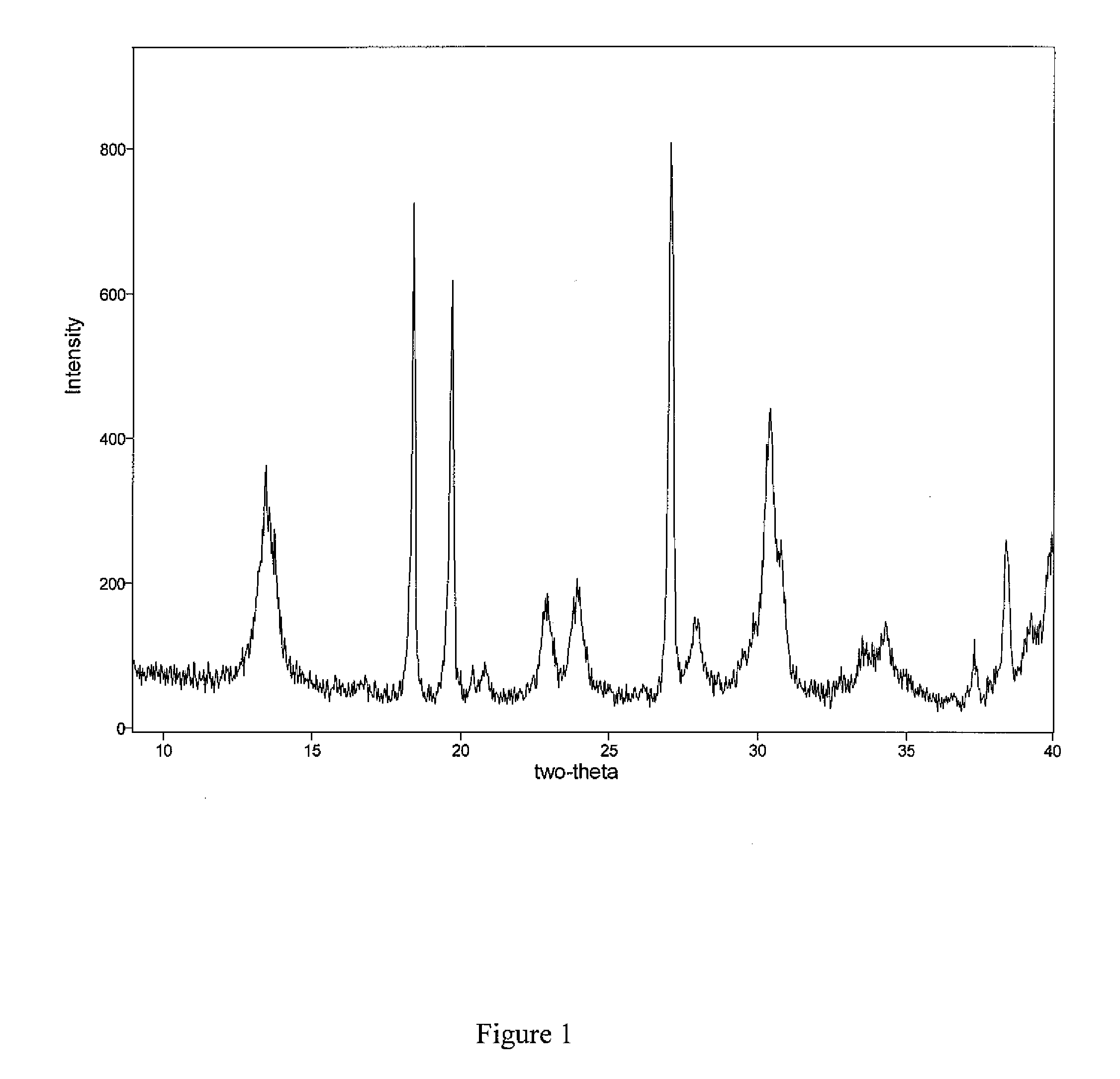

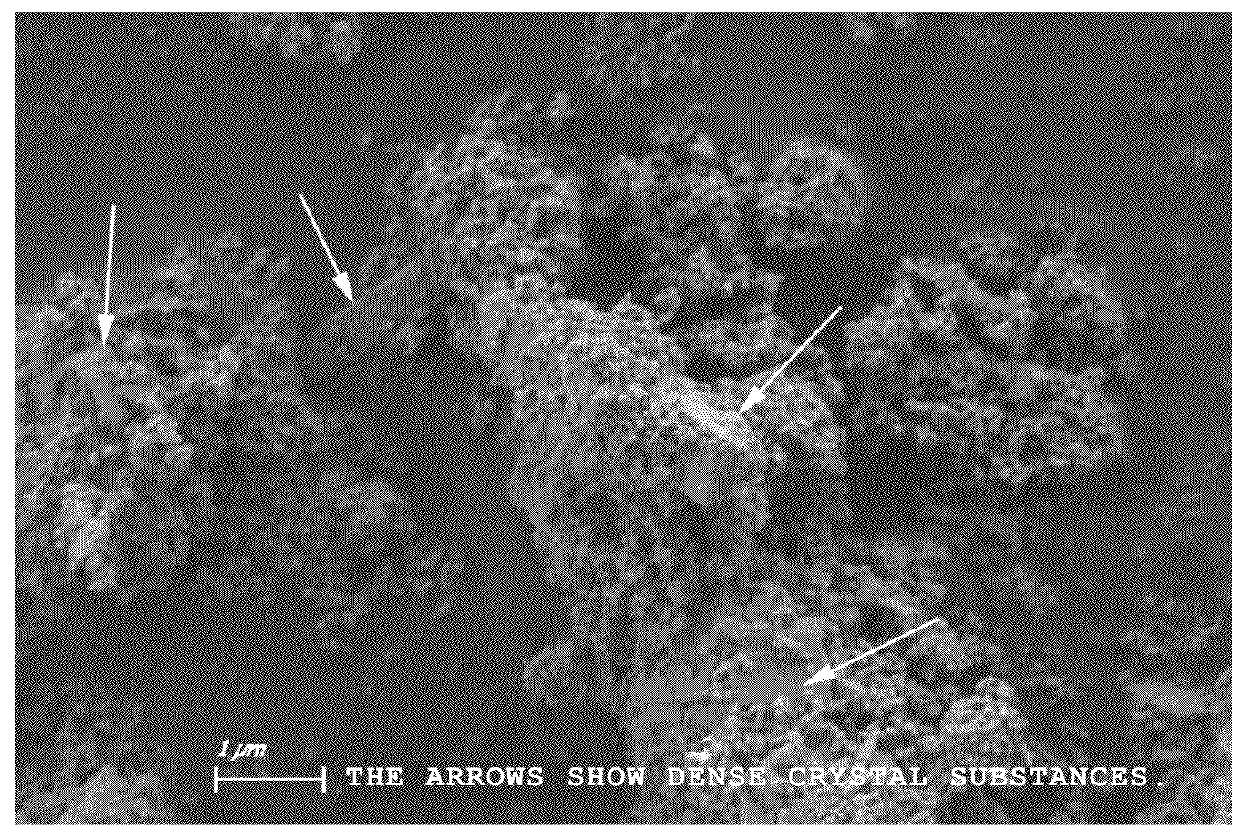

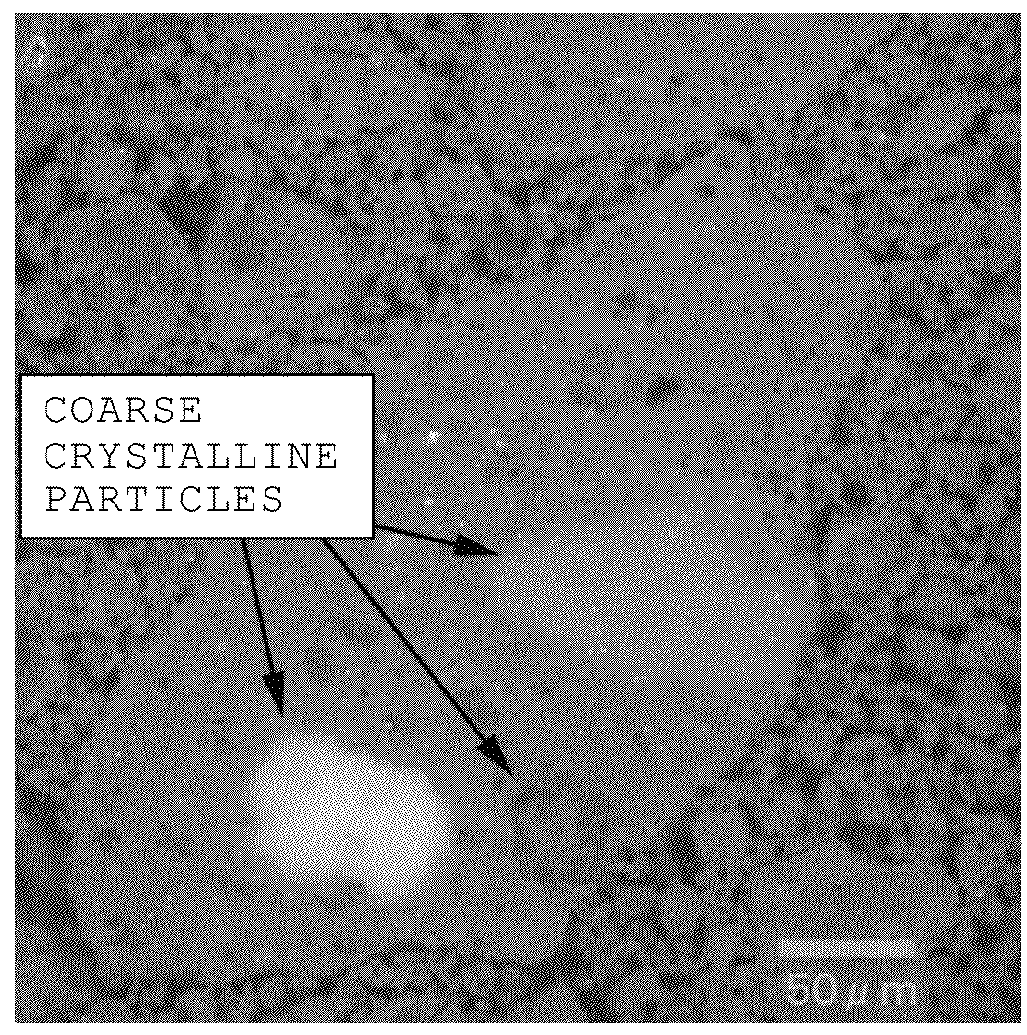

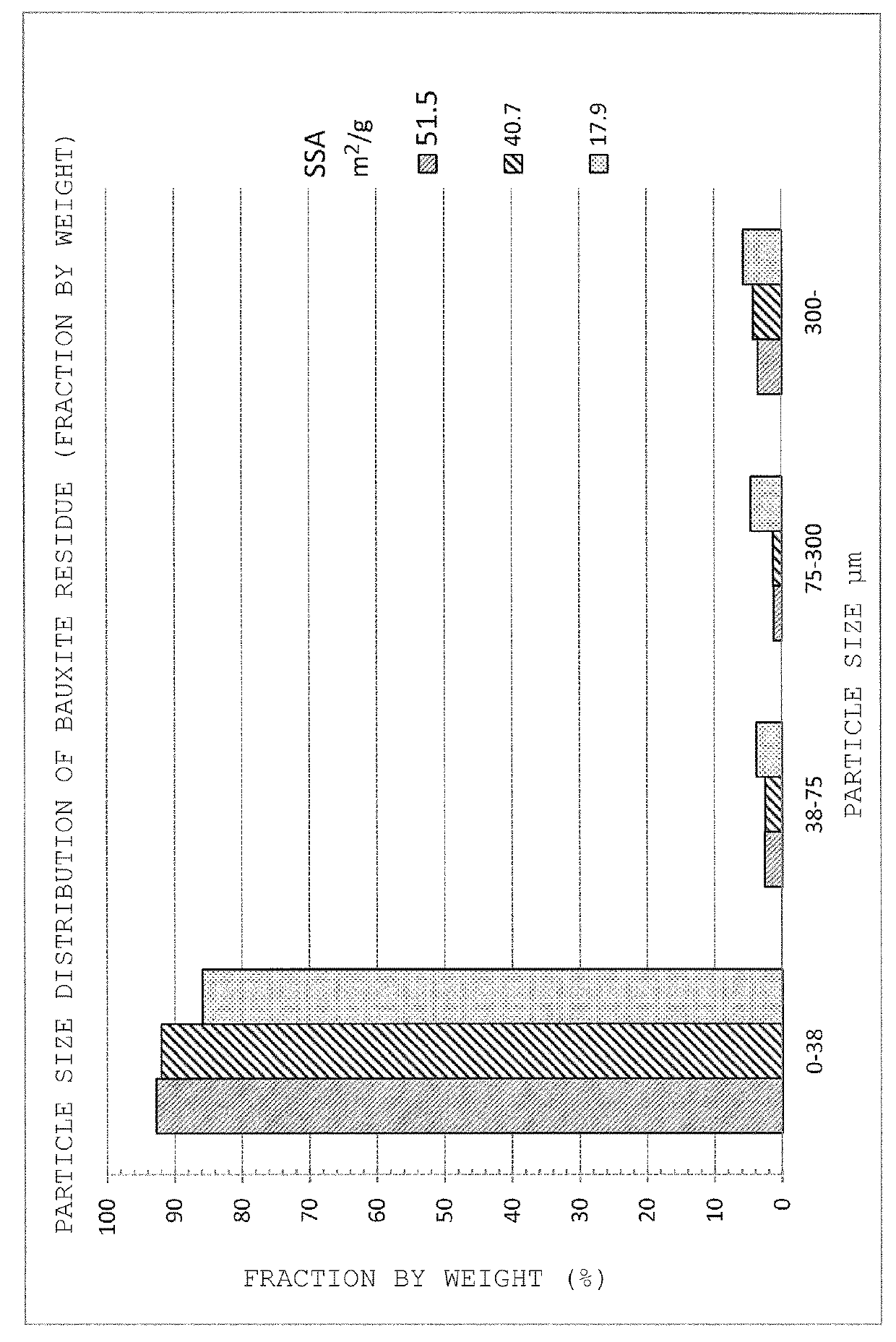

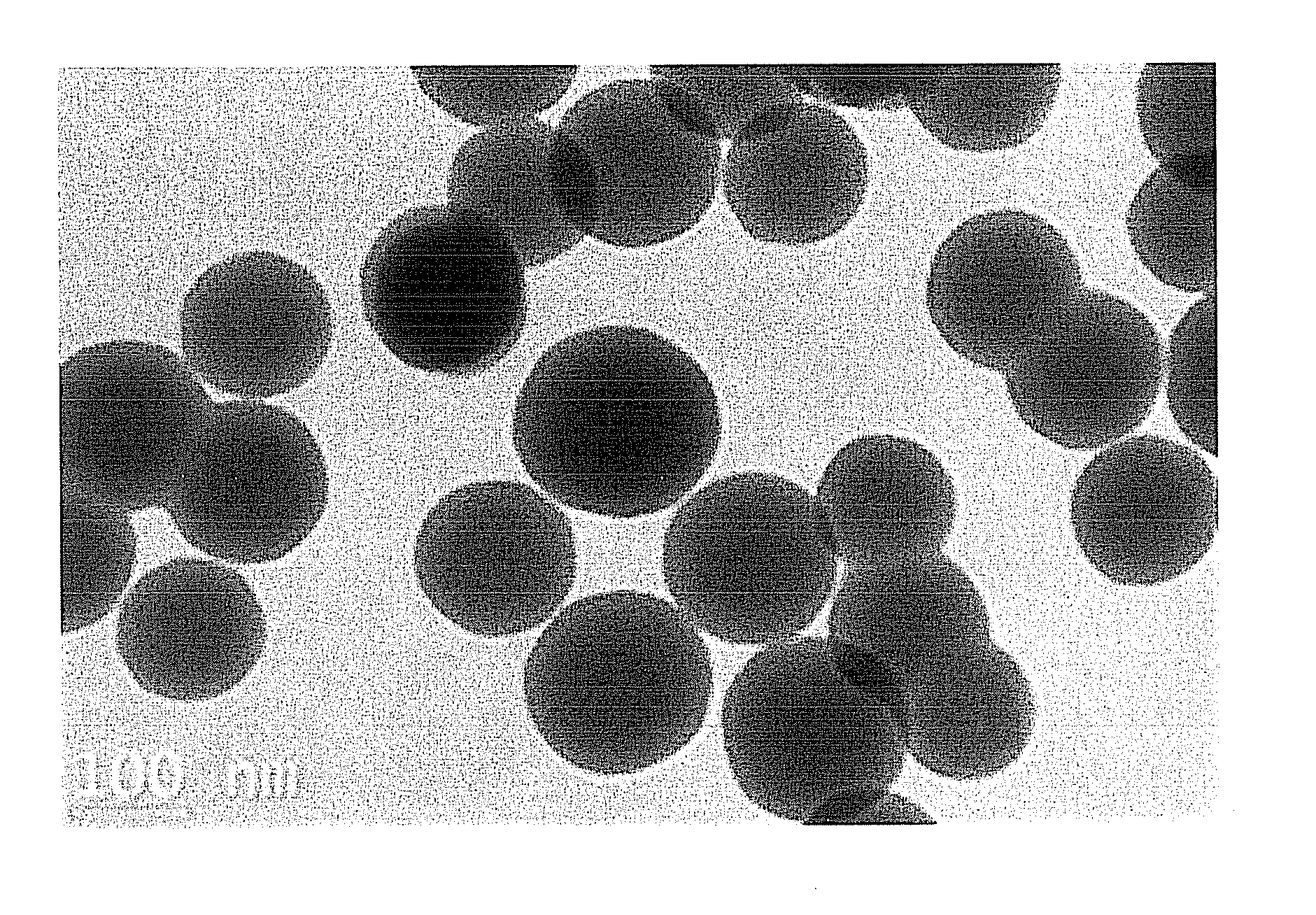

Provided is a method of recovering rare-earth elements by which rare-earth elements can be recovered efficiently from a bauxite residue serving as a raw material and containing the rare-earth elements. Specifically provided is a method of recovering rare-earth elements from a raw material, the raw material being a bauxite residue produced as a by-product in a Bayer process, the method including: using a bauxite residue having a specific surface area of 35 m2 / g or more; adding, to the raw material bauxite residue, a liquid leaching agent formed of an aqueous solution of at least one kind of mineral acid selected from sulfuric acid, hydrochloric acid, nitric acid, and sulfurous acid, thereby preparing a slurry having a liquid-solid ratio of 2 to 30 and a pH of 0.5 to 2.2; subjecting the slurry to leaching treatment of the rare-earth elements under a temperature condition of room temperature to 160° C.; subjecting the slurry after the leaching treatment to solid-liquid separation, yielding a leachate; and separating and recovering the rare-earth elements from the leachate.

Owner:NIPPON LIGHT METAL CO LTD

Cerium salt, producing method thereof, cerium oxide and cerium based polishing slurry

InactiveUS20070166216A1Reduce scratchesScratch can be reducedPigmenting treatmentOther chemical processesCeriumSlurry

A cerium salt wherein, when 20 g of the cerium salt is dissolved in a mixed liquid of 12.5 g of 6N nitric acid and 12.5 g of a 30% hydrogen peroxide aqueous solution, a concentration of an insoluble component present in the solution is 5 ppm or less by mass ratio to the cerium salt before dissolution and cerium oxide produced by processing the cerium salt at high temperatures. Scratch on a surface to be polished can be reduced when a cerium based polishing slurry containing the cerium oxide particles is used, since an amount of impurities in cerium oxide particles and cerium salt particles, raw material thereof, is reduced for high purification.

Owner:HITACHI CHEM CO LTD

Method of use for lanthanum carbonate and lanthanum hydroxycarbonate

A method for treating hyperphosphatemia using lanthanum carbonate, including analytically determining the amount of an impurity in the lanthanum carbonate sample is provided. This X-ray diffraction method preferably uses the Rietveld refinement.

Owner:SHIRE INT LICENSING

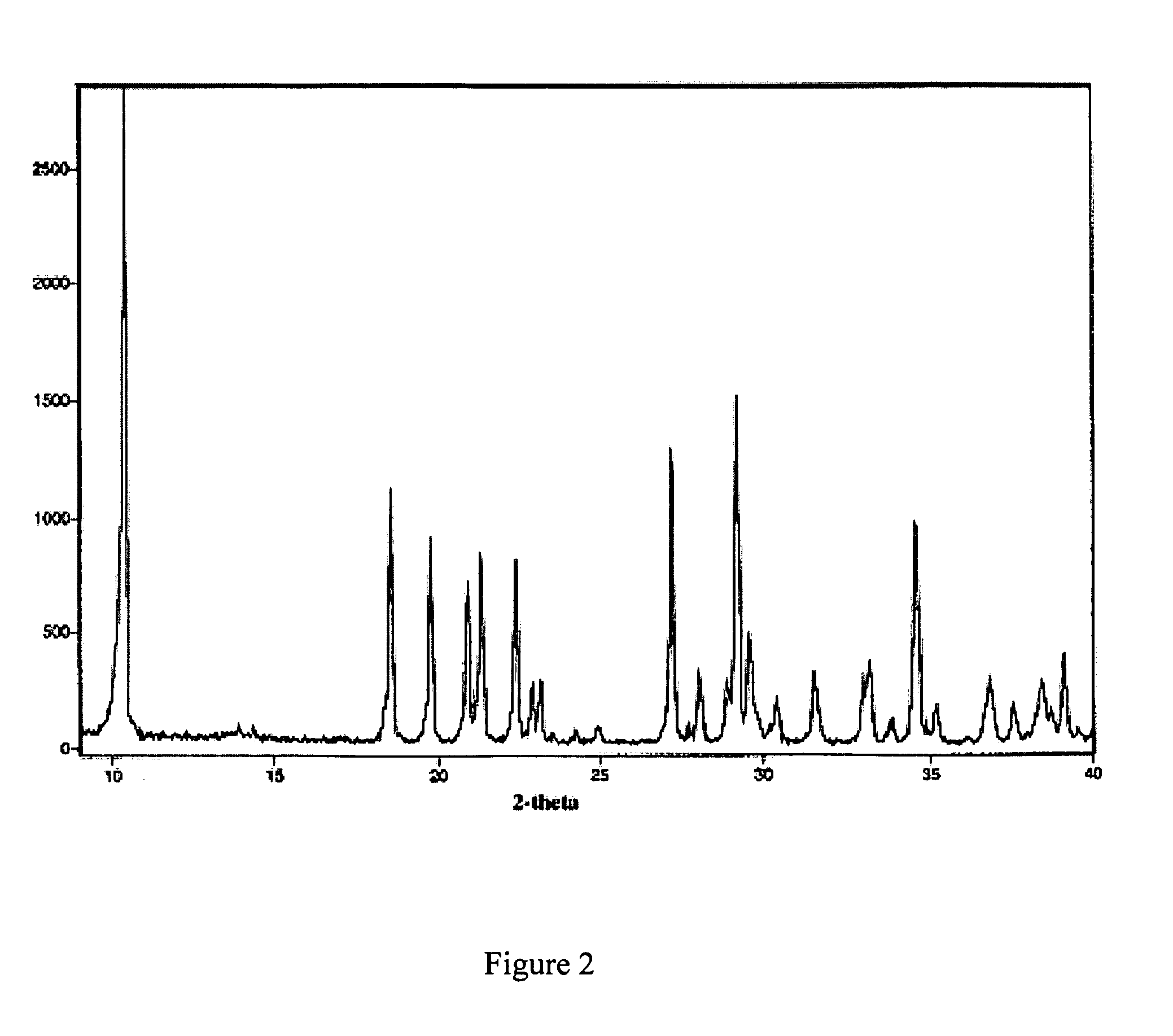

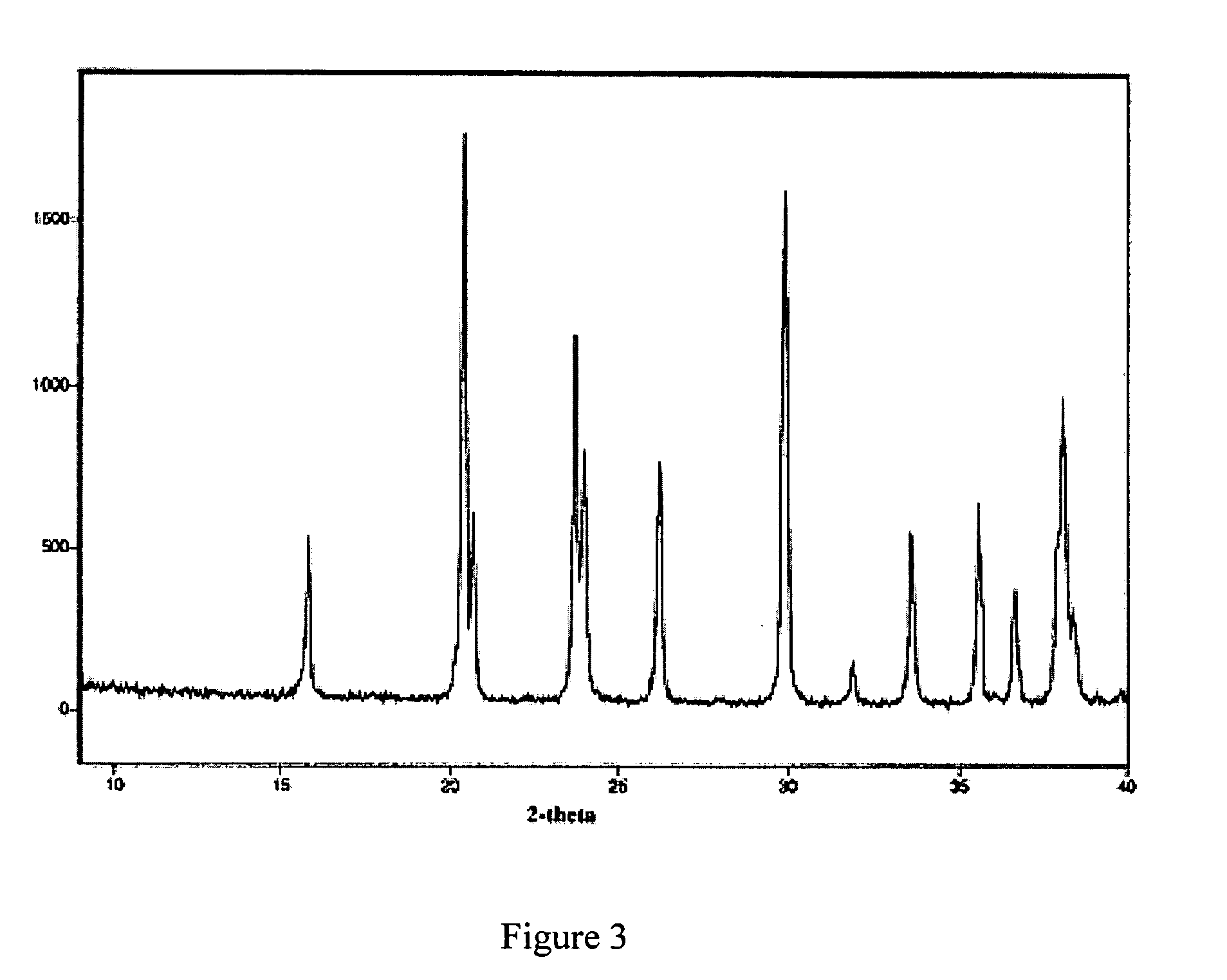

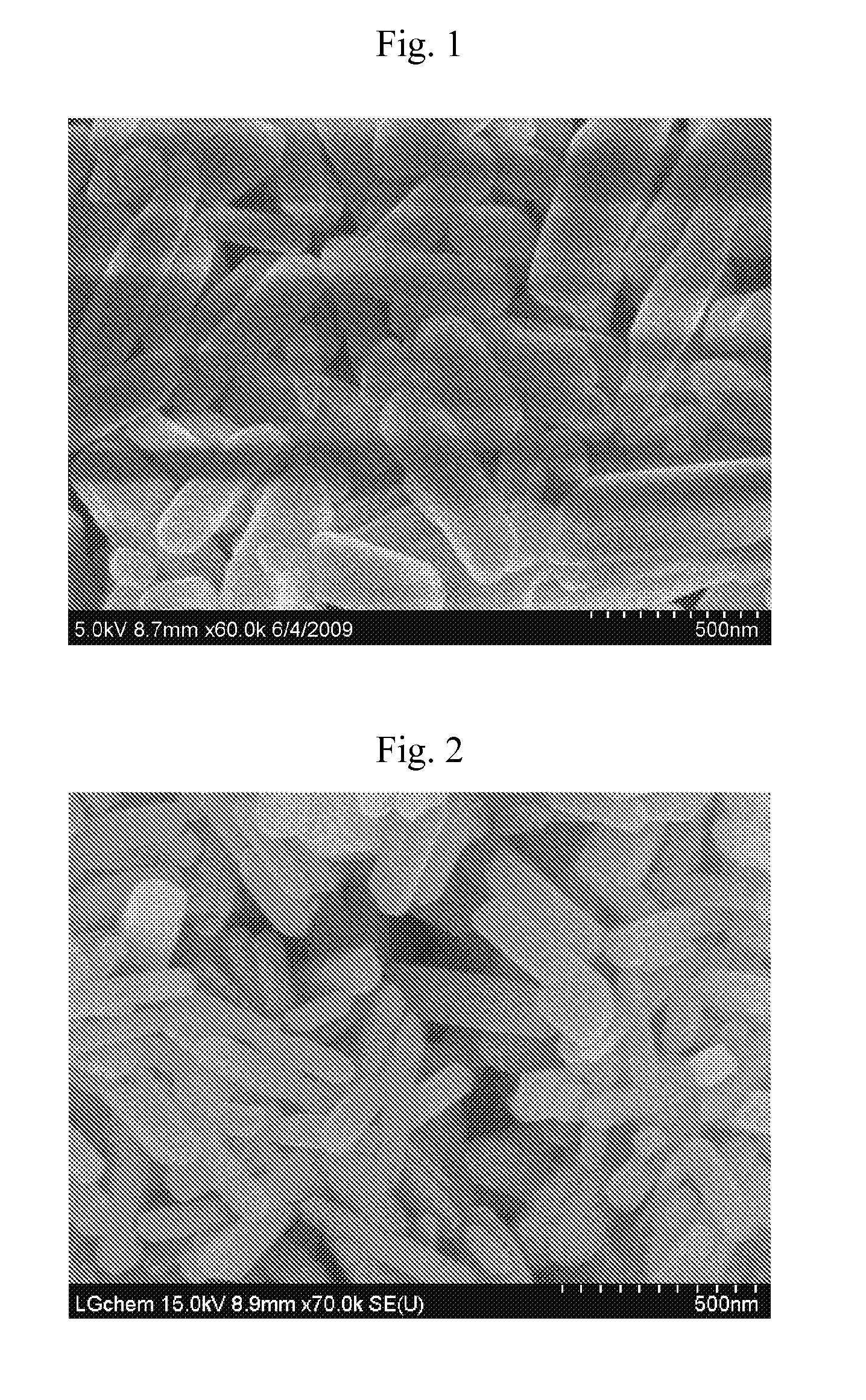

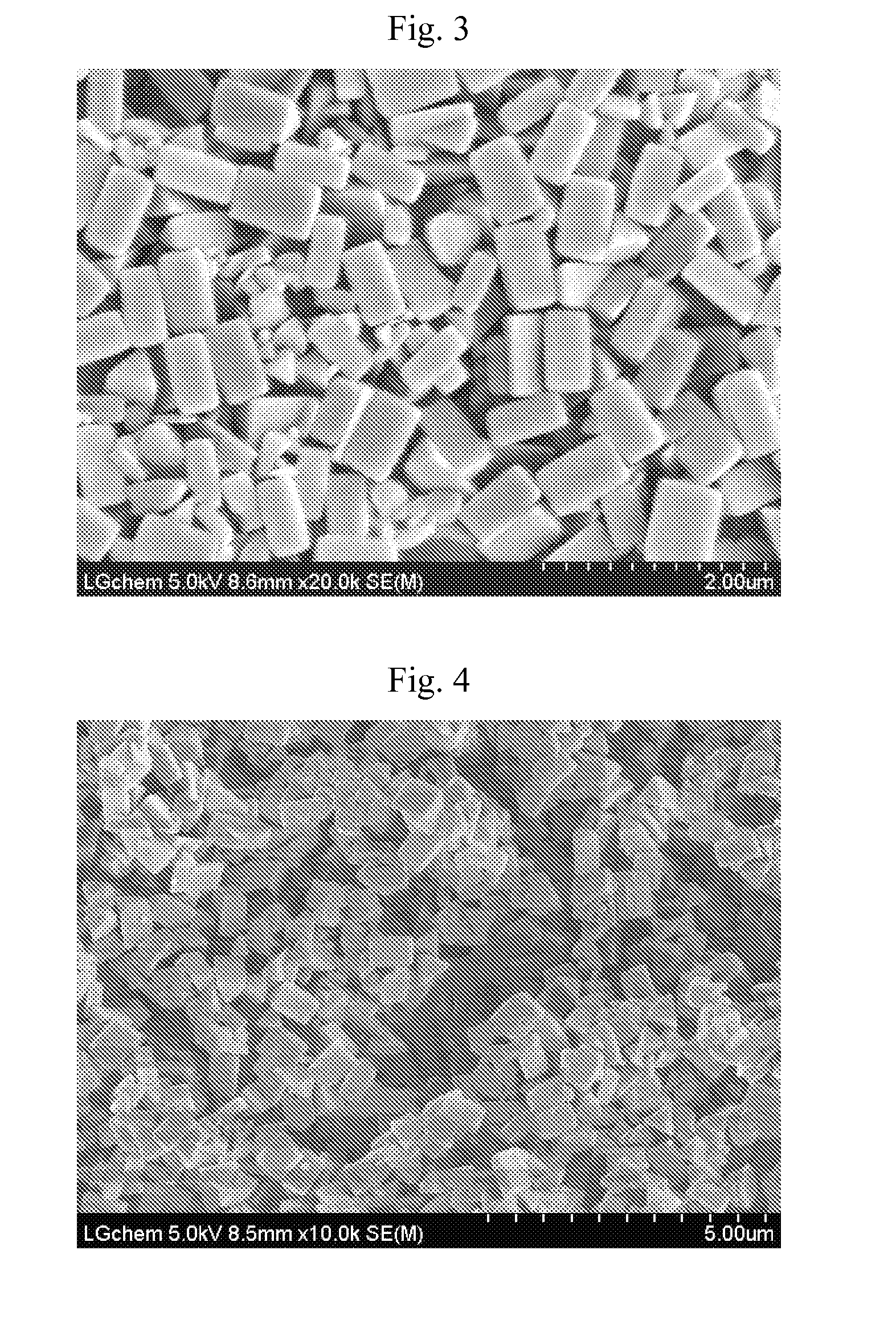

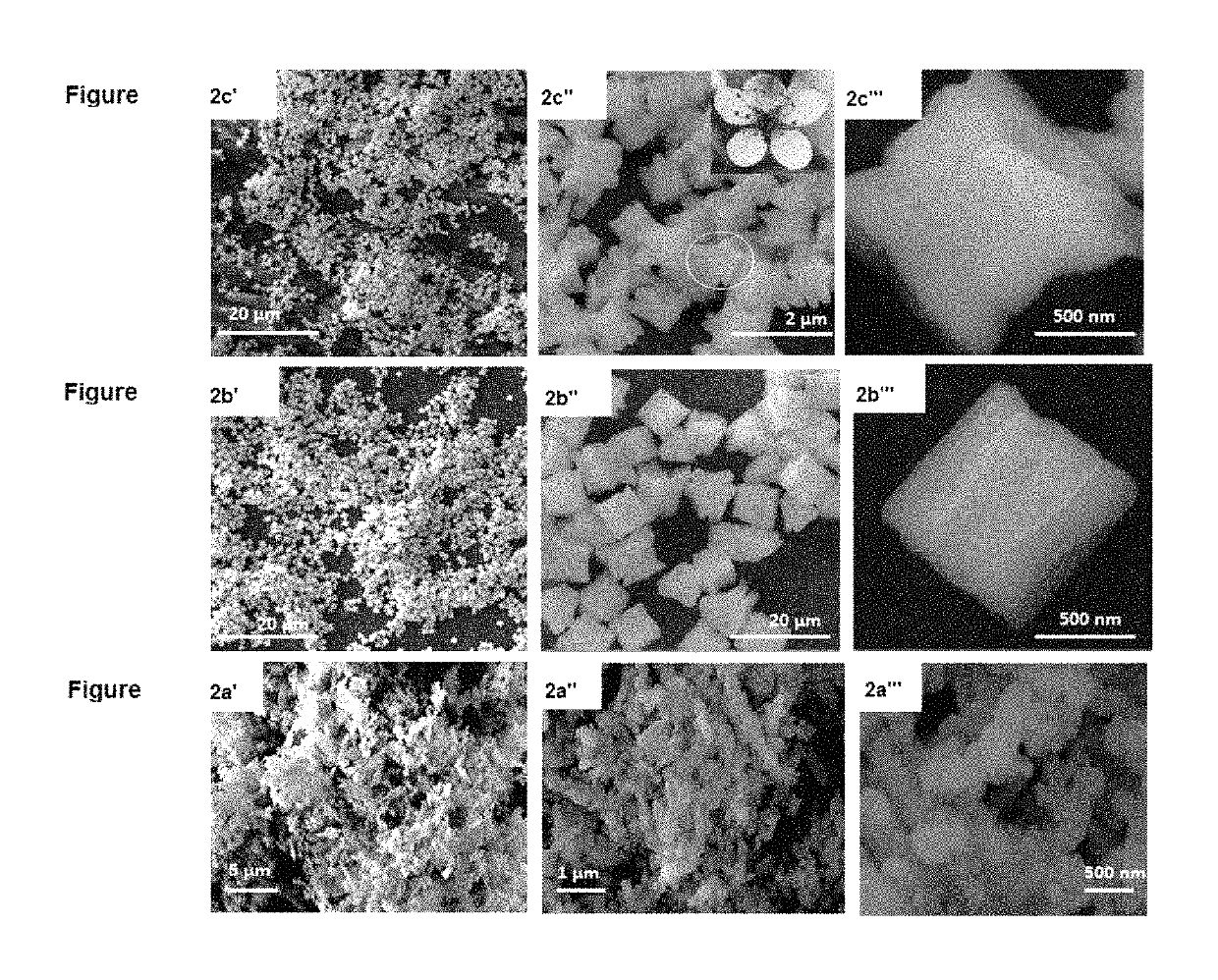

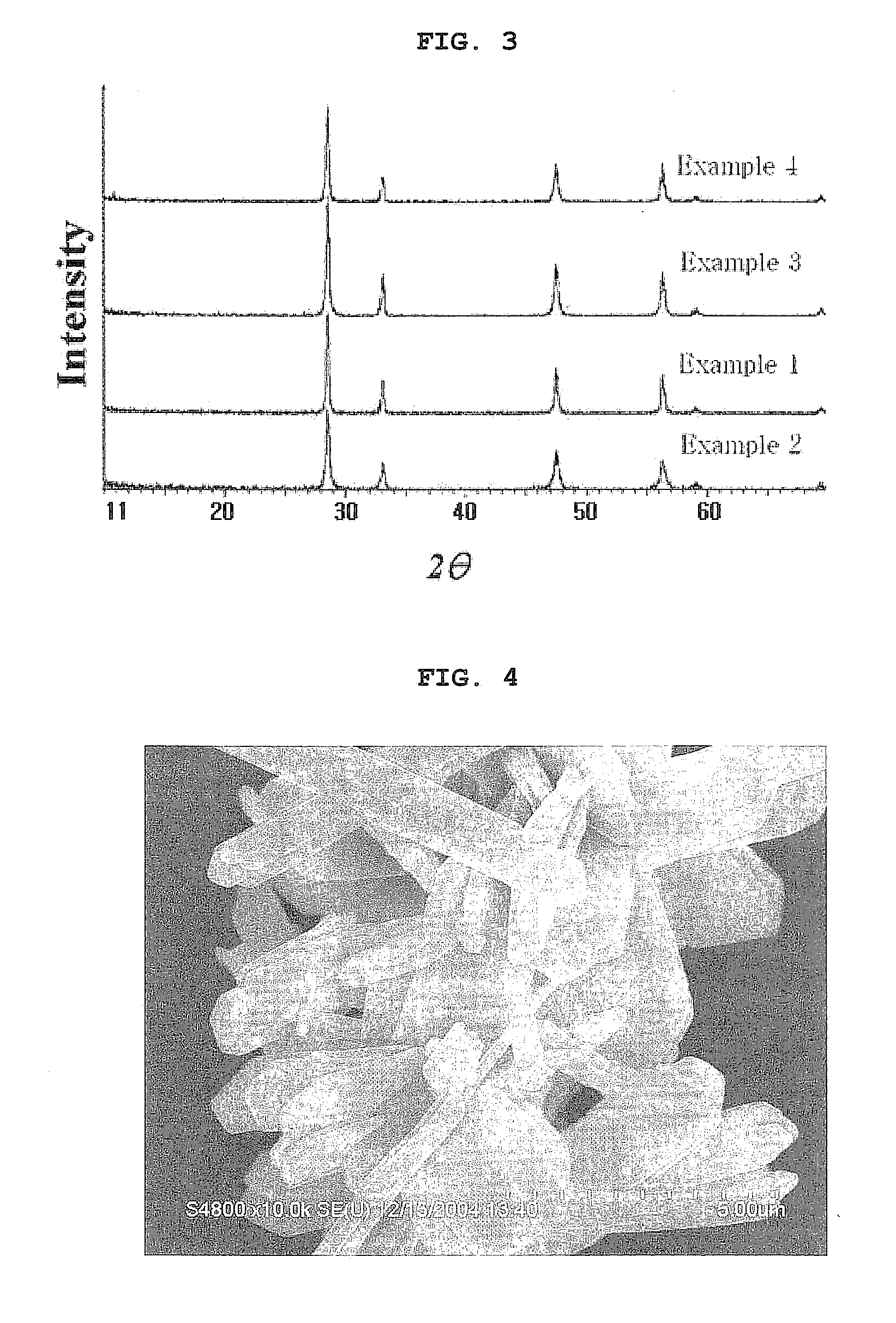

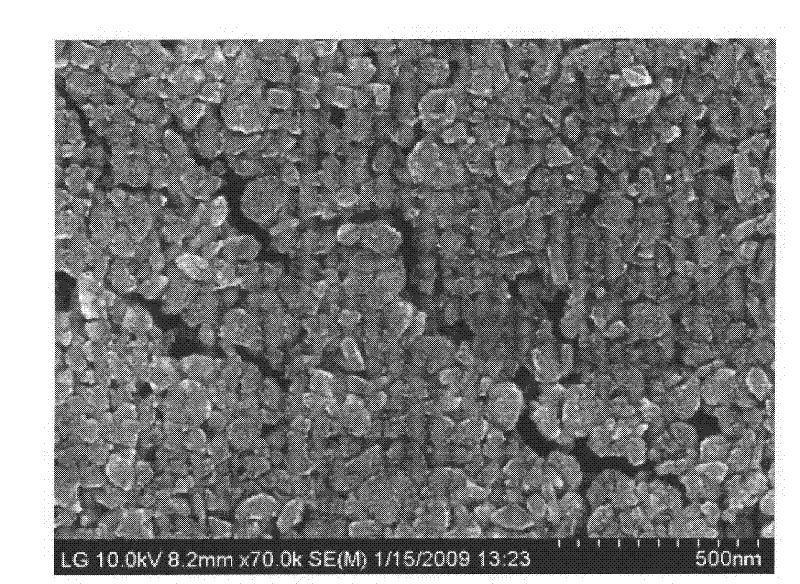

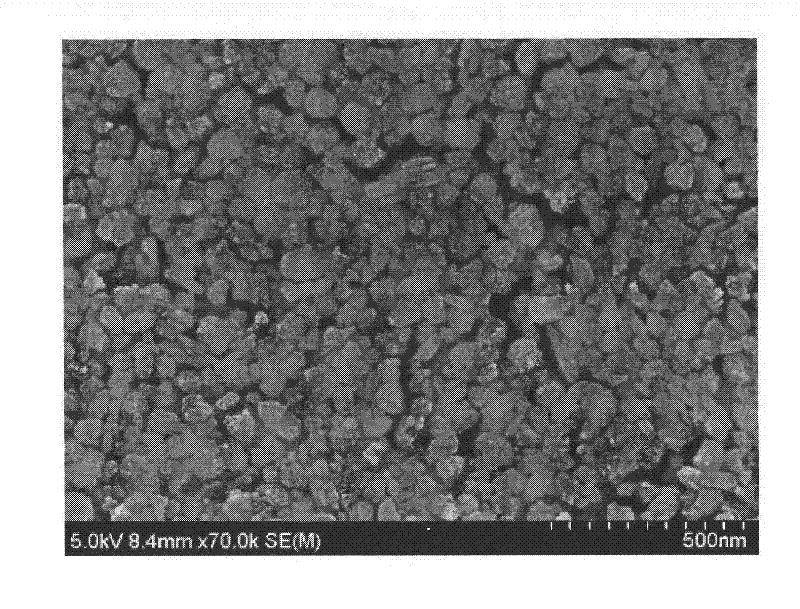

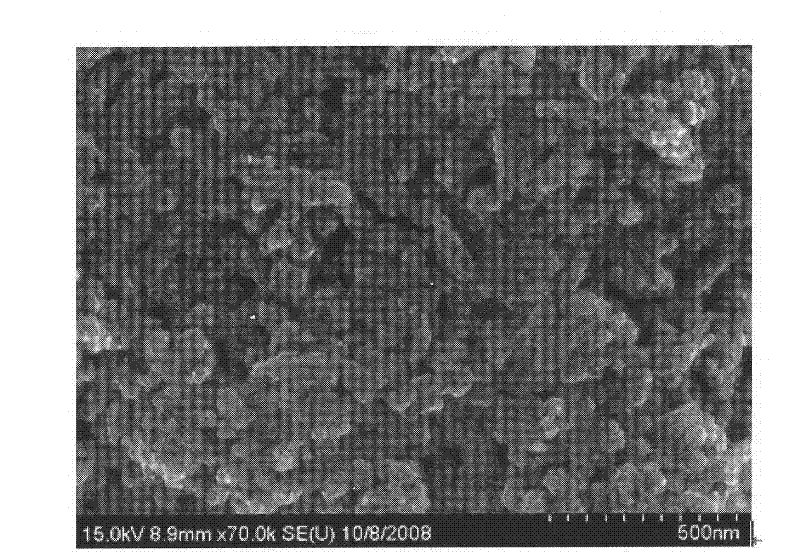

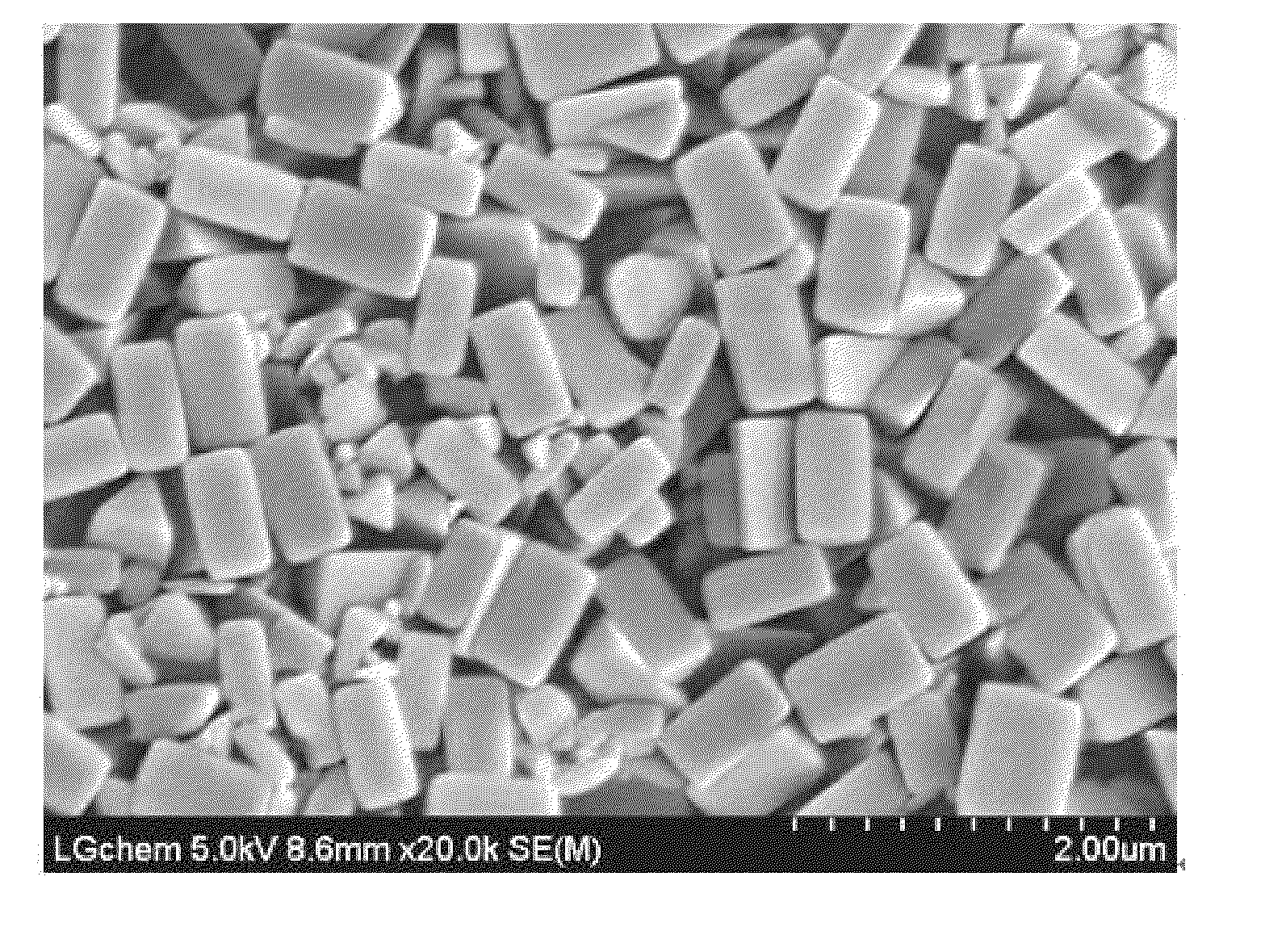

Cerium carbonate powder, method for preparing the same, cerium oxide powder made therefrom, method for preparing the same, and CMP slurry comprising the same

InactiveUS20070079559A1Easy to controlEasy to shapePigmenting treatmentOther chemical processesOrganic solventCerium

Disclosed is a method for preparing cerium carbonate powder by mixing a cerium precursor solution with a carbonate precursor solution to cause precipitation, wherein at least one solvent used in the cerium precursor solution and the carbonate precursor solution is an organic solvent. Cerium carbonate powder obtained from the method, cerium oxide powder obtained from the cerium carbonate powder, a method for preparing the cerium oxide powder, and CMP slurry comprising the cerium oxide powder are also disclosed. The method for preparing cerium carbonate using an organic solvent, allows the resultant cerium carbonate powder to have a size and shape controllable from the initial nucleation step. Additionally, it is possible to easily control the size and shape of cerium oxide powder obtained from the cerium carbonate powder.

Owner:LG CHEM LTD

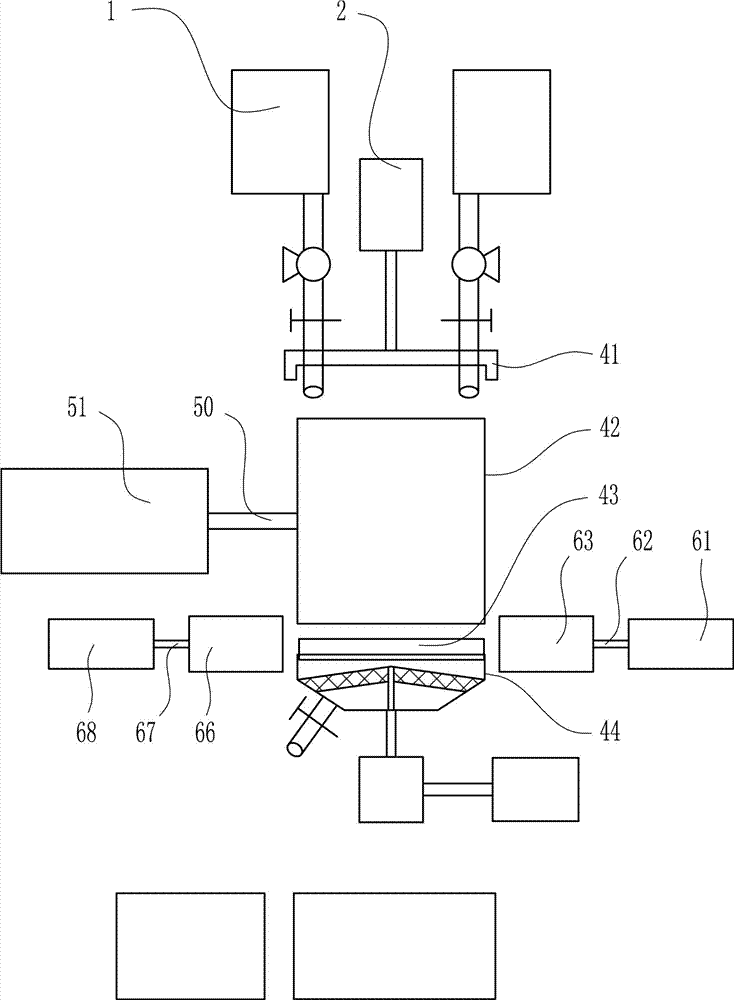

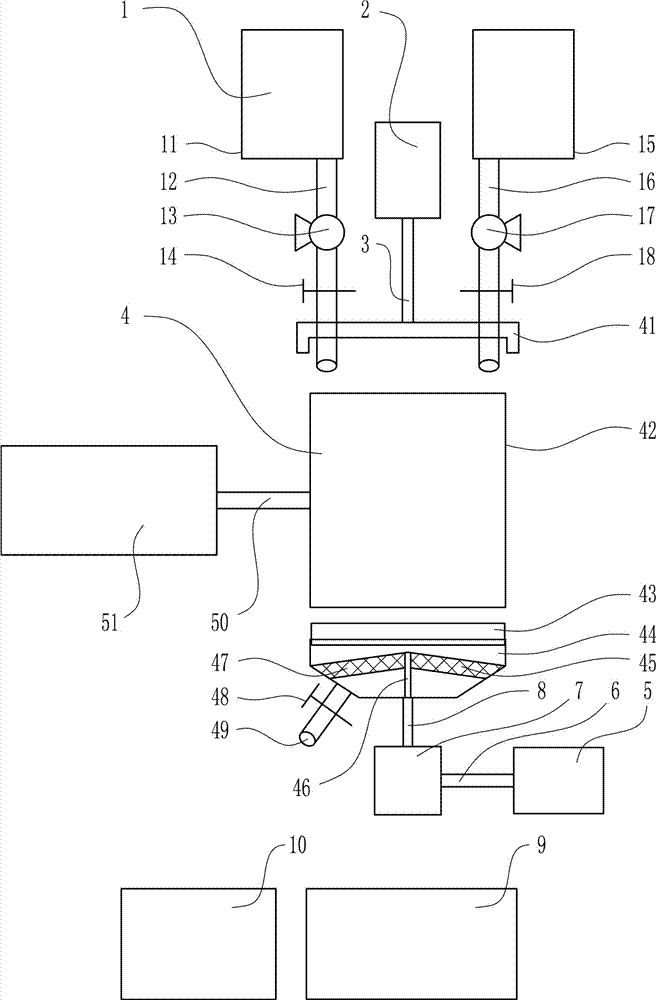

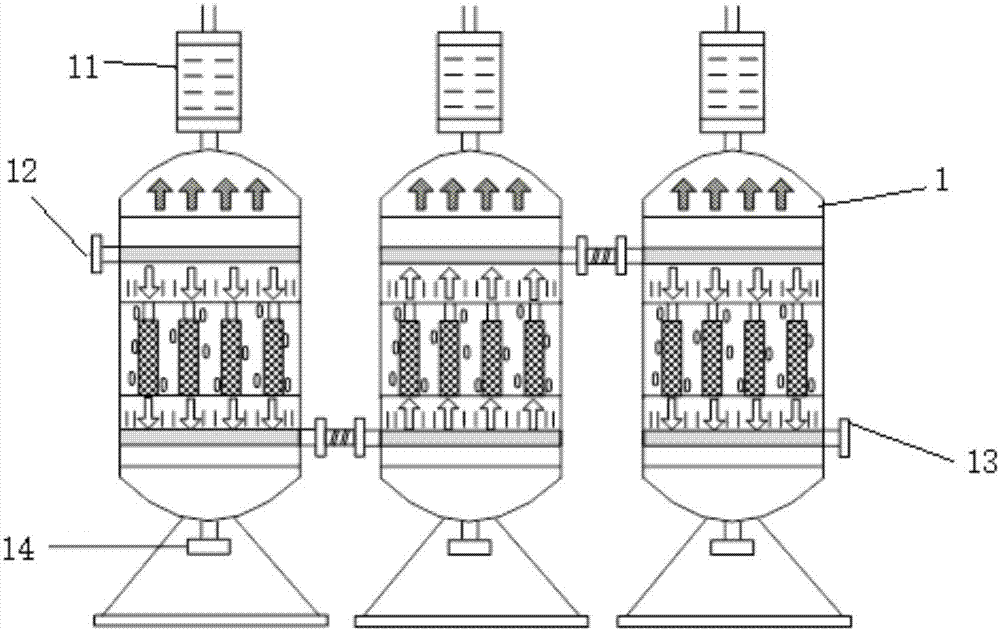

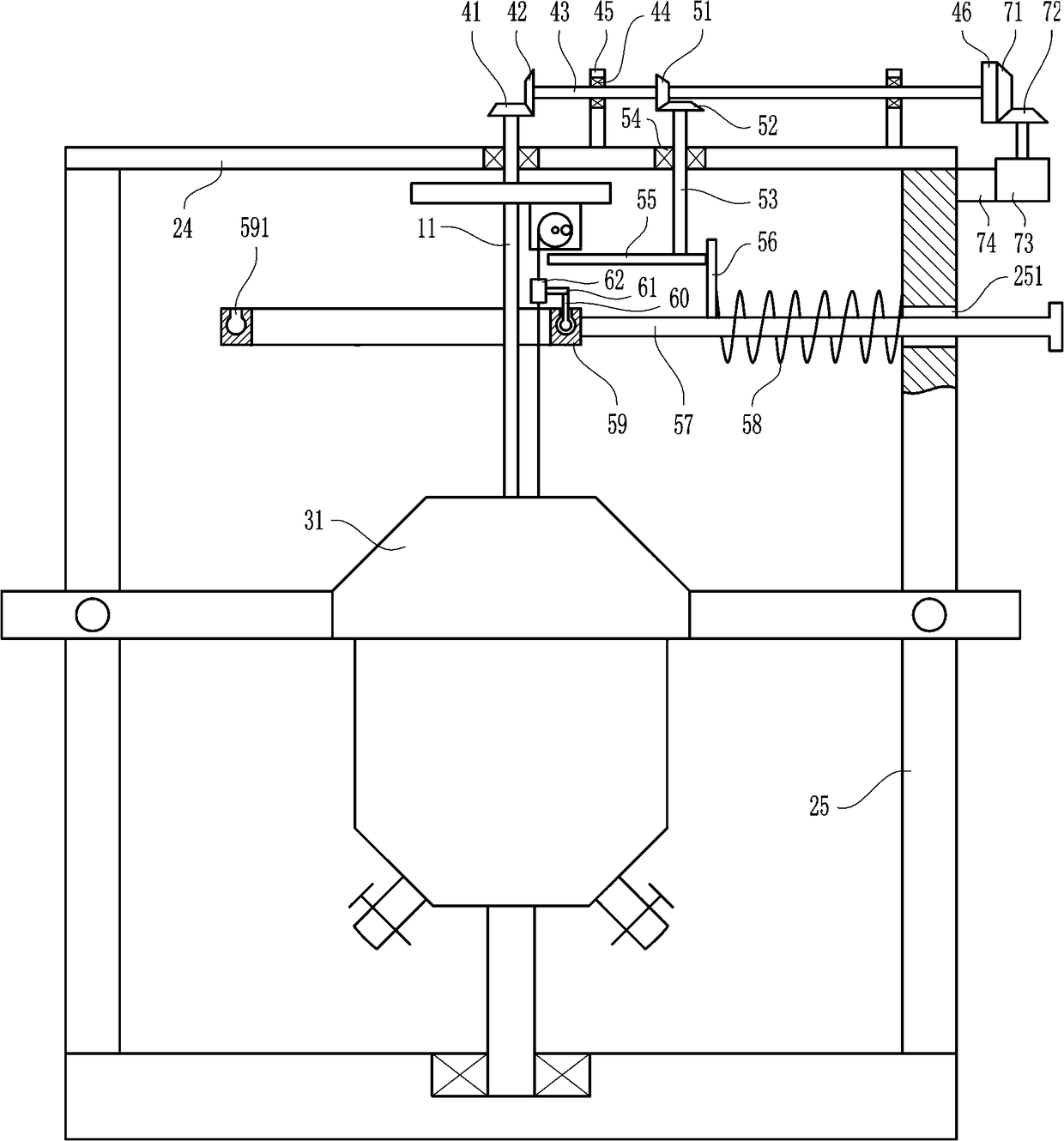

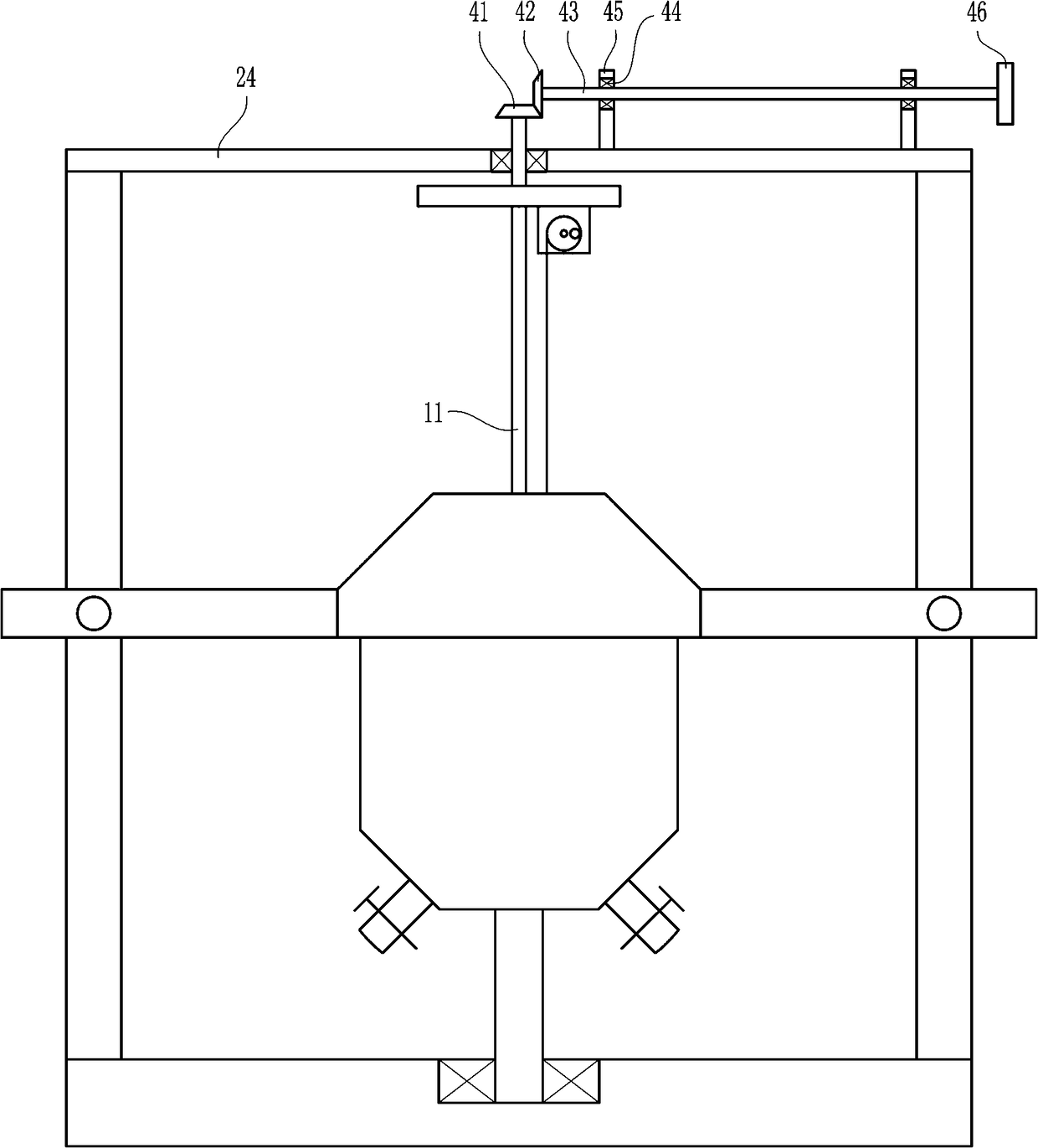

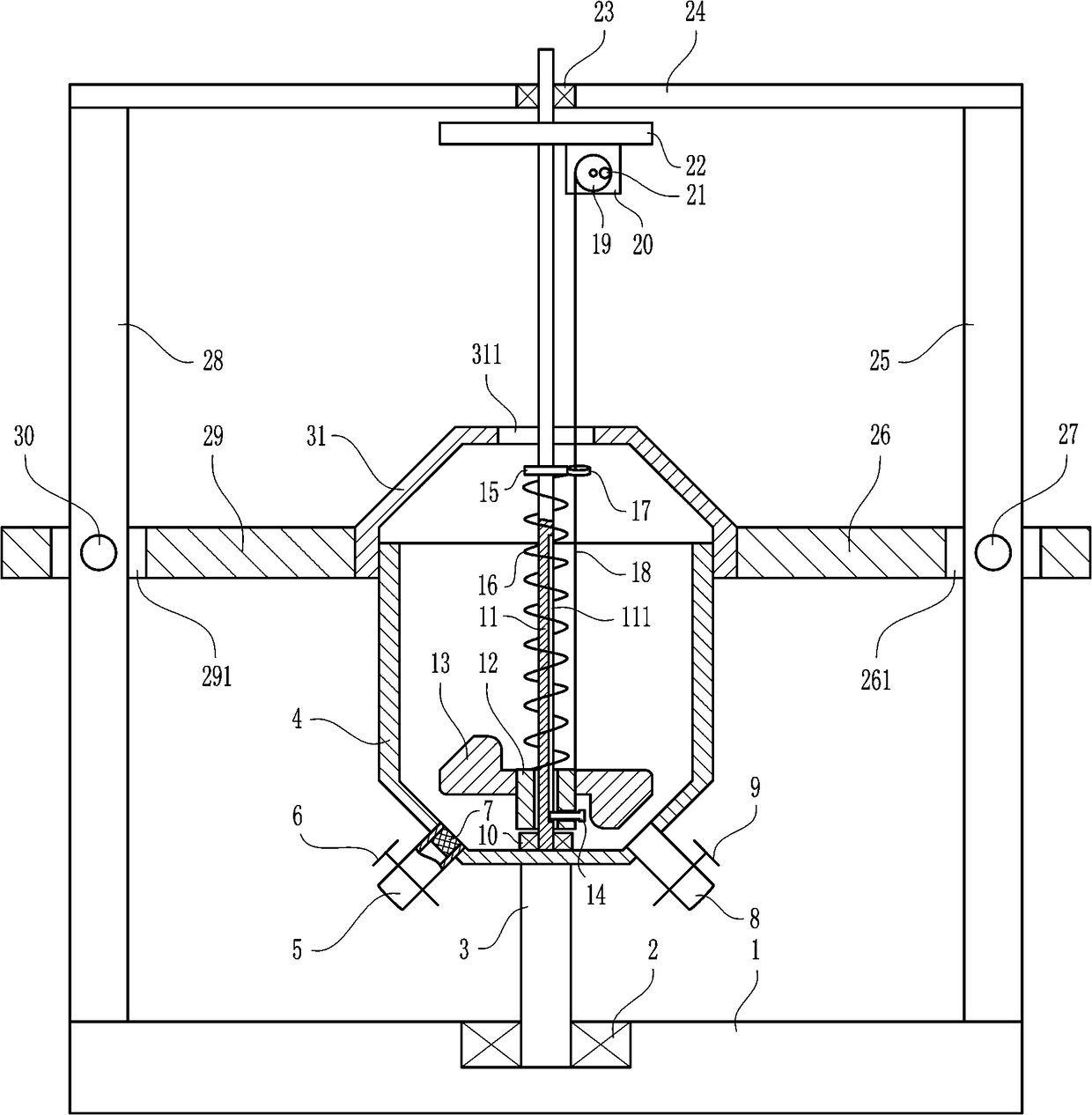

Precipitation apparatus convenient to clean and used for precipitation of rare-earth ore

ActiveCN107099662AStable, safe and reliable operationRun preciselyProcess efficiency improvementRare earth metal carbonatesRare earthEngineering

The invention relates to a precipitation apparatus, especially to a precipitation apparatus convenient to clean and used for precipitation of rare-earth ore. The invention provides the precipitation apparatus convenient to clean and used for precipitation of rare-earth ore to overcome technical problems in the prior art. The precipitation apparatus comprises material liquid feeding devices, an elevating cylinder I, an elevating telescopic rod I, a split precipitation device, a motor I, a rotating shaft I, an elevating cylinder II, an elevating telescopic rod II, etc., wherein the elevating telescopic rod I is connected with the elevating cylinder I; the split precipitation device is arranged below the elevating telescopic rod I and below the material liquid feeding devices; and the motor I is arranged below the right side of the split precipitation device. The precipitation apparatus convenient to clean and used for precipitation of rare-earth ore is unique in structure; and due to a split-type structure is employed, the inner wall of the precipitation apparatus is convenient to clean by workers.

Owner:山东域潇有色新材料有限公司

Preparation method of low-impurity-entrainment lanthanum carbonate or cerium lanthanum carbonate

ActiveCN105502470AReduce concentrationConcentration is not dilutedRare earth metal carbonatesCeriumManganese

The invention relates to a preparation method of low-impurity-entrainment lanthanum carbonate or cerium lanthanum carbonate. The preparation method is characterized in that a lanthanum carbonate or cerium lanthanum carbonate solution is taken as a feed solution, an ammonium bicarbonate solution is taken as an ammonium bicarbonate, and new water or carbon precipitation supernatant is left at the bottom of a precipitation reaction kettle to serve as a base solution. The preparation method comprises the following steps: adding lanthanum carbonate or cerium lanthanum carbonate seed crystal in which seed crystal REO (Rare Earth Oxide) to feed solution REO is 1 percent by weight to 10 percent by weight; adding rare earth chloride and the ammonium bicarbonate solution into a reaction kettle at the same time at 20-50 DEG C to carry out a precipitation reaction, wherein the adding rate ratio is 1:1-3:1; at the end of the reaction, performing solid-liquid separation and water washing to obtain a carbonate lanthanum or cerium lanthanum carbonate product. The preparation method has the advantages that the process parameters of feeding way, relative feeding rate, precipitation pH value and final pH value of a ammonium bicarbonate precipitation lanthanum carbonate or cerium lanthanum carbonate solution are adjusted, so that manganese, copper and the like do not undergo the precipitation reaction, and the formed carbonate lanthanum or cerium lanthanum carbonate product has the characteristics of less soft agglomeration, small crystalline grain size and less entrainment of manganese and copper impurities.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS +2

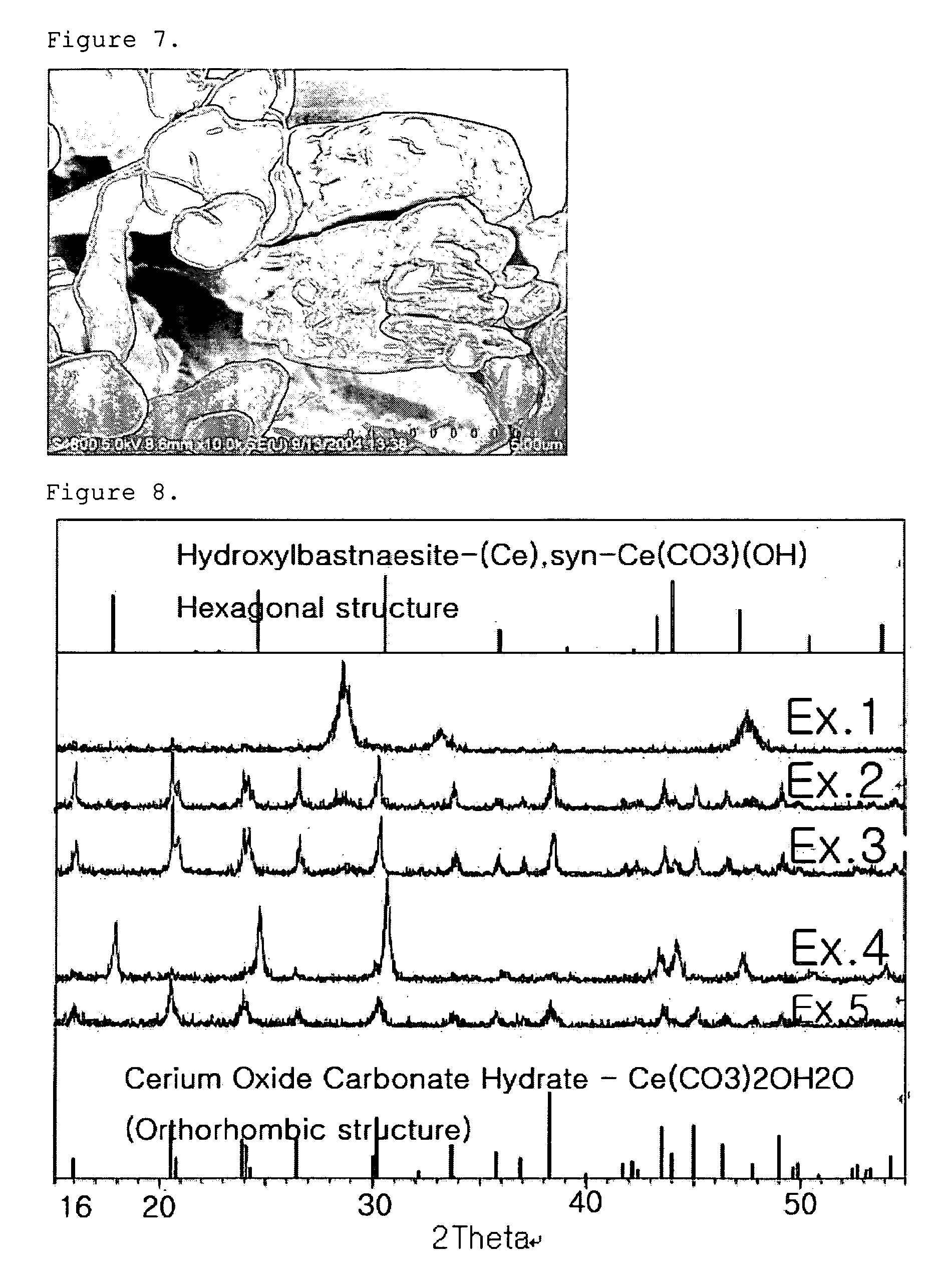

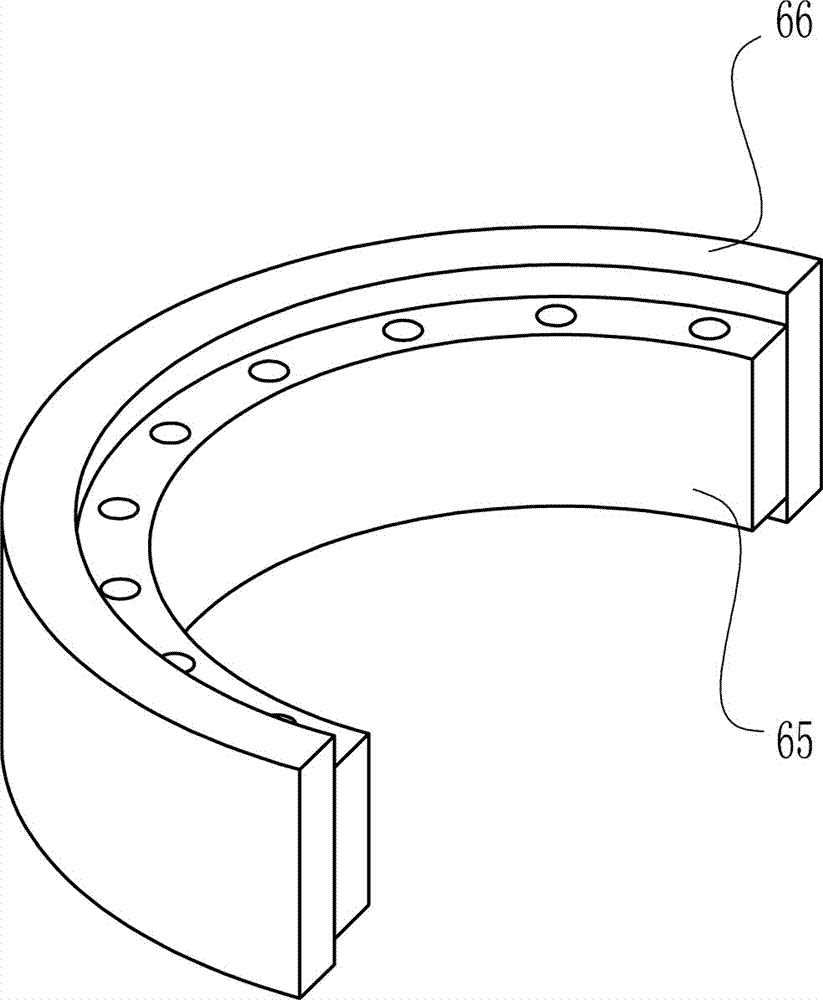

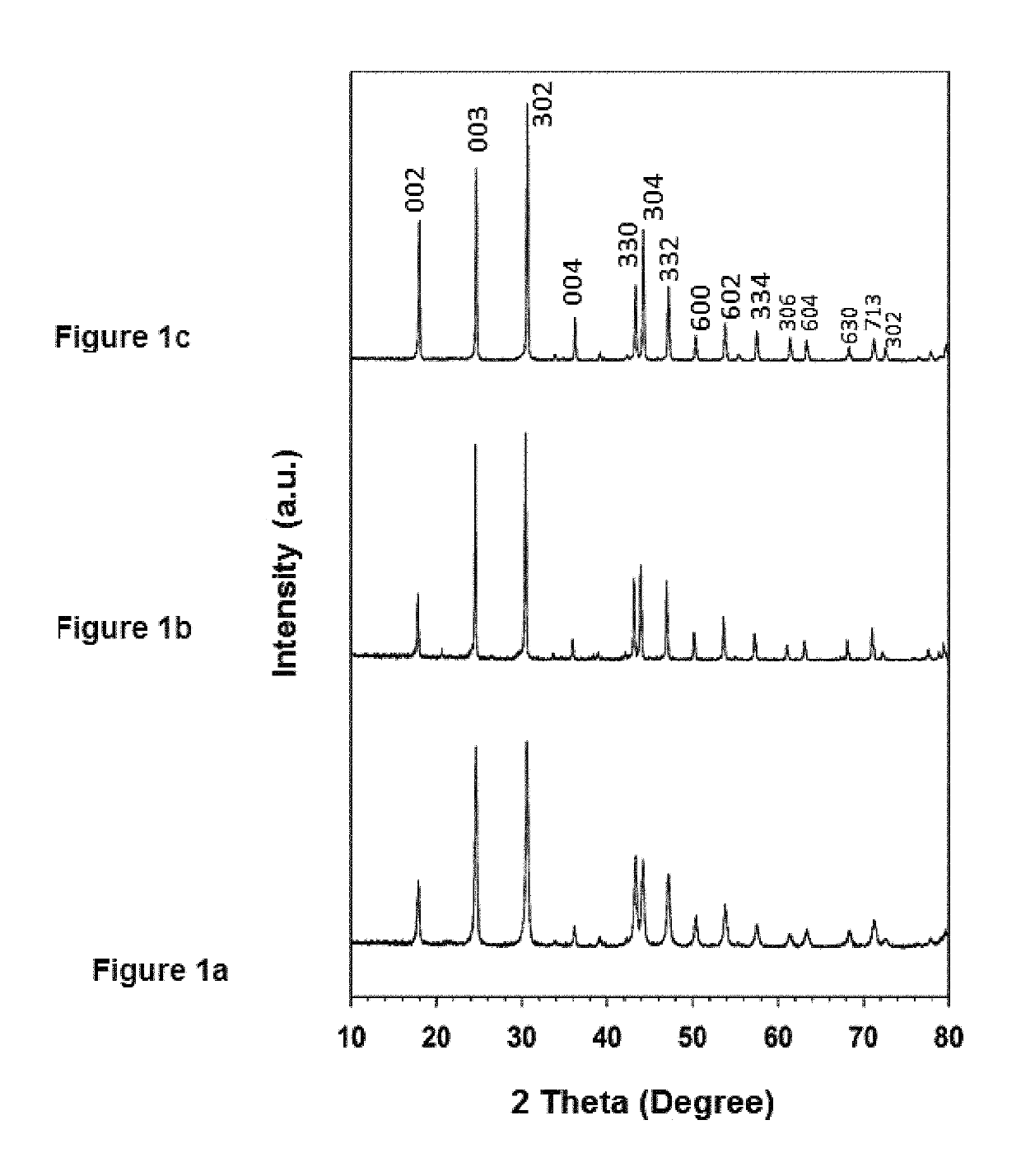

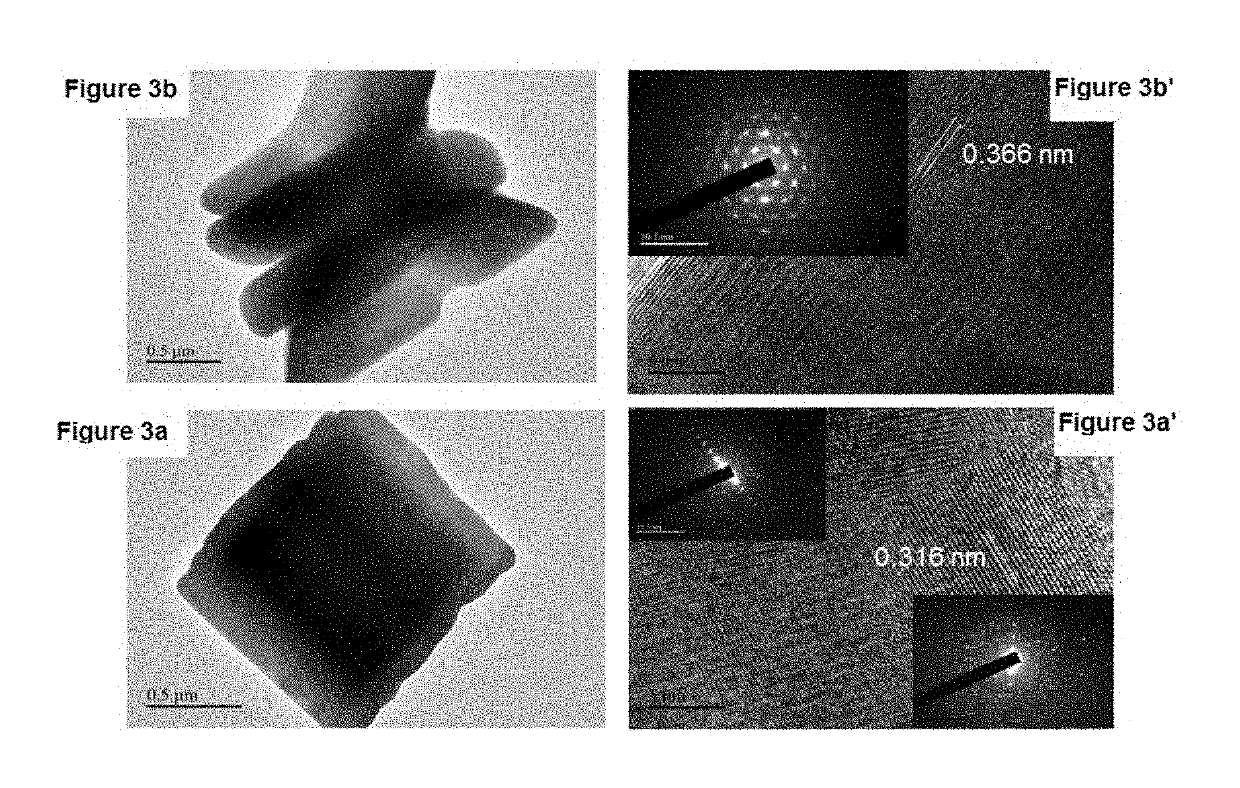

Method for preparing cerium carbonate, method for cerium oxide prepared and crystalline cerium oxide

InactiveUS20110067315A1Easy to controlLow costMaterial nanotechnologyPigmenting treatmentCeriumCrystal structure

The present invention relates to a method for preparing cerium carbonate-based compound, which is capable of easily controlling the crystalline structure, size, shape, or etc. of the cerium carbonate-based compound, and of preparing the cerium carbonate-based compound efficiently at low cost.The method for preparing cerium carbonate-based compound includes comprising the steps of reacting Lanthanite-(Ce) at an elevated temperature to form cerium oxycabonate hydrate (Ce2O(CO3)2.H2O) with orthorhombic crystal structure, or cerium hydroxycarbonate (Ce(OH).(CO3)) with hexagonal crystal structure.

Owner:LG CHEM LTD

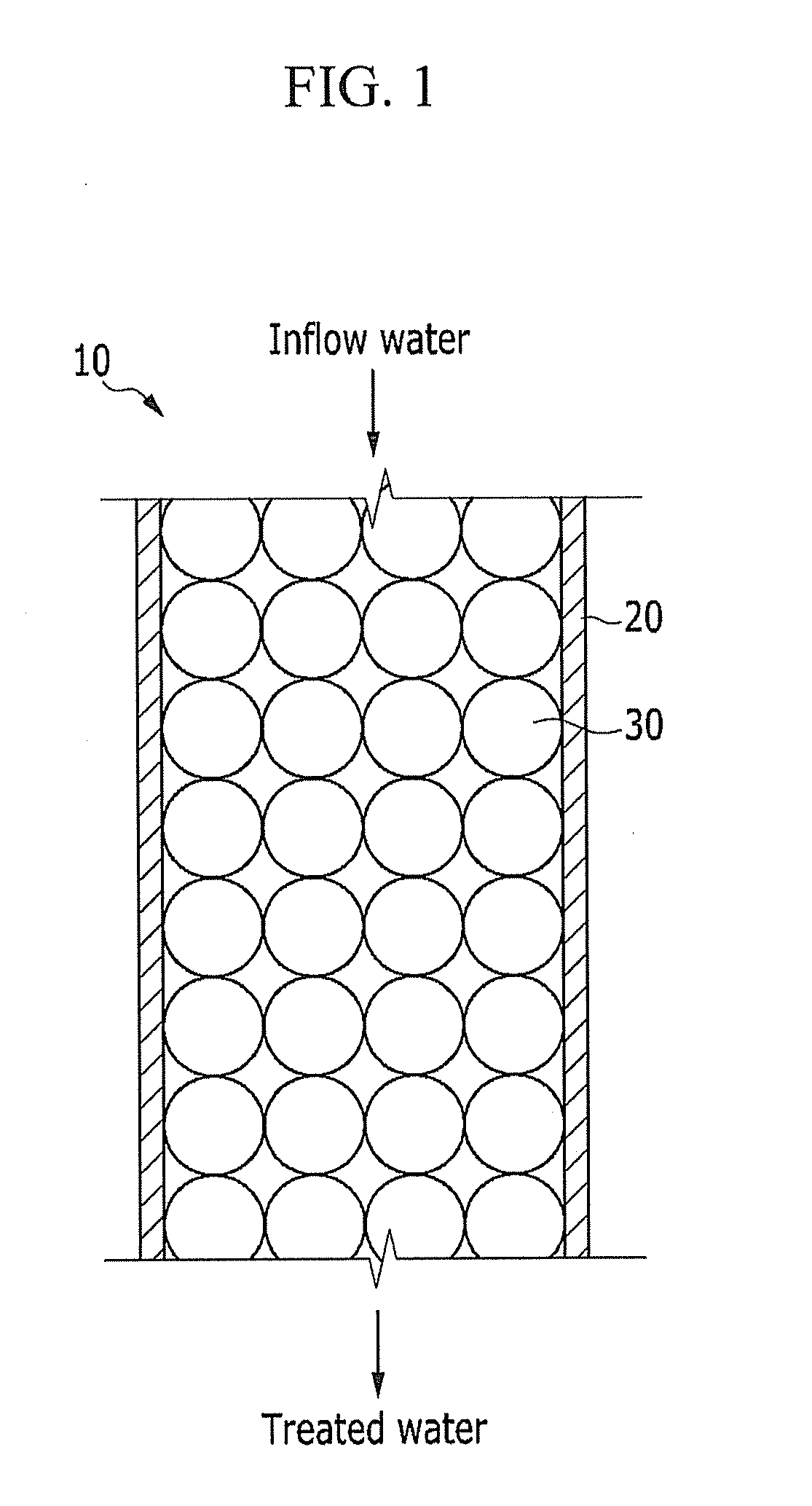

Phosphorus adsorbent, porous fiber and phosphorous adsorption column (as amended)

InactiveUS20180326141A1Other blood circulation devicesOther chemical processesSolubilityExtracorporeal circulation

A phosphorus adsorbent, which is used for adsorbing phosphorus in extracorporeal circulation, is a powder comprising a carbonate of a rare earth metal or an oxide of a Group 4 element and having a solubility in 100 g of water at 20° C. of 10 mg or less. The porous fiber, which comprises the phosphorus adsorbent carried therein, shows a change in pH value of from −1.0 to +1.0 inclusive before and after stirring in physiological saline for 4 hours. The phosphorus adsorption columns respectively comprise the phosphorus adsorbent and the porous fiber each disposed therein.

Owner:TORAY IND INC

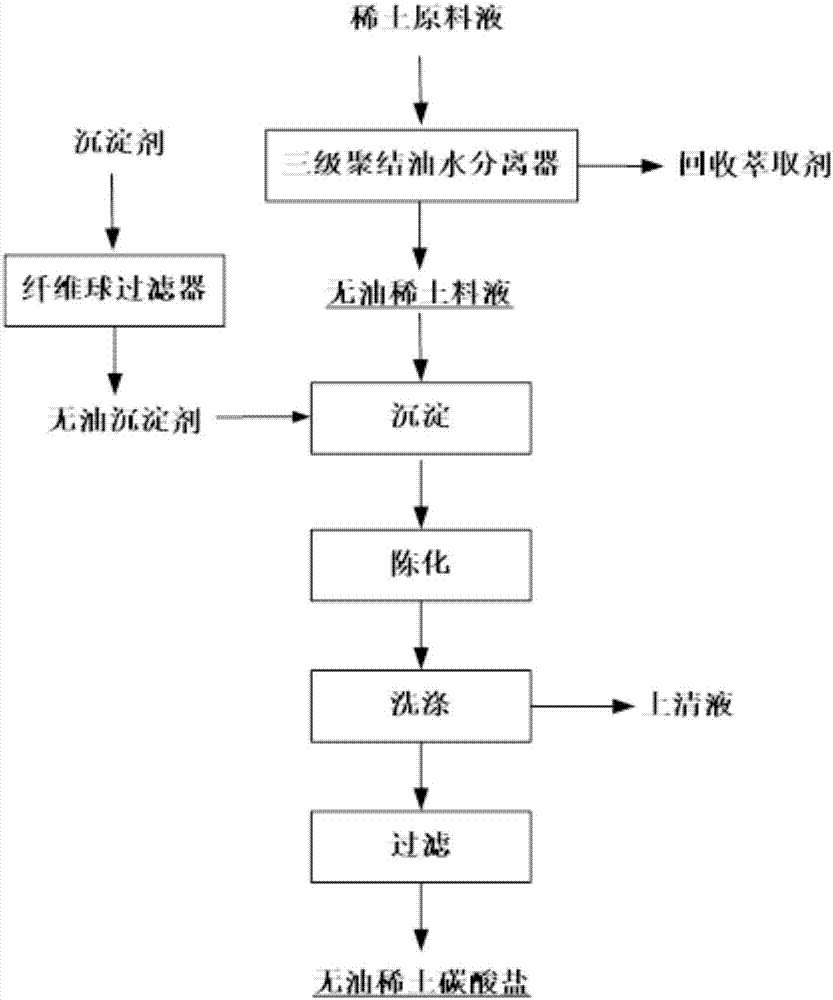

Preparation method of oil-free rare earth carbonate

InactiveCN107879370ASolve the problem of non-recyclable and non-recyclable extractantLow costRare earth metal carbonatesRare earthCarbonate

The invention discloses a preparation method of oil-free rare earth carbonate, which includes steps of: deoiling a rare earth material liquid, obtained via extraction and separation, and a precipitator; mixing the oil-free rare earth material liquid and the precipitator solution and performing precipitation; and washing and filtering solid rare earth carbonate to obtain the oil-free rare earth carbonate. The method solves the problem that the deoiling material cannot be used repeatedly and the extraction agent cannot be recycled.

Owner:BAOTOU RES INST OF RARE EARTHS +1

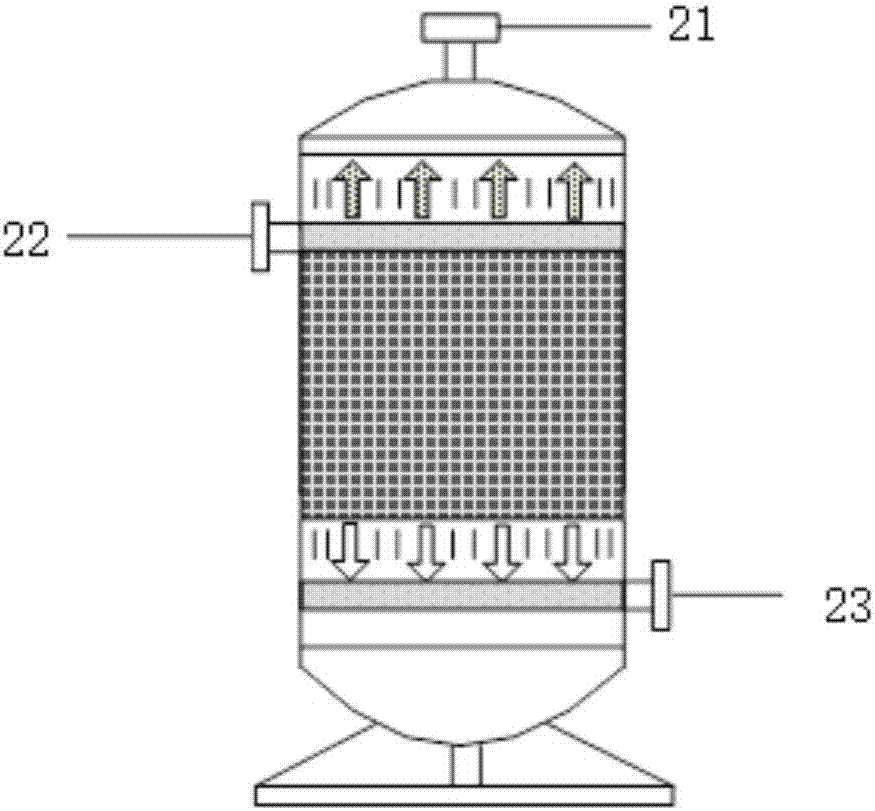

Precipitation reactor for producing ultra-fine cerium carbonate

InactiveCN104437286ASmall micro mixing performanceGood micro mixing performanceChemical/physical/physico-chemical stationary reactorsLiquid-liquid reaction processesCeriumEngineering

The invention relates to liquid-liquid mixing reaction precipitation devices, and in particular relates to a precipitation reactor for producing ultra-fine cerium carbonate. A main body of a kettle body is a cylinder body, wherein the lower end of the cylinder body is closed to form an inverse truncated cone shape, and the central part of a seal head at the bottom of the kettle body adopts an internal cone shape. According to the precipitation reactor disclosed by the invention, fluids in upper and middle areas form axial circulation, and the fluid in a bottom area of a crystallizer forms radial circulation so as to ensure that the crystallizer is large in internal circulation quantity and relatively short in mixing time, the shearing rate can be significantly increased, and micro-mixing and micro mass transfer of liquid-liquid phase reaction materials can be enhanced; areas with poor mixing cannot exist, deposited dead angles cannot be formed at the bottom, and precipitation particles are high in suspension efficiency and relatively uniform in distribution of solid hold-up; and good stirring effects can be achieved under relatively small stirring power, and the energy consumption can be reduced. Cerium carbonate prepared by using the precipitation reactor disclosed by the invention is relatively fine in particle size, narrow in particle size distribution range and relatively low in cost, and is suitable for industrial application.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

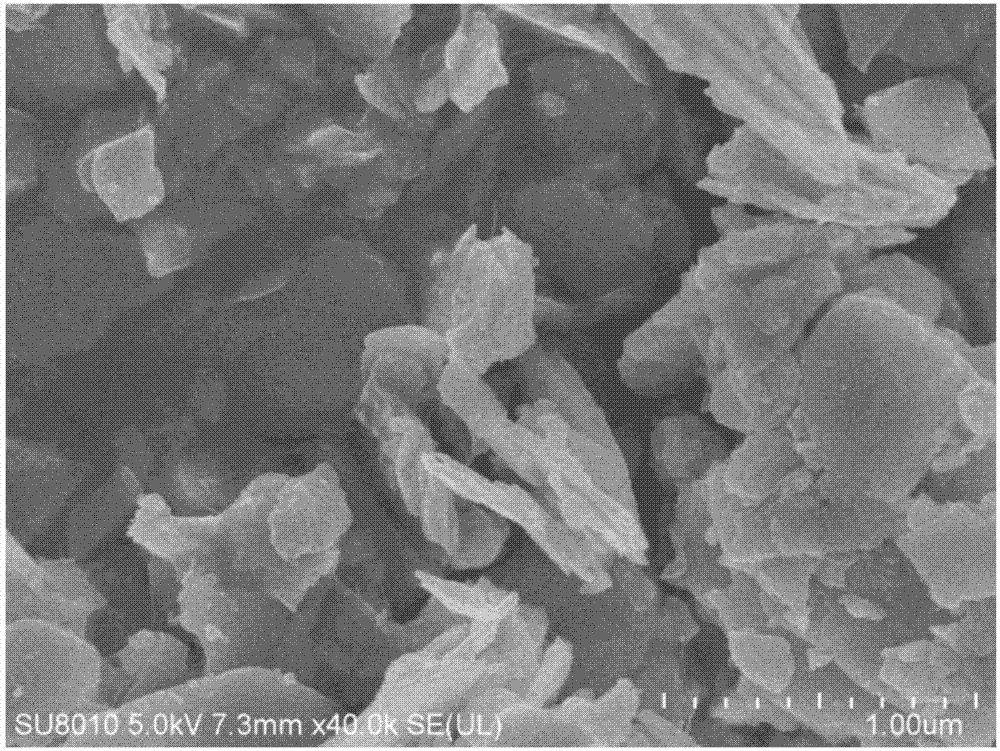

Low temperature hydrothermal method for the preparation of LaCO3OH nanoparticles

ActiveUS10322409B1Reducing the nitrogen monoxideReducing the nitrogen oxideExhaust apparatusDispersed particle separationNanoparticleNitrogen oxide

A hydrothermal method of preparing uniform, monodisperse ceramic lanthanum hydroxyl carbonate (LaCO3OH) having cherry-blossom-like nanogears and / or nanocubes is described. The method produced a hexagonal crystal with a crystal lattice in which at least on lanthanum ion is substituted with calcium ion. The ceramic nanoparticles produced by the method are good catalyst for the reduction of nitrogen oxides with a hydrocarbon. A method of reducing exhaust gases is described.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Method of recovering rare-earth elements

ActiveUS9228248B2Improve leaching rateRaise the ratioMetal recyclingLanthanide oxides/hydroxidesRare-earth elementSlurry

Provided is a method of recovering rare-earth elements by which rare-earth elements can be recovered efficiently from a bauxite residue serving as a raw material and containing the rare-earth elements. Specifically provided is a method of recovering rare-earth elements from a raw material, the raw material being a bauxite residue produced as a by-product in a Bayer process, the method including: using a bauxite residue having a specific surface area of 35 m2 / g or more; adding, to the raw material bauxite residue, a liquid leaching agent formed of an aqueous solution of at least one kind of mineral acid selected from sulfuric acid, hydrochloric acid, nitric acid, and sulfurous acid, thereby preparing a slurry having a liquid-solid ratio of 2 to 30 and a pH of 0.5 to 2.2; subjecting the slurry to leaching treatment of the rare-earth elements under a temperature condition of room temperature to 160° C.; subjecting the slurry after the leaching treatment to solid-liquid separation, yielding a leachate; and separating and recovering the rare-earth elements from the leachate.

Owner:NIPPON LIGHT METAL CO LTD

Yttrium hydroxycarbonate modified with heterogeneous metal, method of preparing the same, and adsorbent and filter device including the same

InactiveUS20130129592A1Improve performanceMaterial nanotechnologyDispersed particle separationPore diameterOrganic chemistry

Example embodiments relate to a yttrium hydroxycarbonate modified with a heterogeneous metal, a method of preparing the same, an adsorbent for a heavy metal including the same, and a filter device including the same. The modified yttrium hydroxycarbonate may have a pore size distribution with a pore diameter peak of less than or equal to 10 nm.

Owner:SAMSUNG ELECTRONICS CO LTD +1

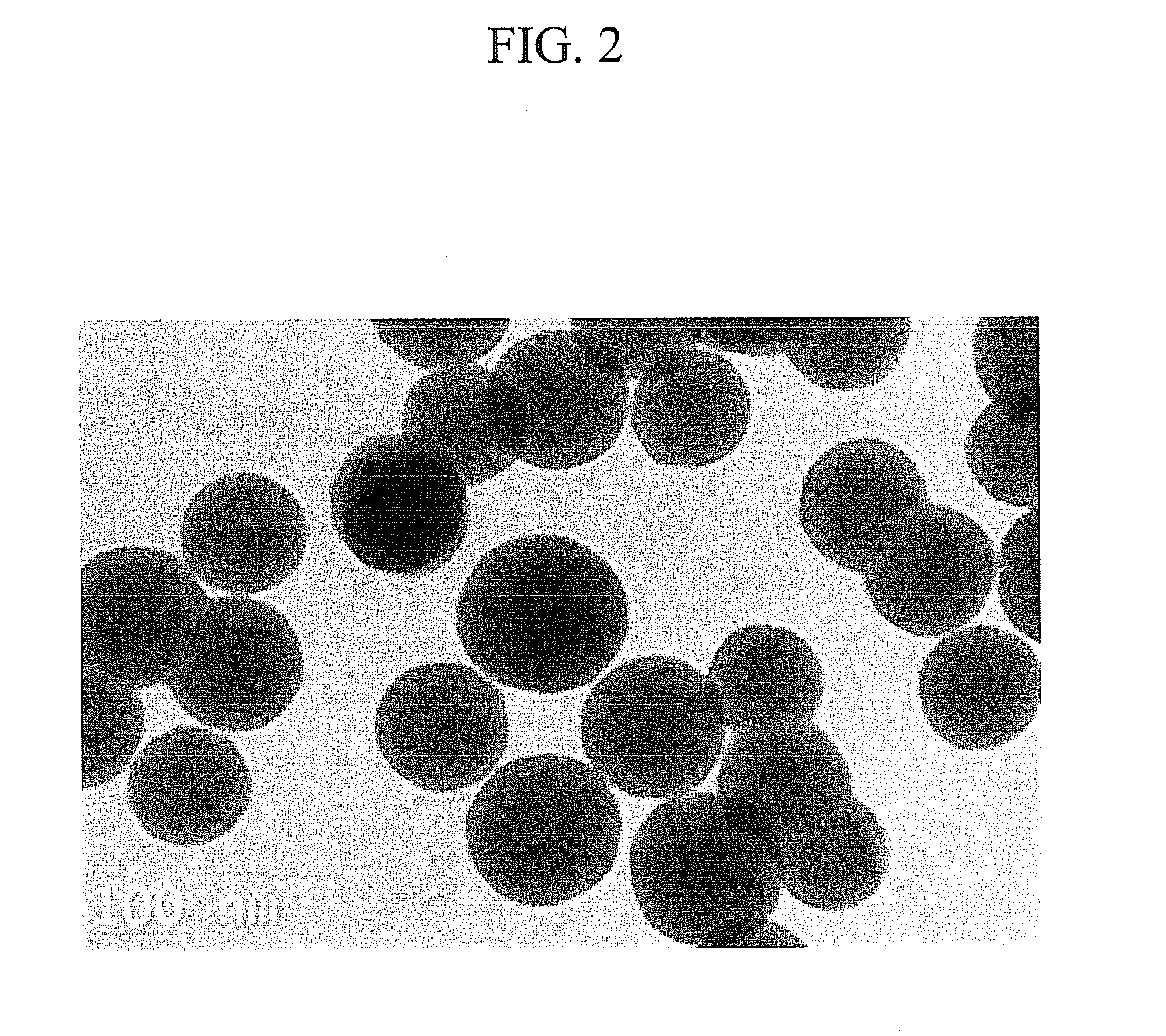

Nano-dephosphorizer, preparation method and application of same

InactiveCN107876000ALarge saturated adsorption capacitySignificant phosphorus fixation effectMaterial nanotechnologyOther chemical processesEmission standardNanoscopic scale

The invention provides a nano-dephosphorizer lanthanum carbonate hydrate, La2(CO3)3.nH2O, 1 <= n <= 8. The invention also provides a preparation method of the nano-dephosphorizer lanthanum carbonate hydrate. The method includes steps of: 1) adding an ionic liquid to a metal lanthanum ion solution with stirring to form a mixed solution; 2) adding a precipitant to the mixed solution to perform a precipitation reaction, and performing after-treatment to a reaction product to obtain the nano-dephosphorizer lanthanum carbonate hydrate, which is more than 100 mg / L in maximum saturation adsorption capacity and has strong removal capability on low-content phosphorus components in ecologic water domains, living or industrial wastewater, etc. After treatment, content of phosphates in the water sample can reach national first-level emission standard of phosphates. The nano-dephosphorizer has important significance for alleviating the gaining pressure of phosphorus environment pollution and a problem of daily production and domestic water.

Owner:ZHEJIANG UNIV

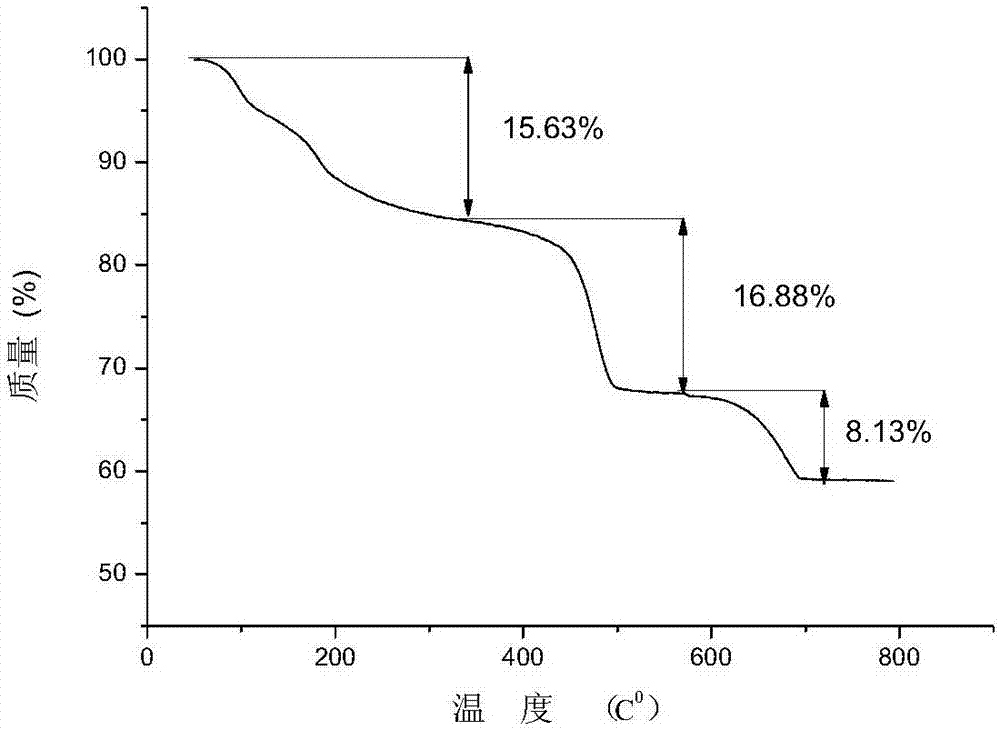

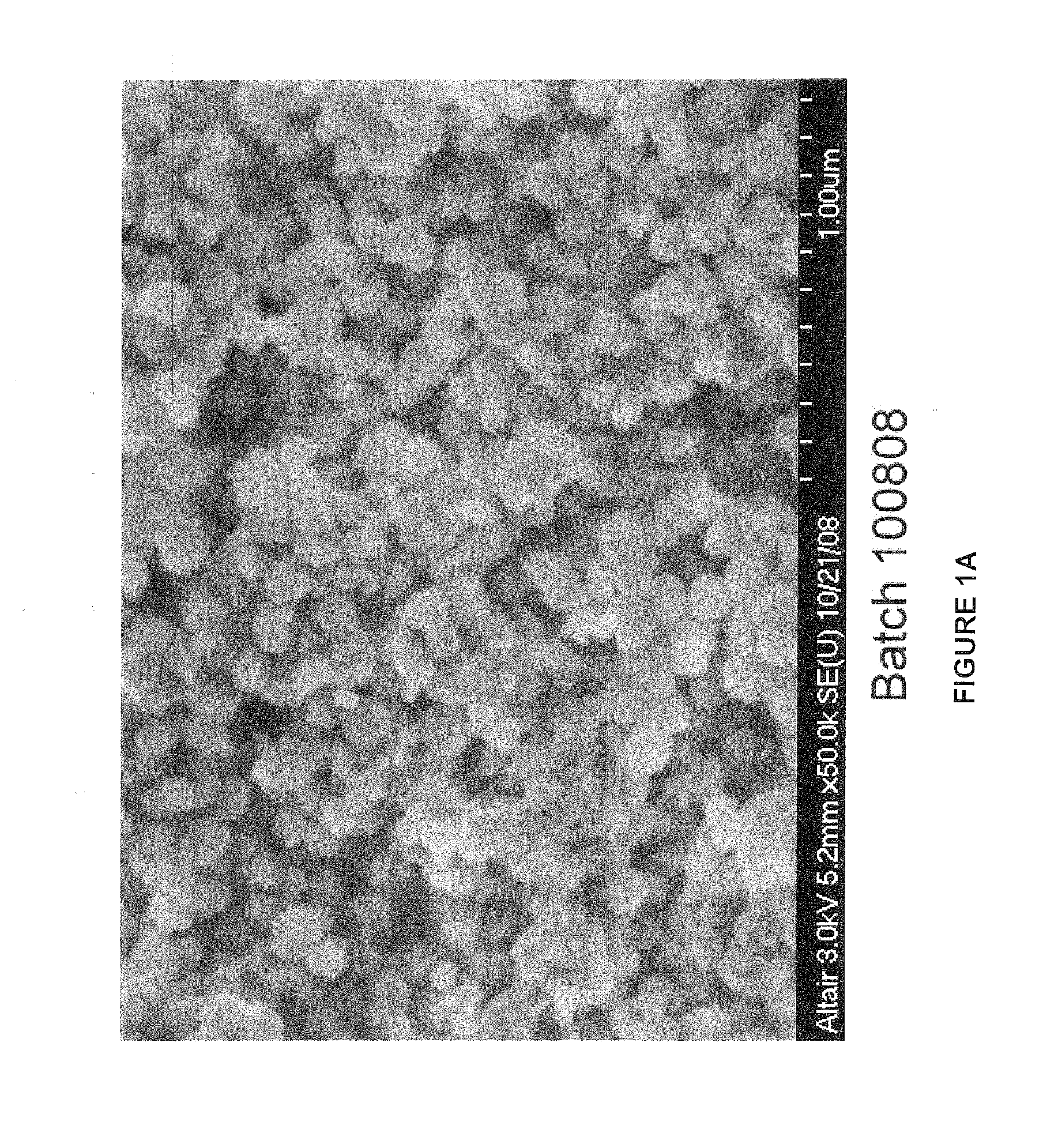

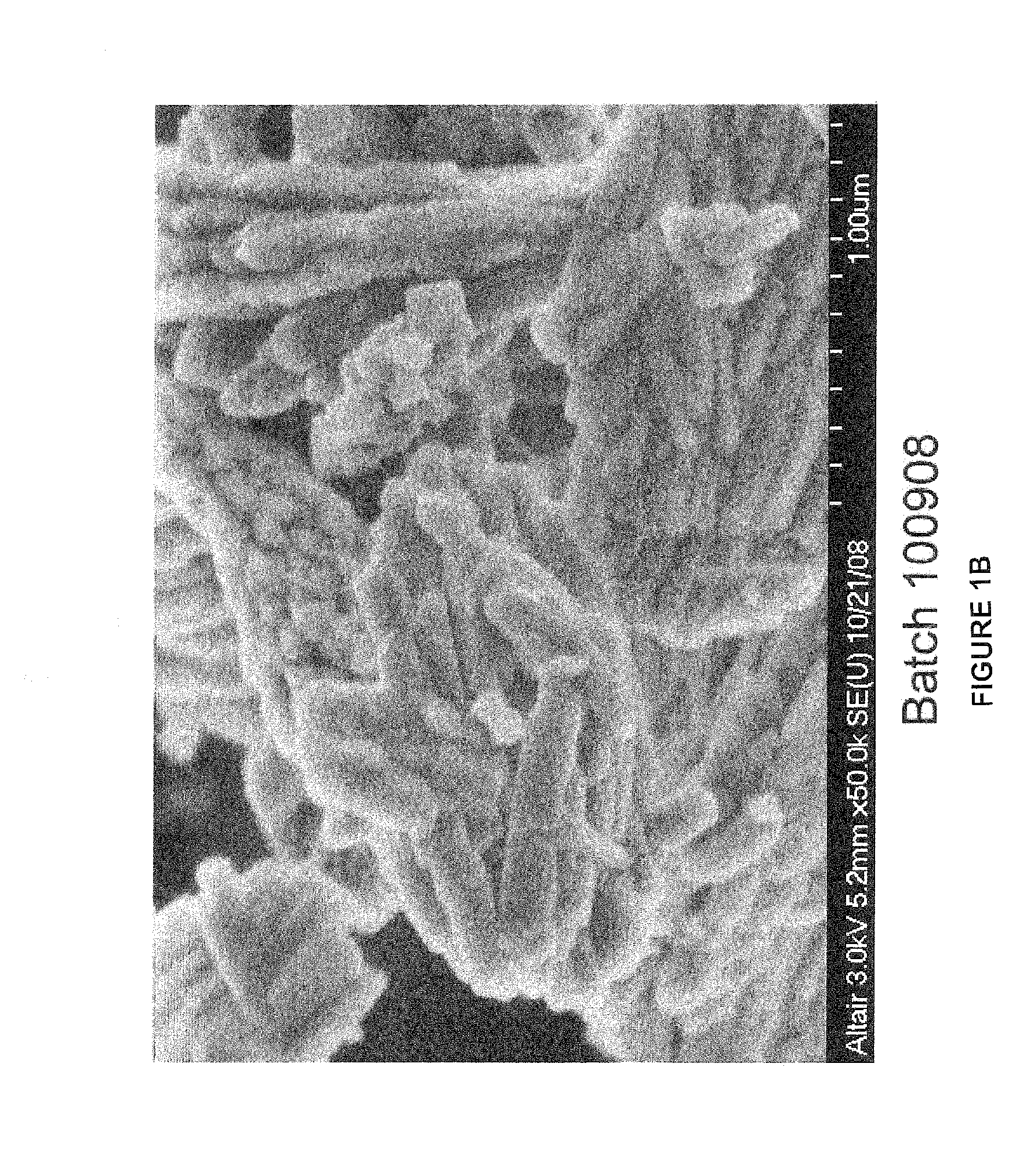

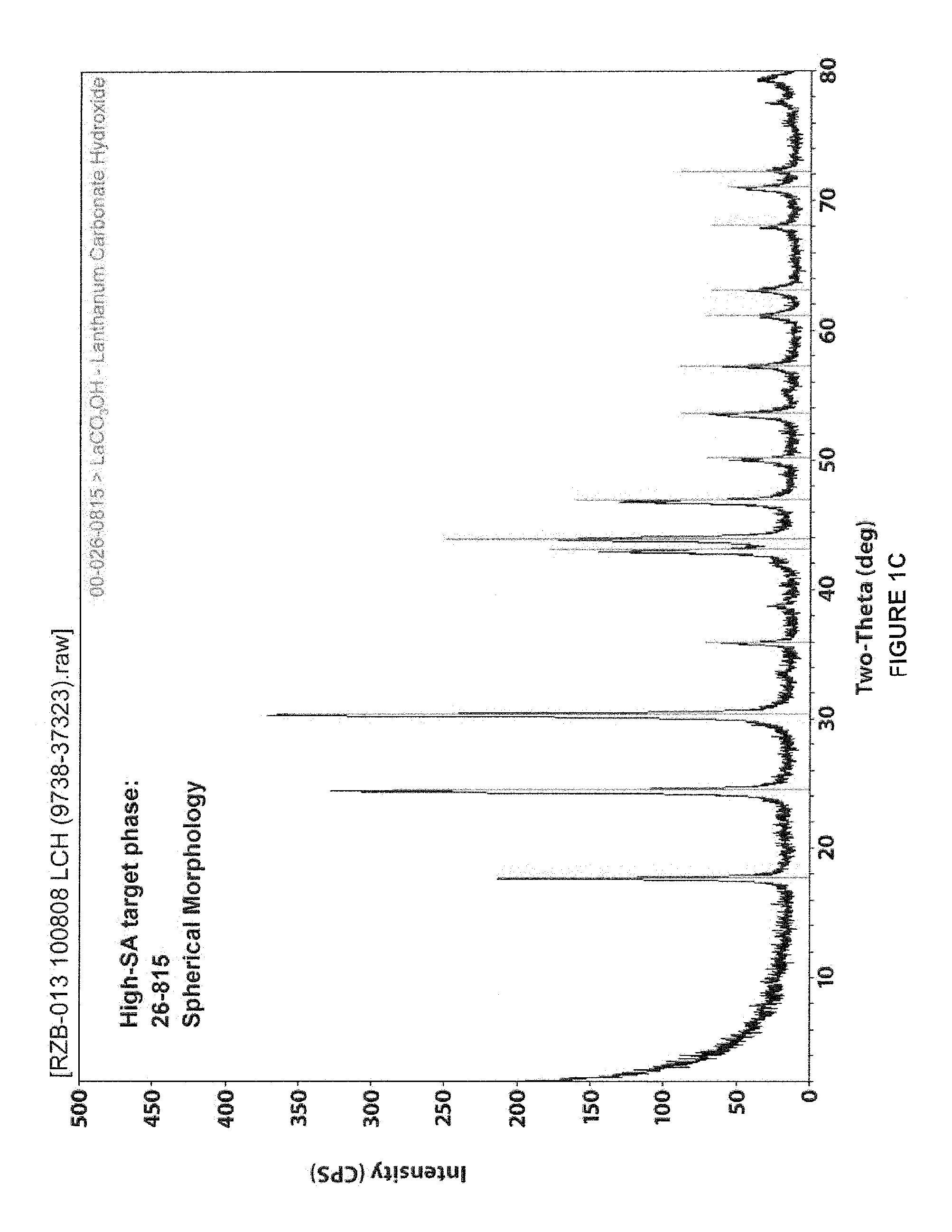

Lanthanum carbonate hydroxide, lanthanum oxycarbonate and methods of their manufacture and use

Owner:UNICYCIVE THERAPEUTICS INC

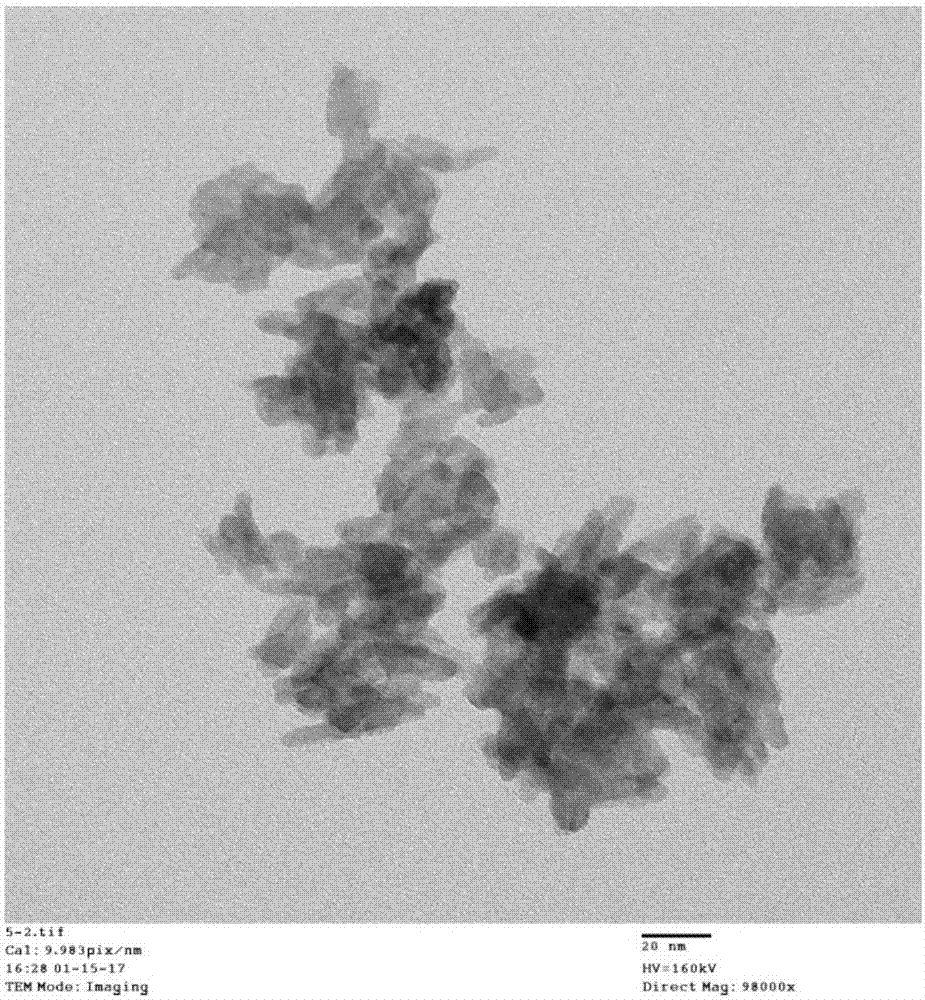

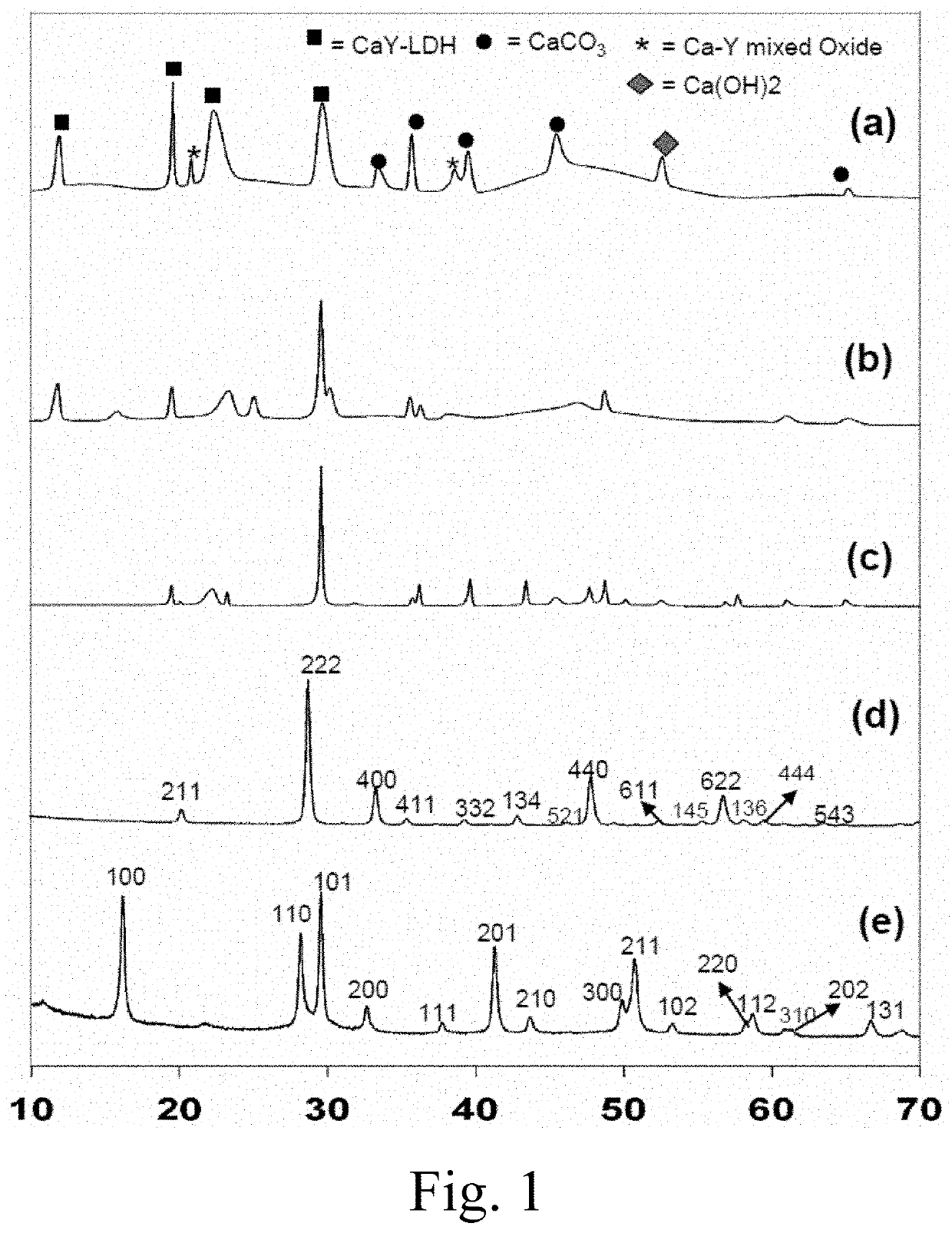

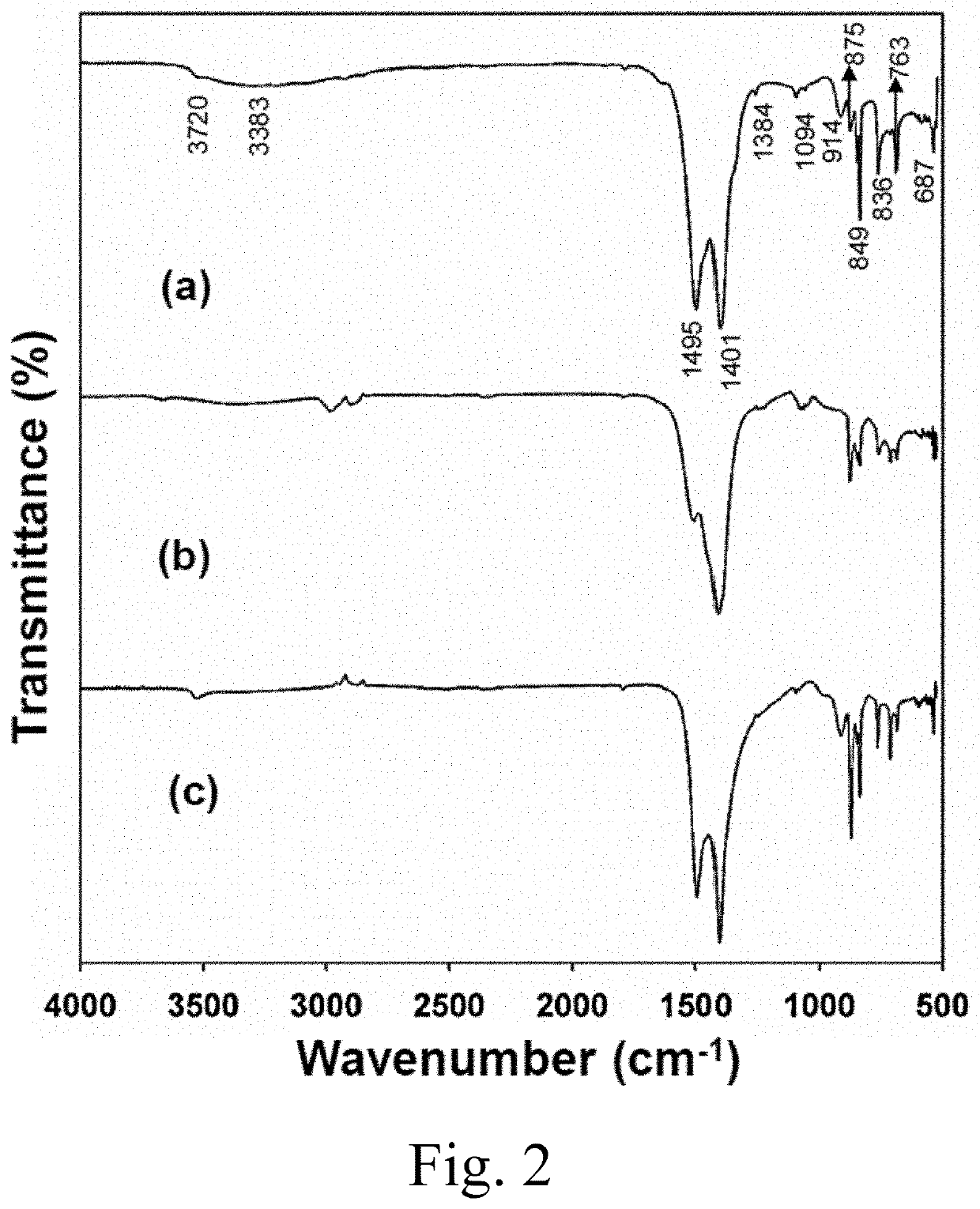

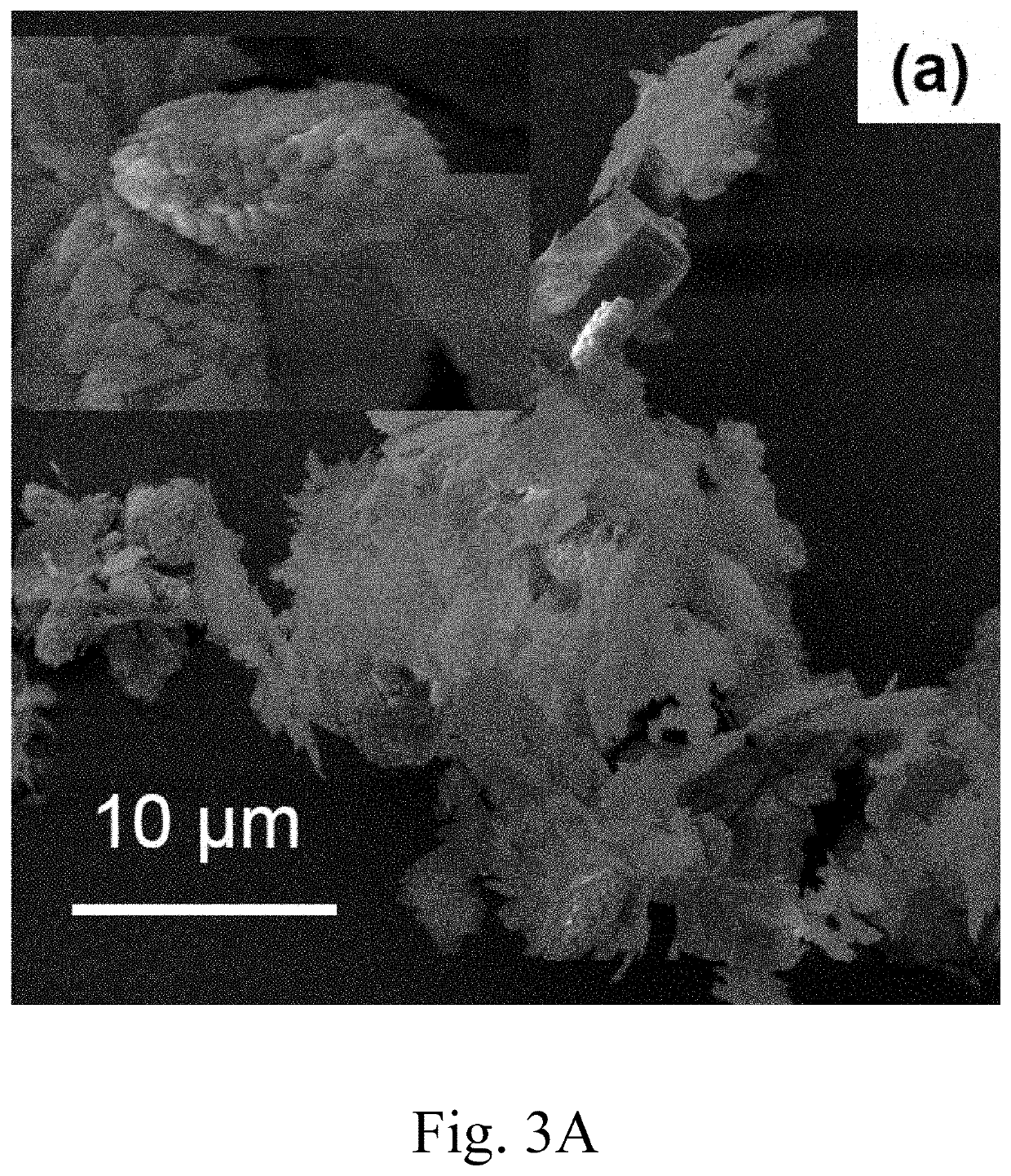

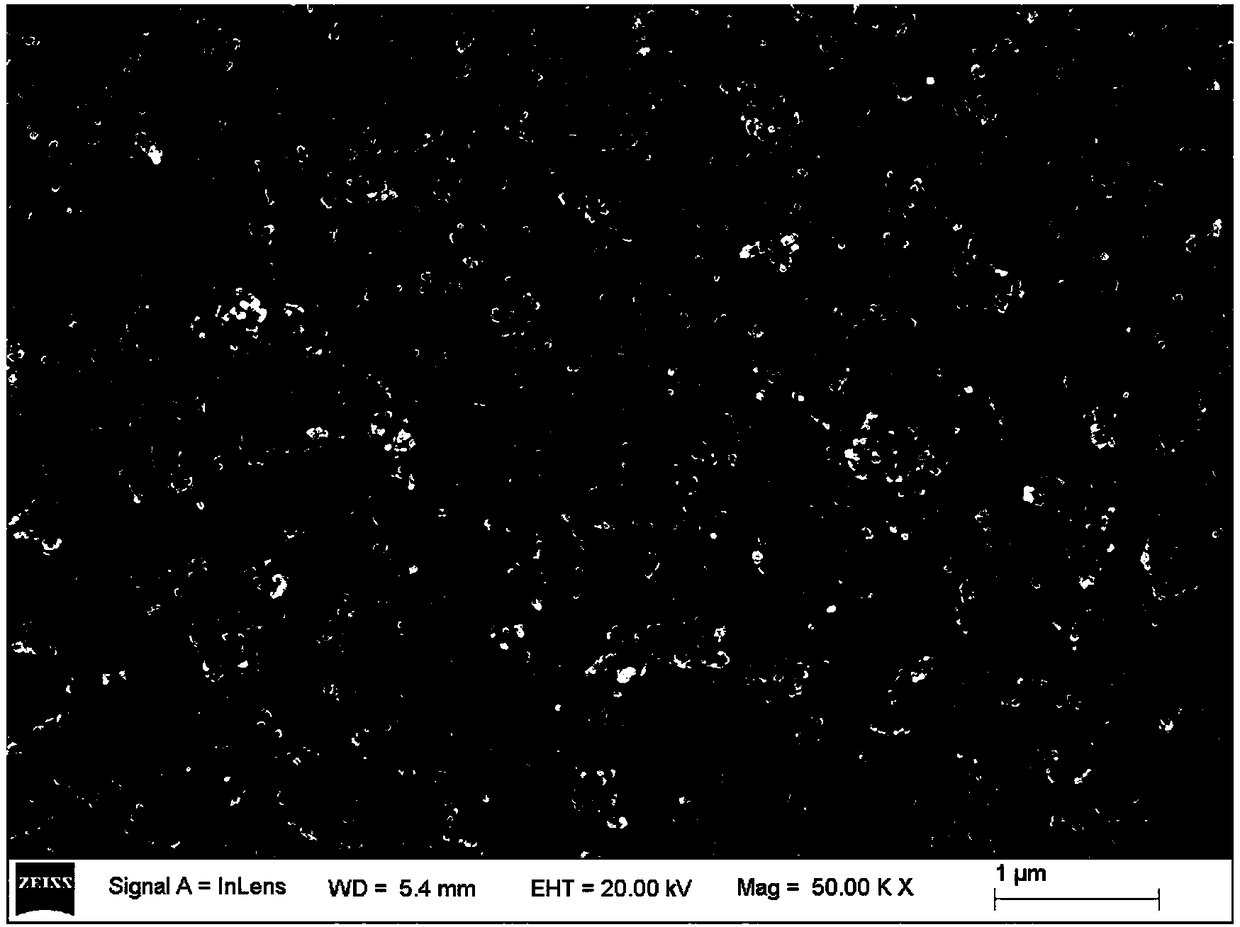

Ca-y-carbonate nanosheets, their use, and synthesis

Nanosheets of Ca2+ and Y3+, with CO32− in the interlayer with a uniform diameter and lengths of several tens of microns have been successfully synthesized in a hydrotalcite layer structure (a layered double hydroxide), using a hydrothermal method. The formation mechanism of lamellar CaY—CO32− layered double hydroxides (LDHs) depends on the molar ratio of Ca and Y and the reaction time and temperature. The resulting LDH materials exhibit excellent affinity and selectivity for heavy transition metal and metalloid ions.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Series of micro/nano-rare earth materials and preparation method thereof

InactiveCN108585014AUniform sizeSize is easy to controlRare earth metal oxides/hydroxidesOrganic compound preparationRare earthSlurry

The invention discloses a series of micro / nano-rare earth materials and a preparation method thereof. The method prepares a large amount of a series of rare earth micro / nano-materials with high dispersion, uniform particle size distribution and controllable sizes. The rare earth micro / nano-material comprises one or more of an oxidized rare earth material, a hydroxide rare earth material, a rare earth carbonate material, a rare earth oxalate material and a rare earth subcarbonate material. The preparation method comprises preparing a rare earth salt or a mixed solution of a rare earth salt andadditives, fast mixing the rare earth salt or the mixed solution and a precipitant solution in a nucleating reactor for a reaction, placing the slurry in a crystallization tank, carrying out crystallization, carrying out washing for solid and liquid separation to obtain products, and calcining the products to obtain a rare earth oxide material. The particle sizes of the product can be controlled in a range of 20-2000nm. The preparation method is easy to operate, has high efficiency and is used for large-scale production. The rare earth micro / nano-material can be used in the fields of catalysis, polishing, luminescence and magnetism.

Owner:BEIJING UNIV OF CHEM TECH +1

Production technology of low-chlorine cerium carbonate

The invention discloses a production technology of low-chlorine cerium carbonate. The technology comprises the following steps: 1, mixing cerium carbonate with water to form a mixed solution; 2, adding concentrated nitric acid to the mixed solution obtained in step 1, adjusting the pH value of the obtained solution to 1.5-2 by using ammonia water, heating the adjusted solution, and adjusting the pH value of the heated solution to 4-4.5 by using cerium carbonate in order to obtain an acid solution; 3, filtering the acid solution obtained in step 2 to obtain a filtrate; 4, diluting the filtrate obtained in step 3 to make the CeO2 concentration reach 70 g / L, adding an ammonium bicarbonate solution slowly first and then fast to precipitate at 55 DEG C, and allowing the obtained solution to stand after precipitation is completed in order to obtain a precipitate; and 5, washing the precipitate obtained in step 4 with water, centrifuging and dehydrating the washed precipitate, and packaging the dehydrated precipitate. The Cl<-> content of the cerium carbonate product produced through the method is smaller than 0.002%. The content of Fe, Ca, Na, K, Pb, Zn, Mn, Al, Cu, Ni, Co and Cr is smaller than 0.002%.

Owner:四川沃耐稀新材料科技有限公司

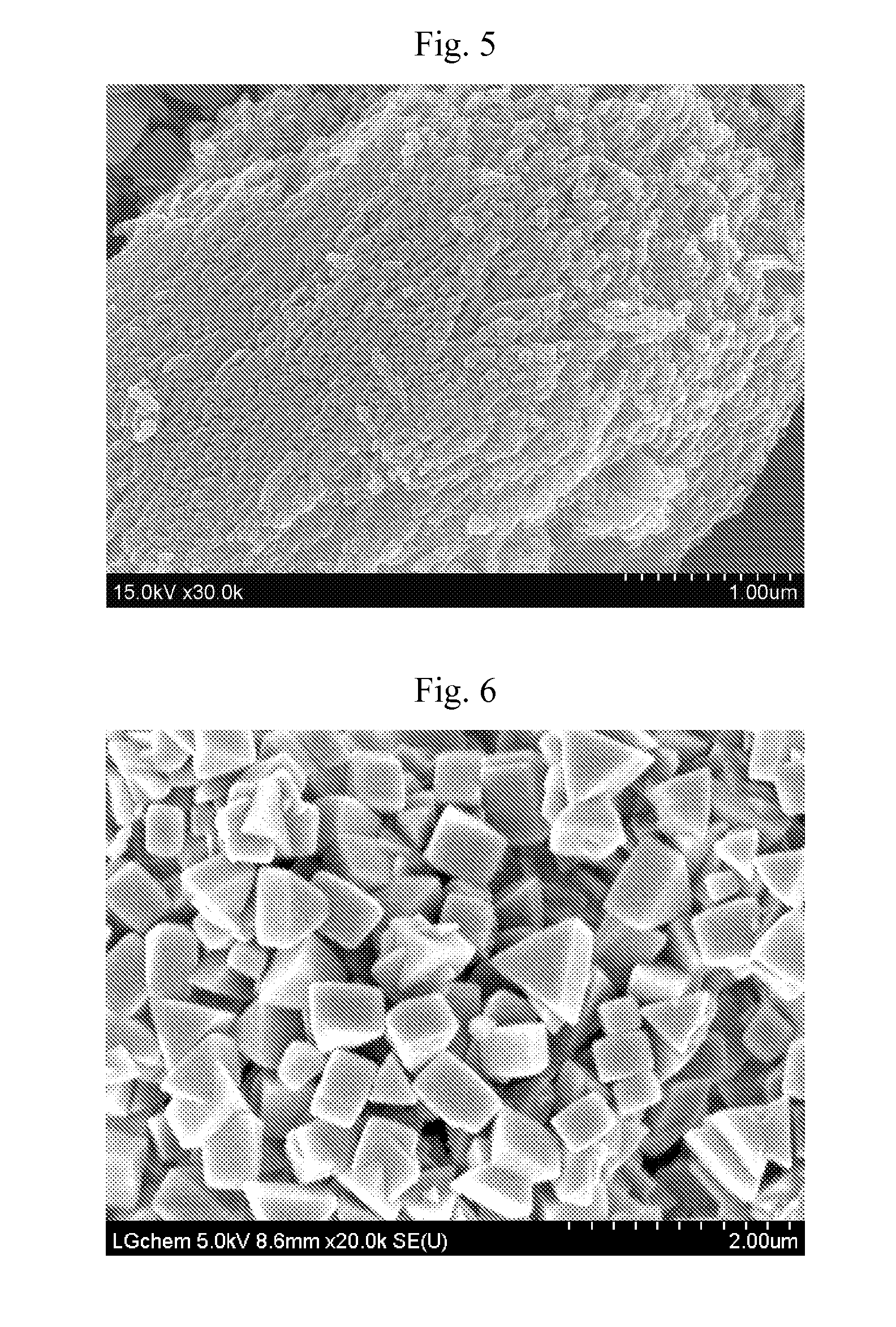

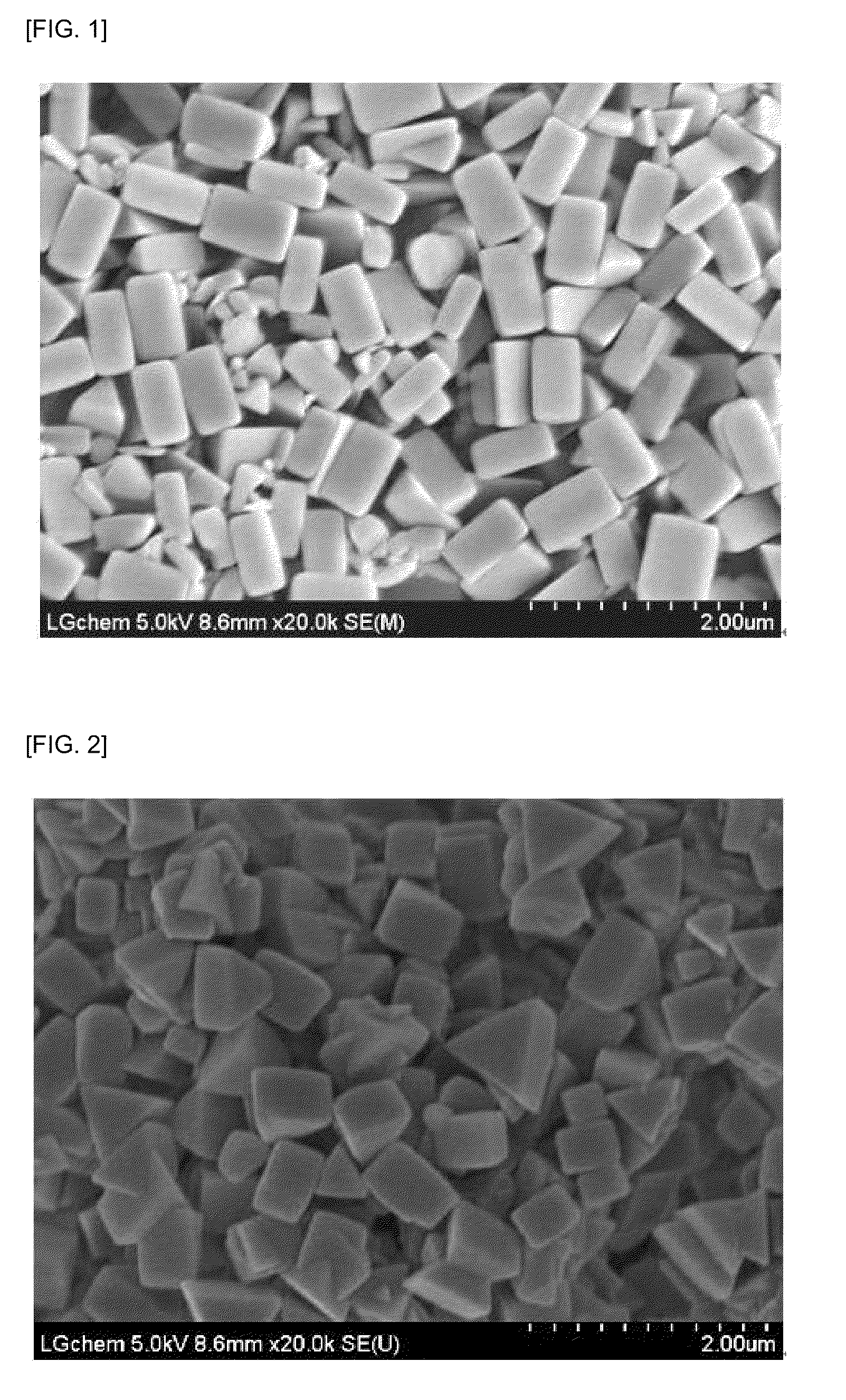

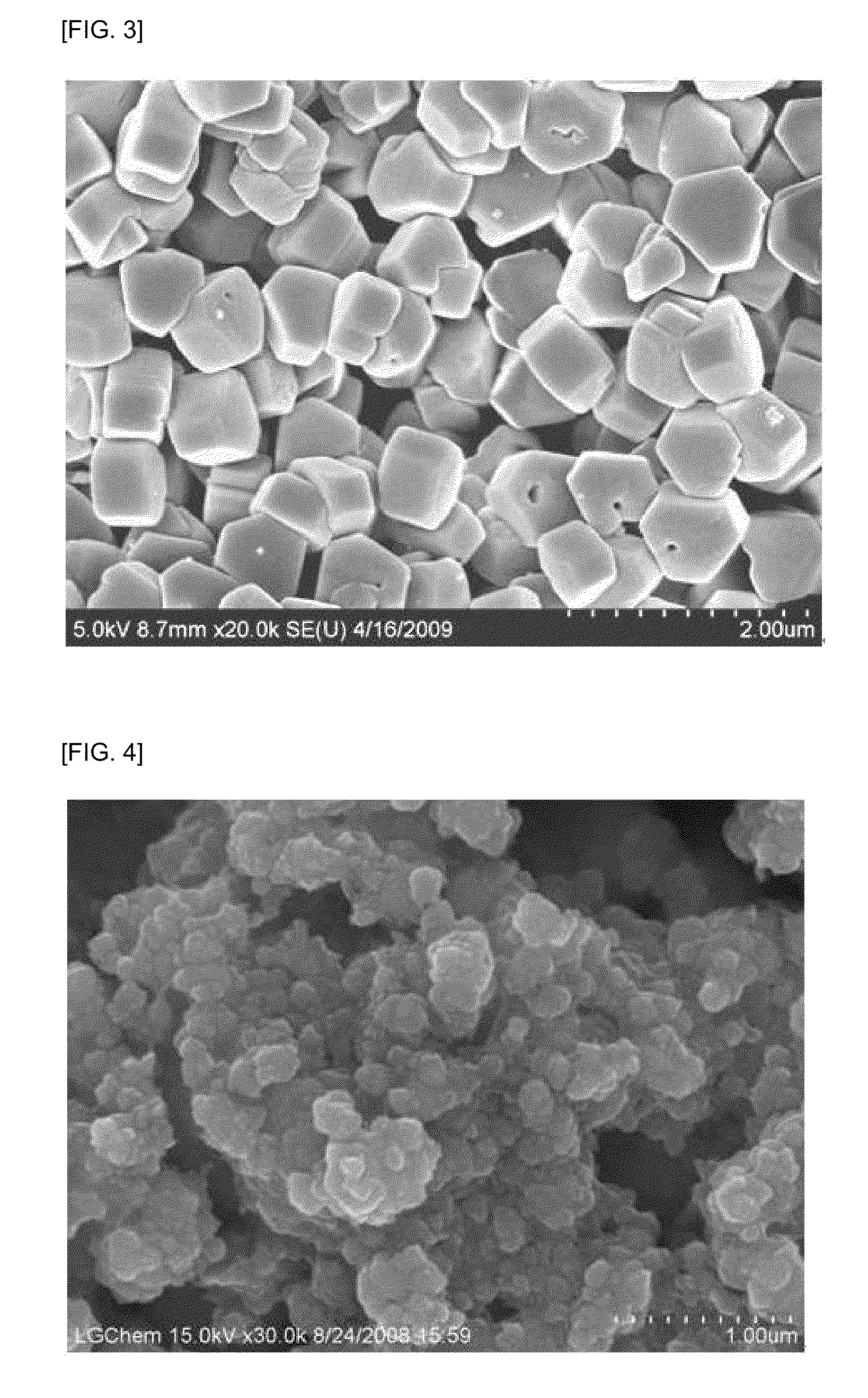

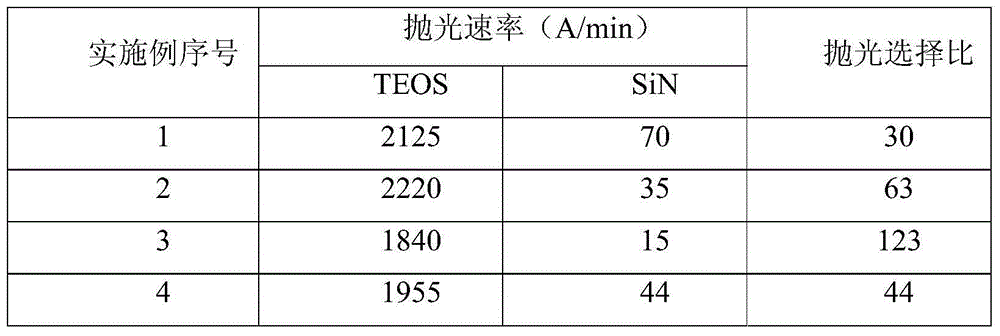

Cerium oxide powder for abrasive and cmp slurry comprising the same

ActiveUS20100062687A1Easy to polishImprove polishing effectPigmenting treatmentOther chemical processesCeriumCrystal structure

Disclosed are cerium oxide powder for an abrasive; CMP slurry including the same; and a shallow trench isolation (STI) process using the CMP slurry. At least two kinds of cerium oxides prepared by using cerium carbonates having different crystal structures are mixed in an appropriate ratio and used as an abrasive for CMP slurry, thereby adjusting required polishing properties of the CMP slurry. Also, in a disclosed method of preparing a cerium carbonate, the crystal structure of the cerium carbonate can be easily controlled. Based on the finding that in a cerium oxide for an abrasive, the kind of improved polishing property depends on the crystal structure of a cerium carbonate, at least one from among polishing properties, such as the polishing rate of a silicon oxide layer, the polishing rate of a silicon nitride layer, the polishing selectivity between the silicon oxide layer and the silicon nitride layer, and WIWNU, can be adjusted by using at least two kinds of cerium oxides selected from the group including (i) a cerium oxide prepared by using a lanthanite-(Ce) crystal structured cerium carbonate, (ii) a cerium oxide prepared by using an orthorhombic crystal structured cerium carbonate, and (iii) a cerium oxide prepared by using a hexagonal crystal structured cerium carbonate, as an abrasive for CMP slurry, and adjusting the mixing ratio of the cerium oxides.

Owner:LG CHEM LTD

Preparation method of cerium carbonate and cerium oxide

ActiveCN102161497AHigh yieldImprove productivityMaterial nanotechnologyCerium oxides/hydroxidesCeriumNuclear chemistry

The invention relates to a preparation method of cerium carbonate, cerium carbonate and a preparation method of cerium oxide by utilizing the cerium carbonate, wherein the earning rate or productivity of cerium carbonate is improved and cerium carbonate of uniform articles is prepared. According to the preparation method of cerium carbonate, cerium precursor and urea are mixed. Then the temperature of the mixture is increased to more than 50 DEG C without any other reaction medium. With the presence of macromolecular dispersant, cerium precursor reacts with urea.

Owner:LG CHEM LTD

Crystalline cerium oxide and preparation method of the same

ActiveUS20120000137A1Improve polishing effectSimple and economical and efficientPigmenting treatmentMaterial nanotechnologyCrystal structureCerium oxide

The present invention relates to crystalline cerium oxide prepared in a simple, economical, and efficient manner, of which crystal structure, shape, and size can be easily adjusted and that exhibits excellent polishing properties, and a preparation method thereof. The crystalline cerium oxide can be prepared as sub-micron crystalline cerium oxide that has a mean volume diameter and a diameter standard deviation within a predetermined range.

Owner:LG CHEM LTD

Method for producing high-purity lanthanum carbonate

InactiveCN106315655ALarge particle sizeSmall specific surface areaRare earth metal carbonatesCentrifugationAmmonium hydroxide

The invention discloses a method for producing high-purity lanthanum carbonate. The method comprises the following steps that 1, lanthanum carbonate is added into water to form a mixed solution; 2, concentrated nitric acid is added into the mixed solution obtained in the step 1 to be dissolved, the pH value is adjusted to range from 1.5 to 2 with ammonium hydroxide, the pH is adjusted to range from 4 to 4.5 with cerous carbonate after heating, and an acid solution is obtained; 3, the acid solution obtained in the step 2 is filtered, and filtrate is obtained; 4, the filtrate in the step 3 is concentrated; 5, the concentrated solution obtained in the step 4 is placed in a crystallizing disc to be naturally crystallized, and centrifugal dewatering is carried out; 6, water is added into crystals obtained after centrifugation in the step 5, and dissolving and diluting are carried out; 7, the solution obtained after being treated in the step 6 is heated to 50 DEG C, an ammonium bicarbonate solution is added slowly and then fast for sedimentation, and still standing is carried out after sedimentation is completed; 8, the sediment obtained after being treated in the step 7 is washed, and then centrifugal dewatering and packaging are carried out.

Owner:乐山沃耐稀电子材料有限公司

Preparation method for cerium oxide crystal and application thereof in chemical mechanical polishing (CMP)

InactiveCN105800665AImprove polishing rateHigh TEOS/SiN polishing selectivityOther chemical processesCerium oxides/hydroxidesCeriumCarbonate

The invention aims to provide a preparation method for a cerium oxide crystal. The method comprises the following steps: preparing cerium carbonate through a two-step precipitation process, and subjecting obtained cerium carbonate to high-temperature calcination so as to obtain cerium oxide. The prepared cerium oxide particles have uniform particle size, and are easily dispersed in a liquid phase through mechanical force; and a chemical mechanical polishing (CMP) liquid with the dispersed cerium oxide as a grinding material shows excellent planarization polishing efficiency when applied in polishing through shallow trench isolation (STI).

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

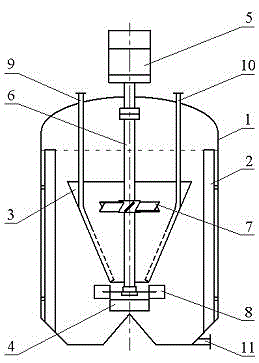

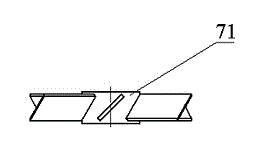

Multi-mode stirring type co-precipitation precipitation device for rare earth

ActiveCN109126669AVarious mixing methodsEasy to operateChemical/physical/physico-chemical stationary reactorsProcess efficiency improvementRare earthUltimate tensile strength

The invention relates to a co-precipitation precipitation device for rare earth, in particular to a multi-mode stirring type co-precipitation precipitation device for the rare earth. To solve the technical problem of providing the multi-mode stirring type co-precipitation precipitation device, capable of being adjusted and stirring rare earth mixture liquid in various ways, for the rare earth, thetechnical scheme of the multi-mode stirring type co-precipitation precipitation device for the rare earth is that the multi-mode stirring type co-precipitation precipitation device for the rare earthcomprises various parts such as a base, a first bearing, a support shaft, a cylinder, a drain pipe, a first valve, a filter screen, a discharge pipe, a second valve, a second bearing and long connecting shaft; the first bearing is embedded in the base; the lower end of the support shaft and the first bearing are in interference connection. The multi-mode stirring type co-precipitation precipitation device for the rare earth has the advantages of being easy to adjust and capable of stirring the rare earth mixture liquid in various ways, realizing uniform mixing reaction of the rare earth mixture liquid, having simple structure, easy operation and low labor intensity, and being time-saving and labor-saving.

Owner:东港智科产业园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com