Preparation method of cerium carbonate and cerium oxide

一种碳酸铈、氧化铈的技术,应用在碳酸盐/酸式碳酸盐的制备、氧化铈/氢氧化铈、稀土金属化合物的制备/处理等方向,能够解决存在危险性、收益率或生产率差、碳酸铈粒径均匀性不够充分等问题,达到高收益率、高生产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

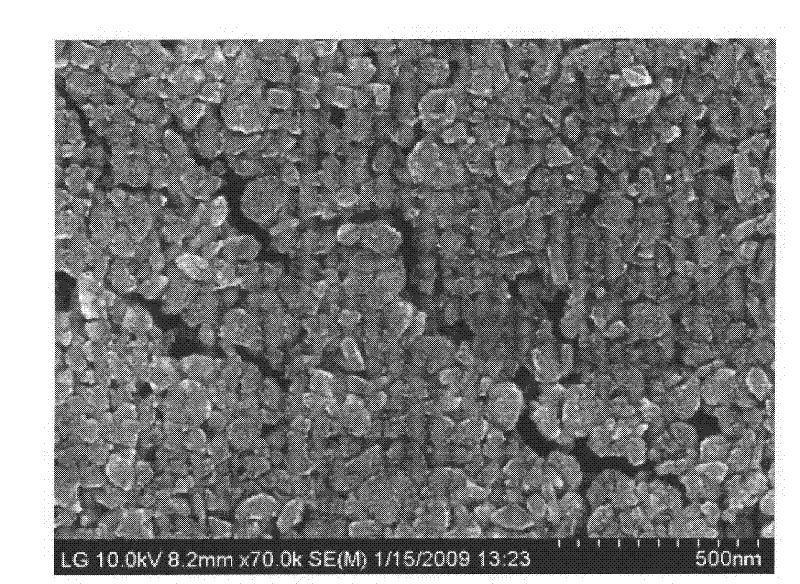

[0070] The shape and crystal structure of cerium carbonate were confirmed by electron micrographs and X-ray diffraction analysis, and the electron micrographs are shown in figure 1 .

[0071] like figure 1 As shown by the XRD analysis results of the cerium carbonate obtained in Example 1, the cerium carbonate in Example 1 has a uniform particle size and only contains cerium carbonate with a hexagonal crystal structure (100% by volume).

[0072] Example 2

Embodiment 2

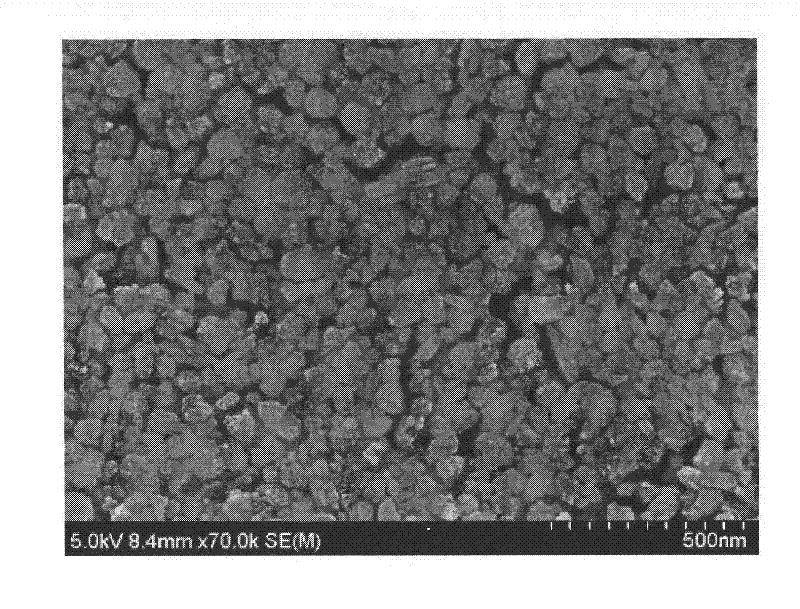

[0074] The shape and crystal structure of cerium carbonate were confirmed by electron micrographs and X-ray diffraction analysis, and the electron micrographs are shown in figure 2 .

[0075] like figure 2 As shown, the cerium carbonate in Example 2 has a uniform particle size, and it can be seen from the X-ray diffraction spectrum that it only contains cerium carbonate with a hexagonal crystal structure (100% by volume).

[0076] Example 3

Embodiment 3

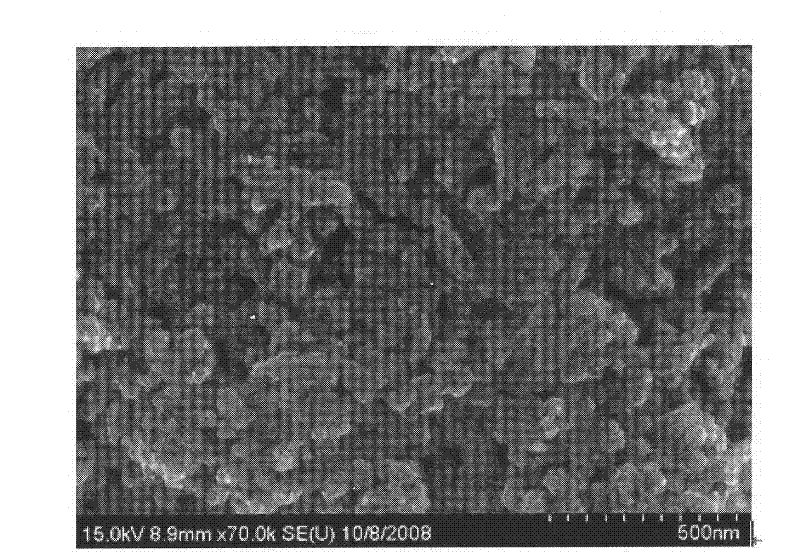

[0078] The shape and crystal structure of cerium carbonate were confirmed by electron micrographs and X-ray diffraction analysis, and the electron micrographs are shown in image 3 .

[0079] like image 3 As shown, the cerium carbonate in Example 3 has a uniform particle size, and it can be seen from the X-ray diffraction spectrum that it only contains cerium carbonate with a hexagonal crystal structure (100% by volume).

[0080] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com