Preparation method of oil-free rare earth carbonate

A rare-earth carbonate and rare-earth feed solution technology, which is applied in the direction of rare-earth metal compounds, rare-earth metal carbonates, chemical instruments and methods, etc., can solve the problems of non-recyclable extraction agents and non-recyclable oil removal materials, etc., and achieve low cost, The effect of high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

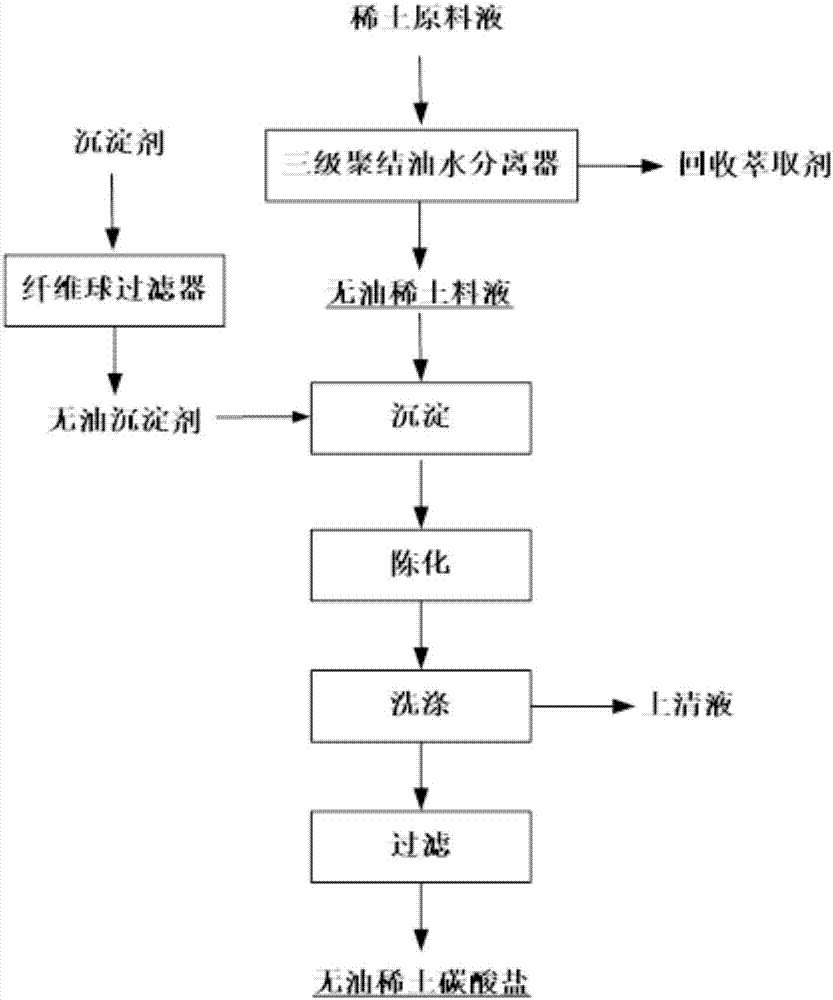

[0029] The preparation method of oil-free rare earth carbonate specifically comprises the following steps:

[0030] Step 1: degreasing the raw materials;

[0031] Step 11: degreasing the rare earth material liquid obtained by extraction and separation;

[0032] Pass the single or mixed rare earth feed liquid through the three-stage coalescing oil-water separator. The rare earth feed liquid includes: rare earth chloride feed liquid, rare earth nitrate feed liquid or rare earth sulfuric acid feed liquid, and the flow rate is controlled at 100L / h~200L / h to obtain Oil-free single or mixed rare earth feed liquid, and the extraction agent is recovered through the oil collection cup 11. The rare earth elements in the rare earth feed liquid include: one or more of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu.

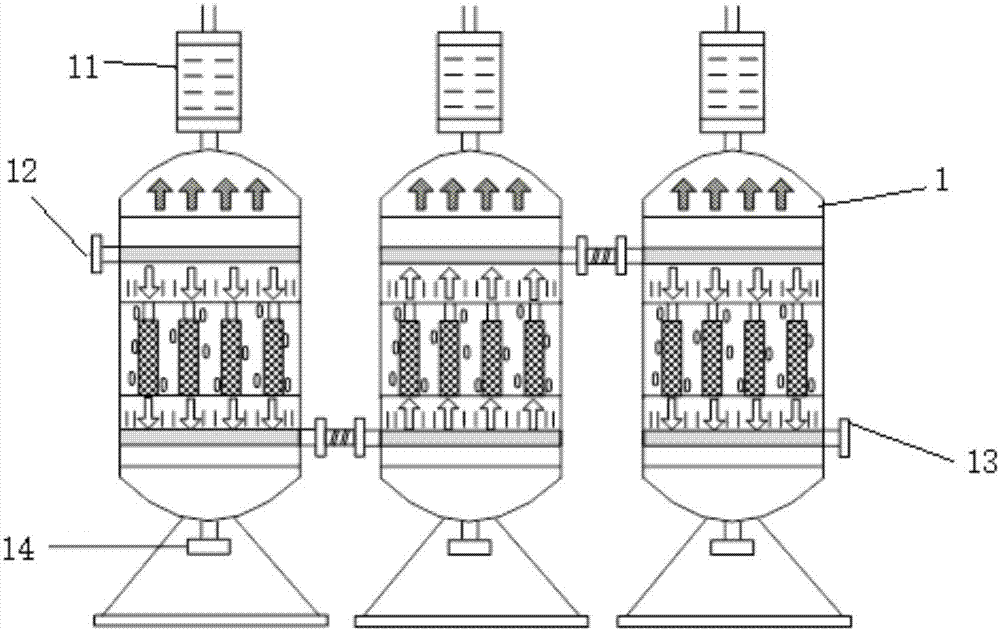

[0033] The three-stage coalescing oil-water separator includes three coalescing oil-water separator splits 1. The coalescing oil-water separator split 1 is provided...

Embodiment 1

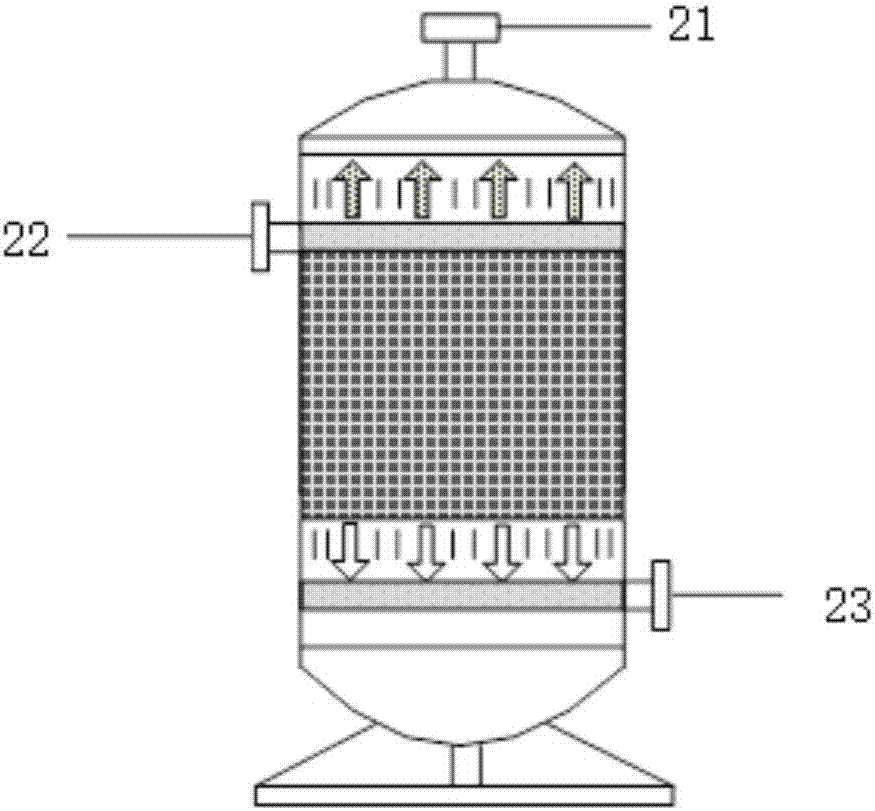

[0048] 1) Raw material treatment: Pass the lanthanum chloride feed liquid obtained by extraction and separation through a three-stage coalescing oil-water separator (the coalescence material is modified polyvinyl chloride), and the flow rate is controlled at 100L / h to obtain an oil-free lanthanum chloride feed liquid. And reclaim extractant by oil collecting cup; Add deionized water to dissolve precipitant ammonium bicarbonate again and become concentration and be 8% solution to pass fiber ball filter (fiber ball raw material is modified polyester), flow velocity is controlled at 15L / h, Obtain an oil-free ammonium bicarbonate solution;

[0049] 2) Precipitation: add the oil-free lanthanum chloride feed solution obtained in step (1) to the reaction kettle and raise the temperature to 30°C, add oil-free ammonium bicarbonate to it, and when the pH value of the reaction system is 6.7, an easily filterable crystal form is obtained Precipitation, the crystalline precipitate and the ...

Embodiment 2

[0053] 1) raw material treatment: the cerium chloride feed liquid obtained by extraction and separation is passed through a three-stage coalescing oil-water separator (the coalescence material is modified polyvinyl chloride), and the flow rate is controlled at 150L / h to obtain an oil-free cerium chloride feed liquid, And reclaim the extractant by the oil collecting cup; Add the precipitating agent ammonium bicarbonate and deionized water and dissolve into a concentration of 10% solution to pass through the fiber ball filter (the fiber ball raw material is modified polyester), and the flow rate is controlled at 16L / h. Obtain an oil-free ammonium bicarbonate solution;

[0054] 2) Precipitation: Add the oil-free cerium chloride feed solution obtained in step (1) to the reaction kettle and raise the temperature to 50°C, add oil-free ammonium bicarbonate to it, and when the pH value of the reaction system is 7.0, an easily filterable crystal form is obtained Precipitation, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com