Precipitation apparatus convenient to clean and used for precipitation of rare-earth ore

A sedimentation device and a convenient cleaning technology, applied in the direction of rare earth metal carbonates, rare earth metal compounds, chemical instruments and methods, etc., can solve the problems of material liquid impurities sticking to the inner wall and difficult to clean, and achieve easy maintenance and repair, Easy to remove, uniquely structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

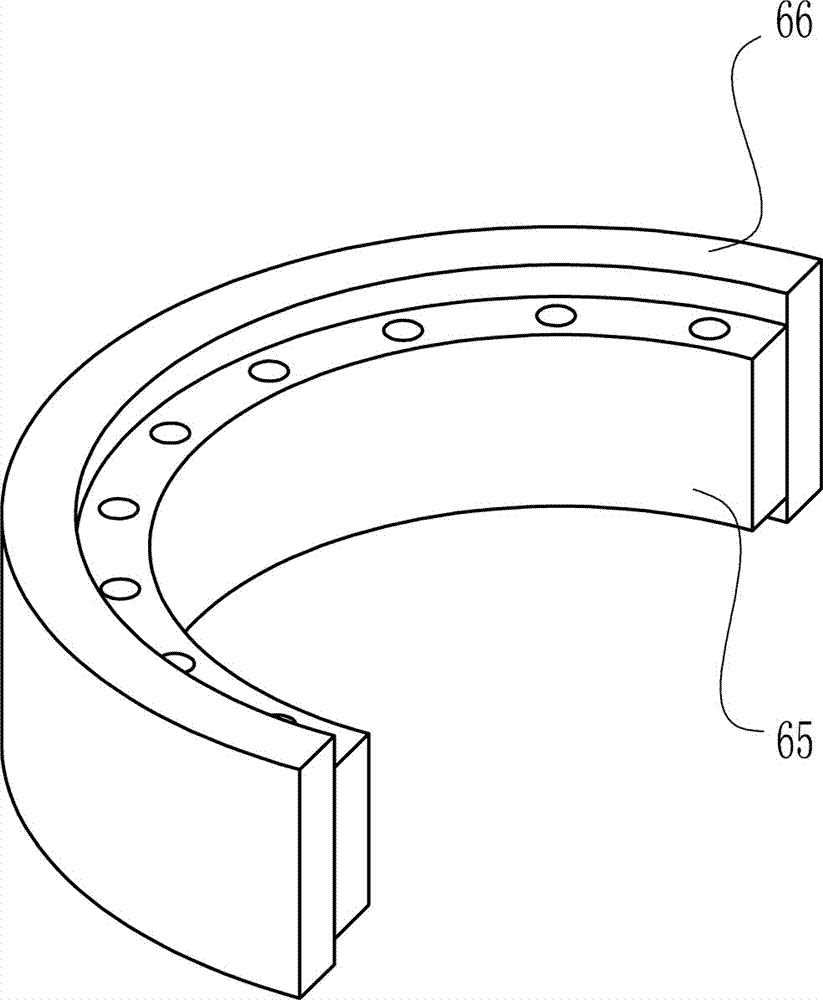

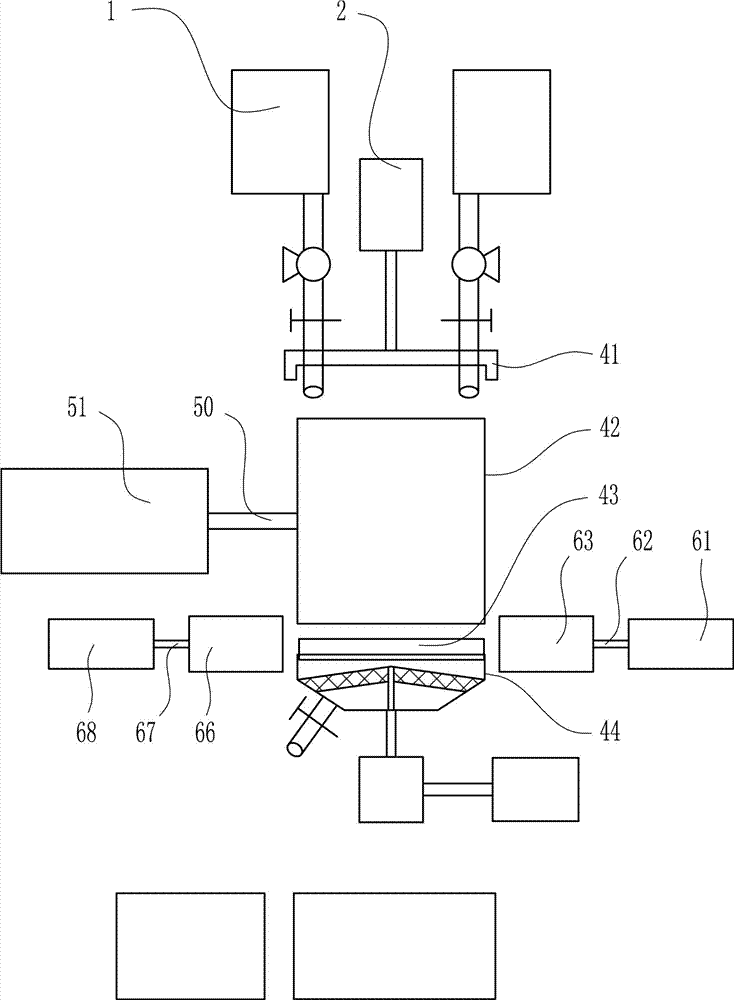

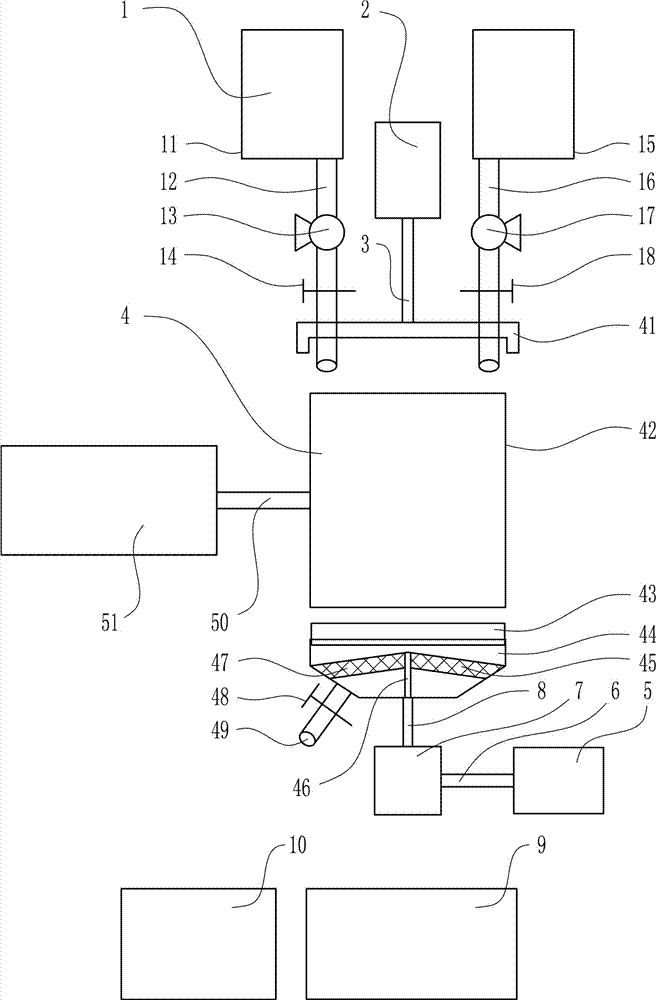

[0029] A convenient cleaning type precipitation device for rare earth ore precipitation, such as Figure 1-5 As shown, it includes feeding liquid device 1, upper and lower cylinder I2, upper and lower telescopic rod I3, split sedimentation device 4, motor I5, rotating shaft I6, upper and lower cylinder II7, upper and lower telescopic rod II8, material receiving cylinder 9 and liquid receiving cylinder 10 ;The upper and lower telescopic rods I3 are arranged below the upper and lower cylinders I2, the upper and lower telescopic rods I3 are connected with the upper and lower cylinders I2, and the split sedimentation device 4 is arranged below the upper and lower telescopic rods I3, and the split sedimentation device 4 is set in the feeding liquid device 1, a motor I5 is set on the lower right of the split sedimentation device 4, a rotating shaft I6 is set on the left side of the motor I5, the rotating shaft I6 is connected with the motor I5, and an upper and lower air cylinder is ...

Embodiment 2

[0031] A convenient cleaning type precipitation device for rare earth ore precipitation, such as Figure 1-5 As shown, it includes feeding liquid device 1, upper and lower cylinder I2, upper and lower telescopic rod I3, split sedimentation device 4, motor I5, rotating shaft I6, upper and lower cylinder II7, upper and lower telescopic rod II8, material receiving cylinder 9 and liquid receiving cylinder 10 ;The upper and lower telescopic rods I3 are arranged below the upper and lower cylinders I2, the upper and lower telescopic rods I3 are connected with the upper and lower cylinders I2, and the split sedimentation device 4 is arranged below the upper and lower telescopic rods I3, and the split sedimentation device 4 is set in the feeding liquid device 1, a motor I5 is set on the lower right of the split sedimentation device 4, a rotating shaft I6 is set on the left side of the motor I5, the rotating shaft I6 is connected with the motor I5, and an upper and lower air cylinder is ...

Embodiment 3

[0034] A convenient cleaning type precipitation device for rare earth ore precipitation, such as Figure 1-5 As shown, it includes feeding liquid device 1, upper and lower cylinder I2, upper and lower telescopic rod I3, split sedimentation device 4, motor I5, rotating shaft I6, upper and lower cylinder II7, upper and lower telescopic rod II8, material receiving cylinder 9 and liquid receiving cylinder 10 ;The upper and lower telescopic rods I3 are arranged below the upper and lower cylinders I2, the upper and lower telescopic rods I3 are connected with the upper and lower cylinders I2, and the split sedimentation device 4 is arranged below the upper and lower telescopic rods I3, and the split sedimentation device 4 is set in the feeding liquid device 1, a motor I5 is set on the lower right of the split sedimentation device 4, a rotating shaft I6 is set on the left side of the motor I5, the rotating shaft I6 is connected with the motor I5, and an upper and lower air cylinder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com