Full-automatic fluid pressure and four sides rotating panel binding apparatus

A fully automatic and jigsaw technology, which is applied in the direction of wood compression, etc., can solve the problems of lack of safe operation device, poor reliability of manual operation, and inability to calculate and control, etc., to reduce labor intensity of workers, reduce friction power and glue cleaning time , Safe, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

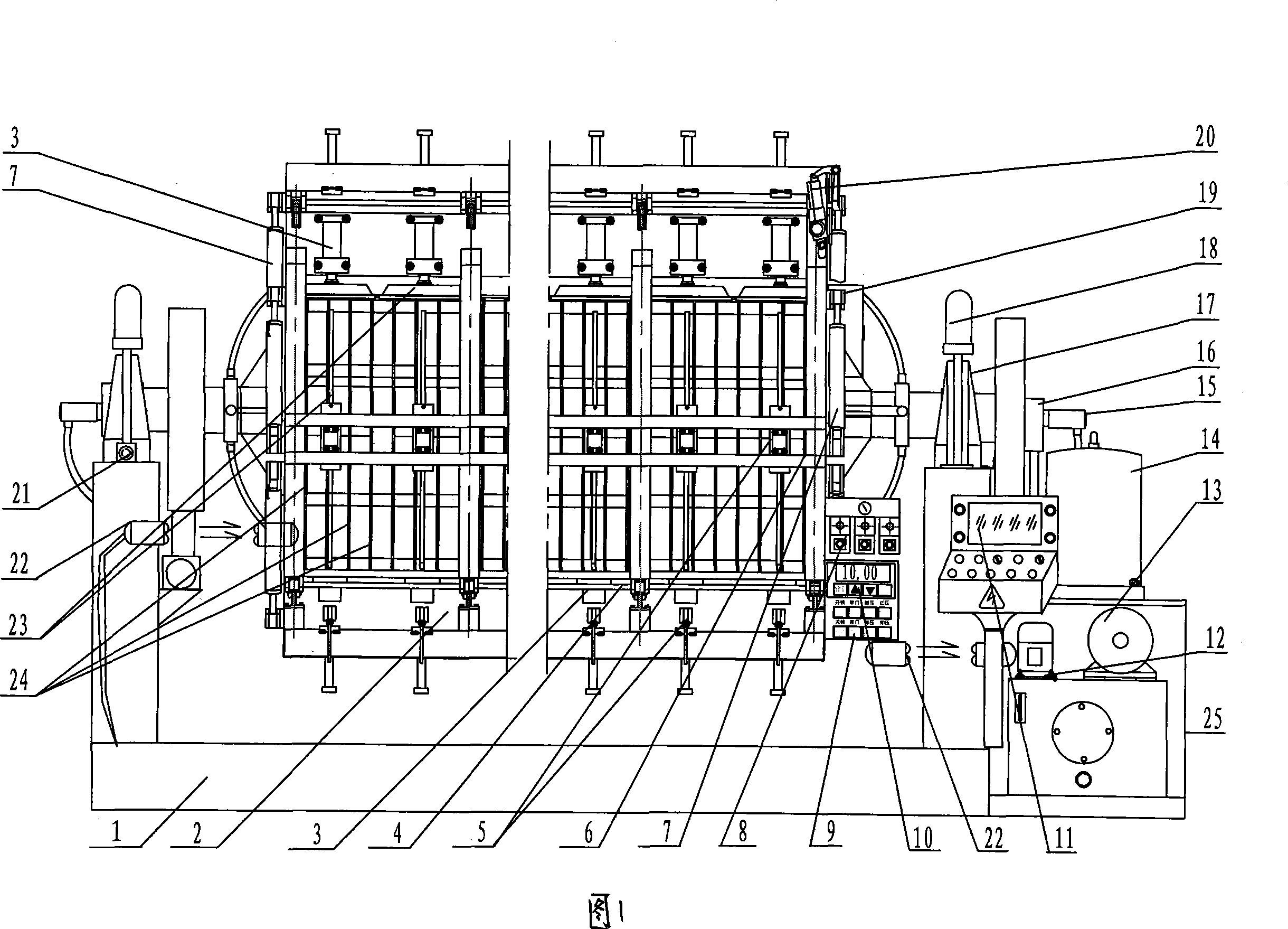

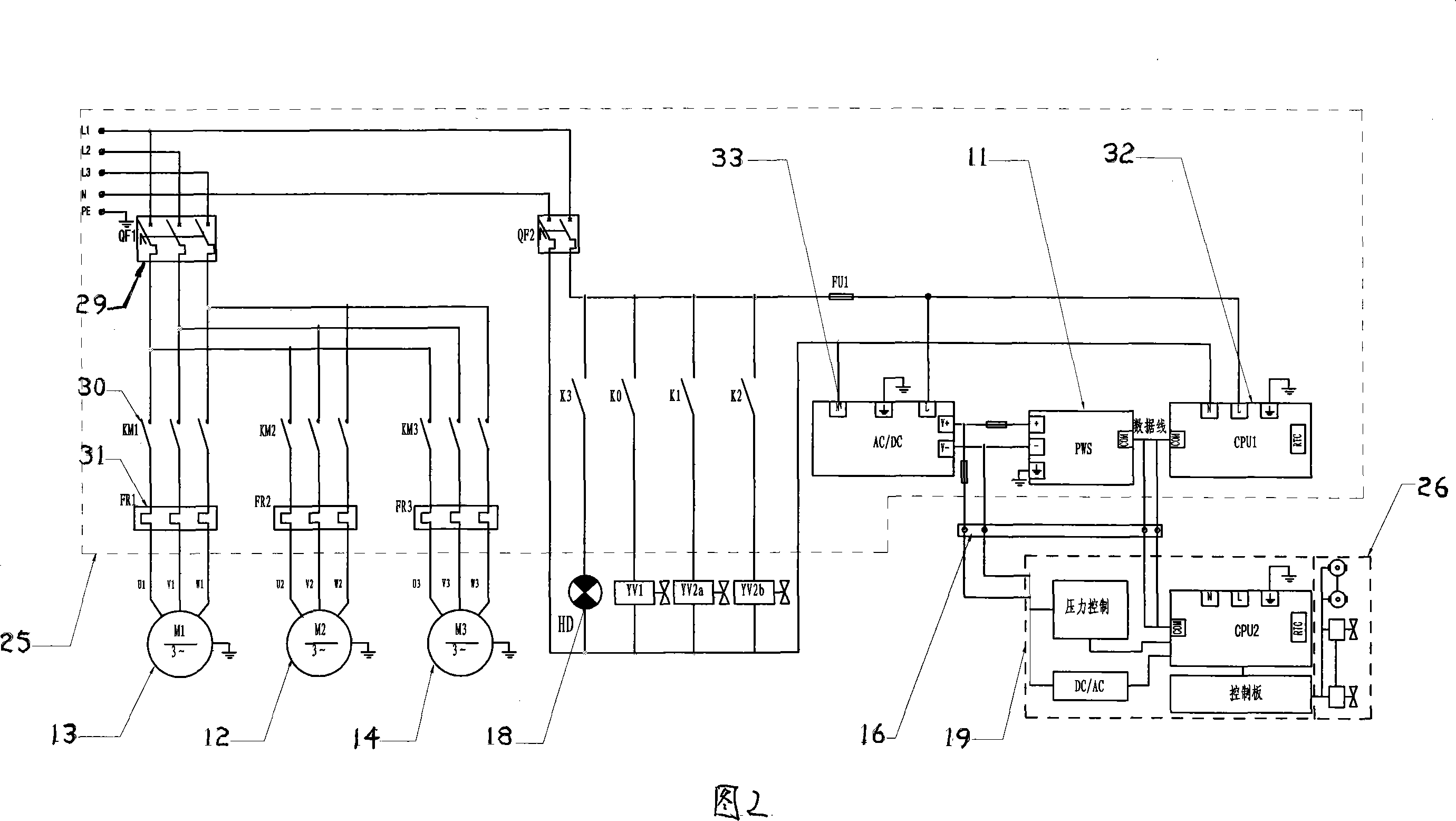

[0010] For better understanding and implementation, specific embodiments are given below in conjunction with the accompanying drawings to describe the present invention in detail. Embodiment 1, see Fig. 1, 2, 3, 4, 5, process and make frame 1, assemble four-sided rotary workbench 2 into four completely identical faces mutually 90°, install positive pressure oil cylinder 3 on the top of each face , the side pressure oil cylinder 5 is installed on the side, the positive pressure oil cylinders 3 are connected through the positive pressure oil cylinder oil pipe 4, and the side pressure oil cylinders 5 are connected through the side pressure oil cylinder oil pipe 6, and each side is equipped with a pressure frame door, a pressure frame door A rotating shaft is installed on the rotating shaft, and a side lifting door oil cylinder and an oil pipe 7 and an electric switch door lock actuator 20 are installed on the rotating shaft, which are used for loading and unloading after the autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com