Preparation method for cerium oxide crystal and application thereof in chemical mechanical polishing (CMP)

A technology of cerium oxide and crystal, which is applied in the field of preparation of cerium oxide crystal to achieve the effect of high TEOS polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

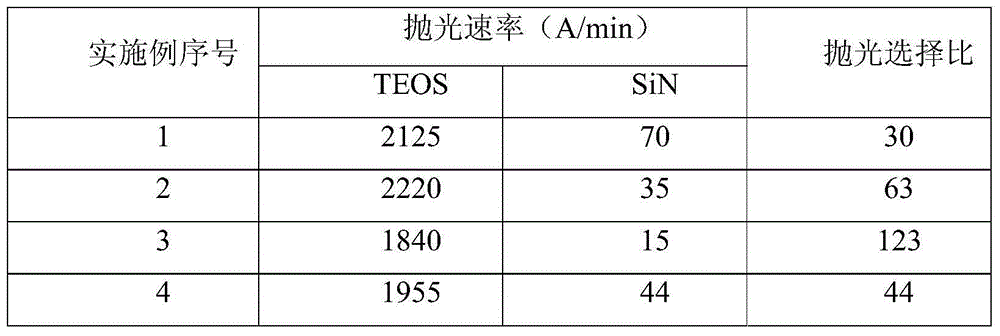

Examples

Embodiment 1

[0021] At room temperature, first dissolve 0.05mol of PVP (the average molecular weight is 10000) in 1L of deionized water, weigh 0.05mol of cerium nitrate and dissolve it in the above-mentioned PVP aqueous solution, and add a concentration of 0.05M ammonia water to the above-mentioned mixed solution under stirring conditions, Obtain the precipitated turbid solution, the temperature of the precipitation reaction process is 20°C; the precipitation end point is controlled by detecting the pH value of the turbid solution, and when the pH of the precipitate reaches 8.5, stop adding ammonia water and continue stirring for 30 minutes; heat the above precipitation mixture to 100°C, Add carbon dioxide gas by bubbling into the precipitation mixed solution, and stir the mixed solution at the same time. When the pH of the mixed solution reaches 6.5, stop bubbling, continue to heat and stir for 10 hours for hydrothermal crystallization reaction, and wash the obtained precipitate 3 times wit...

Embodiment 2

[0023] At room temperature, first dissolve 0.1 mol of PVA (average molecular weight of 1000) in 1 L of deionized water, weigh 1.0 mol of cerium acetate and dissolve them in the above PVA aqueous solution, and add ammonia water with a concentration of 1.0 M to the above mixed solution under stirring conditions. , to obtain a precipitated turbid solution, the temperature of the precipitation reaction process is 60°C; the precipitation end point is controlled by detecting the pH value of the turbid solution, and when the pH of the precipitate reaches 12.0, stop adding ammonia water and continue stirring for 30 minutes; heat the above precipitation mixture to 80°C , and add carbon dioxide gas by bubbling into the precipitation mixed solution, and stir the mixed solution at the same time. When the pH of the mixed solution reaches 8.5, stop bubbling, continue to insulate and stir for 10 hours for hydrothermal crystallization reaction, and the resulting precipitate is washed with pure ...

Embodiment 3

[0025] At room temperature, first dissolve 0.25mol PEG (average molecular weight 3000) in 1L deionized water, weigh 0.5mol cerium acetate and dissolve it in the above PEG aqueous solution, and add 0.5M sodium hydroxide to the above mixed solution under stirring , to obtain a precipitated turbid solution, the temperature of the precipitation reaction process is 30 °C; the precipitation end point is controlled by detecting the pH value of the turbid solution, and when the pH of the precipitation reaches 9.5, stop adding the sodium hydroxide solution and continue stirring for 30 minutes; heat the above precipitation mixture to 100°C, and add carbon dioxide gas into the precipitation mixed solution by bubbling, and stir the mixed solution at the same time. When the pH of the mixed solution reaches 7.0, stop bubbling, continue to keep warm and stir for 6.5 hours for hydrothermal crystallization reaction, and the obtained precipitate is purified After washing with water for 3 times, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com