Silica sol with double grain diameters and preparation method thereof

A silicon dioxide, double particle size technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of micro-defects on the polished surface, and achieve the effect of simple method, improved polishing rate, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

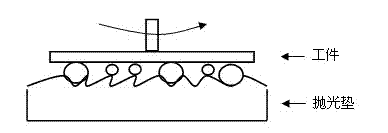

Method used

Image

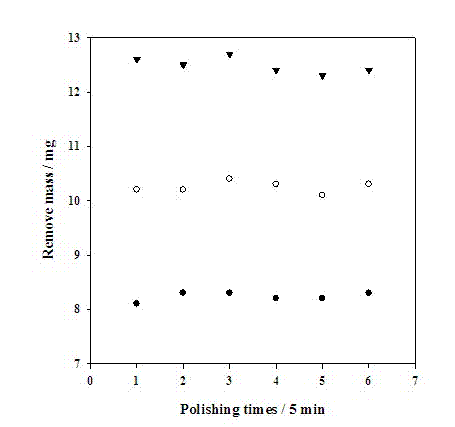

Examples

Embodiment 1

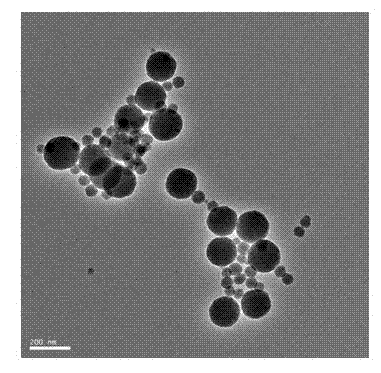

[0030] Alkaline silica sol with a particle size of 80 nm is used as the raw material, the specific gravity is 1.16, diluted with 20 times the volume of distilled water, and the mass fraction is 10% sodium hydroxide as the catalyst. Constant, the stirring speed is 300 revolutions per minute, after the reaction time reaches 40 h, the pH is distilled under reduced pressure to reach 1.3, and the stirring is stopped after 2 hours of heat preservation to obtain a double particle size silica sol. From figure 2 It can be seen that the supported silica sol has two particle sizes, and it is a double particle size silica sol.

[0031] The basic parameters of the double particle size silica sol obtained by the reaction are shown in Table 1 (the percentage in brackets is the proportion of the number of particles):

[0032] Table 1

[0033] Test items Test Results testing method pH value 9.7 pH acidity meter Silica specific gravity 1.3 Hydrometer viscos...

Embodiment 2

[0035] Alkaline silica sol with a particle size of 80 nm is used as the raw material, and the specific gravity is 1.16. It is diluted with 10 times the volume of distilled water, and the mass fraction is 10% sodium hydroxide as the catalyst. Constant, the stirring speed is 300 rpm, the reaction time is 30 hours, and then the pH is distilled under reduced pressure to reach 1.3, and the stirring is stopped after 2 hours of heat preservation to obtain a double particle size silica sol.

[0036] The basic parameters of the double particle size silica sol obtained by the reaction are shown in Table 2 (the percentage in parentheses is the proportion of the number of particles):

[0037] Table 2

[0038] Test items Test Results testing method pH value 9.8 pH acidity meter Silica concentration 1.31 Hydrometer viscosity 3.8 mPa s Viscometer a particle size range 70 nm (about 30%) TEM Two particle size range 190 nm (about 70%) TEM...

Embodiment 3

[0040] Alkaline silica sol with a particle size of 80 nm is used as the raw material, the specific gravity is 1.16, diluted with 20 times the volume of distilled water, and the mass fraction is 10% sodium hydroxide as the catalyst. Constant, the stirring speed is 300 revolutions per minute, after the reaction time reaches 35 h, the pH is distilled under reduced pressure to reach 1.3, and the stirring is stopped after 2 hours of heat preservation to obtain a double particle size silica sol.

[0041] The basic parameters of the double particle size silica sol obtained by the reaction are shown in Table 3 (the percentage in brackets is the proportion of the number of particles):

[0042] table 3

[0043] Test items Test Results testing method pH value 9.8 pH acidity meter Silica concentration 1.31 Hydrometer viscosity 3.7 mPa s Viscometer a particle size range 75 nm (approximately 25%) TEM Two particle size range 180 nm (abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com