Nano-dephosphorizer, preparation method and application of same

A phosphorus removal agent, nano technology, applied in the direction of nano technology, nano technology, chemical instruments and methods, etc., to achieve the effect of fast adsorption rate, good selectivity and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

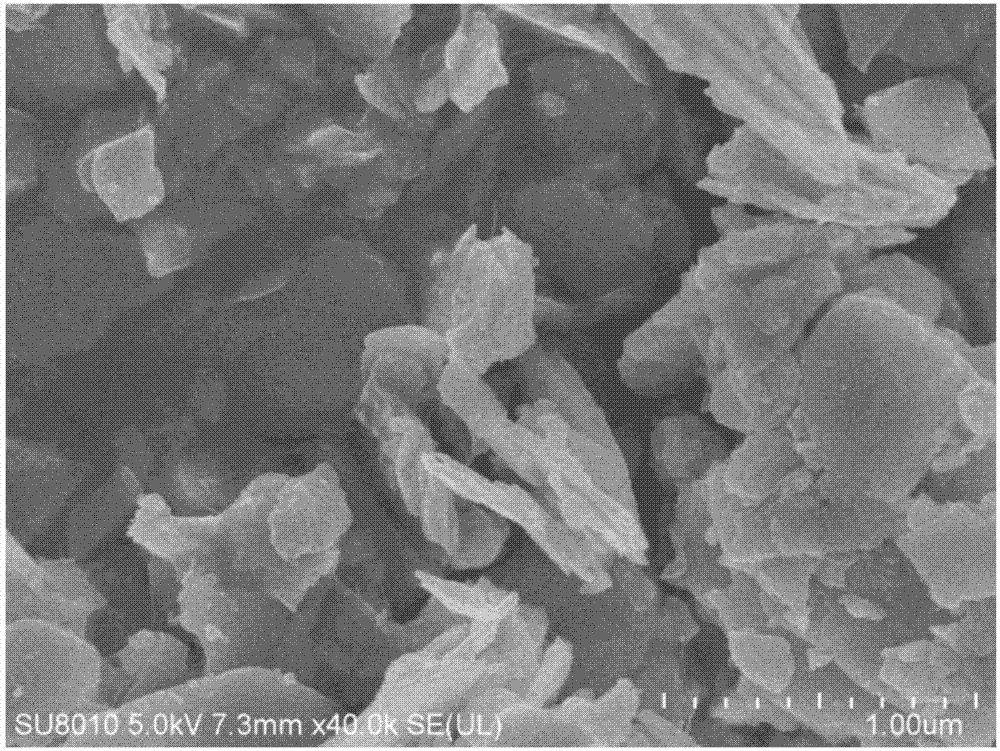

[0038] At 200mM La(NO 3 ) 3Add 10 g of 1-butyl-3-methylimidazolium tetrafluoroborate (bmimBF 4 ) ionic liquid, keep the system temperature at 20°C, add 100mL of 0.5mol / L NaHCO dropwise to the solution under rapid stirring 3 solution, adjust the pH of the reaction to 8, react continuously for 2 hours, and then stand at room temperature for 12 hours. Separated by filtration under reduced pressure, washed with distilled water and ethanol for 3 times, dried at 60°C, and ground to obtain the nano-phosphorus removal agent lanthanum carbonate hydrate, and its scanning electron microscope (SEM) is as follows: figure 1 As shown, it can be seen from the SEM spectrum that the prepared lanthanum carbonate sample has an irregular sheet-like structure, and the particle size ranges from tens to hundreds of nanometers.

Embodiment 2

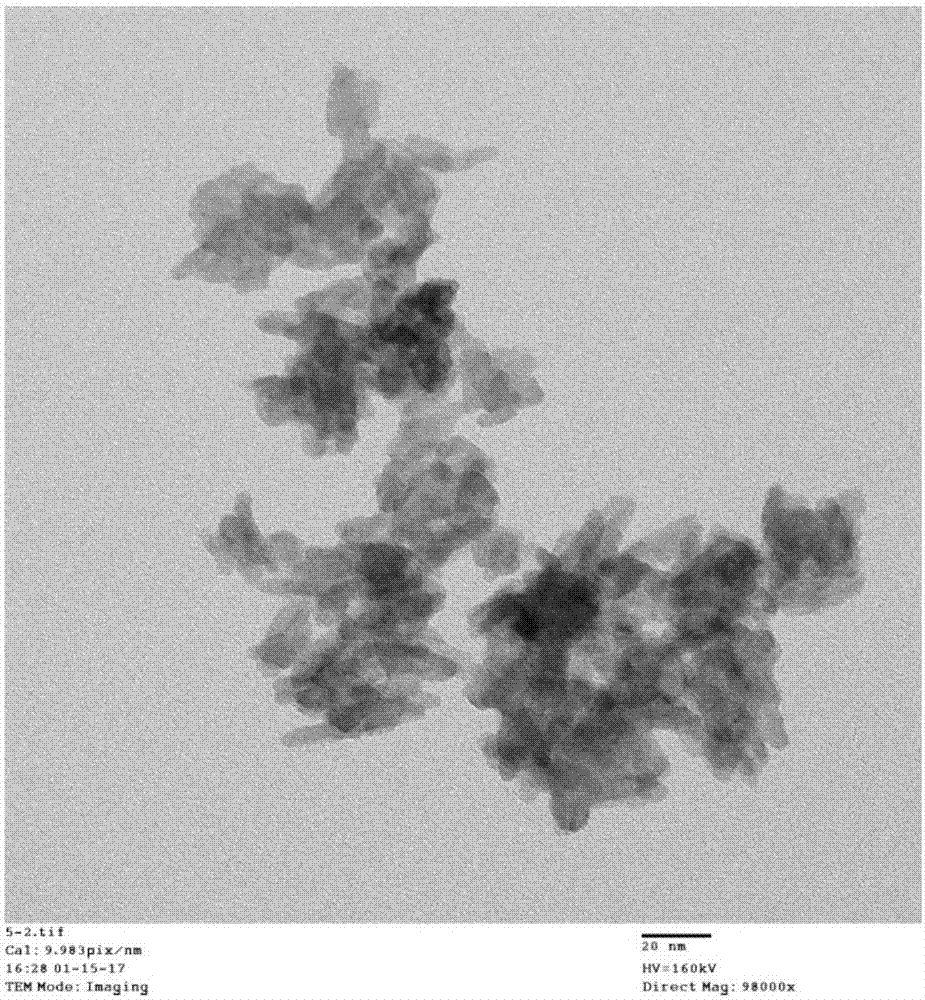

[0040] in 50mM LaCl 3 ·7H 2 Add 5g bmimBF to 800mL aqueous solution of O 4 , keep the system temperature at 30°C, add 200mL of 1mol / L Na 2 CO 3 solution, adjust the pH of the reaction to 10, react continuously for 2 hours, and then stand at room temperature for 12 hours. Separated by filtration under reduced pressure, washed with distilled water and ethanol for 3 times, dried at 60°C, and ground to obtain the nano-phosphorus removal agent lanthanum carbonate hydrate, and its transmission electron microscope (TEM) is as follows: figure 2 As shown, it can be seen from the TEM spectrum that the average particle size of lanthanum carbonate hydrate is less than 10 nanometers, and the shape is a mixed particle of rod type + sheet type.

Embodiment 3

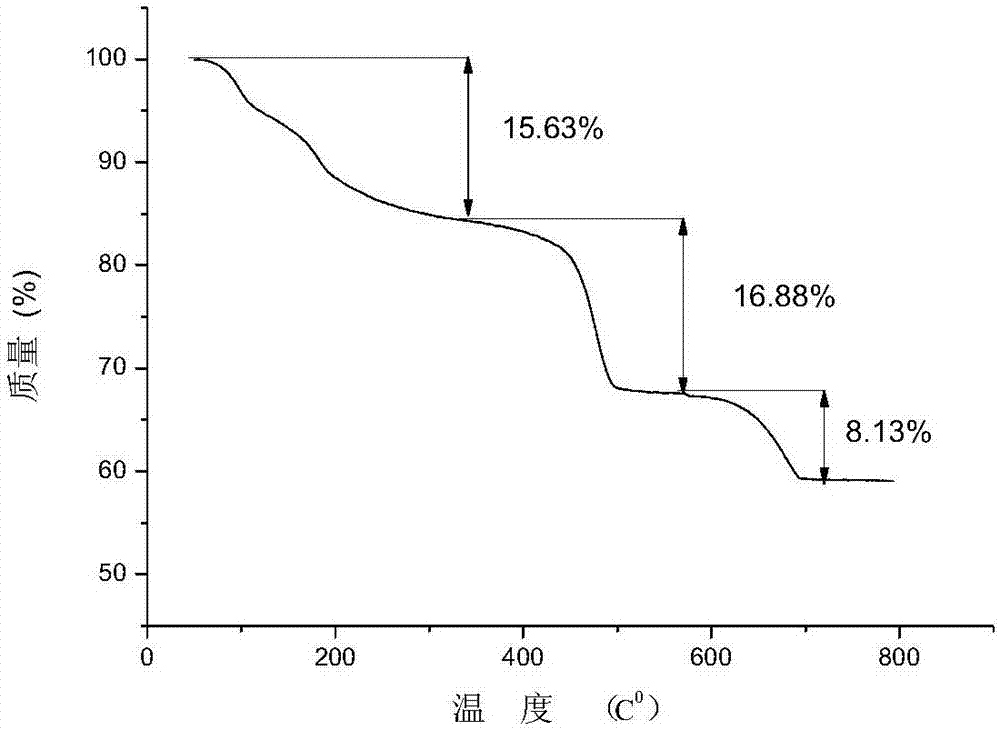

[0042] at 50mM La 2 (AC) 3 Add 2g bmimBF to 100mL aqueous solution 4 , keep the system temperature at 40°C, add 100mL of 0.1mol / L NaHCO dropwise to the solution under rapid stirring 3 solution, adjust the pH of the reaction to 7, continue to react for 1 h, and then stand at room temperature for 2 h. Separated by filtration under reduced pressure, washed with distilled water and ethanol for 3 times, dried at 35°C, and ground to obtain the nano-phosphorus removal agent lanthanum carbonate hydrate. Its thermogravimetric analysis (TGA) is as follows: image 3 As shown, from the TGA spectrum, it can be seen that the prepared lanthanum carbonate sample has three stages of weight loss on heating, which is consistent with La 2 (CO 3 ) 3 ·8H 2 O thermal decomposition process, so the nano phosphorus removal agent lanthanum carbonate hydrate prepared in this embodiment should be La 2 (CO 3 ) 3 ·8H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Maximum saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com