Hollow octahedral NaP molecular sieve and preparation method thereof

A technology of octahedral molecular sieve and molecular sieve, which is applied in the field of hollow octahedral NaP molecular sieve and its one-step preparation method, which can solve the problems of limited application and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Add idle or discarded molecular sieves to the mixture of sodium hydroxide and distilled water, and stir at room temperature for 0.5 hours. Among them idle or waste molecular sieve is MCM-22, [Na 2 O] / [H 2 O]=0.12, wt% (MCM-22)=0.06, the silicon-aluminum ratio of MCM-22 molecular sieve is 12. The second step: transfer the mixture obtained in the first step to a high-pressure reactor, put it into a homogeneous reactor, and carry out alkali heat treatment for 12 hours under the conditions of controlling 170 ° C and a rotating speed of 15 r / min. After the crystallization is completed, it is filtered, Washing, drying and calcining directly obtain hollow octahedral NaP molecular sieves.

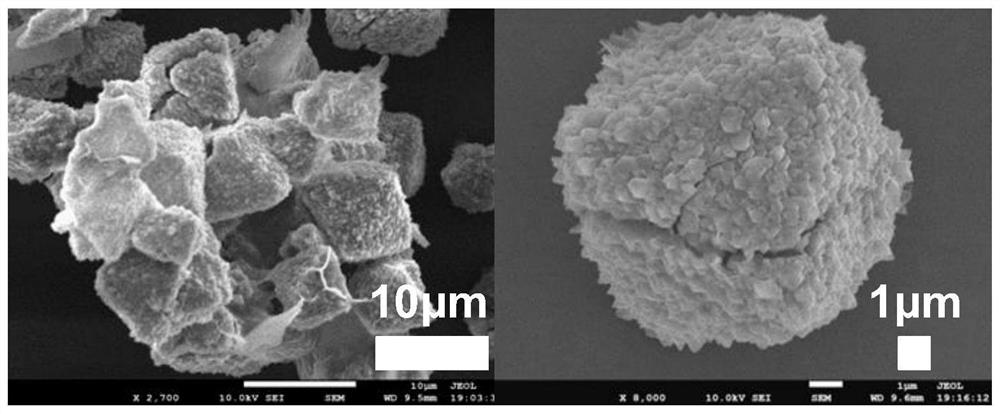

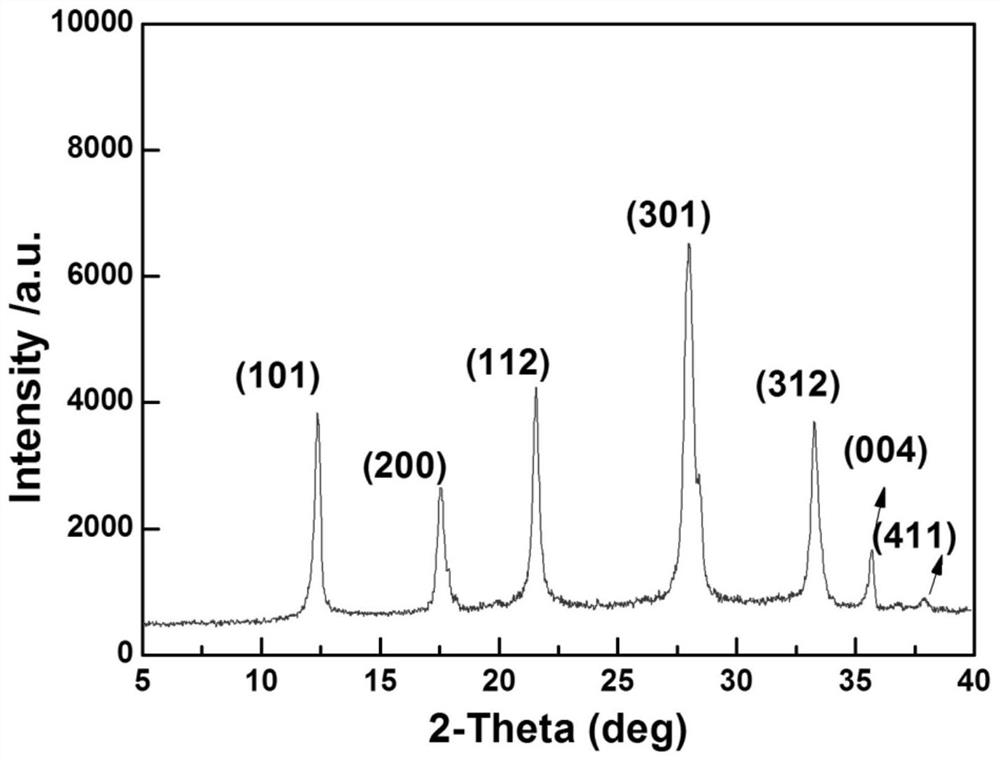

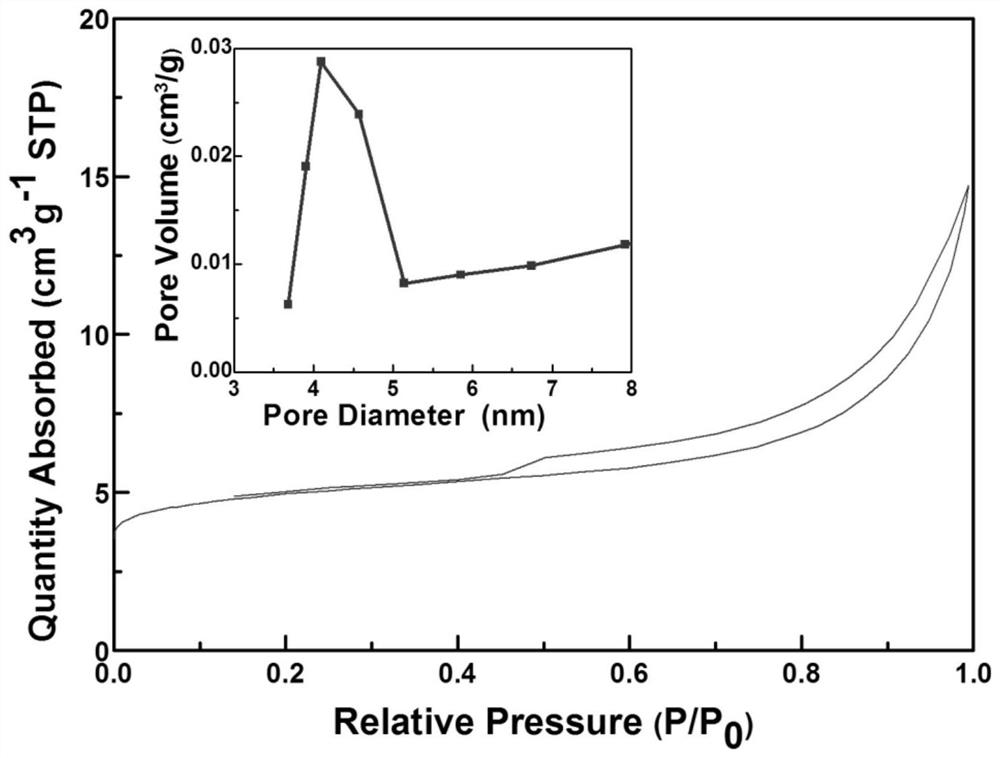

[0032] The scanning electron microscope and transmission electron microscope photos of the hollow octahedral NaP molecular sieve are as follows: figure 1 As shown, the catalyst is a hollow octahedral molecular sieve (4-6 μm) formed by stacking sheet-like NaP molecular sieves (300...

Embodiment 2

[0034] Step 1: Add idle or discarded molecular sieves to the mixture of sodium hydroxide and distilled water, and stir at room temperature for 0.5 hours. Among them idle or waste molecular sieve is MCM-22, [Na 2 O] / [H 2 O]=0.15, wt% (MCM-22)=0.06, the silicon-aluminum ratio of MCM-22 molecular sieve is 20. The second step: transfer the mixture obtained in the first step to a high-pressure reactor, put it into a homogeneous reactor, and carry out alkali heat treatment for 12 hours under the conditions of controlling 170 ° C and a rotating speed of 15 r / min. After the crystallization is completed, it is filtered, Washing, drying and calcining directly obtain hollow octahedral NaP molecular sieves. The scanning electron micrograph of the obtained product is as Figure 4 As shown, similar to the morphology of the product prepared in Example 1, it is a hollow octahedral NaP molecular sieve.

Embodiment 3

[0036] Step 1: Add idle or discarded molecular sieves to the mixture of sodium hydroxide and distilled water, and stir at room temperature for 0.5 hours. Among them idle or waste molecular sieve is MCM-22, [Na 2 O] / [H 2 O]=0.18, wt% (MCM-22)=0.06, the silicon-aluminum ratio of MCM-22 molecular sieve is 25. The second step: transfer the mixture obtained in the first step to a high-pressure reactor, put it into a homogeneous reactor, and carry out alkali heat treatment for 12 hours under the conditions of controlling 170 ° C and a rotating speed of 15 r / min. After the crystallization is completed, it is filtered, Washing, drying and calcining directly obtain hollow octahedral NaP molecular sieves. The scanning electron micrograph of the obtained product is as Figure 5 As shown, similar to the morphology of the product prepared in Example 1, it is a hollow octahedral NaP molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com