A simultaneous desulfurization, denitrification and mercury removal device

A desulfurization and denitrification, gas cylinder technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., to achieve good discharge conditions, convenient and practical pipeline design, stable and reliable experimental system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

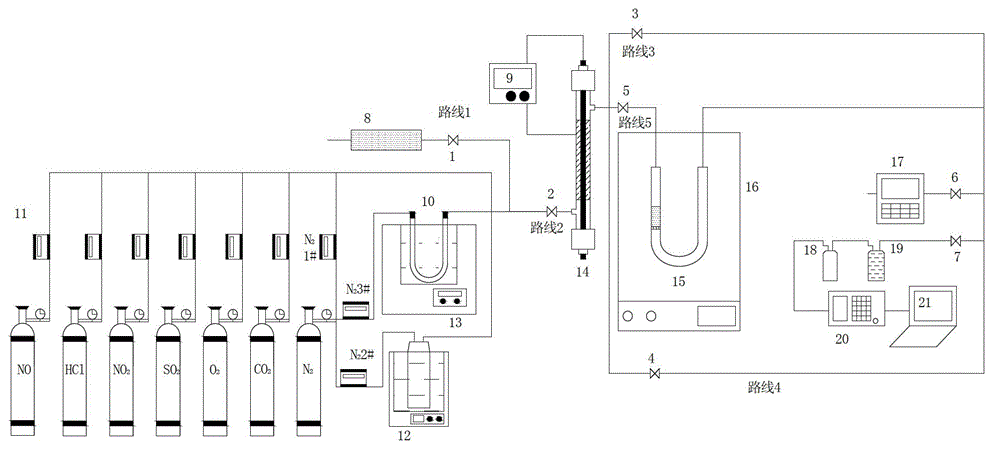

[0021] 1. Press figure 1 All components are assembled into a complete simultaneous desulfurization, denitrification and mercury removal device. The main body of the pipeline is made of ultra-low adsorption D8×6 polytetrafluoroethylene tube. A short section of D6×9 silicone tube can be flexibly connected between any two interfaces. The tail gas treatment device is a powdered activated carbon adsorption column 8, whose function is to adsorb trace amounts of gas-phase mercury present in the gas flow. The solutions used in this system are all ready-to-use and ready-to-use.

[0022] 2. To produce simulated coal-fired flue gas containing typical concentration components (20μg / m at 140°C 3 Hg 0 , 13%CO 2 , 9% moisture, 500ppm NO, 5%O 2 , 500ppm SO 2 , 20ppm HCl, and 20ppm NO 2 ) as an example, the operation is as follows:

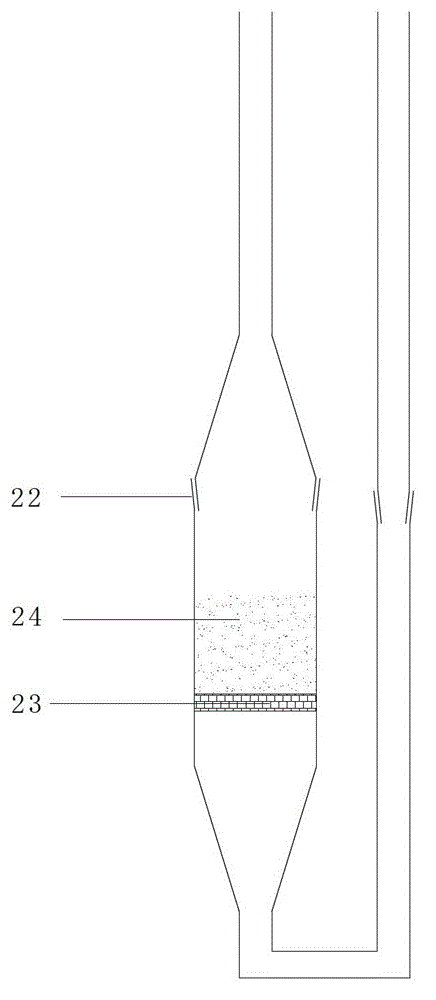

[0023] 2.1 will figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com