Method for acquiring isoparaffin from long-carbon-chain mixed n-alkanes and isoparaffin

A technology for isoparaffins and n-paraffins, applied in the field of high-purity long-carbon chain isoparaffins, can solve problems such as unsatisfactory effects, and achieve the effects of remarkable adsorption effect, low cost and large saturated adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

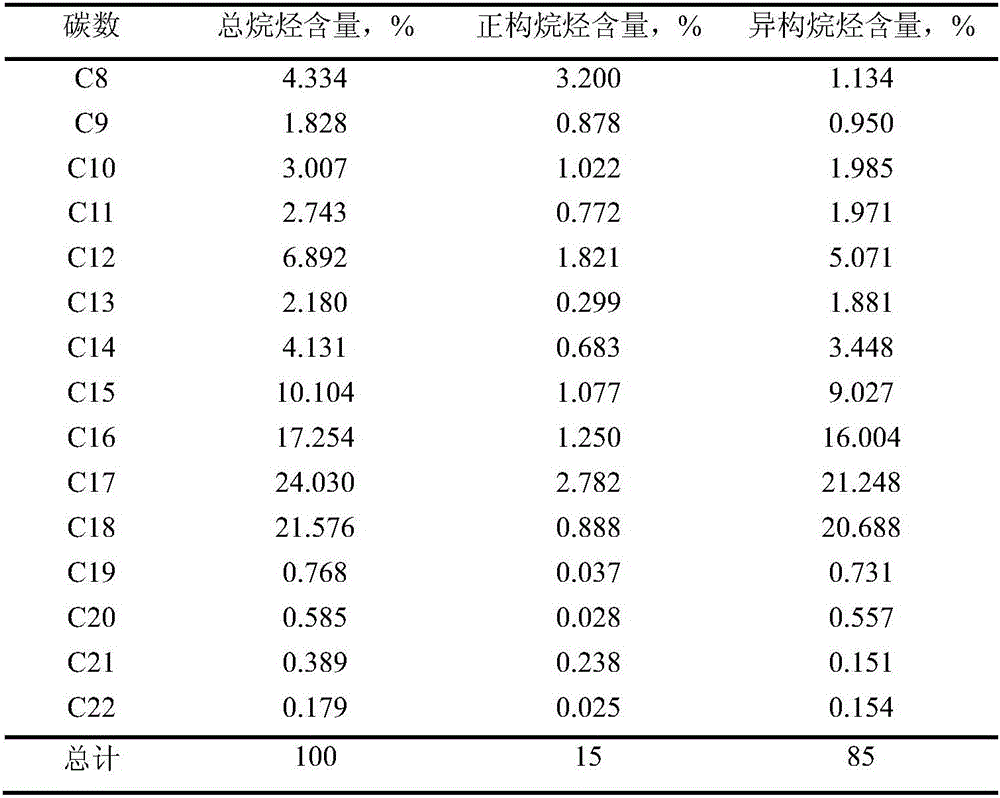

[0026] (1) Composition of raw material solution I

[0027] From the composition (table 1) of raw material liquid I, it can be seen that the mass content of normal paraffins with 8 to 22 carbon atoms is 15%, and the mass content of isoparaffins with 8 to 22 carbon atoms is 85%. %.

[0028] Table 1

[0029]

[0030] (2) Adsorption and separation process

[0031] The 100ml adsorption bed is divided into 3 adsorption separation zones, based on the volume of the adsorption bed, the volume percentages of the first adsorption separation zone, the second adsorption separation zone and the third adsorption separation zone are 5% and 80% respectively and 15%, first load 15ml of 13X molecular sieve in the third adsorption separation zone, then load 80ml of HY molecular sieve in the second adsorption separation zone, and finally load 5ml of 5A molecular sieve in the first adsorption separation zone.

[0032] After filling, when the adsorption temperature is 100°C, the pressure is 3M...

Embodiment 2

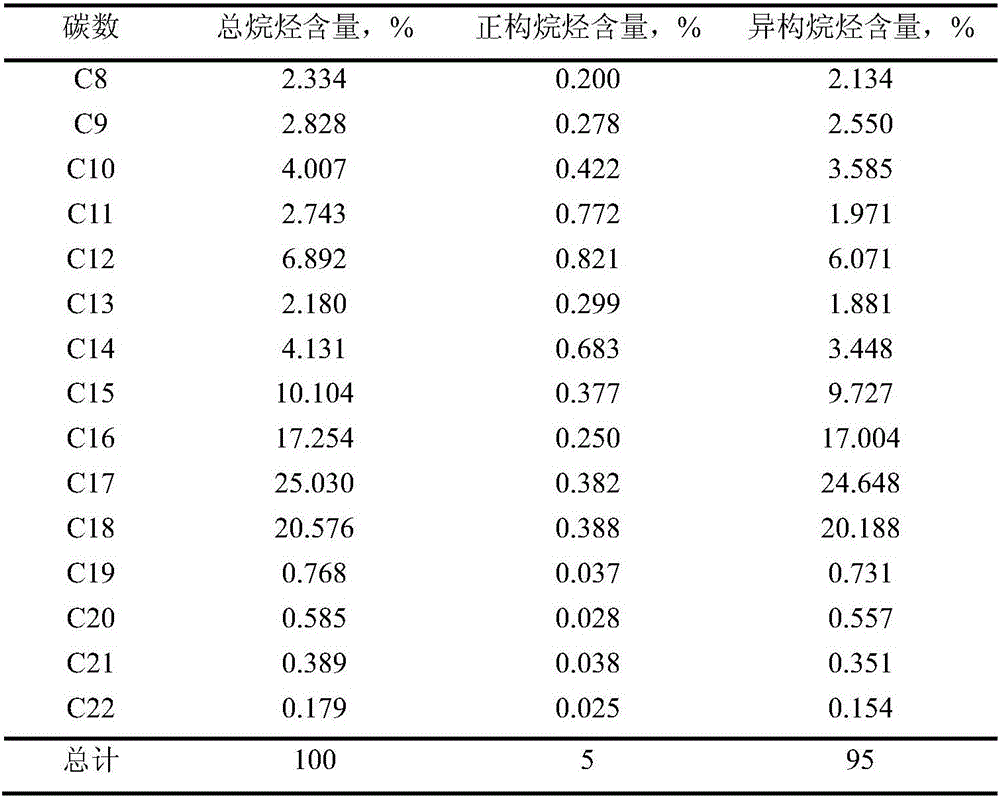

[0036] (1) Composition of raw material liquid II

[0037] From the composition (table 2) of raw material liquid II, it can be seen that the mass content of normal paraffins with 8 to 22 carbon atoms is 5%, and the mass content of isoparaffins with 8 to 22 carbon atoms is 95%. %.

[0038] Table 2

[0039]

[0040] (2) Adsorption and separation process

[0041] The 100ml adsorption bed is divided into 3 adsorption separation zones. Based on the volume of the adsorption bed, the volume percentages of the first adsorption separation zone, the second adsorption separation zone and the third adsorption separation zone are 25% and 50% respectively and 25%, first load 25ml of 13X molecular sieve in the third adsorption separation zone, then load 50ml of HY molecular sieve in the second adsorption separation zone, and finally load 25ml of 5A molecular sieve in the first adsorption separation zone.

[0042] After filling, when the adsorption temperature is 30°C, the pressure is no...

Embodiment 3

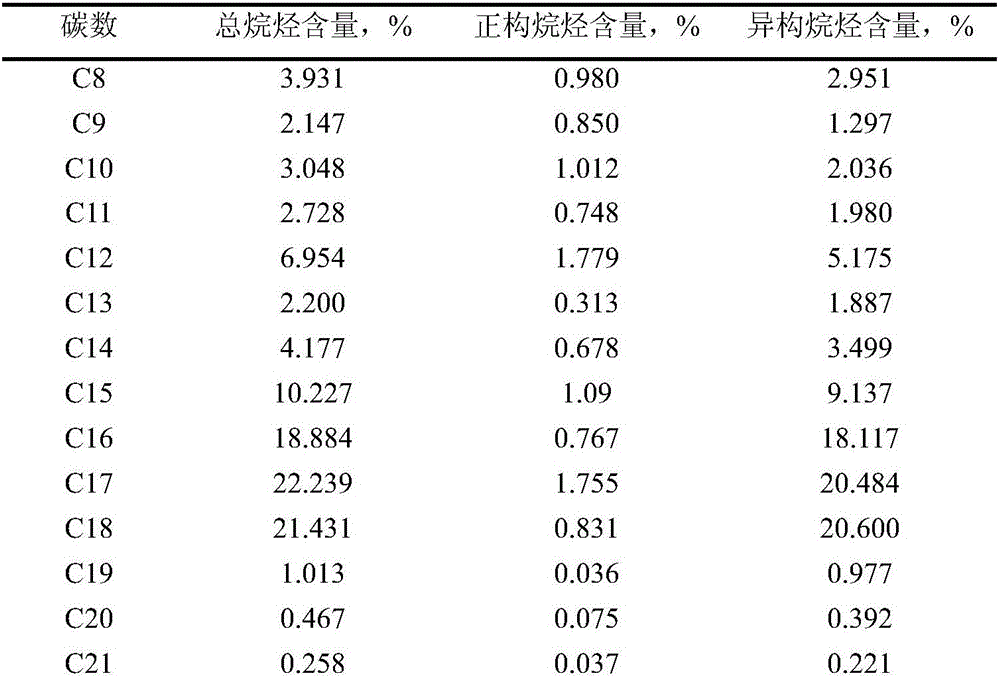

[0046] (1) Composition of raw material liquid III

[0047] From the composition (table 3) of raw material liquid III, it can be seen that the mass content of normal paraffins with 8 to 22 carbon atoms is 11%, and the mass content of isoparaffins with 8 to 22 carbon atoms is 89%. %.

[0048] table 3

[0049]

[0050]

[0051] (2) Adsorption and separation process

[0052] Divide the 100ml adsorption bed into 3 adsorption separation zones. Based on the volume of the adsorption bed, the volume percentages of the first adsorption separation zone, the second adsorption separation zone and the third adsorption separation zone are 10% and 70% respectively and 20%, first load 20ml of 13X molecular sieve in the third adsorption separation zone, then load 70ml of HY molecular sieve in the second adsorption separation zone, and finally load 10ml of 5A molecular sieve in the first adsorption separation zone.

[0053] After filling, when the adsorption temperature is 50°C, the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com