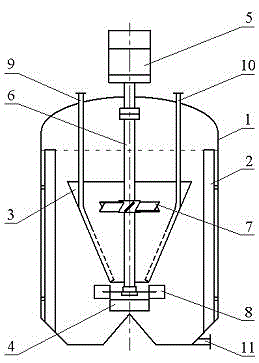

Precipitation reactor for producing ultra-fine cerium carbonate

A cerium carbonate and reactor technology, applied in the field of liquid-liquid mixing reaction precipitation devices, can solve the problems of insignificant increase in shear rate and shear stress, uneven particle size distribution, solid crystal grain deposition, etc., and achieve enhanced micro mixing and The effects of microscopic mass transfer, shortened mixing time, and uniform grain size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Adopting a specific structure of the precipitation reactor of the present invention, the first liquid inlet pipe 9 and the second liquid inlet pipe 10 run through the top of the precipitation reactor kettle body 1 axisymmetrically, close to the inner wall of the conical guide tube 3, and extend To the lower edge of the conical guide tube 3, the lower ends of the first liquid inlet pipe 9 and the second liquid inlet pipe 10 are closed, and the lower side walls of the first liquid inlet pipe 9 and the second liquid inlet pipe 10 are provided with evenly distributed inlet pipes. liquid hole. There are 4 straight baffles 2, the width of which is 60mm, which is 20mm away from the inner wall of the cylinder, and is installed on the inner wall of the precipitation reactor kettle body 1 at equal intervals, and the top of the baffles 2 is flush with the liquid surface.

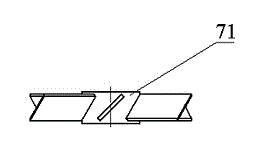

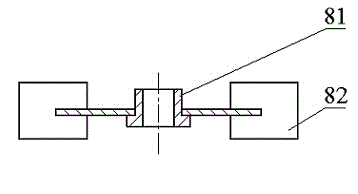

[0046] The first layer of axial flow agitator 7 adopts such as figure 2 The shown six inclined blades open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com