Patents

Literature

58results about How to "Reduce screening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

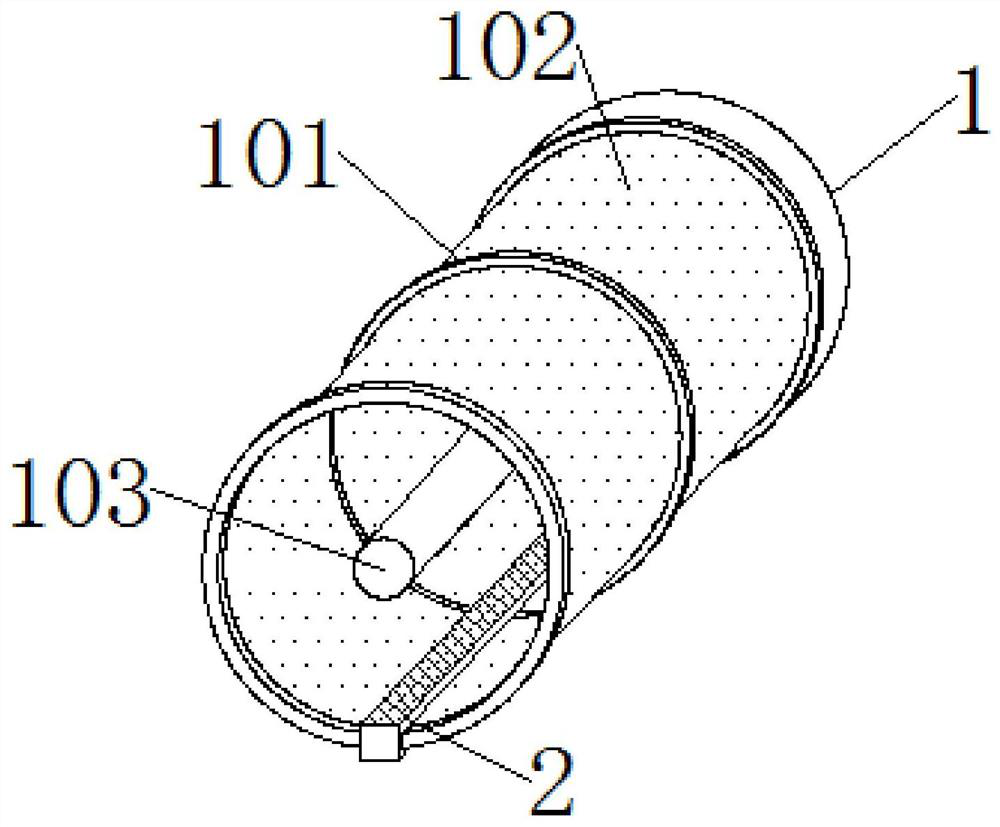

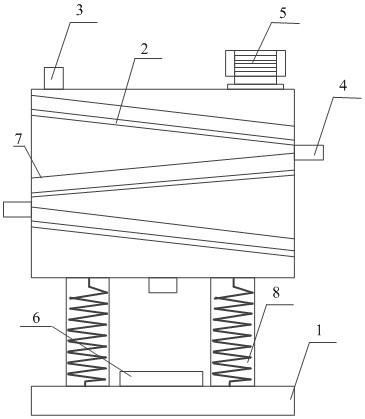

Rotary vibrating screening machine

ActiveCN104353608AIncrease productivityImprove efficiencySievingScreeningBarrel ShapeMultiple stages

The invention discloses a rotary vibrating screening machine, which comprises a barrel-shaped screening box, a rotating mechanism, a vibrating mechanism and a multistage screening mechanism, wherein the rotating mechanism comprises a rotating shaft and a driving mechanism for driving the rotating shaft to rotate; the rotating shaft is arranged on an elastic bracket in a rotating way; the screening box is fixedly arranged on the rotating shaft in a sleeving way; the elastic bracket is driven by the vibrating mechanism to rotate; the multistage screening mechanism comprises a plurality of stages of screening groups which are obliquely arranged from top to bottom; the screening groups are fixedly arranged between the screening box and the rotating shaft; the diameters of screen pores in the screening groups are gradually reduced from top to bottom; discharge ports corresponding to oversize materials and undersize materials are formed in the downwards-inclined tail end of the screening group of each stage; a feed port for uniformly spreading the materials on the upper end face of the screening group at the highest position is formed in the upper end of the screening box. The rotary vibrating screening machine is simple in structure; the materials can be screened in multiple stages according to production needs, so that the production efficiency and the uniformity of screened particles are effectively improved, and the production cost is lowered.

Owner:ANHUI UNIV OF SCI & TECH

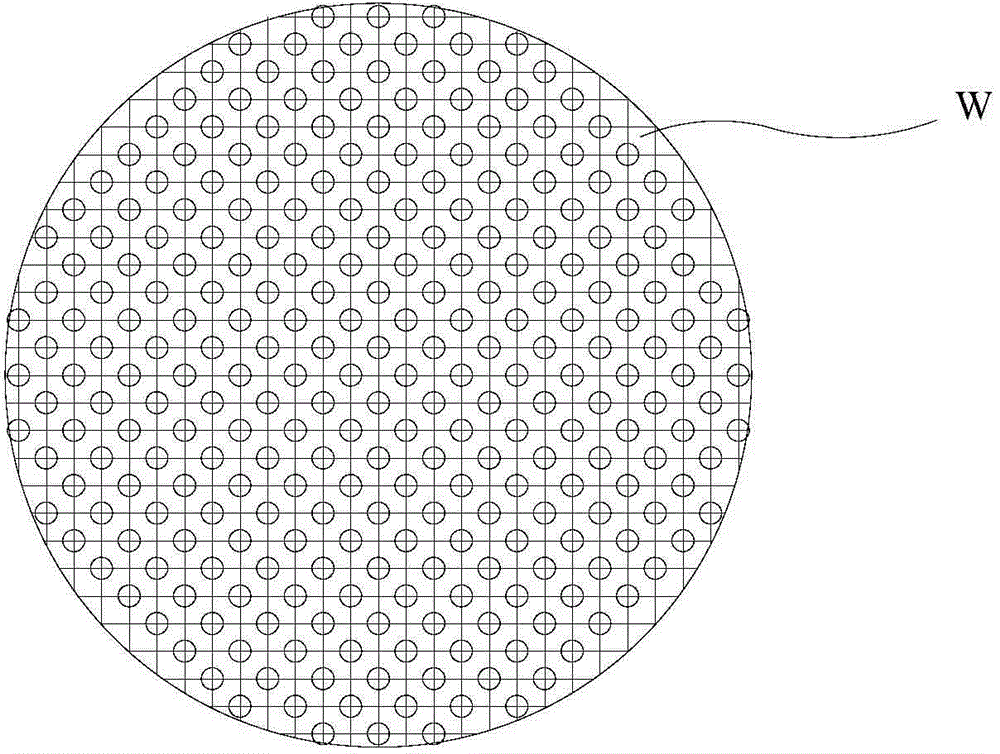

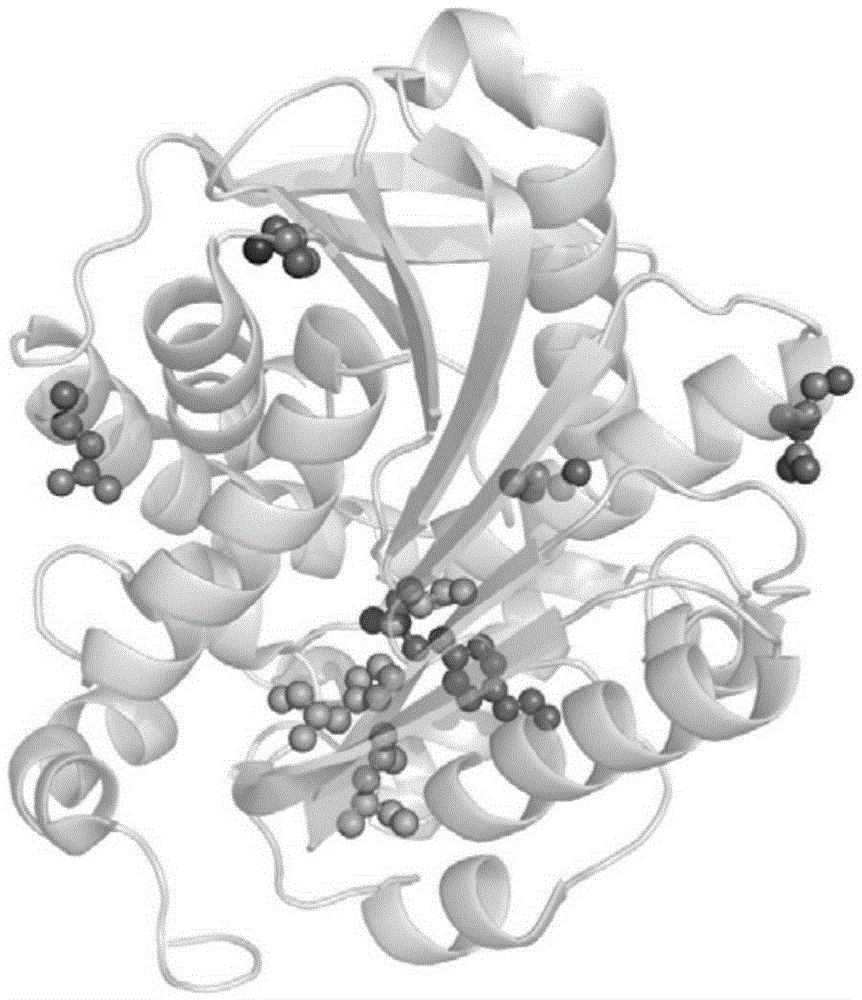

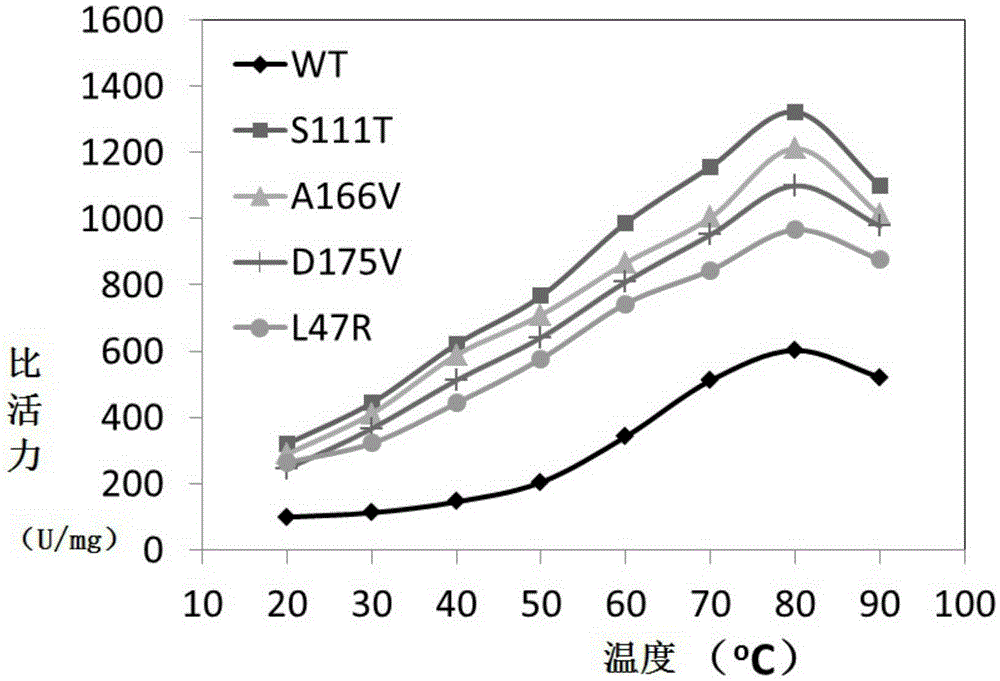

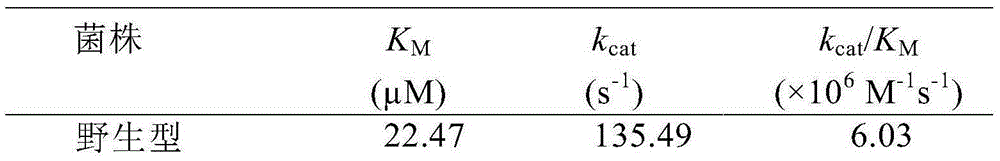

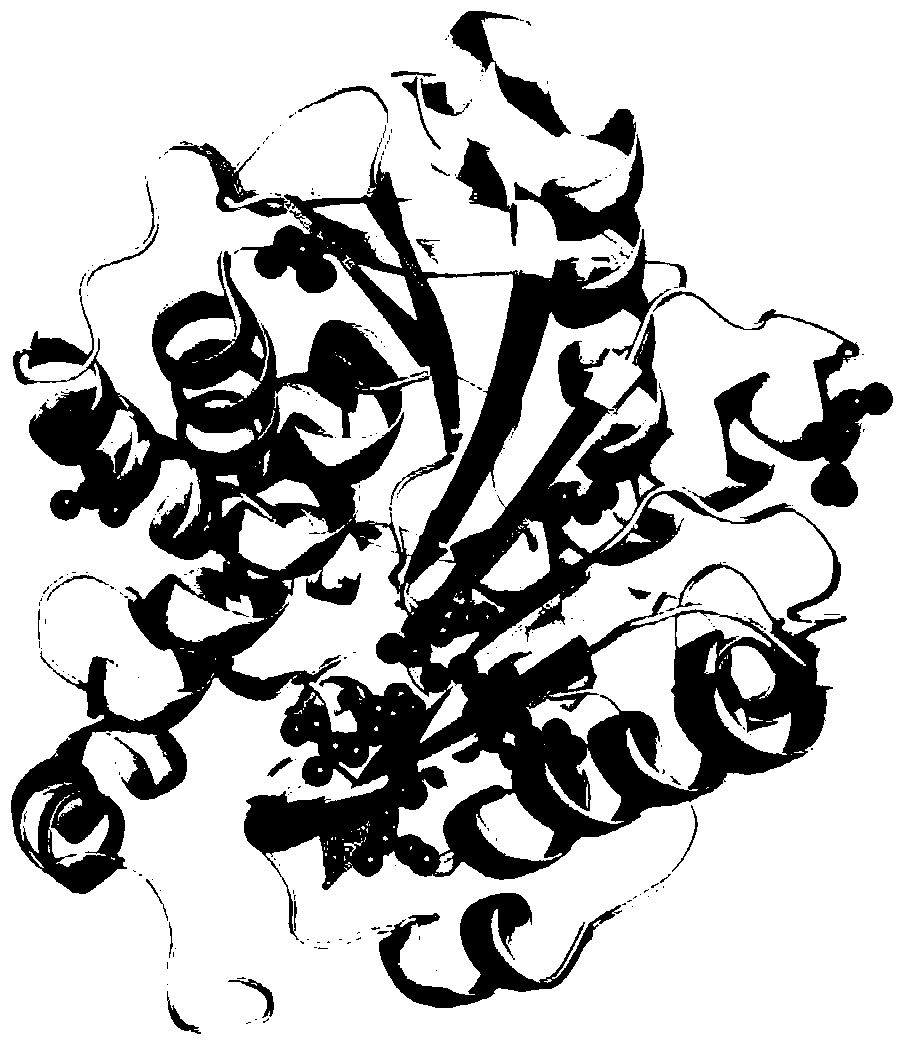

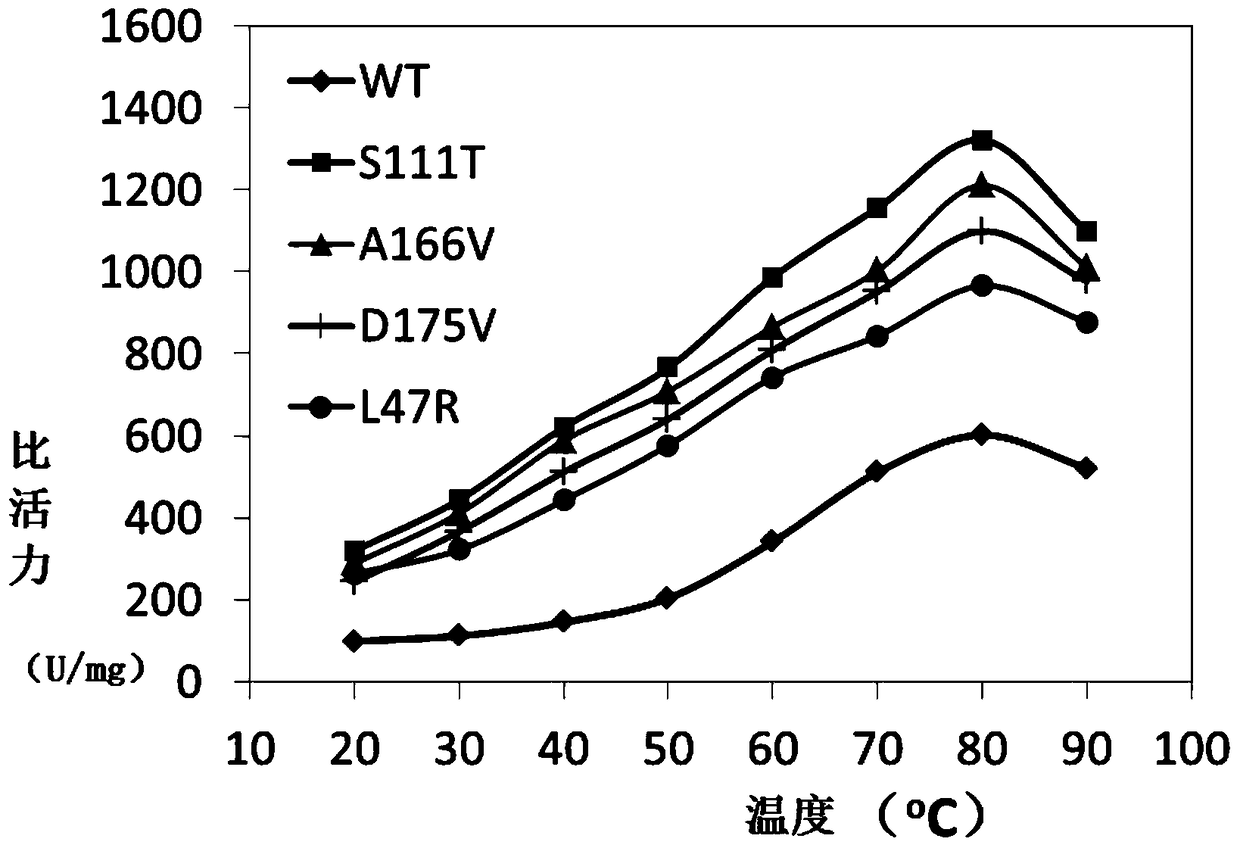

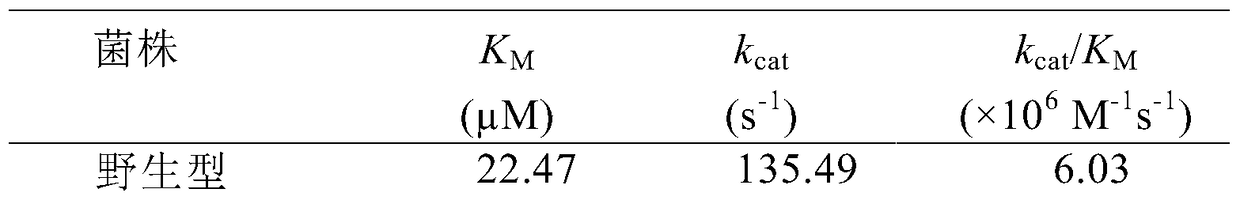

Thermophilic esterase AFEST mutant and screening method and application thereof

ActiveCN105420211AShort screening cycleReduce screening efficiencyImmobilised enzymesFungiCarboxylic esterBiology

The invention discloses a thermophilic esterase AFEST mutant. An amino acid sequence of the thermophilic esterase AFEST mutant is different from an amino acid sequence SEQ ID NO.2 of wild type thermophilic esterase AFEST in 1-5 amino acid residues; the difference comprises replacement or deficiency or insertion of amino acid and is further shown in L47R or S111T or A166V or D175V. The invention further discloses a gene for coding the thermophilic esterase AFEST mutant, a recombinant vector containing the gene and an engineering bacterium containing the gene. The invention further discloses a screening method of the thermophilic esterase AFEST mutant and application of the thermophilic esterase AFEST mutant in hydrolysis of short-chain carboxylic ester substrates. According to the thermophilic esterase AFEST mutant, the hydrolytic activity on p-nitrophenol butyric ester is increased by 4 times or above, and the heat stability equivalent to that of the wild type thermophilic esterase AFEST is maintained.

Owner:WUHAN HANHAI NEW ENZYMES BIOLOGICAL TECH CO LTD

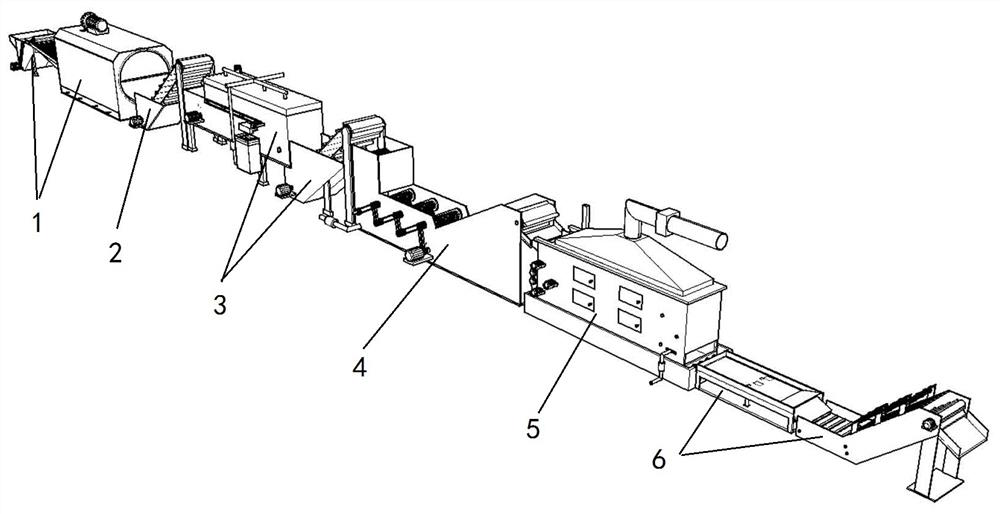

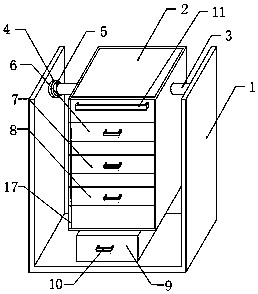

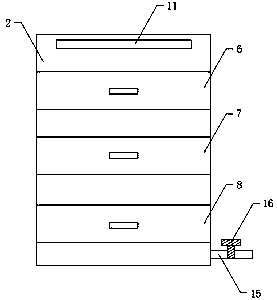

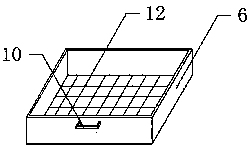

Full-automatic traditional Chinese medicinal material preliminary processing production line and use method thereof

InactiveCN111774303AAvoid accumulationAvoid blockingSievingGas current separationProcess engineeringManufacturing line

Provided are a full-automatic traditional Chinese medicinal material preliminary processing production line and a use method thereof. The full-automatic traditional Chinese medicinal material preliminary processing production line comprises a screening device, a washing device and a soaking device. The discharging end of the screening device is matched with the feeding end of a first conveying device, and the discharging end of the first conveying device is matched with the feeding end of the washing device. The discharging end of the washing device is matched with the feeding end of a secondconveying device, and the discharging end of the second conveying device is matched with the feeding end of the soaking device. The discharging end of the soaking device is matched with the feeding end of a third conveying device. By means of the structure, the whole production line is high in automation degree, device arrangement is reasonable and compact, and processing and operating are stable;and the full-automatic traditional Chinese medicinal material preliminary processing production line is suitable for processing mass traditional Chinese medicinal materials, and the economic benefitsof enterprises are improved.

Owner:五峰知杏堂药业有限公司

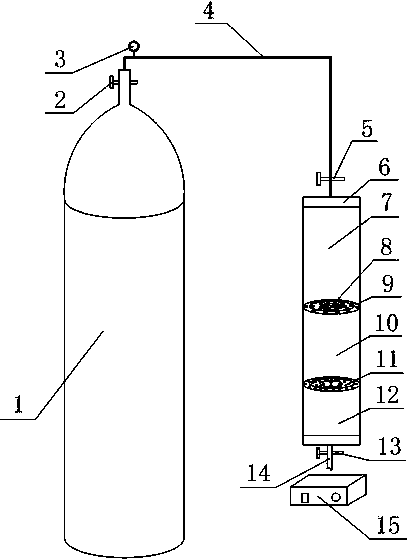

Screening equipment for promoting output of color zone of white-light LED lamp bead and screening method thereof

InactiveCN103433218AStabilize the internal situationGuaranteed puritySievingGas current separationFluorescenceAdhesive

The invention discloses a set of screening equipment for promoting the output of the color zone of white-light LED lamp beads and a screening method of the screening equipment. A plurality of layers of filtering membranes are arranged in the screening equipment, and filtering through holes are formed in all the filtering membranes. The screening equipment is connected with a steel cylinder and a magnetic stirrer, the two filtering membranes with different hole diameters are installed in the screening equipment to form three filtering cavities, and the hole diameter of the upper filtering membrane is larger than the hole diameter of the lower filtering membrane. Fluorescent adhesive having been stirred is added into the first-stage filtering cavity to connect the screening equipment and the steel cylinder in a sealing mode. The magnetic stirrer is started to perform stirring; a first valve, a second valve and a third valve are opened in sequence; when the fluorescent adhesive in the third filtering cavity is stable and does not change, the third valve, the second valve and the first valve are closed in sequence; the fluorescent adhesive in the filtering cavities is taken out in sequence, and then the fluorescent adhesive different in grain diameter and uniform in grain diameter is obtained. According to the equipment and the method, the fluorescent adhesive is screened through air flow, the fluorescent adhesive obtained through the screening is respectively used for manufacturing the LED lamp beads, and thus the output of the color zone of the LED lamp beads can be promoted.

Owner:四川英创力电子科技股份有限公司

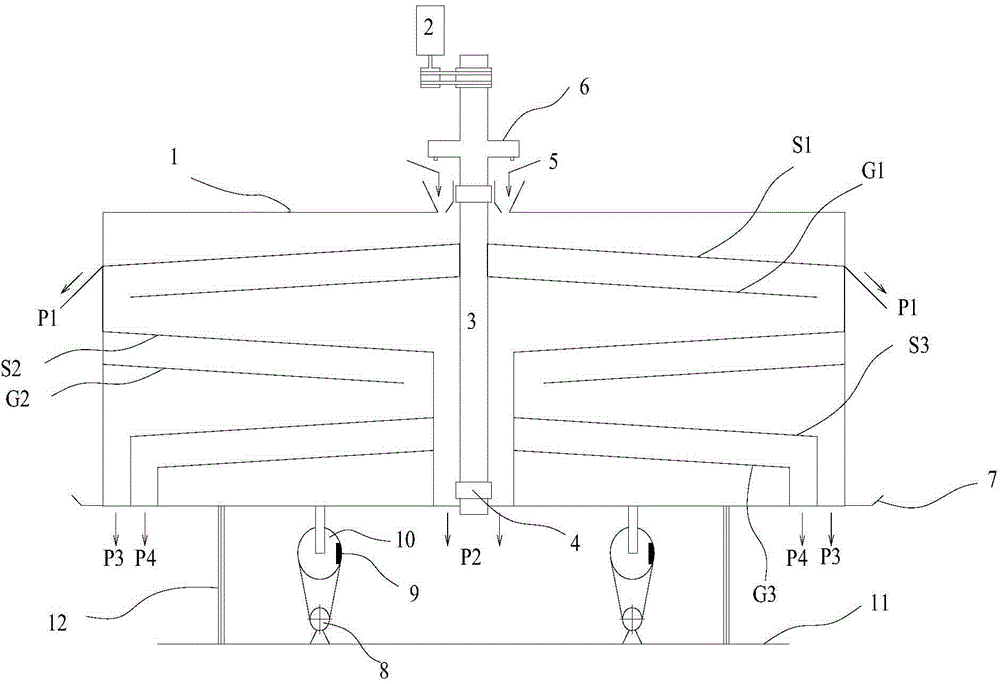

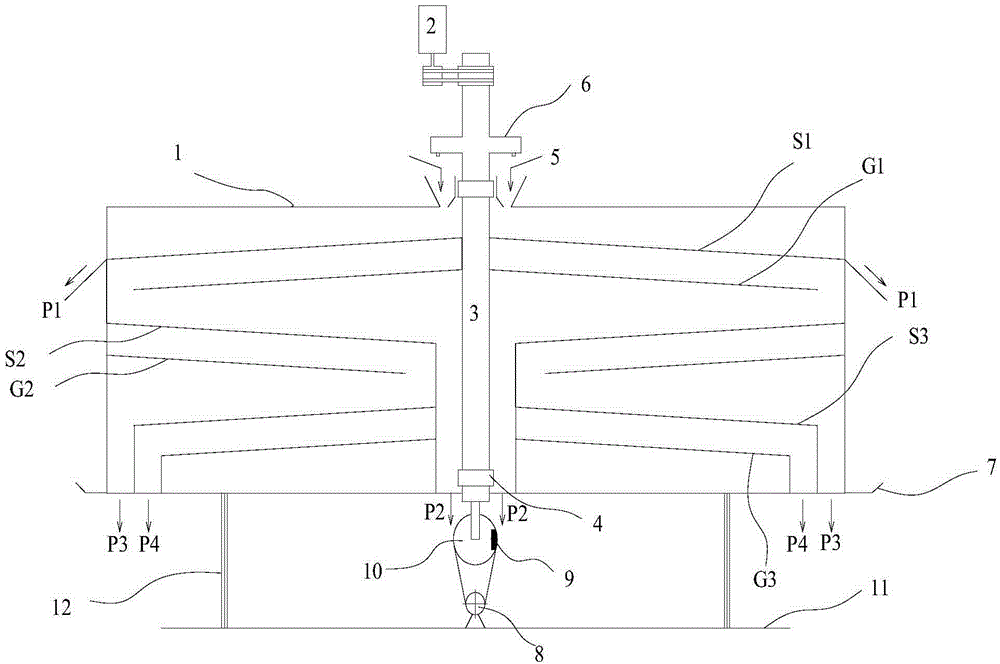

Petroleum drilling fluid screening device

The invention provides a petroleum drilling fluid screening device. The petroleum drilling fluid screening device comprises a tank, a support and guide plates arranged in the tank. The tank is divided into an upper screening area and a lower fluid collecting area by the guide plates. Vibrating screens are obliquely arranged in the screening area. A stirring device is arranged in the fluid collecting area. Chip outlets are formed in the positions, corresponding to the lower ends of the vibrating screens, of the side wall of the tank. A chip collecting tank corresponding to the chip outlets is arranged on the outer side wall of the tank. A fluid outlet pipe is arranged at the bottom end of the side wall of the tank. The tank is fixedly connected with the supports through elastic components. The petroleum drilling fluid screening device has the advantages that the size is small, the structure is simple, the screening efficiency is high, the screening effect is good, and drilling fluid is effectively prevented from splashing.

Owner:天津帅通科技发展有限公司

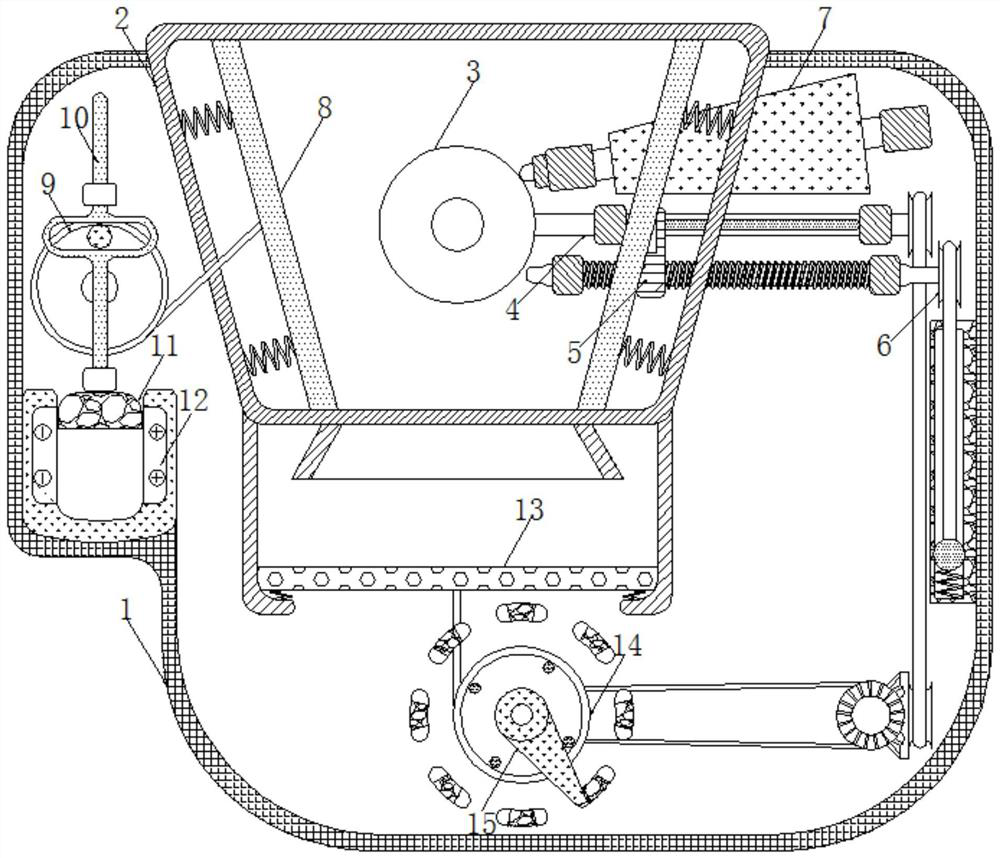

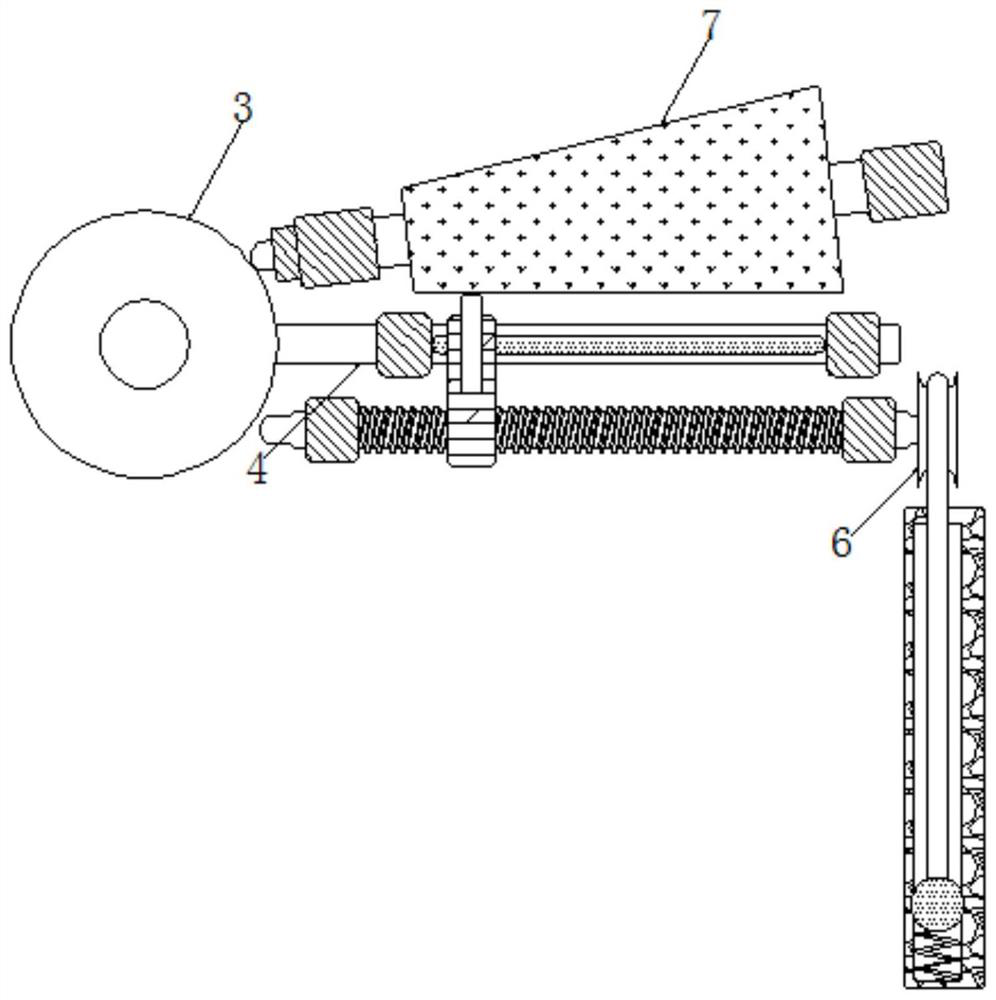

General metal garbage sorting mechanism for public garbage barrel

InactiveCN111674780AEasy to filterHigh tear performanceWaste collection and transferRefuse receptaclesSoftware engineeringElectric machinery

The invention provides a general metal garbage sorting mechanism for a public garbage barrel. The general metal garbage sorting mechanism for the public garbage barrel comprises a garbage barrel body,a material pushing device, a garbage sorting device and a conveying device. A barrel cover is installed on one side of the garbage barrel body, and an outward opening door is arranged on one side ofthe garbage barrel body; first hook frames are installed on two sides of the garbage barrel body, mounting frames are arranged at one ends of the first hook frames, two first fixing plates are arranged on one sides of the mounting frames, a mounting plate is installed between the two first fixing plates, a motor is installed on one side of the mounting plate, and a third pulley is installed at oneend of a motor output shaft. The flow-dividing work can be carried out on the garbage thrown into the garbage barrel body to prevent the situation that a garbage bag is torn insufficiently and laterscreening is affected due to the fact that too much garbage is dumped at one time, the tearing work can be carried out on the garbage bag, and the screening of metal garbage in the later stage is facilitated.

Owner:茹朝贵

Speed-up rubber crushing device based on centrifugal force and capacitance principle

The invention relates to the technical field of rubber, and discloses a speed-up rubber crushing device based on centrifugal force and a capacitance principle. The speed-up rubber crushing device comprises a shell, wherein a cutting bin is fixedly connected into the shell. According to the centrifugal force generated by rubber in the actual process, the capacitance principle is utilized, the variable speed cutting and variable speed screening operation are triggered to improve the linkage between structures, through the joint action of a cutting disc, a linkage rod, a moving block, a first rotating disc and a rotating column, the cutting speed is automatically increased, the situation that the cutting speed is weakened due to the change of current is compensated, the crushing quality problem caused by the reduction of cutting speed is avoided, so that the crushing quality of the rubber is ensured, through the joint action of the linkage rod, the moving block, the rotating column, a screening plate, a third rotating disc and a rotating plate, and the screening speed is automatically increased to avoid the situation that the screening frequency is reduced due to the weakening of current, resulting in rubber accumulation and reduction of the screening efficiency of the rubber.

Owner:赵艳花

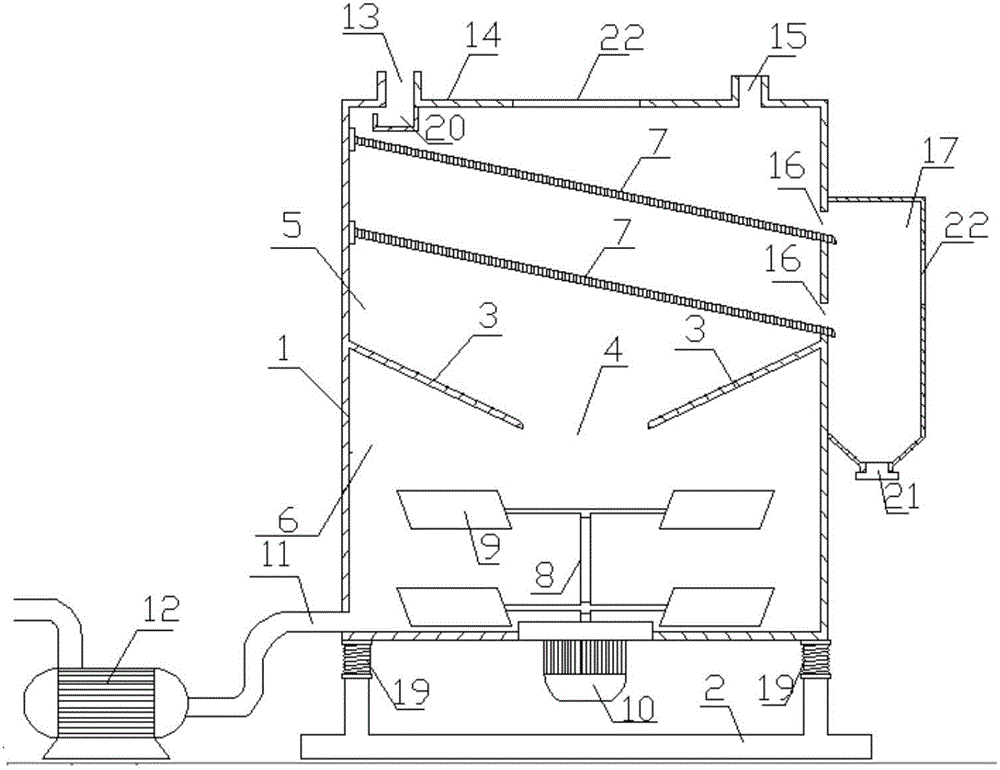

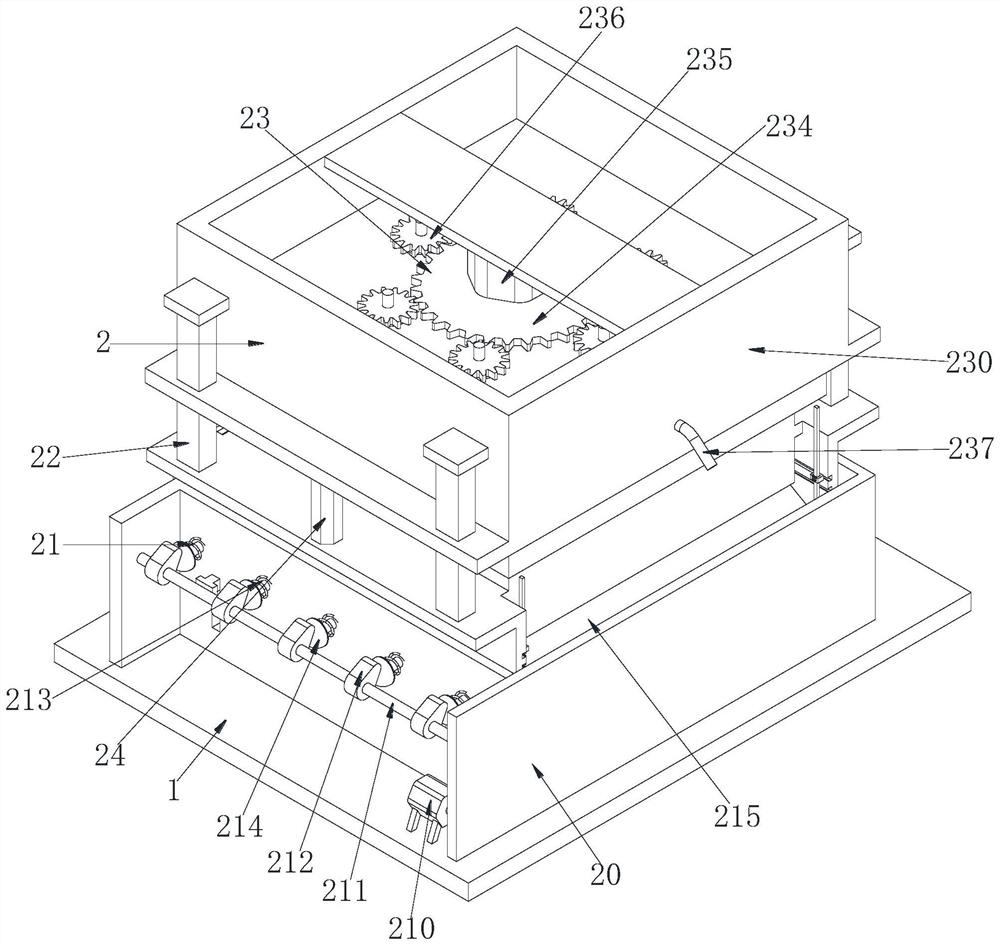

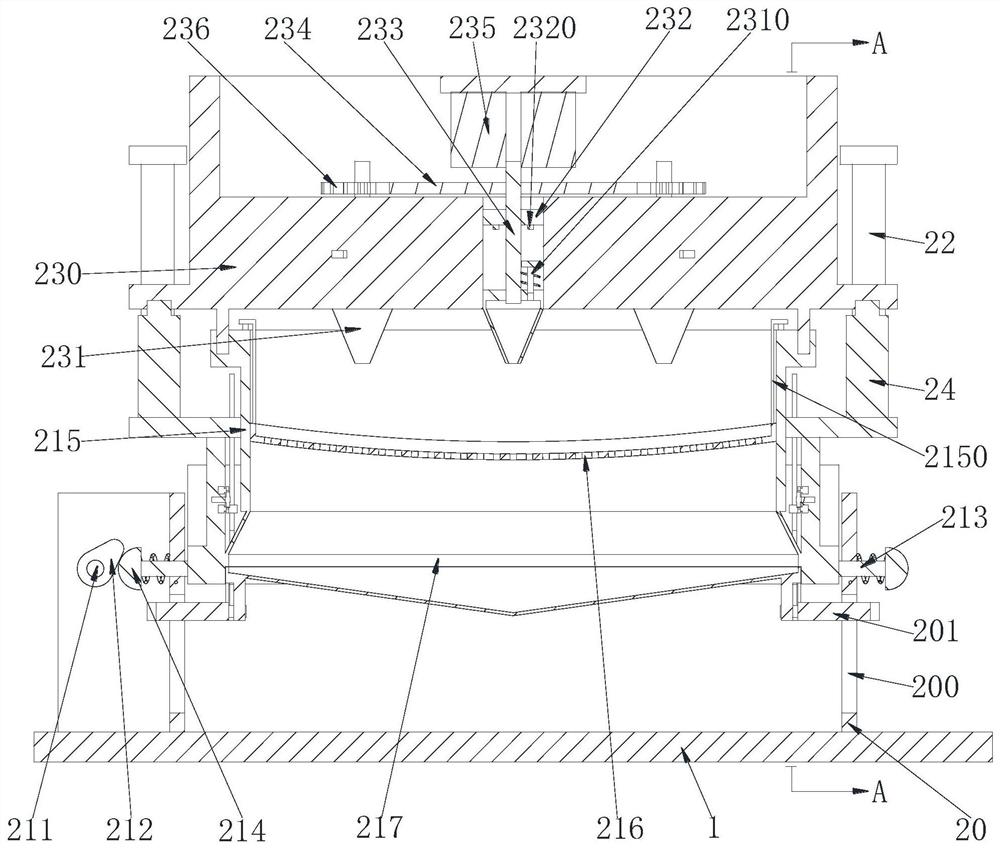

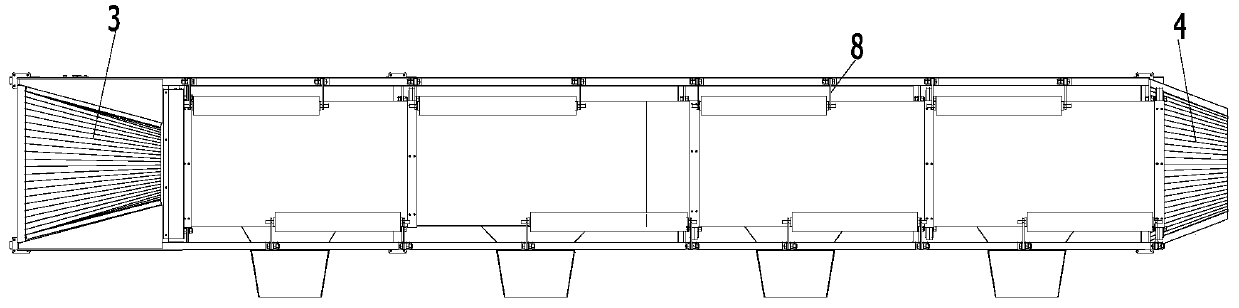

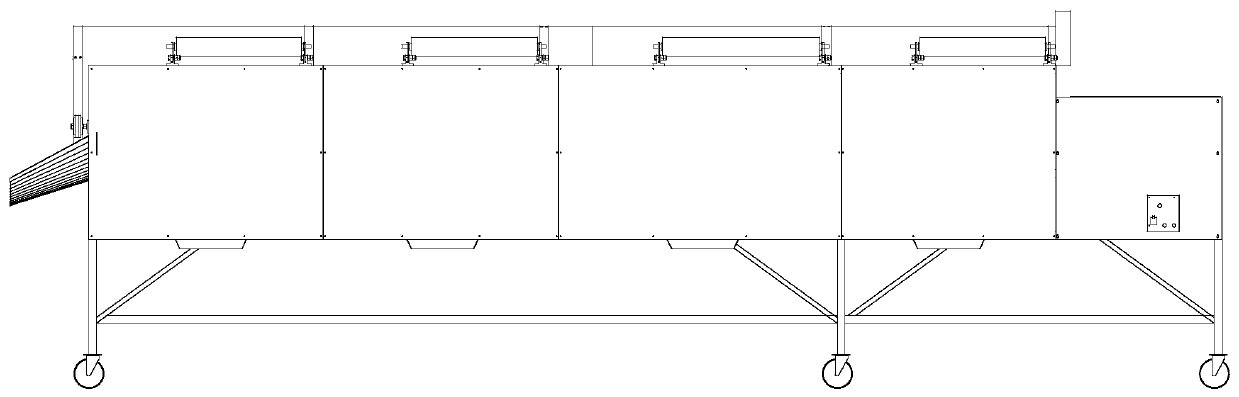

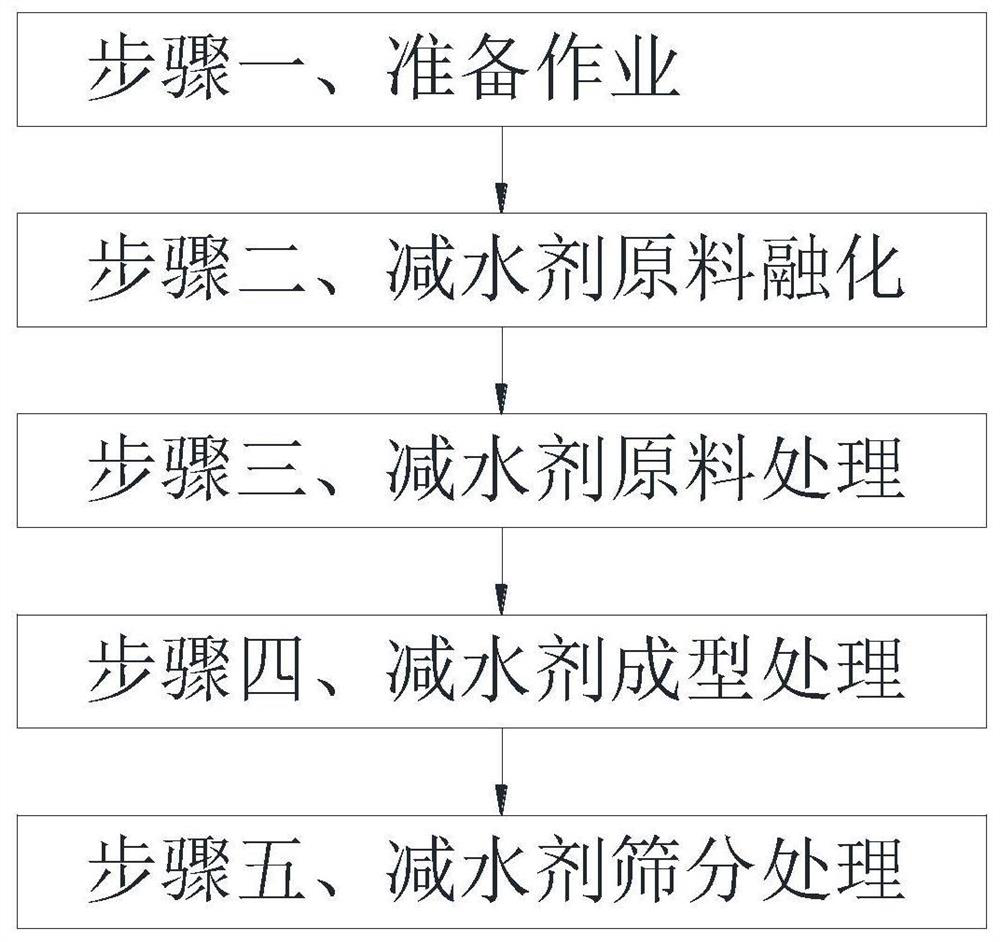

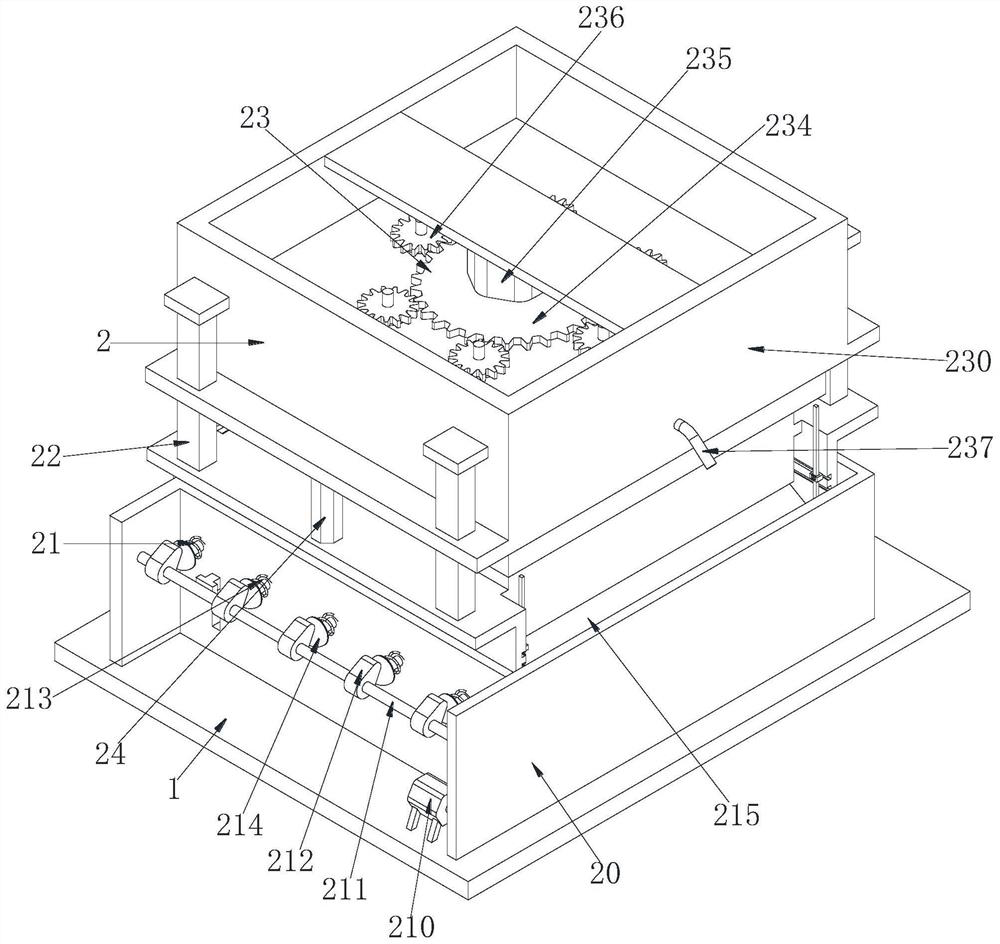

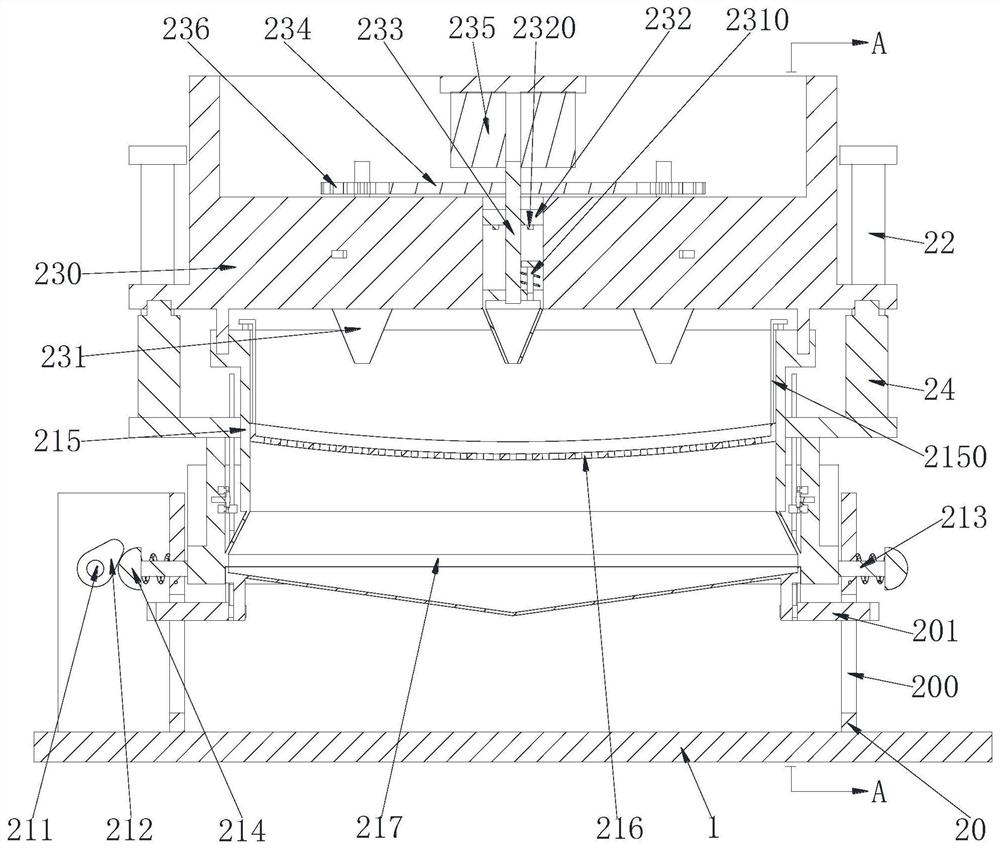

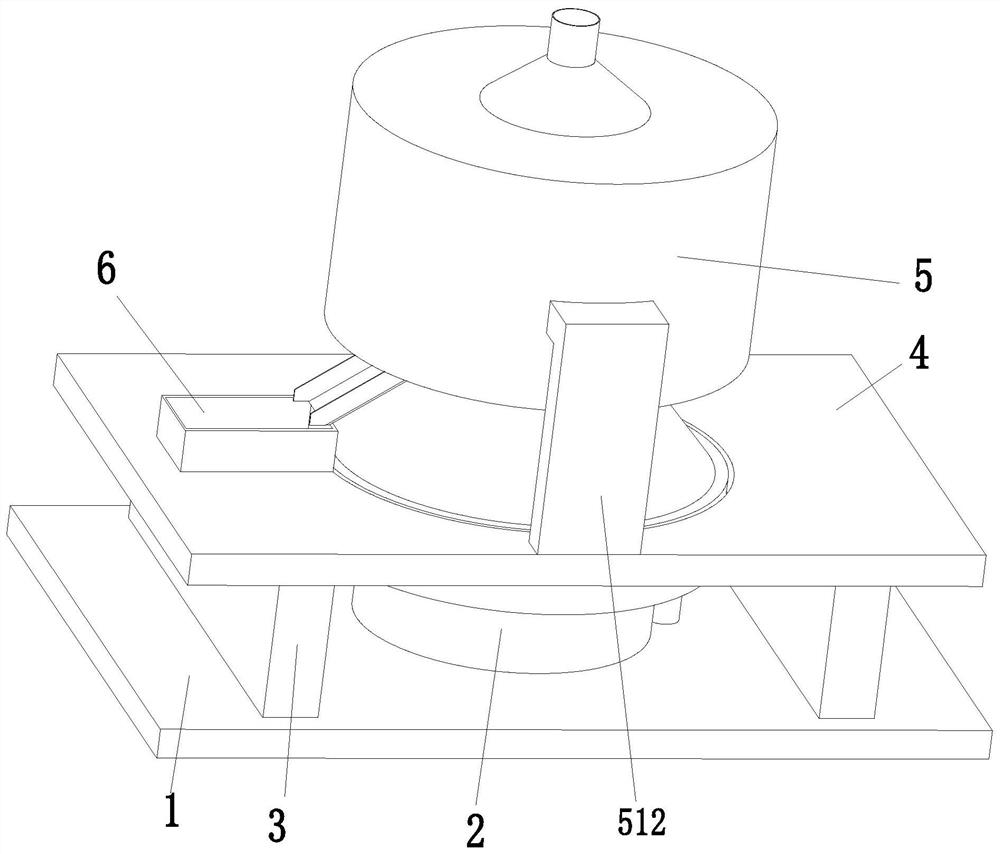

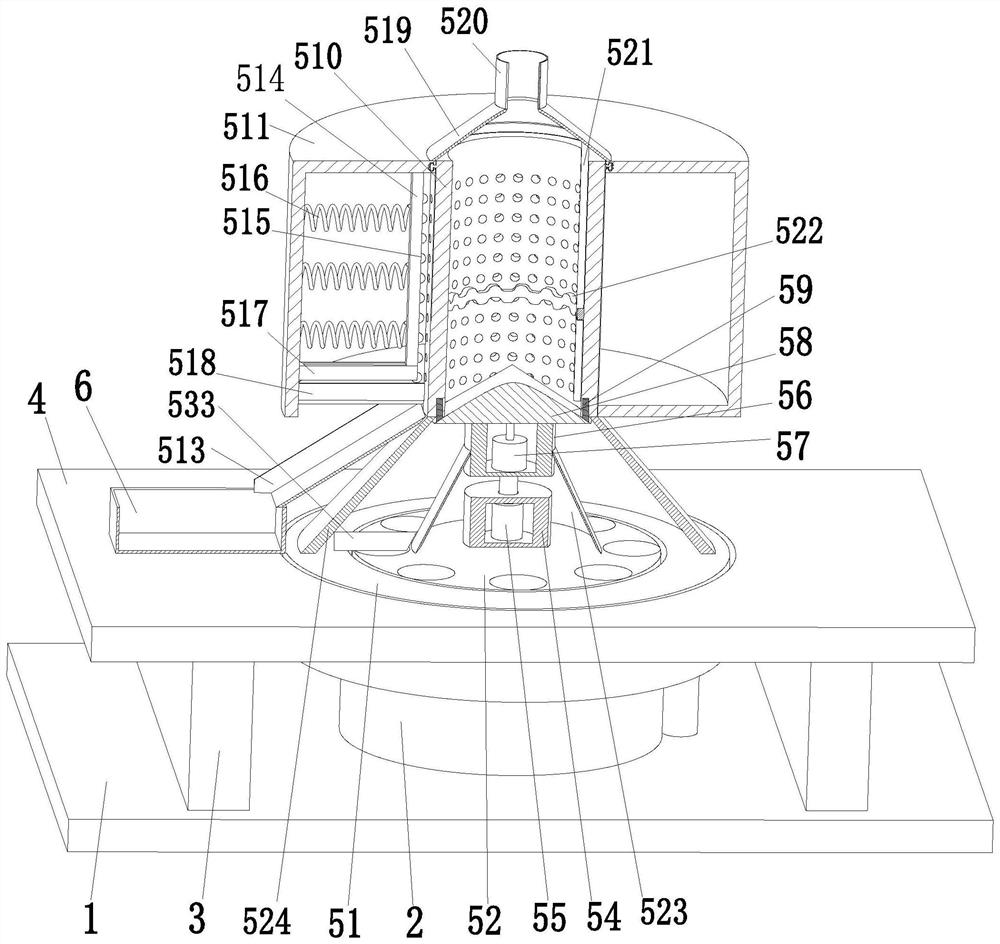

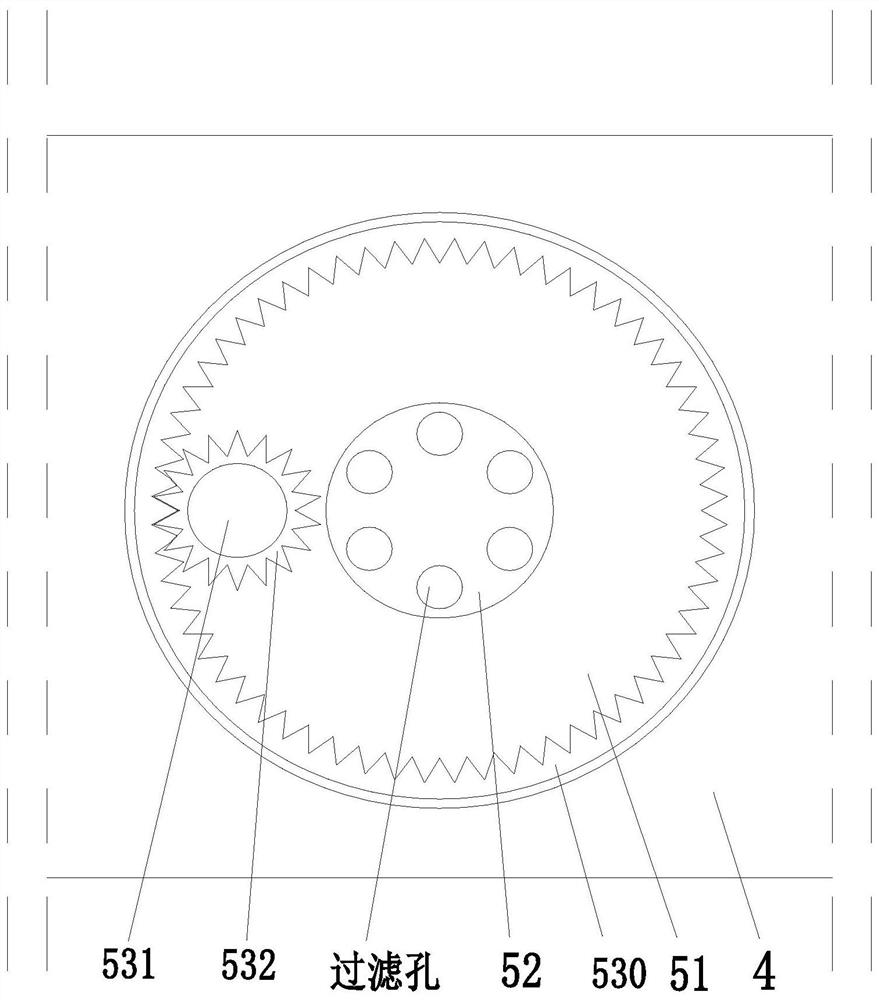

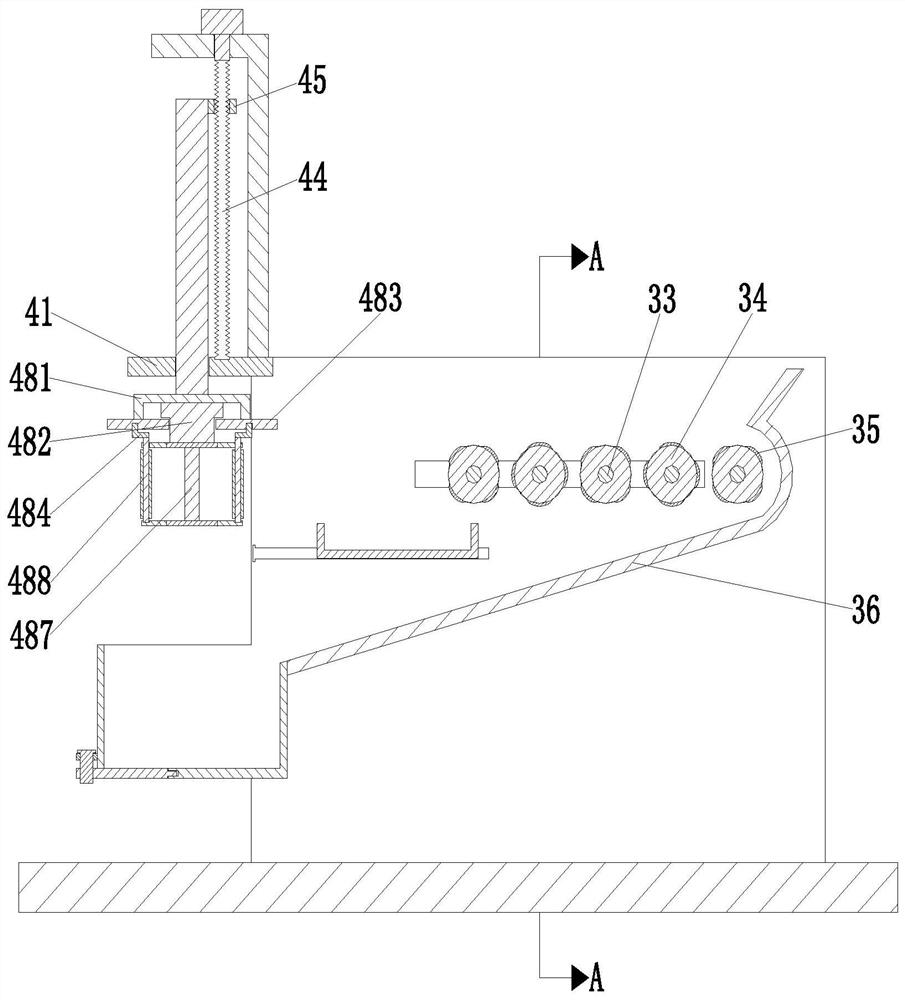

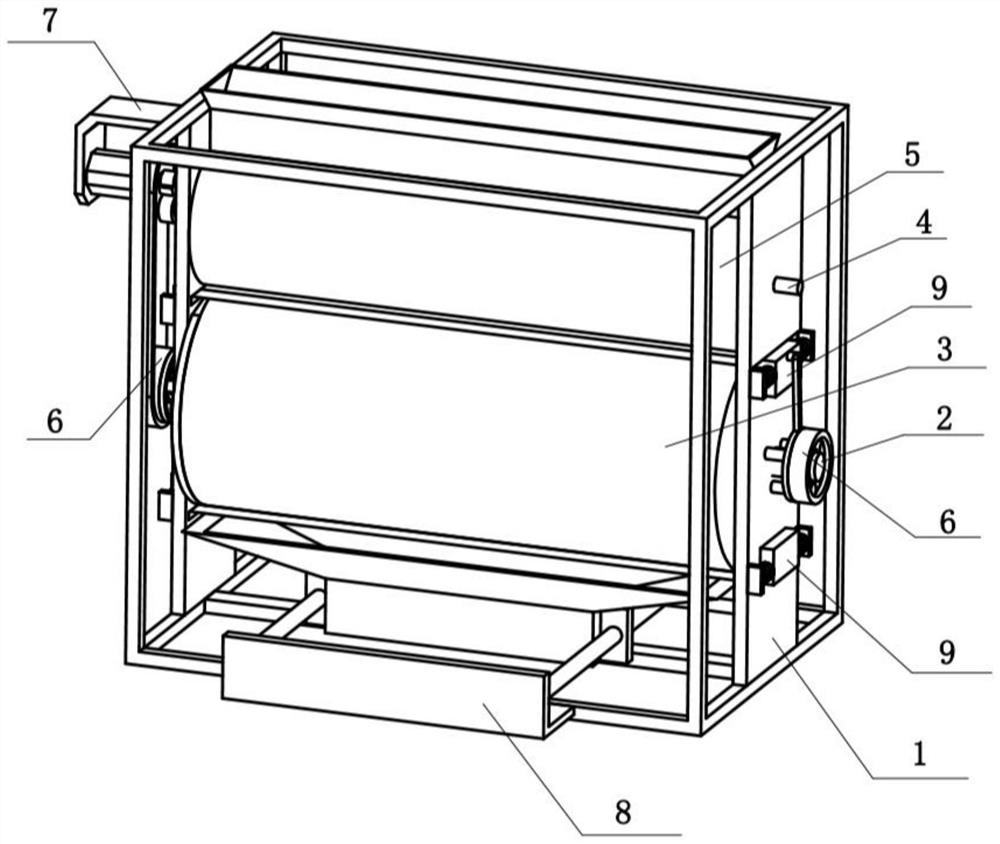

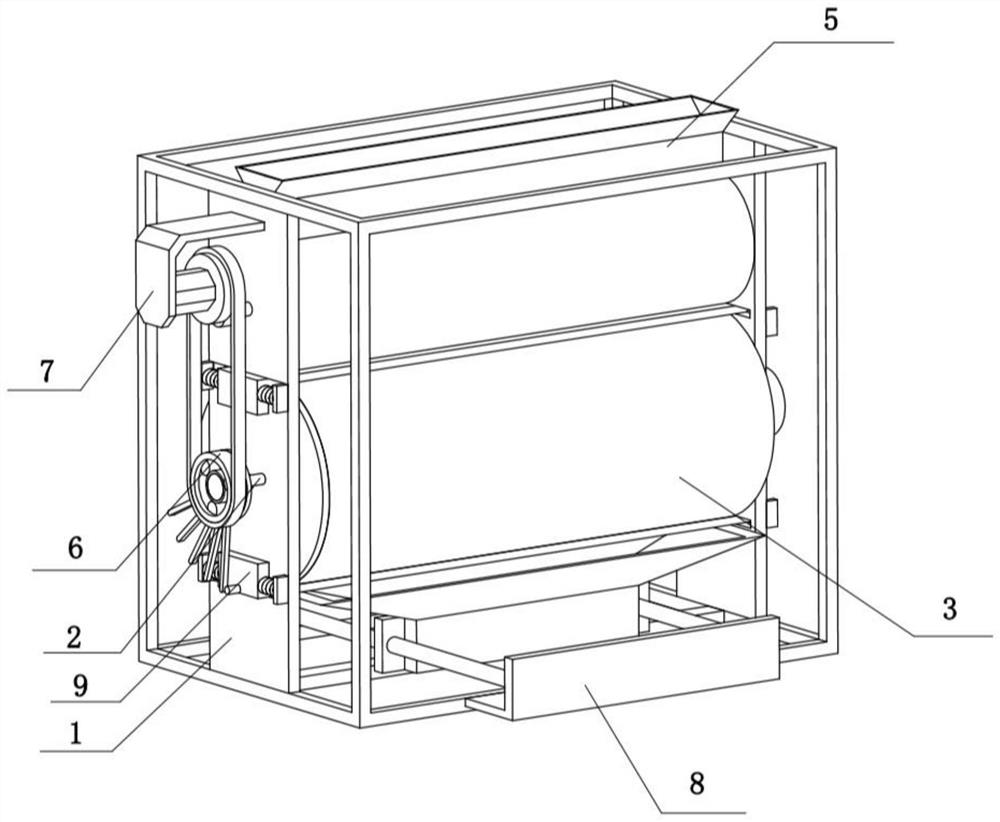

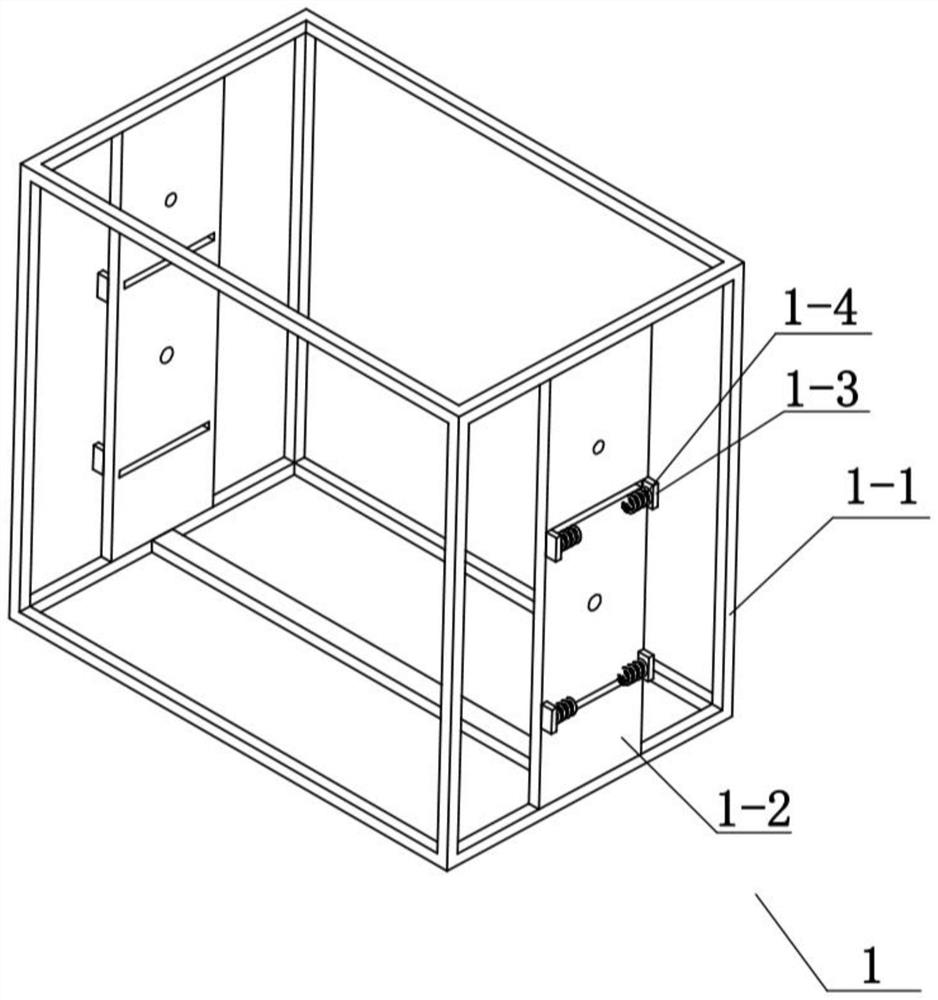

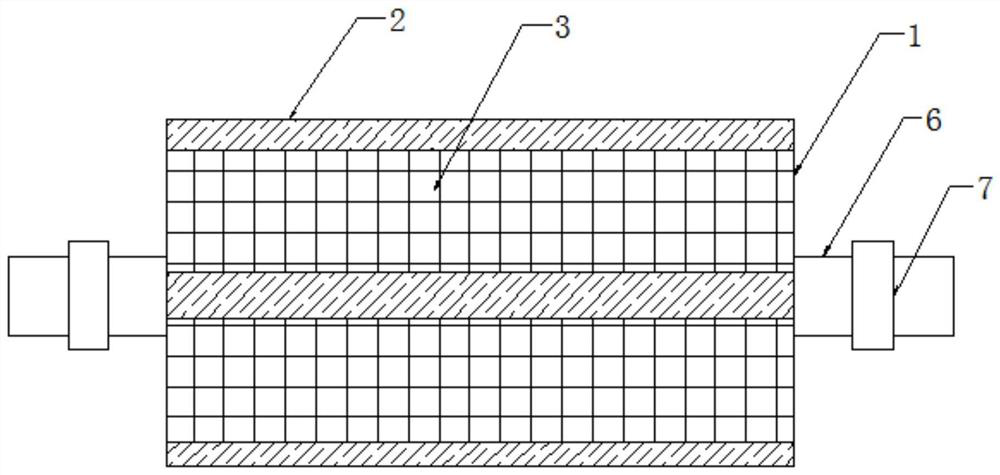

Concrete water reducing agent preparation and processing system

InactiveCN112170193AReduce screening efficiencyImprove screening efficiency and screening effectSievingScreeningProcess engineeringStructural engineering

The invention relates to a concrete water reducing agent preparation and processing system. The concrete water reducing agent preparation and processing system comprises a base and a screening device,and the screening device is arranged on the upper surface of the base; and the screening device comprises a screening support, a screening unit, a screening branch rod, a pneumatic unit and a screening air cylinder. The following problems existing when a concrete water reducing agent is screened after being prepared and formed at present that when an existing water reducing agent screening deviceis used for screening smashed water reducing agent powder, the adopted screening action is single, only simple reciprocating type screening treatment is adopted, the powder is difficult to move alongwith the screening device all the time just like large particles, so that the powder is prone to accumulating on a screening mesh plate to cause mesh blockage, consequently, screening of the water reducing agent is not thorough enough, and the screening efficiency is low can be solved.

Owner:杭州丽可新材料科技有限公司

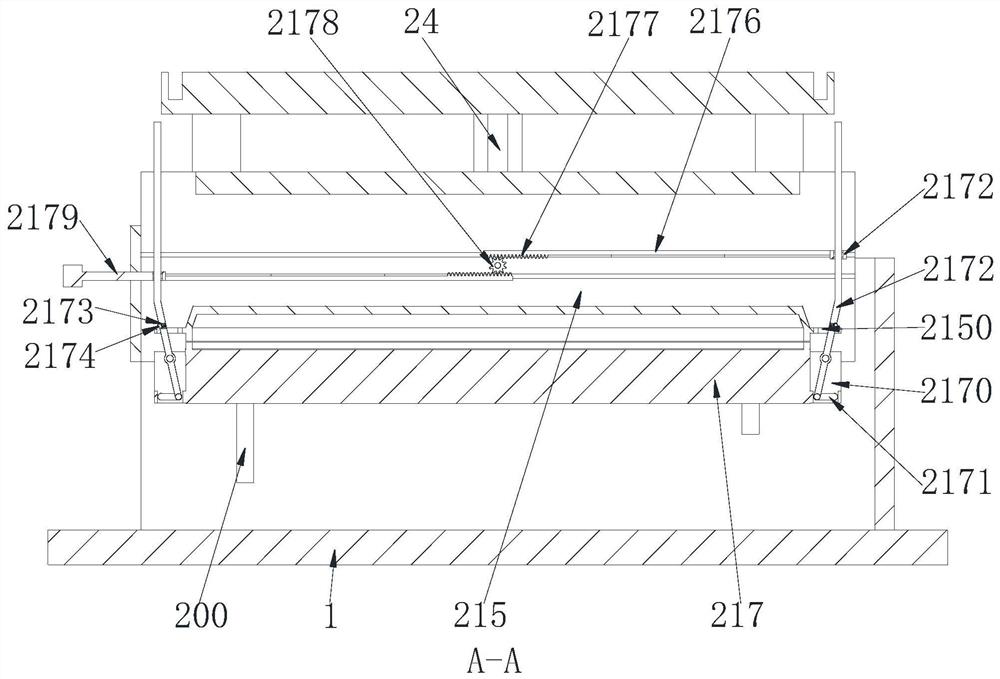

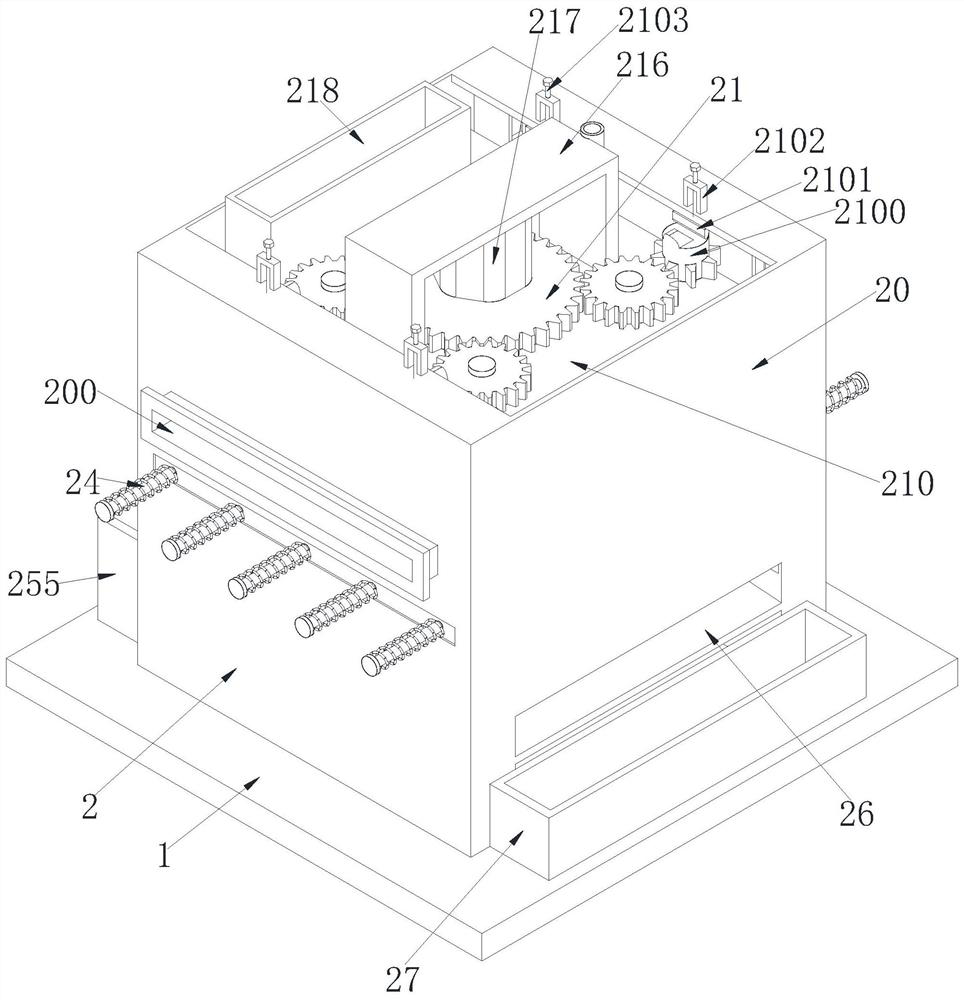

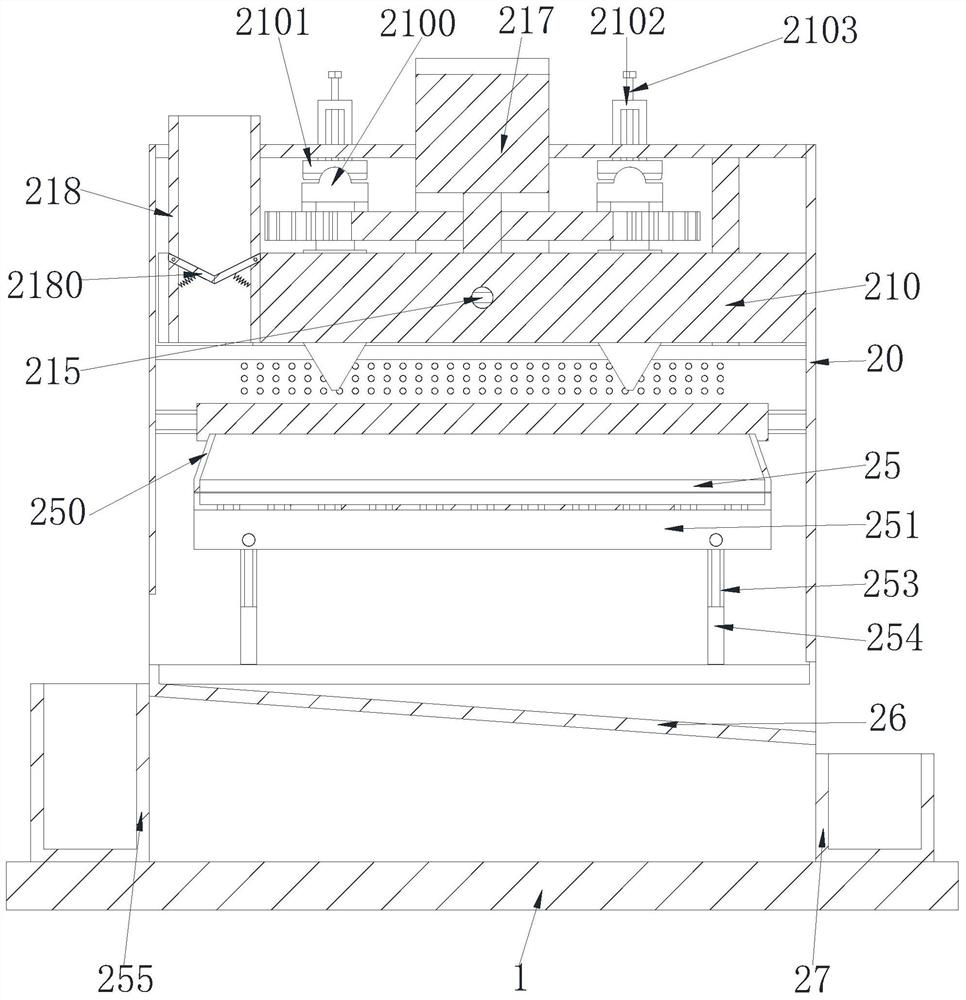

Rice preparing, screening and selecting processing method

ActiveCN112024386AReduce screening efficiencyEasy to fallSievingGas current separationProcess engineeringIndustrial engineering

The invention relates to a rice preparing, screening and selecting processing method. Rice preparing, screening and selecting processing equipment is used in the rice preparing, screening and selecting processing method, the rice preparing, screening and selecting processing equipment comprises a base and a screening device, and the screening device is arranged on the upper surface of the base. The method can solve the following problems, existing during screening and selecting of rice at present, that most existing rice screening machines screen the rice in a screen reciprocating type screening mode, and existing screen frames are round or rectangular, so that the situation that blockage is caused due to the fact that the rice is clamped by the screen frames is prone to occurrence duringrice screening and selecting, the reciprocating type screening mode is poor in rice screening effect, and the screening efficiency is low.

Owner:襄阳市飞钟粮食机械有限公司

Fry quick screening device

InactiveCN108293935AReduce screening efficiencyImprove convenience and efficiencyPisciculture and aquariaEngineeringWater tanks

The invention discloses a fry quick screening device, including a fixing seat and a water tank, wherein bearing blocks are fixedly installed on the inner sides of the fixing seat, rolling bearings arearranged in the two bearing blocks, rotating shafts are arranged in the inner circles of the two rolling bearings, a first screening box, a second screening box and a third screening box are arrangedin the water tank, respectively, a first screening net, a second screening net and a third screening net are correspondingly arranged in the first screening box, the second screening box and the third screening box, sectional shapes are all funnel-shaped, and the diameter of the screening holes increases linearly and successively, so that fries of different specifications can be screened in one time, the screening efficiency is increased, and the fry survival rate is increased, by using the fry physiological characteristics of preferring to float up when vibration happens, the situation of net hole blocking caused by over-stacked fries can be prevented, and further the certain degree of fry screening is improved.

Owner:东莞产权投资有限公司

Dry type plastic sorting technology

InactiveCN102755961AReduce volumeNot easy to separateGas current separationSocial benefitsEconomic benefits

The invention provides a dry type plastic sorting technology. According to the technology, waste is separated from a plurality of plastic-containing wastes which are produced in daily production and daily life. The technology comprises the steps of separating waste, refining, drying, loosing, sieving and winnowing. According to the technology, water is nearly not used in the whole process of separating, thus the working efficiency can be improved, and the separated plastic can be directly used for making plastic products, so that the plastic can be served as a resource for being utilized again, and the environmental pollution caused by directly discarding the plastic can be avoided, and the strategy of sustainable development can be met, and superior economic benefit and social benefit can be achieved.

Owner:王杰生

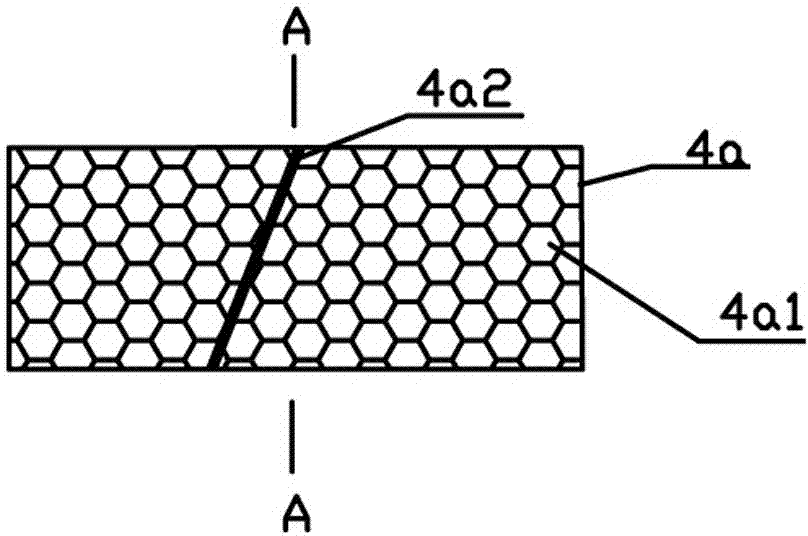

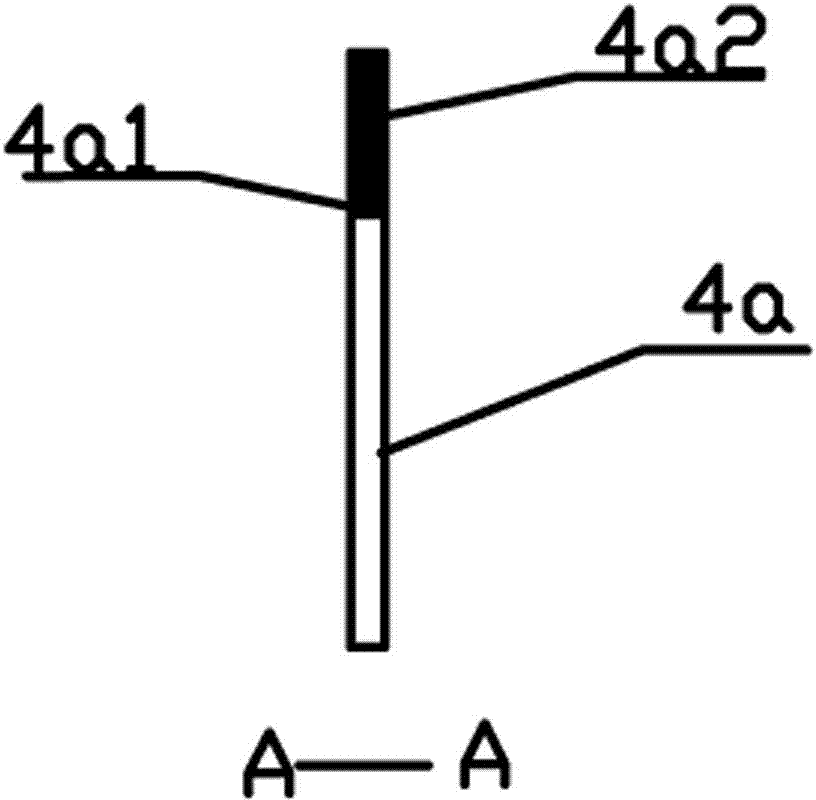

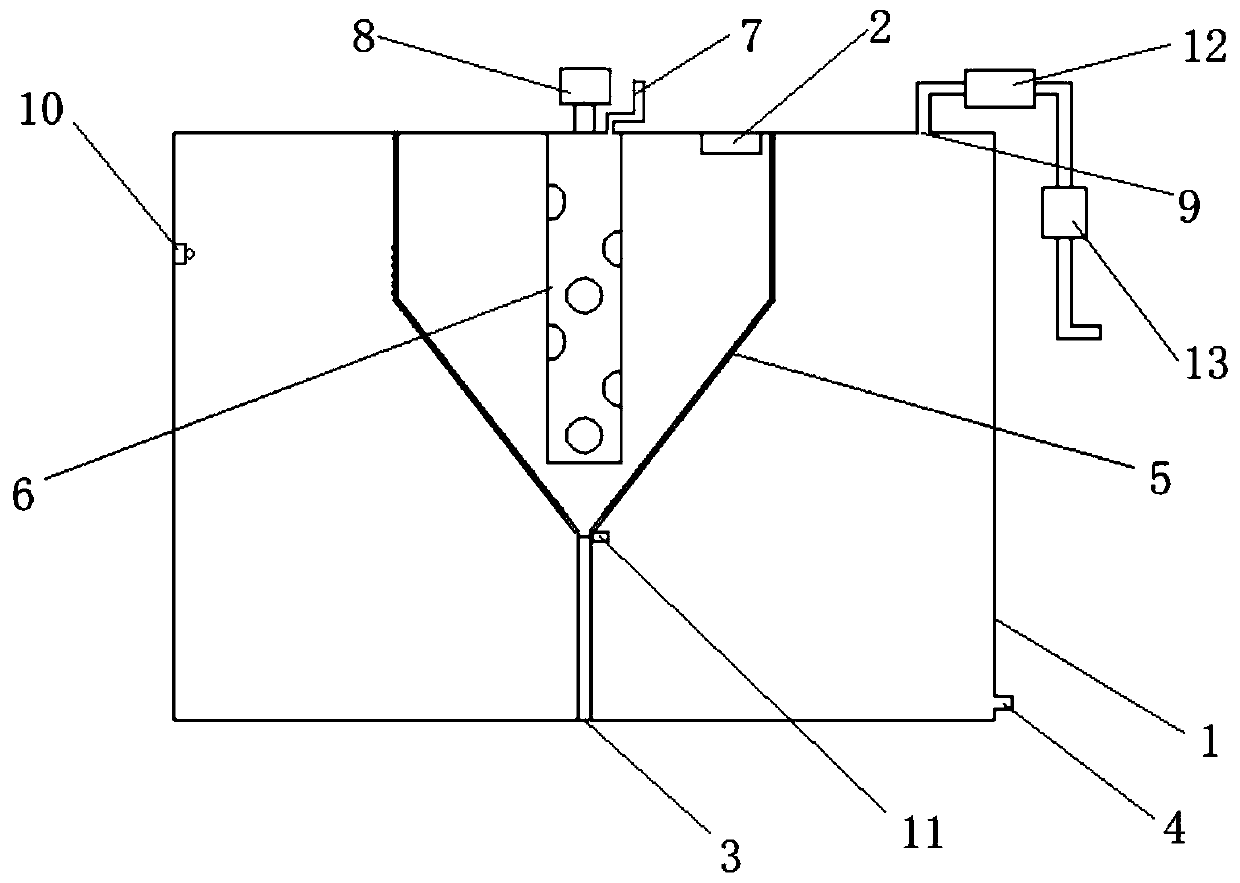

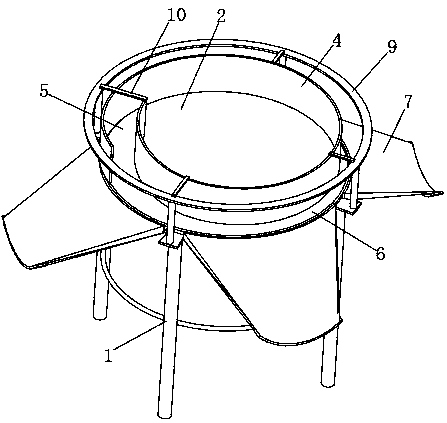

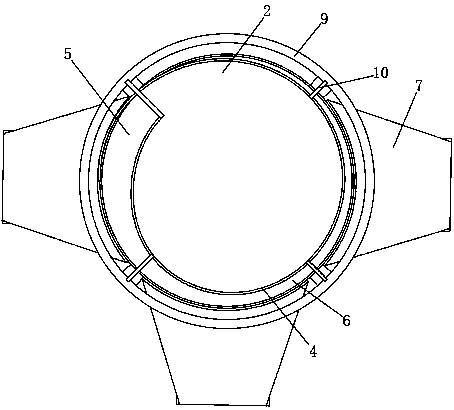

Titanium alloy tiny powder gas screening device

InactiveCN109877042ANo frequent replacementEfficient separationGas current separationTitanium alloyFine powder

The invention relates to a titanium alloy tiny powder gas screening device which comprises a closed container (1). A powder feeding opening (2) is formed in the top of the closed container (1). A rough powder outlet (3) and a fine powder outlet (4) are formed in the bottom of the closed container (1). A funnel-like screen (5) is arranged in the closed container (1). A sleeve (6) with a hole formedin the surface is arranged on the inner side of the funnel-like screen (5). An inert gas input opening (7) is formed in the top end of the sleeve (6). A motor (8) is connected with and drives the sleeve (6) to rotate. The closed container (1) is further provided with a gas exhausting opening (9). Inert gas is adopted for generating corresponding circulating airflow, no residual powder exists on the surface of the screen all the time, the situation that the powder gathers on the surface of the screen, and the screen is blocked is avoided, the screening efficiency is reduced, screening is uniform, safe and efficient, meanwhile, the screen does not need to be replaced frequently, and the device is simple and easy to use.

Owner:苏州双恩智能科技有限公司

Walnut screening machine

The invention discloses a walnut screening machine, and aims to provide a walnut screening machine with high screening efficiency. The machine comprises a rack, a screen drum rotatably mounted on therack, a feeding groove fixedly connected to the rack and located at a feed inlet of the screen drum, discharge grooves fixedly connected to the rack and located below the screen drum and at a discharge end, and a power device for driving the screen drum to rotate. The screen drum is divided into a plurality of sections, and the apertures of screen meshes of each section of the screen drum are sequentially increased from the feed inlet to the other end; the inner wall of the screen drum is provided with a spiral conveying blade; rollers are rotationally arranged on the rack and located on the upper portion and / or side of the outer wall of the screen drum; the axes of the rollers are parallel to the screen drum, and the wall surfaces of the rollers are close to the outer wall surface of thescreen drum; the length of the rollers is not shorter than the length of screen hole areas on the screen cylinder. The machine is suitable for screening various walnuts.

Owner:云南盛昌林产品开发有限公司

Concrete water reducing agent preparation method

ActiveCN112170173AImprove screening effectImprove screening efficiencySievingScreeningProcess engineeringStructural engineering

The invention relates to a concrete water reducing agent preparation method, which uses concrete water reducing agent preparation equipment. The concrete water reducing agent preparation equipment comprises a base and a screening device, and the screening device is arranged on the upper surface of the base. The following problems existing when a concrete water reducing agent is screened after being prepared and formed at present that when an existing water reducing agent screening device is used for screening smashed water reducing agent powder, the adopted screening action is single, only simple reciprocating type screening treatment is adopted, the powder is difficult to move along with the screening device all the time just like large particles, so that the powder is prone to accumulating on a screening mesh plate to cause mesh blockage, consequently, screening of the water reducing agent is not thorough enough, and the screening efficiency is low can be solved.

Owner:灵山县建灵投资有限公司

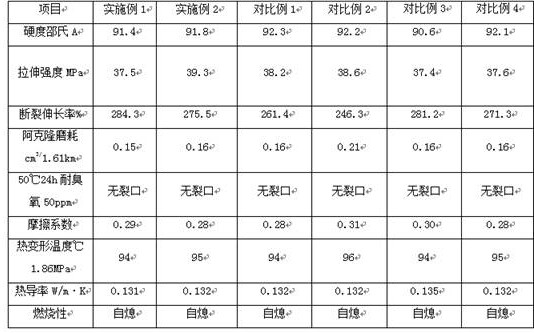

Extrusion molding process method of heat-resistant and corrosion-resistant screen

The invention relates to the technical field of screen production, in particular to an extrusion molding process method of a heat-resistant corrosion-resistant screen. Raw material source is wide, preparation method is simple and convenient, chlorinated polyether and acrylate rubber are blended, co-crosslinked and synergistically matched; the prepared screen can be widely applied to screening machines in the industries of metallurgy, mines, coal, building materials, water conservancy, road construction and the like, and is a substitute product of a steel plate punched screen, a steel wire meshgrid, a stainless steel screen plate and a rubber screen plate. The product has the advantages of light weight, high screening efficiency, no hole blockage, friction resistance, impact resistance, tear resistance, long service life, low noise, convenience in installation, high comprehensive benefits and the like.

Owner:安徽屹翔滤材有限公司

Fruit classifying and screening machine

The invention discloses a fruit classifying and screening machine, and belongs to the technical field of fruit screening. The fruit classifying and screening machine comprises a bracket, a screening turntable rotationally arranged on the bracket, a driving device for driving the screening turntable to rotate, and spiral screening fences mounted on the bracket and positioned above the screening turntable; the spiral screening fences are formed by spirally surrounding in the peripheral direction; a runner is formed between two adjacent fences; a radial distance from the outer fence of the spiralscreening fences to the edge of the screening turntable forms a screening channel; and the screening channel is gradually reduced in the peripheral direction, and communicates with the runner. The fruit classifying and screening machine is simple and fast in screening mode, high in efficiency, small in equipment size, simple in structure and low in cost.

Owner:CHENGDU UNIV

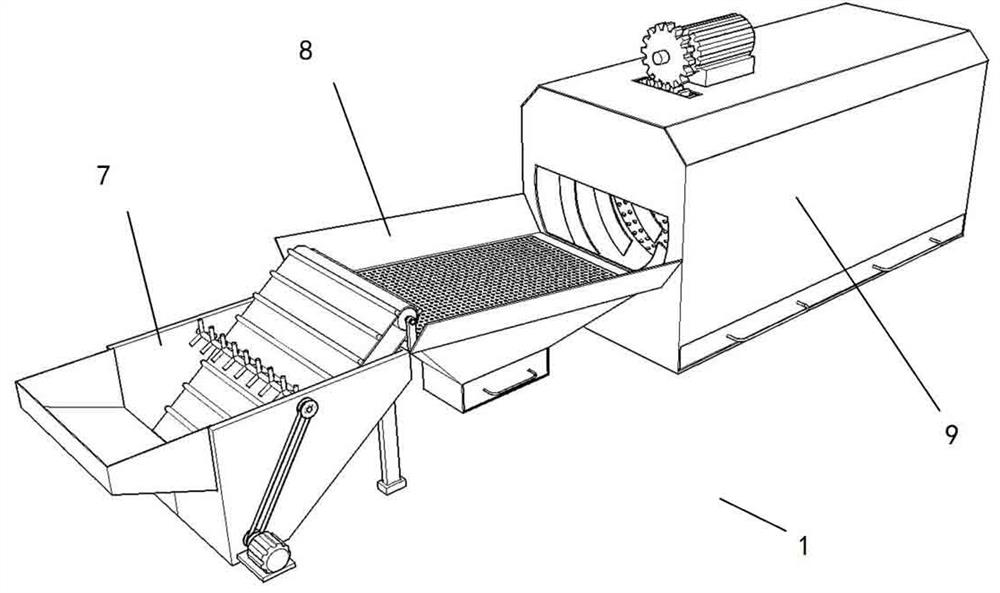

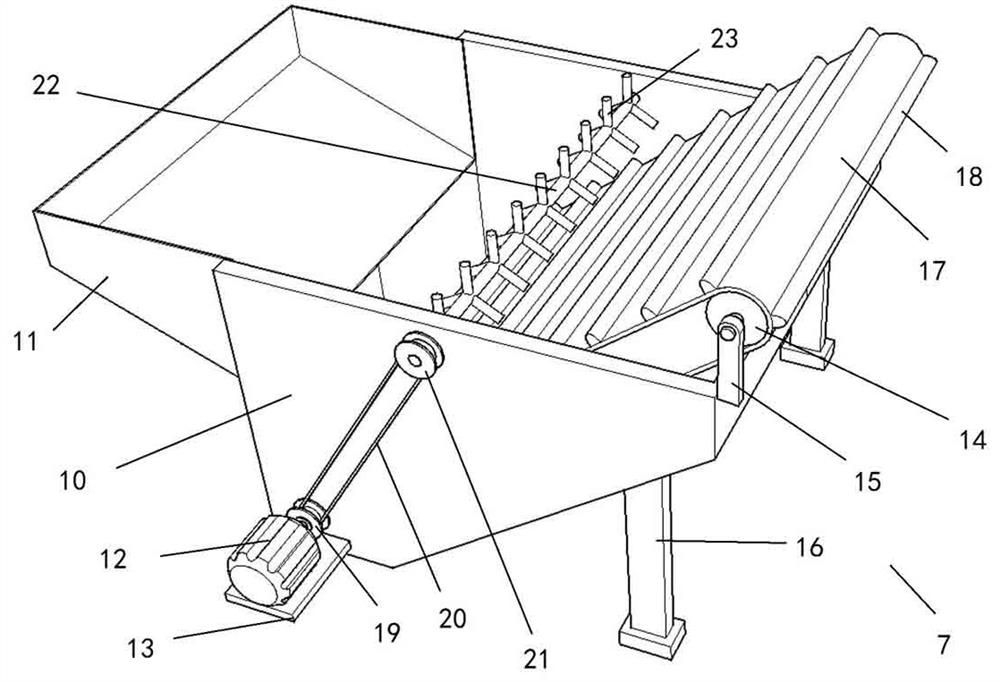

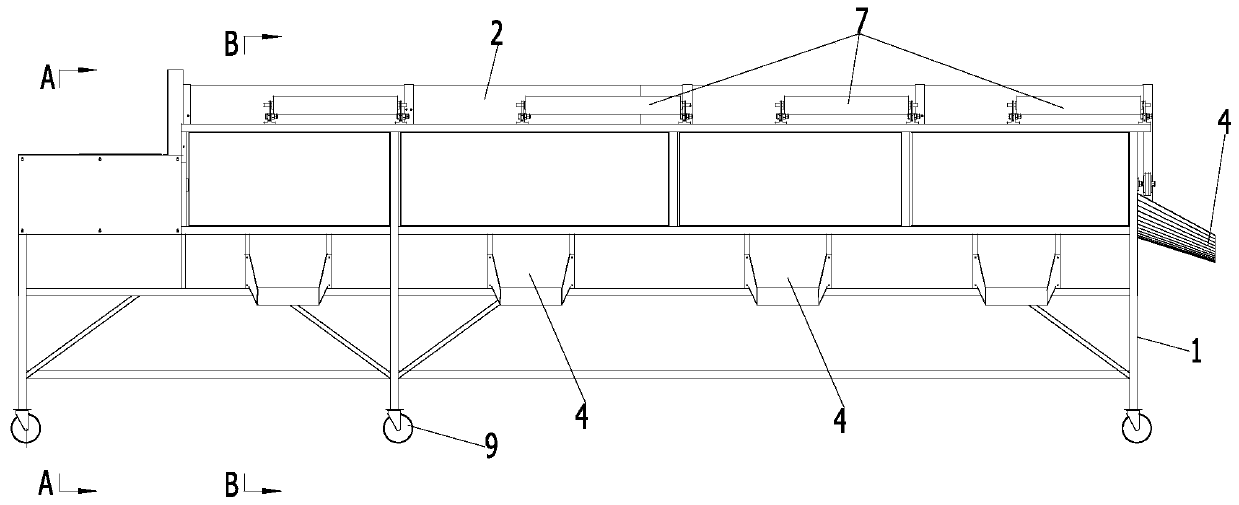

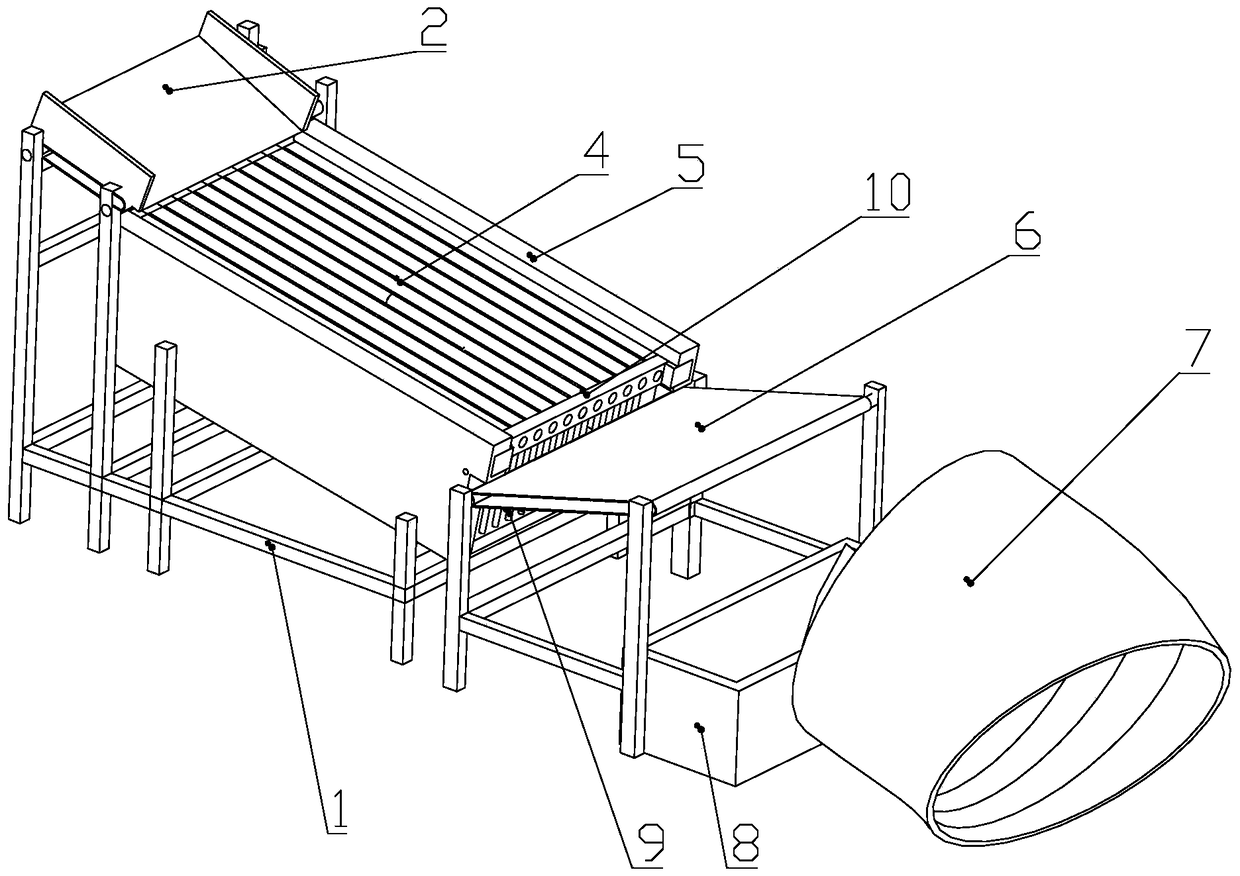

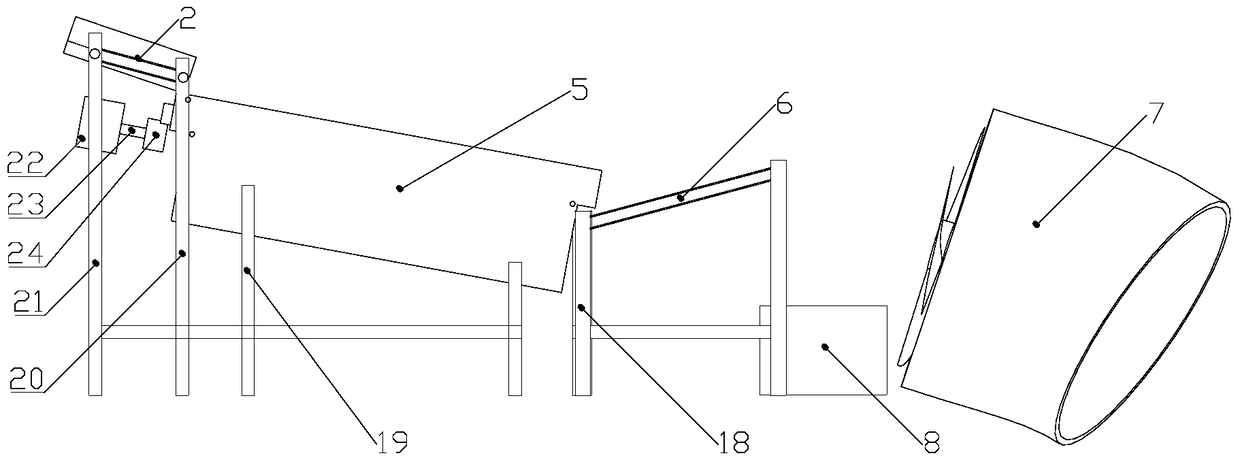

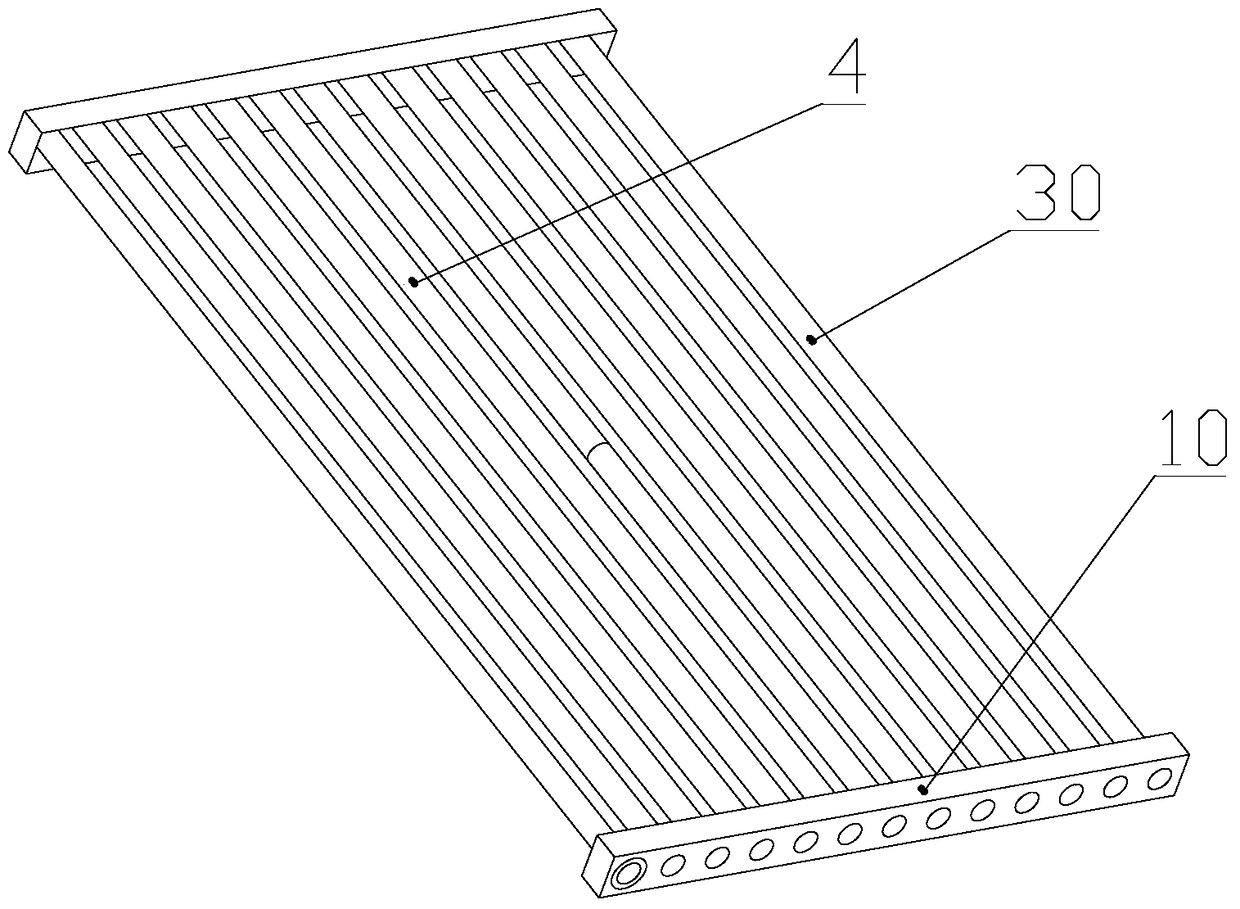

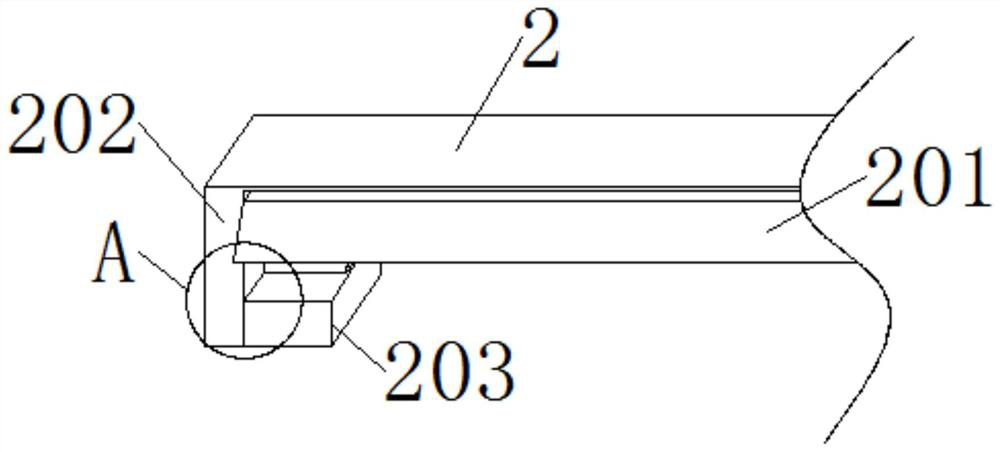

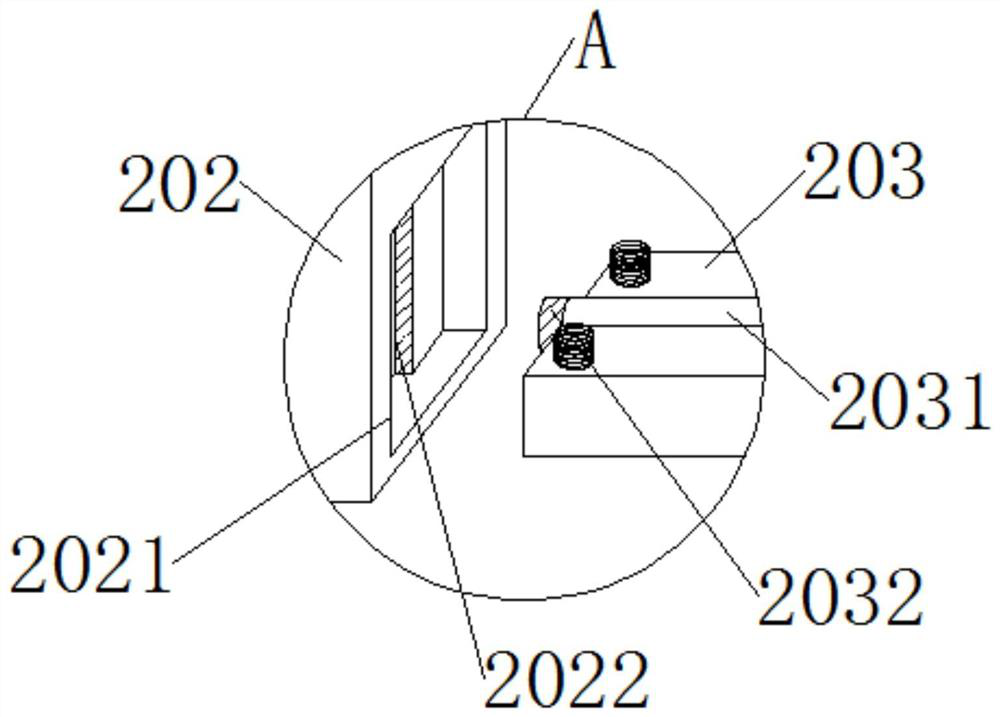

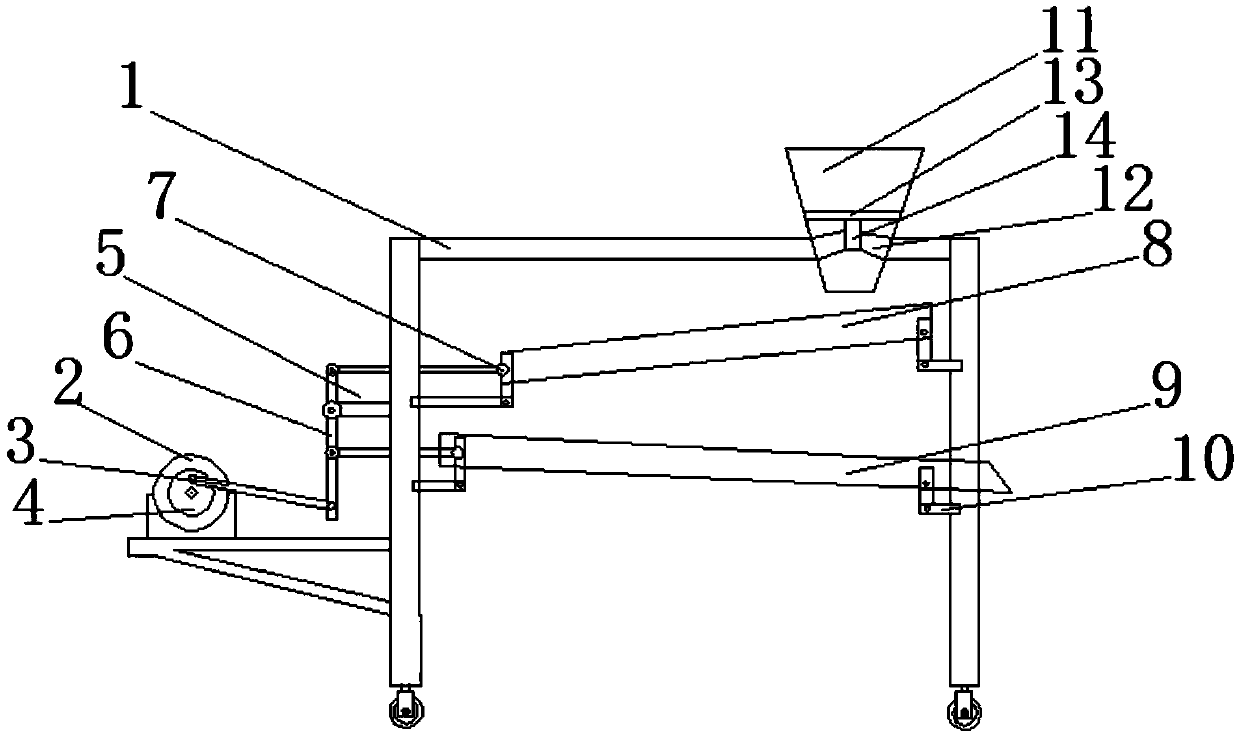

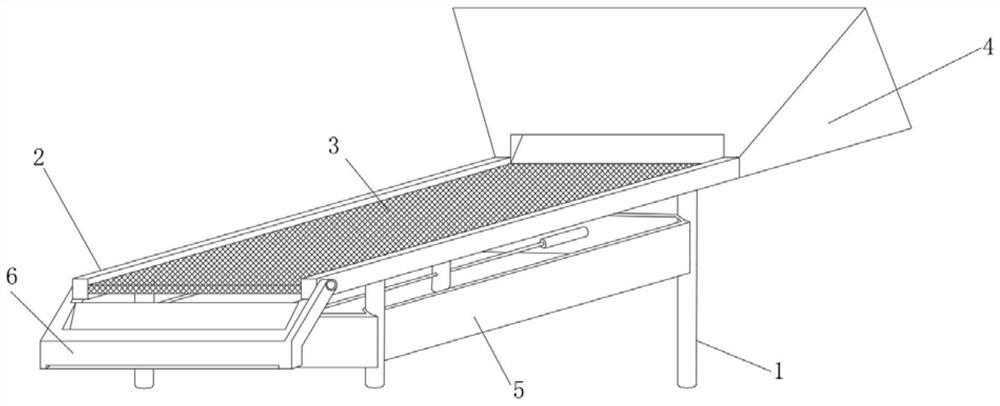

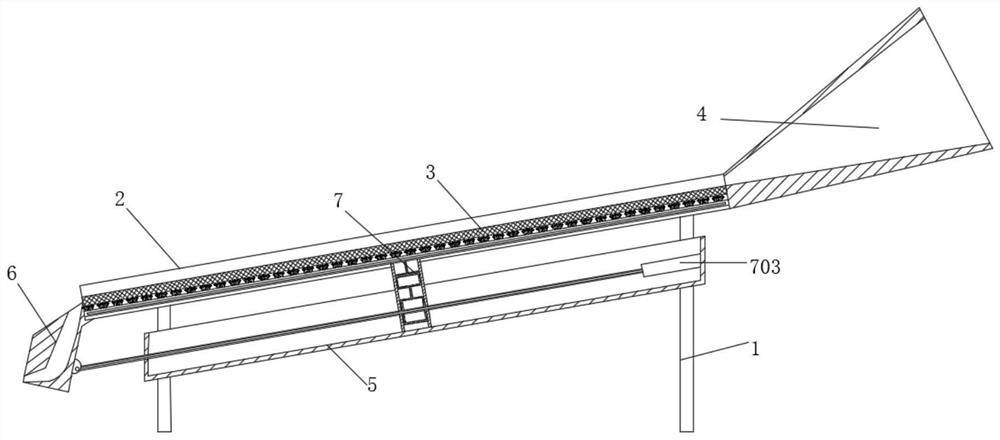

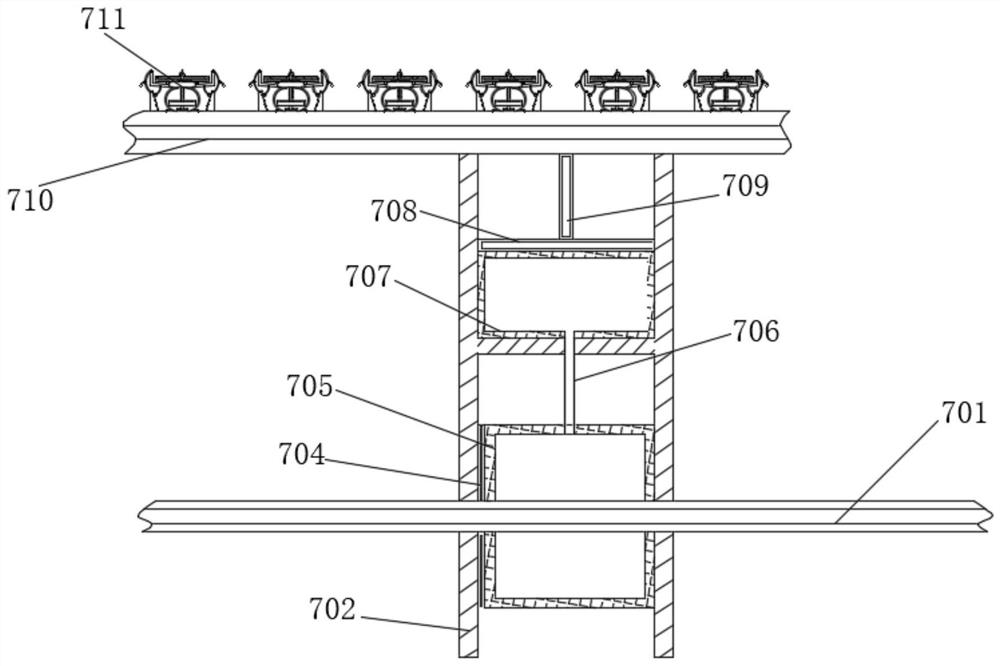

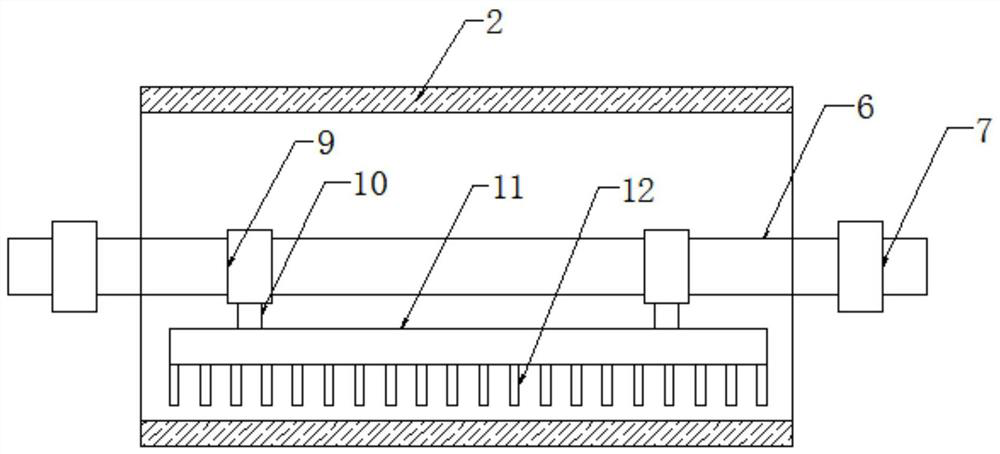

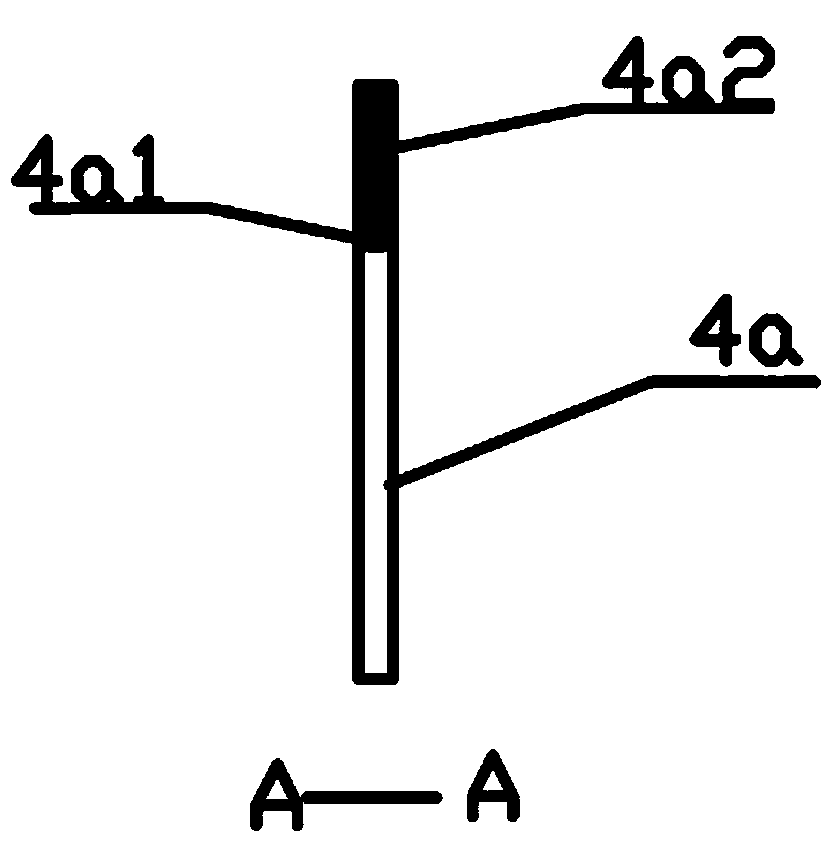

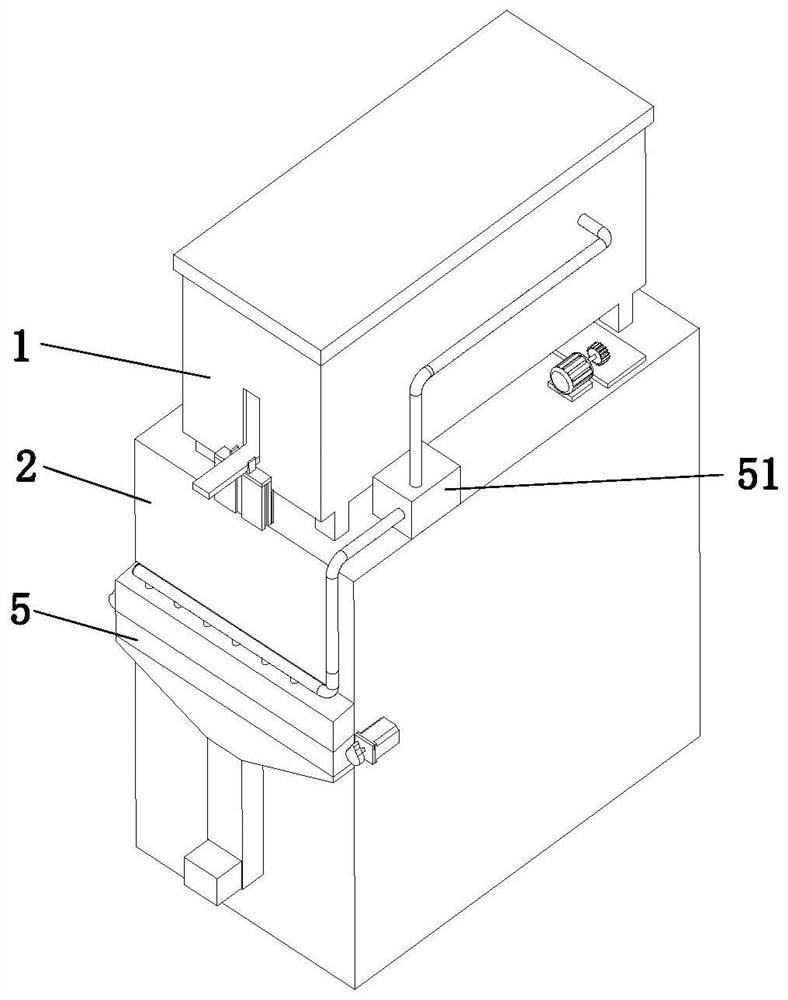

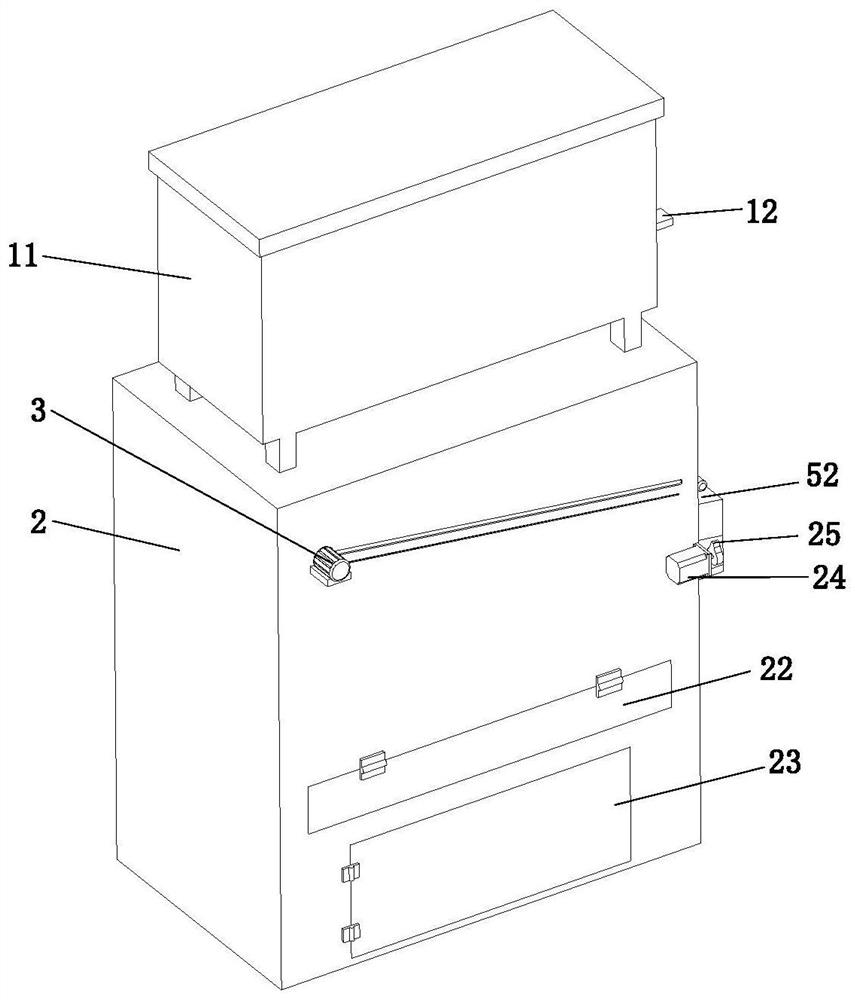

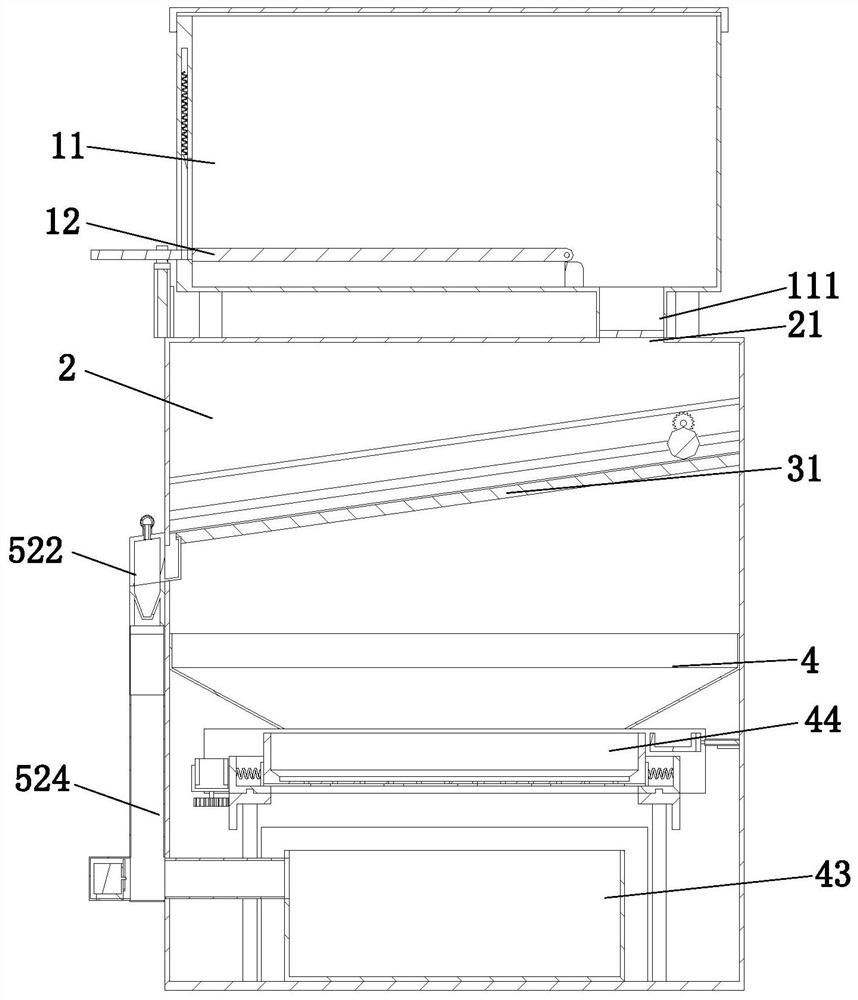

A separation and cleaning device for castor combine harvester

ActiveCN104620780BImprove separation efficiencyReduce screening efficiencyThreshersCastor SeedInsertion stent

The present invention relates to a separation and cleaning device of castor combined harvester, which comprises seven parts: a bracket, a feeding device, a vibrating screen separating device, a driving device for driving the vibrating screen to vibrate, a conveying device, a wind cleaning device and a grain storage device ; Wherein, the feeding device, the vibrating screen separation device, the driving device for driving the vibration of the vibrating screen and the conveying device are installed on the support, the feeding device is installed on one end of the support, and the vibrating screen separation device Installed at the outlet end of the feeding device, the conveying device is installed at the outlet end of the vibrating screen separation device; the grain storage device is installed at the outlet end of the conveying device; the wind cleaning device is installed at the separation and cleaning device of the tail. The separation and cleaning device adopts the dual separation method of vibrating screen vibration separation and wind force cleaning and separation, which greatly reduces the impurity content of the fruit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

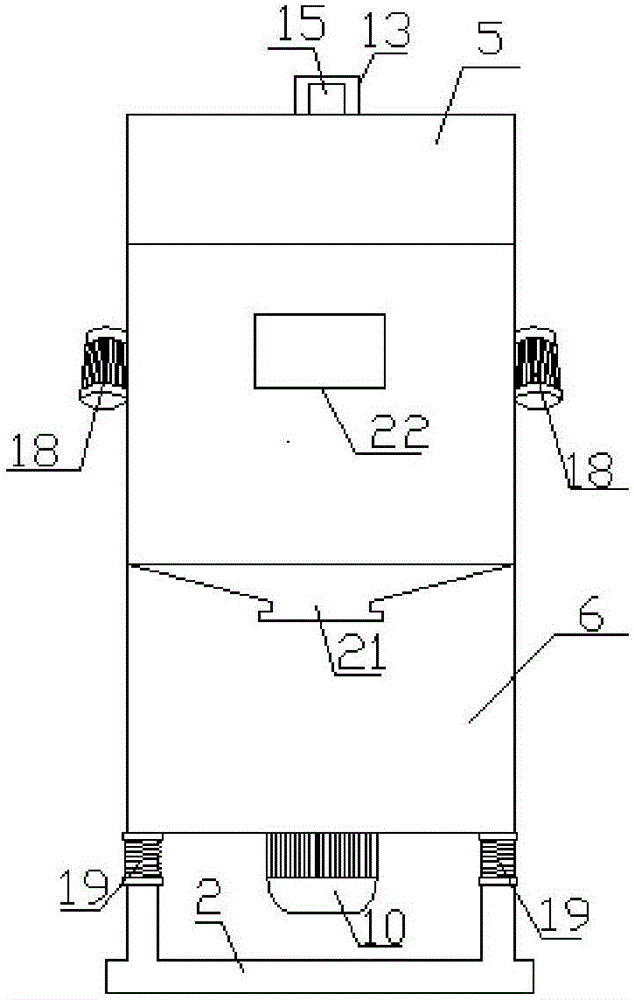

Small-sized vibration sand screening machine

InactiveCN109865664AIncrease sand production rateImprove efficiencySievingScreeningDrive motorBuilding construction

The invention discloses a small-sized vibration sand screening machine. The small-sized vibration sand screening machine comprises a machine frame, a driving motor, a transmission device, a vibrationdevice, a first-stage screen body, a second-stage screen body, fixing bases, a feeding hopper and a sand beating device, wherein the driving motor is arranged at the bottom of the left side of the machine frame, the driving motor is connected with the right transmission device through an eccentric wheel, the vibration device comprises a transmission rod and linkage heads which are vertically arranged, the first-stage screen body and the second-stage screen body are vertically and sequentially distributed on the lower side of the machine frame, the same sides of the first-stage screen body andthe second-stage screen body are connected to one ends of the linkage heads respectively, the other ends of the linkage heads are connected to the transmission rod, the first-stage screen body and thesecond-stage screen body are fixed on the machine frame through the four fixing bases on the lower sides of the first-stage screen body and the second-stage screen body through the linkage rods, andthe feeding hopper is arranged on the top of the machine frame above the first-stage screen body. According to the sand beating device of the vibration sand screening machine and the selection of thetwo-stage screen bodies, the sand discharging rate is greatly improved, the small-sized vibration sand screening machine is small in feeding height, small in size, light in weight, flexible to move, convenient to operate and suitable for various construction sites.

Owner:西安开元合众机电有限责任公司

A kind of thermophilic esterase afest mutant and its screening method and application

ActiveCN105420211BReduce screening efficiencyHigh activityImmobilised enzymesFungiWild typeHydrolysis

Owner:WUHAN HANHAI NEW ENZYMES BIOLOGICAL TECH CO LTD

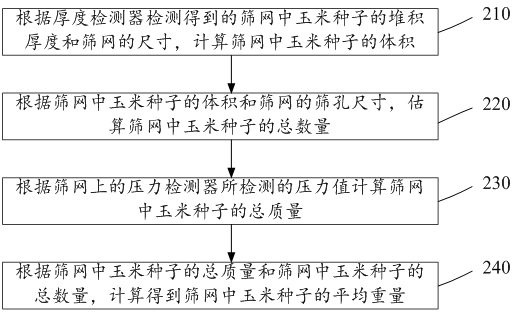

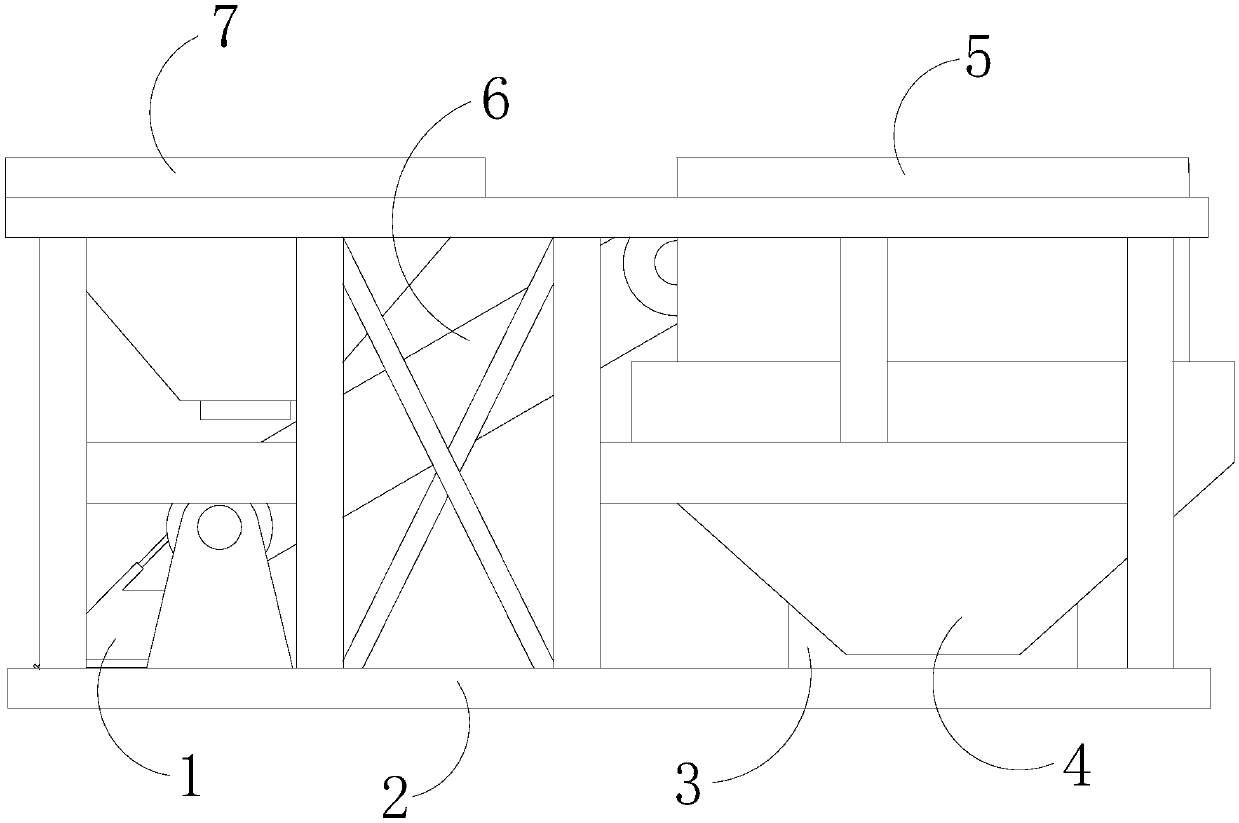

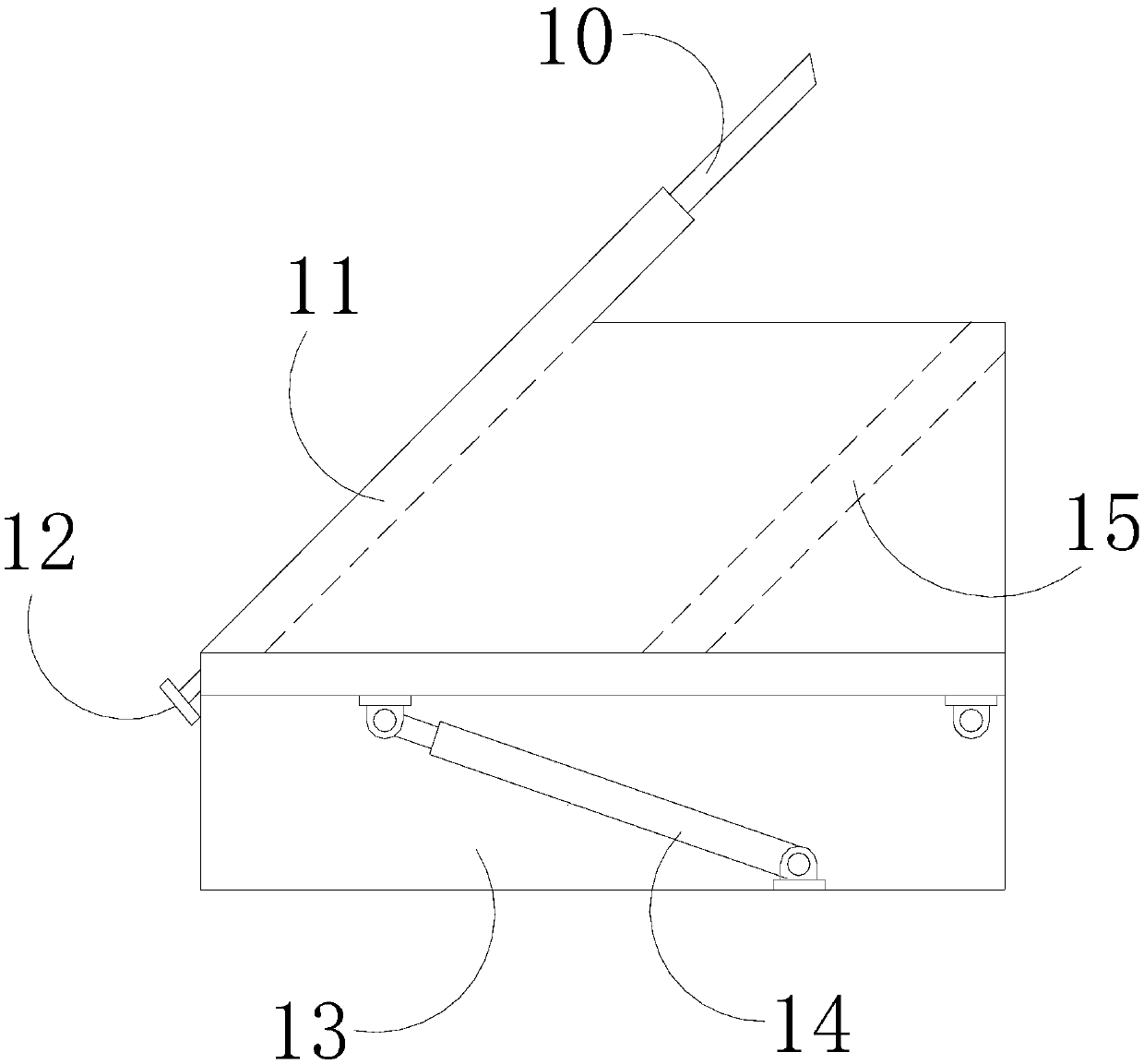

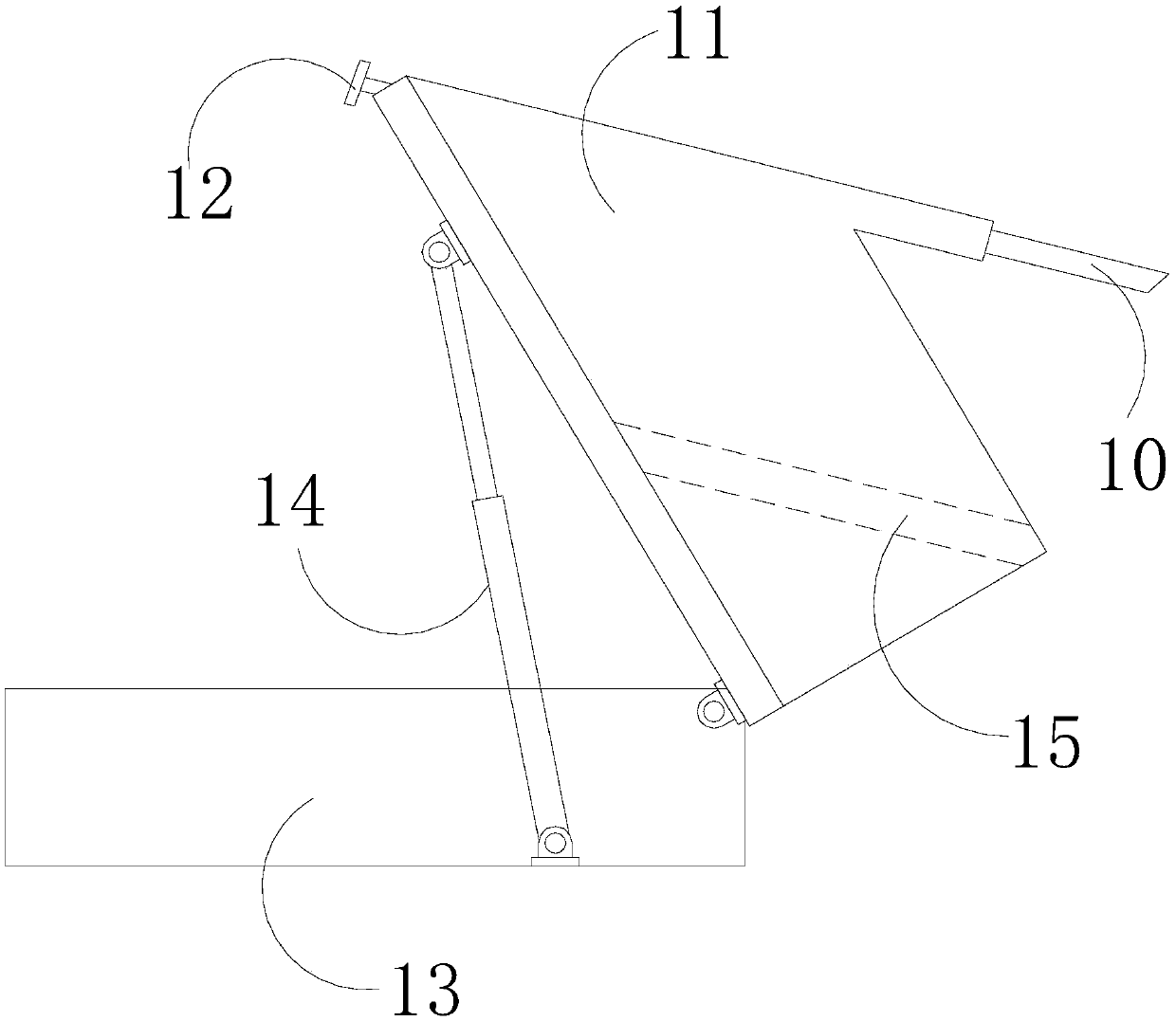

Corn seed screening machine

InactiveCN113198727AImplement automatic filteringAvoid accumulationSievingSeed and root treatmentAgricultural scienceAgricultural engineering

The invention provides a corn seed screening machine. The multiple stages of screens are arranged on a base and stacked in the vertical direction, the sizes of screen holes of the multiple stages of the screens are gradually decreased from top to bottom, a discharging opening is formed in one side of each stage of the screen, so that screening of corn seeds of various sizes is achieved, waste trays are arranged at the bottoms of the multiple stages of the screens, impurities and the unusable corn seeds can be screened, so that the influence on corn planting is avoided, meanwhile, a vibration assembly connected with the multiple stages of the screens is arranged on the base to drive the multiple stages of the screens to vibrate, so that the corn seeds are automatically screened, the screening efficiency is improved, and the labor cost is saved. A scraper is arranged on each screen, the scrapers move back and forth relative to the screens in one direction so that the corn seeds in the screens can be evenly laid on the screens, and the situation that the screening efficiency and effect are reduced due to accumulation is avoided.

Owner:SHANXI AGRI UNIV

Sand screening facility capable of scraping sand on belt and characterized by being adjustable in separation distance between scraping plate and belt

InactiveCN109625850AAdjustable spacingDoes not affect construction progressConveyorsCleaningEngineeringBelt conveyor

The invention discloses a sand screening facility capable of scraping sand on a belt and characterized by being adjustable in the separation distance between a scraping plate and the belt. The sand screening facility structurally comprises a sand scraping device, a supporting frame, a finished product sand conveying device, a discharging drum, a drum screen, a raw material feeding belt conveyor and a raw material storage hopper. The drum screen is arranged on one side of the supporting frame. Compared with the prior art, the sand screening facility has the beneficial effects that the sand which is kept on the belt can be timely scraped, the phenomenon of accumulation of the sand is effectively avoided, and therefore the sand conveying speed cannot be affected; the normal amount of sand canbe held in a screen drum, and therefore the electric energy is saved advantageously as the screening efficiency is improved, and then the screening cost is reduced; meanwhile, the phenomenon that dueto accumulation of the sand, the flowing sand slides to a rotating shaft can be avoided, the phenomenon that the rotating shaft gets stuck is avoided, the belt can normally supply materials, and theconstruction progress is not affected; and the gap between the sand scraping plate and the belt is adjustable, sand scraping operation is more facilitated, the sand scraping plate is convenient to replace and install, and sand discharging operation is also thorough.

Owner:黄崇生

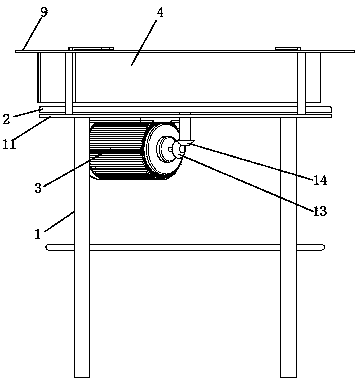

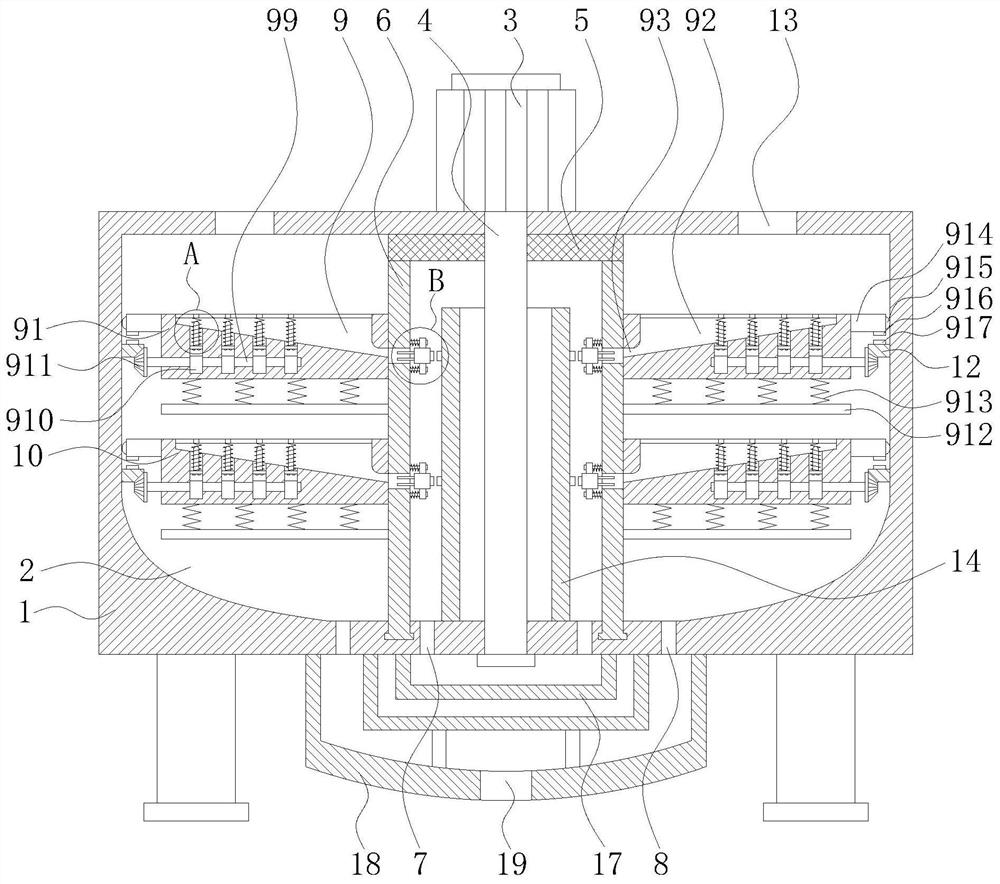

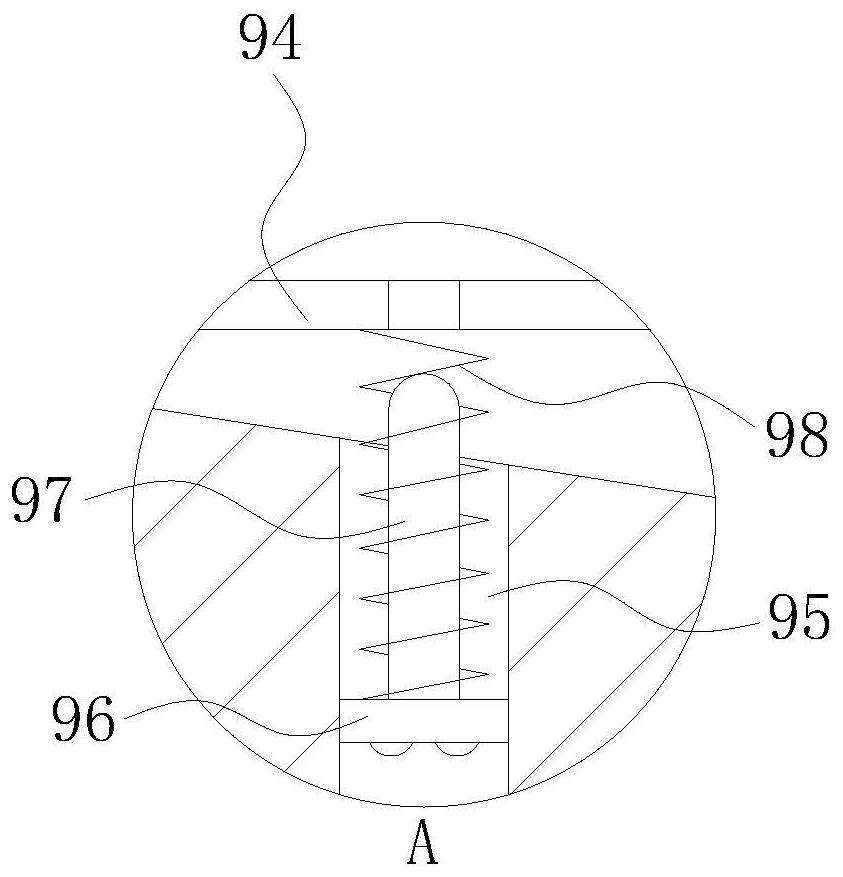

Automatic centrifugal screening treatment system for limestone pulverizing

InactiveCN112474264AReduce cleaning efficiencyReduce screening efficiencySievingScreeningStructural engineeringMechanical engineering

The invention relates to an automatic centrifugal screening treatment system which comprises a base, a discharging barrel, supporting plates, bearing plates, a screening mechanism and a material collecting box, wherein the discharging barrel is mounted in the middle of the upper end face of the base, the discharging barrel is of a cylindrical structure with an opening in the upper end, and the supporting plates are mounted in the positions, located on the left side and the right side of the discharging barrel, of the upper end face of the base; a bearing plate is mounted between the upper endsof the supporting plates, the screening mechanism is mounted in the middle of the bearing plate, and a material collecting box is mounted on the left side of the bearing plate and is of a box-shapedstructure with an opening in the upper end. The system can solve the problems in the process of screening lime powder by using an existing horizontal roller lime powder screening machine that the limepowder screening efficiency is affected as the lime powder screened is low in efficiency to fall, impurities in the screening cylinder is cleaned and is filled repeatedly, and the impurity cleaning efficiency in the screening cylinder is reduced as the overturn process of the screening cylinder is long when the impurities in the screening cylinder are cleaned and the like.

Owner:孙雀

Good and bad screening device after fertilizer production

PendingCN113289885AReduce screening efficiencyAchieve the purpose of self-cleaningSievingScreeningFixed frameAgricultural engineering

The invention relates to the technical field of fertilizer production, and discloses a good and bad screening device after fertilizer production. The device comprises supporting legs, wherein the upper ends of the supporting legs are fixedly connected to a fixed frame; the front side of the fixed frame is fixedly connected to a filter screen; the right end of the fixed frame is fixedly connected to a feed hopper; the left end of the fixed frame is rotationally connected to a discharging hopper through a bearing; the outer walls of the supporting legs are fixedly connected to an ash storage box; and a transmission mechanism is arranged at the bottom of the filter screen. During use, fertilizer is input from the feed hopper, a self-cleaning mechanism can be inserted into meshes of the filter screen in the ascending process, the filter screen can be pulled through a knocking rod to generate the last strong vibration when the self-cleaning mechanism is reset, and when the knocking rod is reset, the knocking rod can strike a screen penetrating needle violently due to inertia to generate vibration, so that dust on hair of a brush is vibrated off, the self-cleaning purpose is achieved, and the purpose of self-cleaning the filter screen in the fertilizer dust screening process is comprehensively achieved.

Owner:李丁

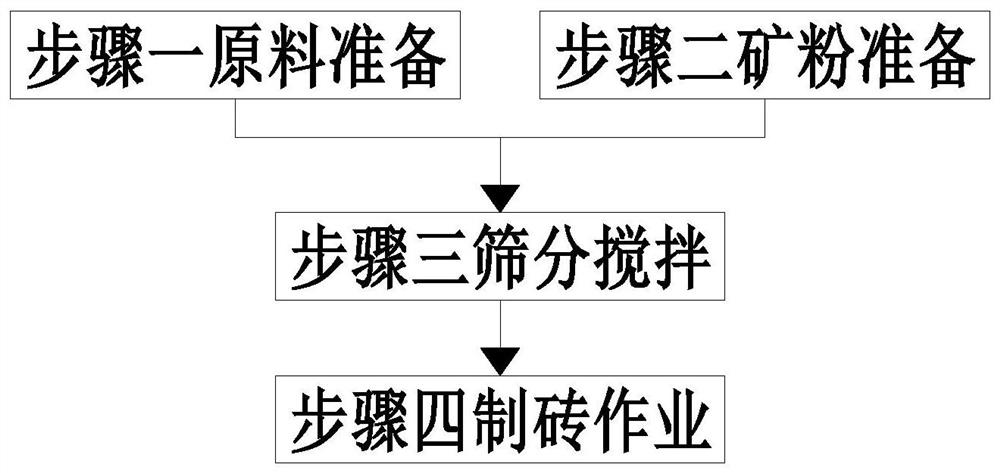

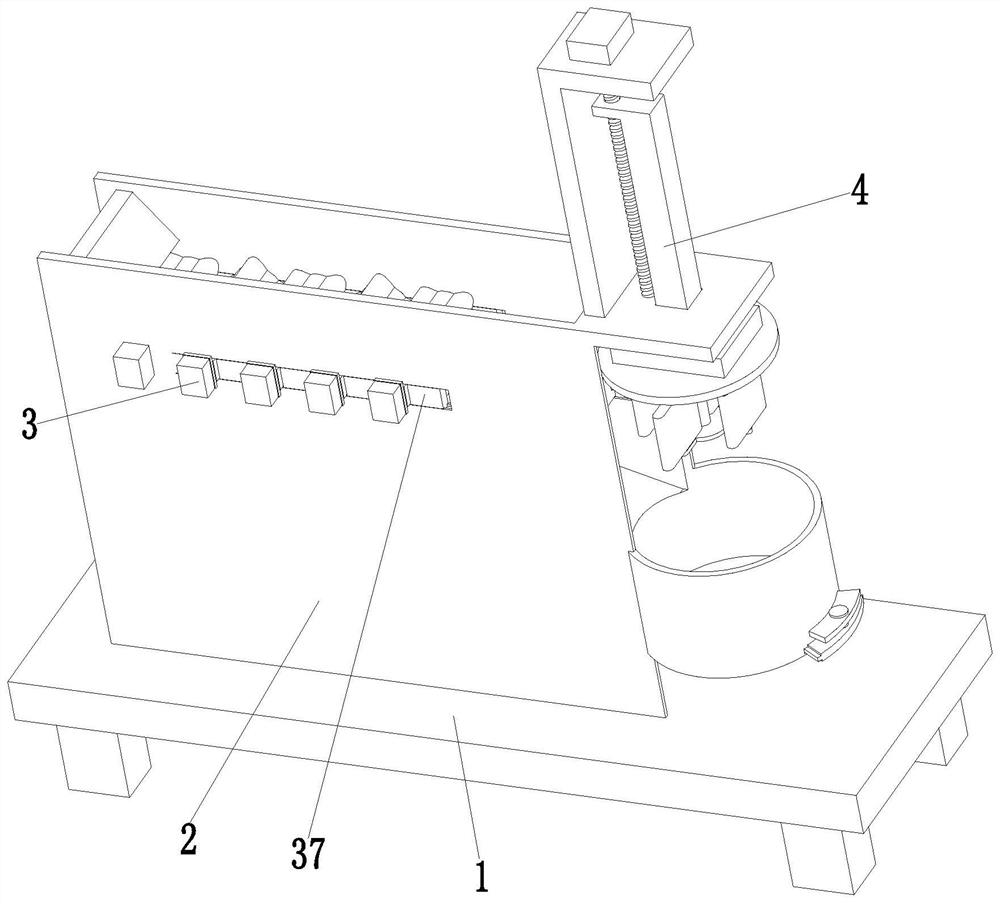

Steel plant solid waste comprehensive utilization and treatment method

The invention relates to a steel plant solid waste comprehensive utilization and treatment method. The method mainly comprises the following steps of raw material classification, mineral powder preparation, screening and stirring, brick making operation and other various procedures. Steel slag screening and stirring equipment used in the method comprises a bottom plate, an adjusting device, a screening device and a stirring device. The method can solve the following problems existing during existing steel slag screening and stirring that a, during traditional steel slag screening, steel slag is usually screened manually through a screen, the labor intensity of manual screening is large, the screening efficiency is low, and the brick making efficiency is reduced; and b, when existing steelslag screening equipment is used for screening the steel slag, screening operation is usually conducted through a vibration screen, the gap of the screen cannot be adjusted, only fixed steel slag blocks can be screened, the screened steel slag cannot be stirred, and the steel slag screening efficiency is reduced.

Owner:新疆隆泰达环保建材科技发展有限公司

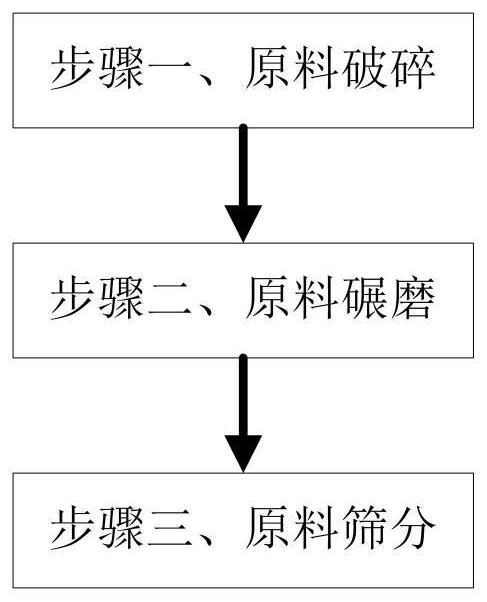

Putty powder preparation method

InactiveCN112371301AReduce processing efficiencyInconvenient to operateSievingScreeningPuttyChemistry

The invention belongs to the technical field of building materials, and particularly relates to a putty powder preparation method. The putty powder preparation method comprises the following steps that S1, raw materials are crushed, specifically, a base material, filler and an auxiliary are mixed and then crushed, so that the raw materials are in a small block shape; S2, the raw materials are ground, specifically, the small-block-shaped raw materials prepared in step 1 are ground, and thus the powdery raw materials are obtained; and S3, the raw materials are screened, specifically, the powderyraw materials prepared in step 2 are screened and then subpackaged, and the process of screening the powdery raw materials in step 3 is completed through the cooperation of a putty powder preparationmachine. According to the putty powder preparation method, fine materials and coarse materials are collected synchronously while the powdery raw materials are screened, the processing efficiency is improved, a screen plate does not need to be dismounted during collection, and the operation is convenient; and when the raw material powder particles of putty powder are screened, the fine materials clamped in screen holes of the strip-shaped screen plate can be vibrated off, and thus the blockage of the screen holes is avoided.

Owner:安庆皖塑化工科技有限公司

Screening and output integrated particle screening system

The present invention relates to the technical field of screening, more specifically, a particle screening system with integrated screening and output, including a support assembly, a screening assembly, a screening bucket, a feeding assembly, a storage assembly, a differential assembly, a driving assembly, and an output assembly And the opening and closing assembly, the driving assembly can drive the left differential assembly to rotate, the left differential assembly drives the screening assembly to rotate multiple times, separates particles of different sizes, and the screening assembly drives the right differential assembly to rotate. The speed assembly rotates, and when the differential assembly on the left drives the opening and closing assembly at the lower end to slide, a discharge of small particles is carried out. Fast and efficient screening.

Owner:安徽多广新材料科技有限公司

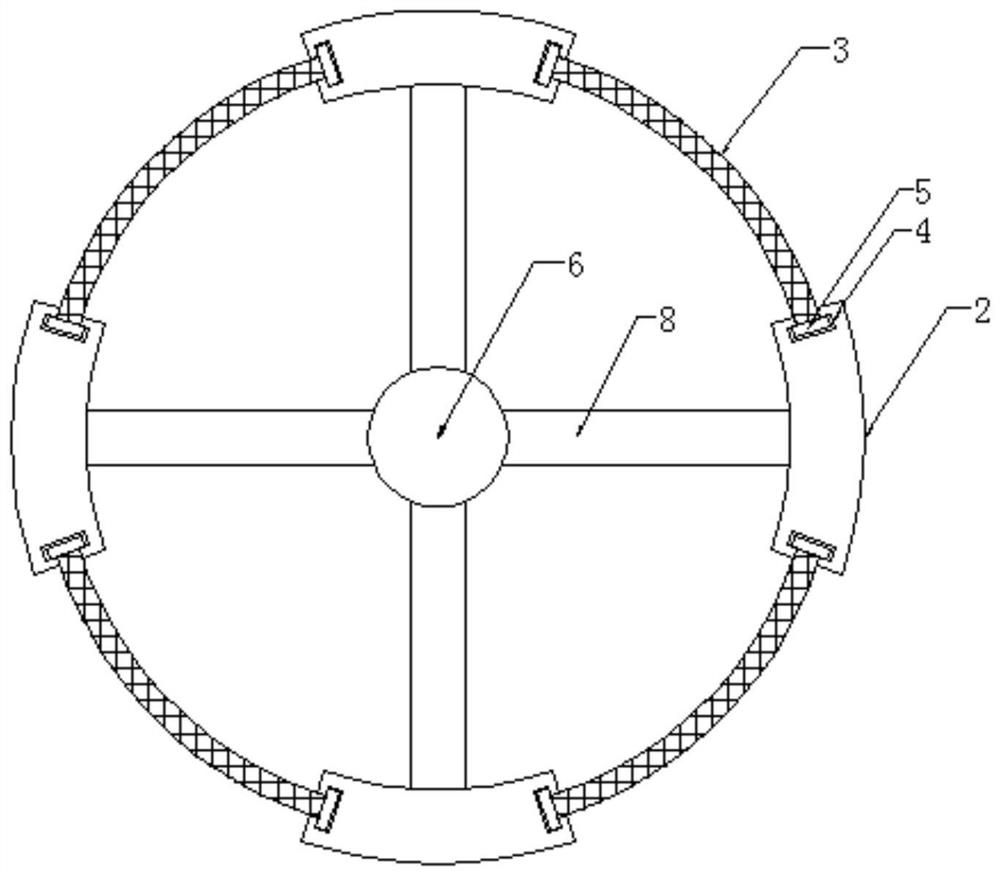

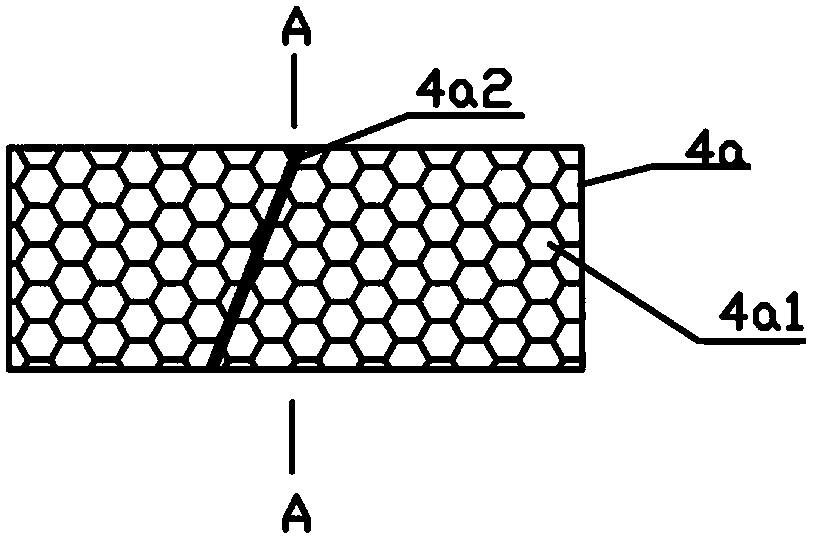

Screening cage for wheat scourer and using method of screening cage

InactiveCN112893078AImprove convenienceReduce wasteSievingScreeningAgricultural engineeringStructural engineering

The invention discloses a screening cage for a wheat scourer and a using method of the screening cage. The screening cage comprises a screening cage body which is composed of a plurality of arc-shaped mounting plates and a plurality of screens; convex clamping grooves are formed in the two ends of each arc-shaped mounting plate; and clamping blocks are fixedly connected to the two ends of each screen. According to the screening cage for the wheat scourer and the using method of the screening cage, the screening cage body is composed of the plurality of arc-shaped mounting plates and the plurality of screens, the damaged screens can be replaced, and resource waste is reduced; the arc-shaped mounting plates and the screens are slidably clamped through the convex clamping grooves and the clamping blocks, so that the convenience of mounting and dismounting of the screening cage is improved, and the complexity of replacing the screens by workers is reduced; and wheat accumulated at the bottom of the screening cage body can be segmented through lantern rings, connecting rods, a material distributing plate and material pulverizing teeth, so that the situation that the wheat is accumulated at one position to block screen holes and the wheat screening efficiency is reduced is avoided.

Owner:青海和众网络科技有限公司

Plastic dry sorting process

InactiveCN102755961BReduce volumeNot easy to separateGas current separationSocial benefitsEconomic benefits

The invention provides a dry type plastic sorting technology. According to the technology, waste is separated from a plurality of plastic-containing wastes which are produced in daily production and daily life. The technology comprises the steps of separating waste, refining, drying, loosing, sieving and winnowing. According to the technology, water is nearly not used in the whole process of separating, thus the working efficiency can be improved, and the separated plastic can be directly used for making plastic products, so that the plastic can be served as a resource for being utilized again, and the environmental pollution caused by directly discarding the plastic can be avoided, and the strategy of sustainable development can be met, and superior economic benefit and social benefit can be achieved.

Owner:王杰生

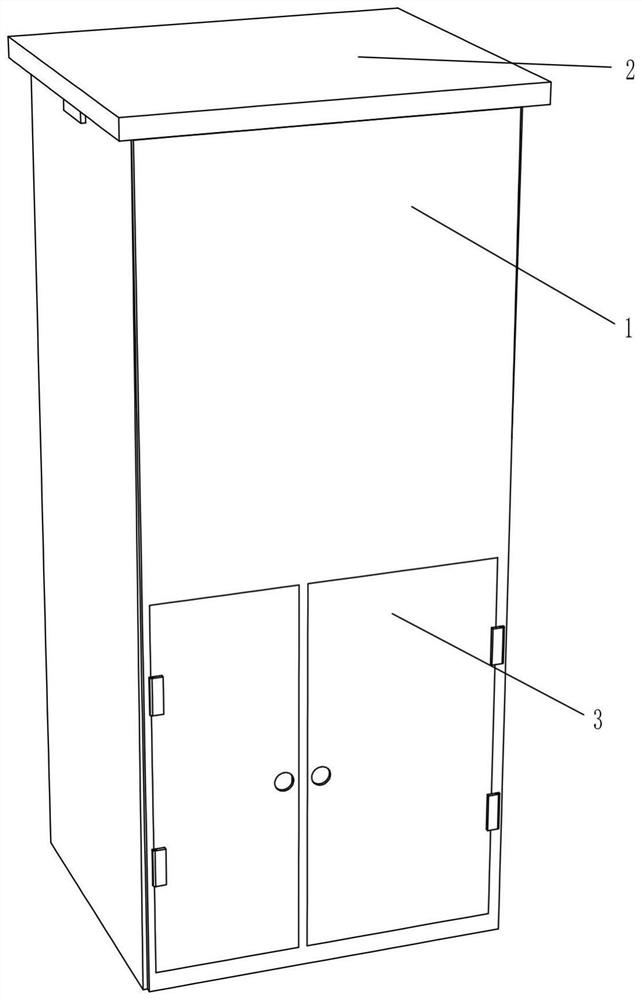

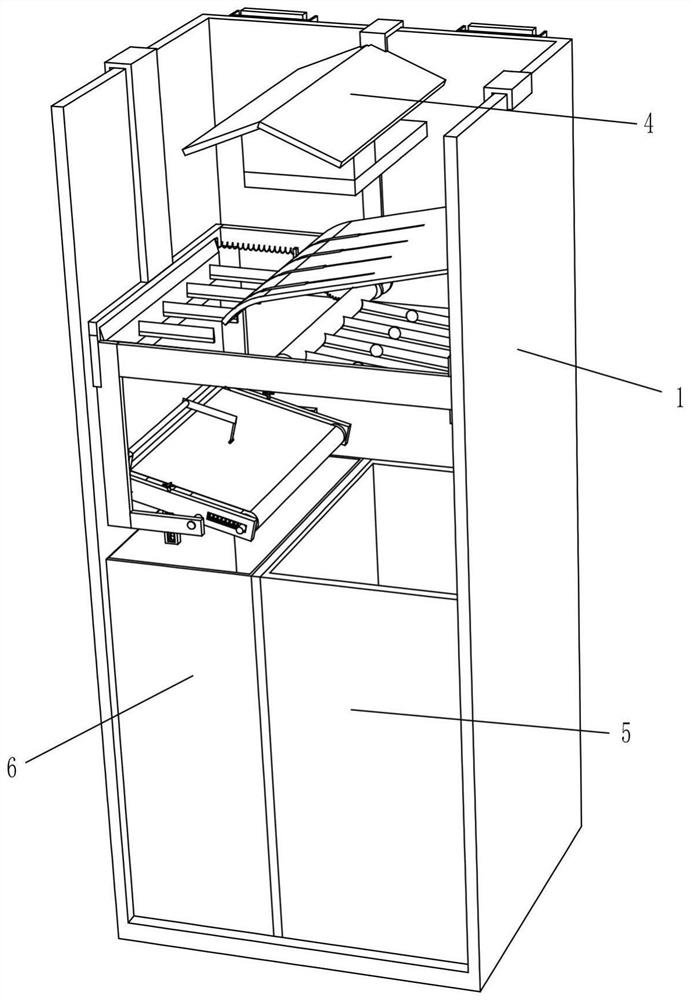

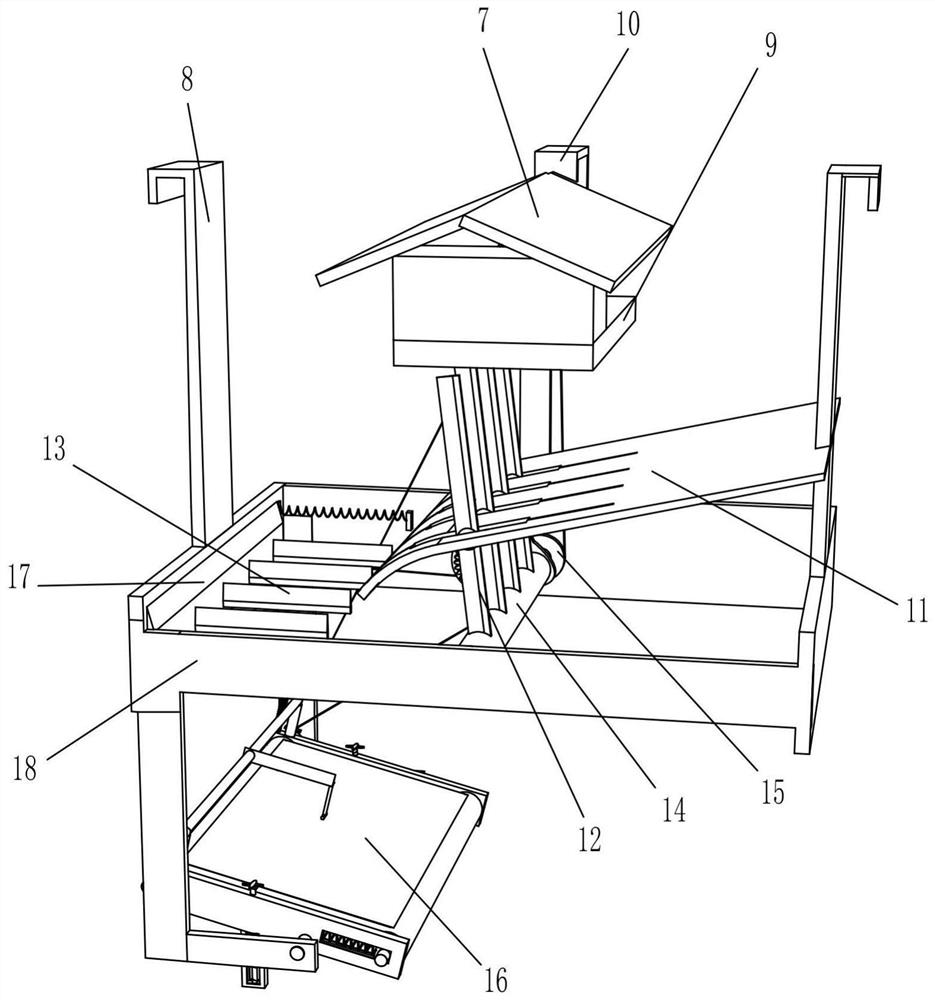

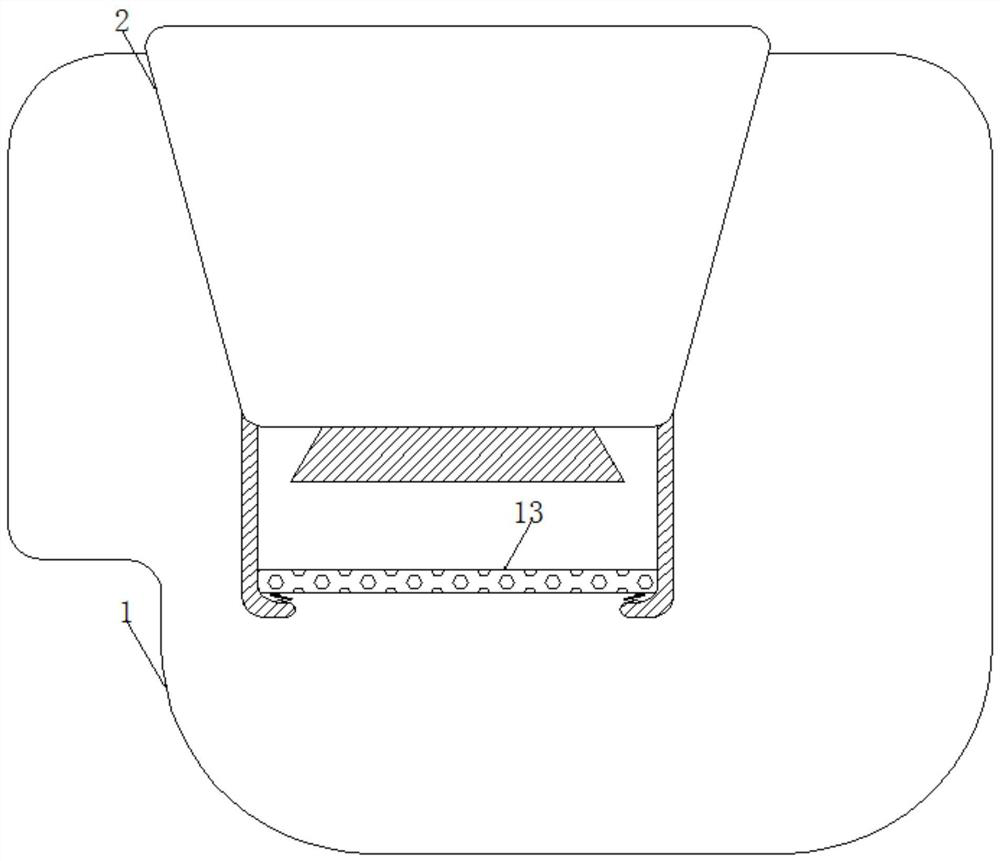

A drug particle screening device

InactiveCN110860455BAvoid cloggingReduce screening efficiencySievingScreeningDrugs preparationsPharmaceutical drug

The invention discloses a drug particle screening device, and belongs to the technical field of drug preparation. The drug particle screening device comprises a feeding mechanism, a cabinet body, a screening mechanism and a recycling mechanism, wherein the feeding mechanism is installed at the top of the cabinet body; the screening mechanism and the recycling mechanism are both arranged in the cabinet body; a circulating mechanism is arranged on the side of the cabinet body and comprises a circulating assembly and a receiving assembly; one end of the circulating assembly extends into the feeding mechanism, and the other end of the circulating assembly extends into the receiving assembly; and one end of the receiving assembly penetrates through the side wall of the cabinet body to be matched with the recycling mechanism. According to the drug particle screening device, when large-particle medicines are clamped in screening holes, a driving motor drives a driving gear on an output shaftof the driving motor to rotate, and the driving gear rotates to drive a shifting gear meshing with the driving gear and a repressing roller fixedly connected with the shifting gear to roll the large-particle medicines getting stuck in the screening holes so that the crushed medicines can be small enough to pass through the screening holes, so that the situation that the large-particle medicines block the screening holes so as to reduce the screening efficiency is avoided.

Owner:LANZHOU UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com