Plastic dry sorting process

A plastics and sorting technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve problems such as low efficiency, water pollution, and high consumption, and achieve high drying efficiency and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

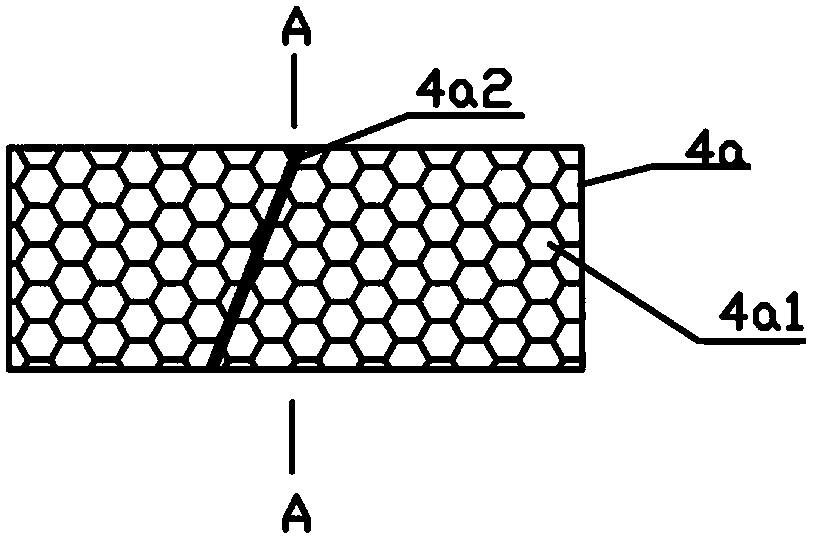

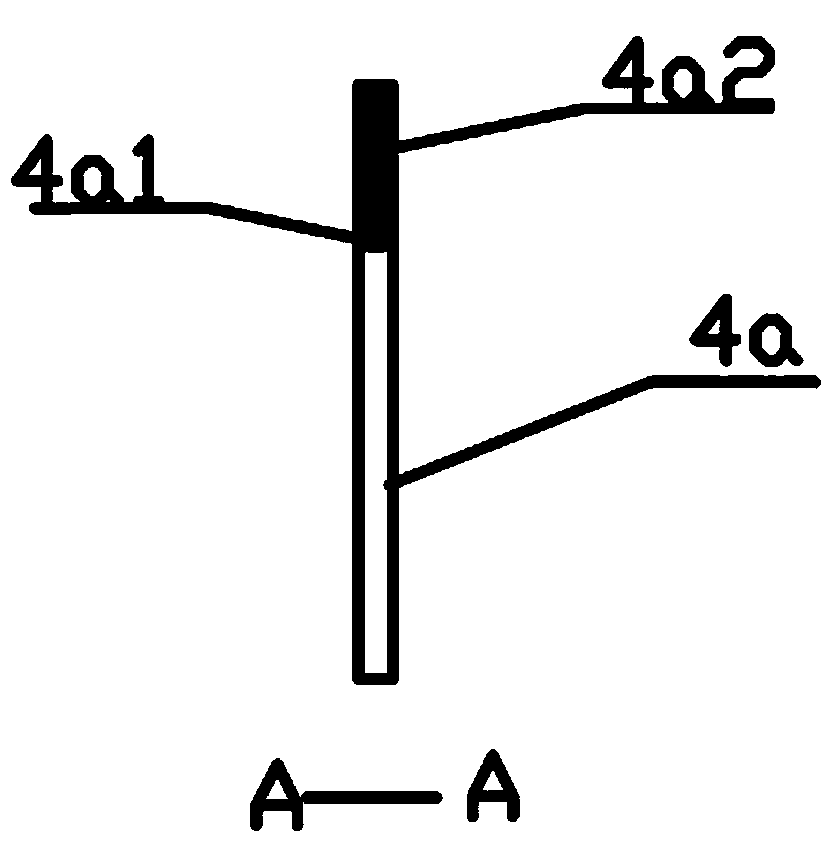

[0025] to combine figure 1 , figure 2 , image 3 , the machine used in refinement 1 process is a shearing machine; the machine used in drying 2 process is a drum dryer and a hot air blower. The drum dryer and the hot air blower are connected through a ventilation pipe, and one end of the ventilation pipe is connected to the air outlet pipe of the hot air blower. , the other end of the ventilation pipe is inserted into the drum dryer; the machinery used in the loosening process is a blender; the vibrating screening machine 4a used in the screening 4 process is greater than 4 meters in length, with a vibration frequency of 2-8 Hz and a vibration amplitude of 4- 8 mm, the aperture of the vibrating screening machine 4a screen 4a1 is 3-5 mm, the vibrating screening machine 4a screen 4a1 is fixed with a guide plate 4a2, the guide plate 4a2 is perpendicular to the vibrating screening machine screen 4a1, and the guide plate 4a2 is vertical The height is 6-12 mm, and the material gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com