Sand screening device capable of automatically collecting gravel particles

A particle and sand screening technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problem of easy clogging of filter screen holes and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

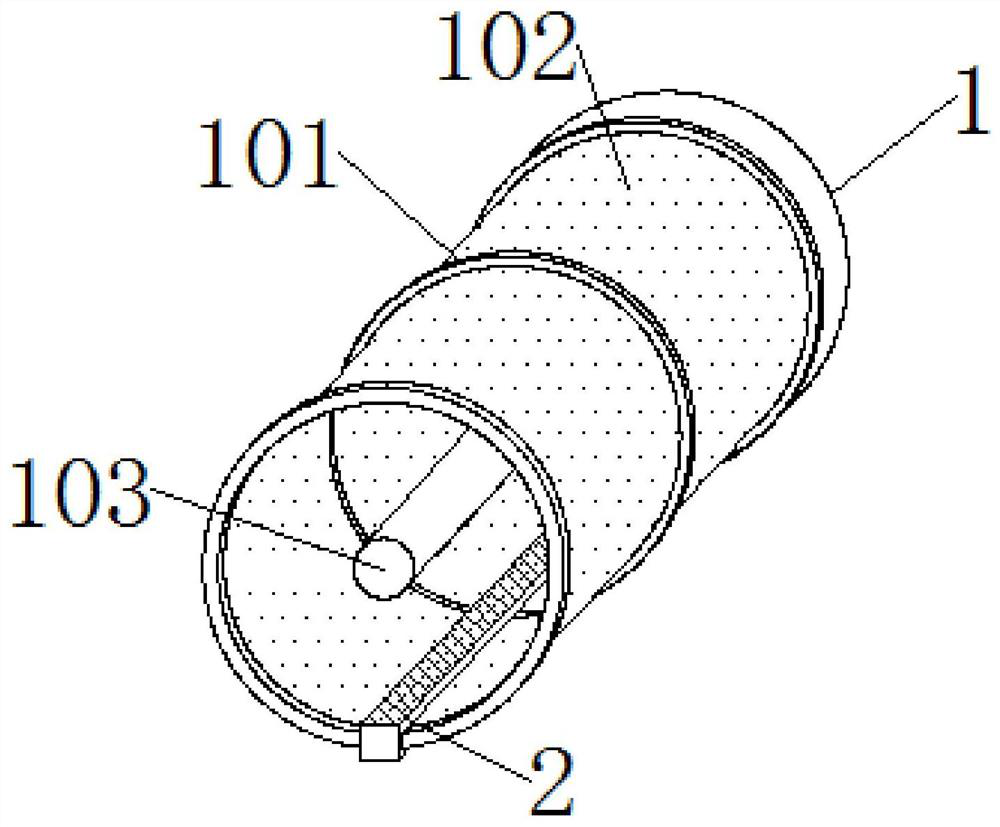

[0040] Please refer to Figure 1 to Figure 6 :

[0041] A sand screening device capable of collecting sand and gravel particles by itself, including: a main body 1, a support frame 101 is connected around the main body 1 to support and connect the filter screen 102 between them, and a rotating shaft 103 is connected to a motor in the middle of the main body 1 to drive the main body 1 for rotation;

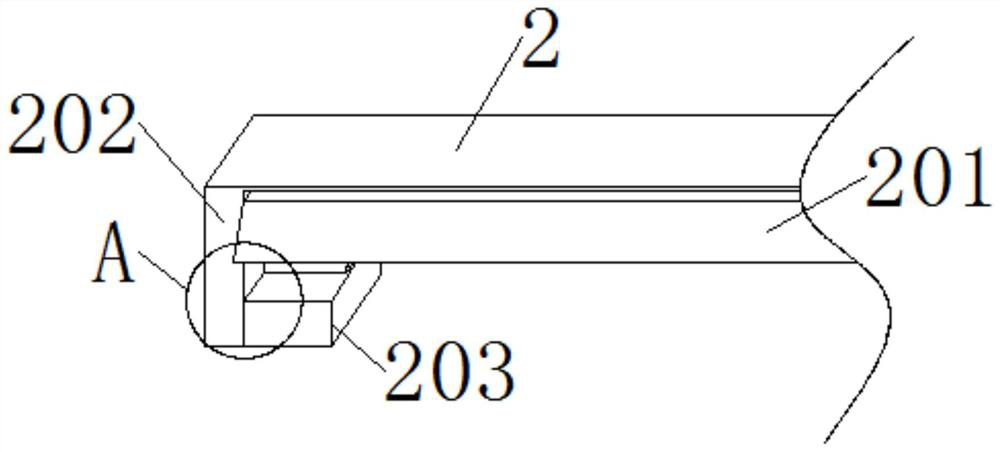

[0042] The collection structure 2 is arranged on one side of the inner wall of the main body 1 by inserting and fitting the collection structure 2 .

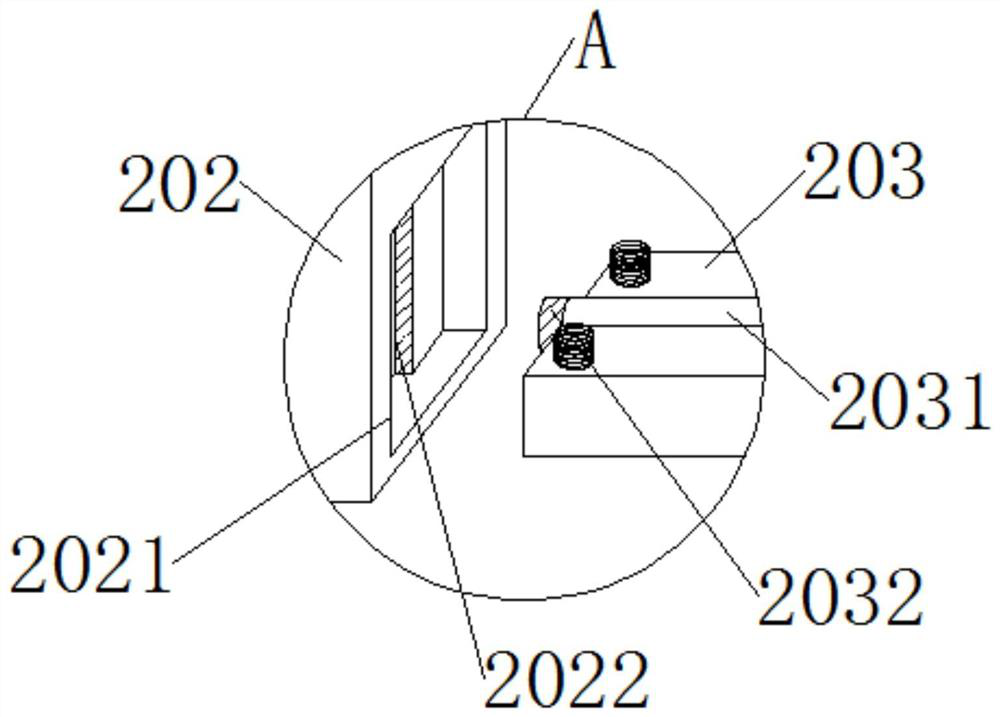

[0043] Wherein, the collection structure 2 includes;

[0044] Inclined collection block 201, the oblique collection block 201 is a rectangular-shaped protrusion extending obliquely from one side of the collection structure 2; at the same time, when the collection structure 2 moves along with the rotation of its main body 1, the main body 1 rotates and sieves sand. The sieved sand and gravel will also follow it for a certain rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com