Screening and output integrated particle screening system

A particle screening technology, applied in solid separation, filtration, transportation and packaging, etc., to achieve fast and efficient screening, speed up screening efficiency, and prevent the accumulation of small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

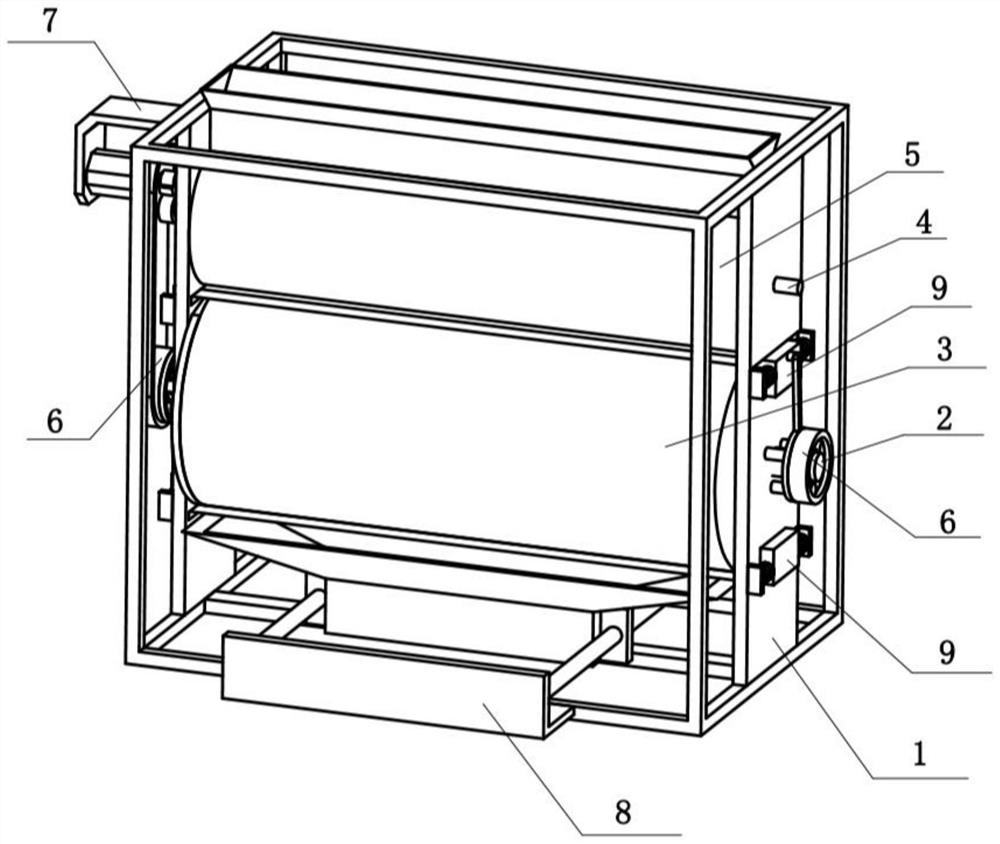

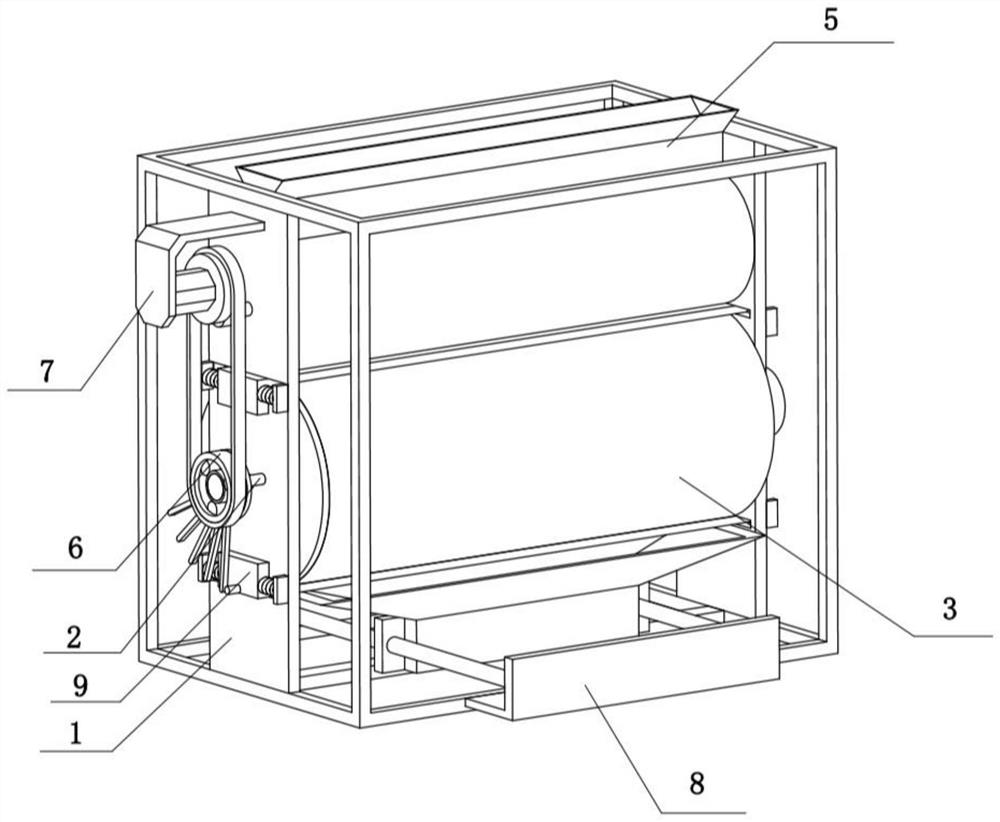

[0034] Combine below Figure 1-11 Describe this embodiment, the particle screening system with integrated screening and output includes a support assembly 1, a drive assembly 7 and an output assembly 8, the drive assembly 7 is fixedly connected to the upper part of the left side of the support assembly 1, and the output assembly 8 is fixedly connected to the support assembly 1 At the lower end of the screen, the particle screening system with integrated screening and output also includes a screening assembly 2, a screening bucket 3, a feeding assembly 4, a storage assembly 5, a differential assembly 6 and an opening and closing assembly 9. The screening assembly 2 is rotatably connected to the support The lower part of the assembly 1, the screening bucket 3 is fixedly connected to the lower part of the support assembly 1, the feeding assembly 4 is rotatably connected to the upper part of the support assembly 1, the storage assembly 5 is fixedly connected to the upper part of th...

specific Embodiment approach 2

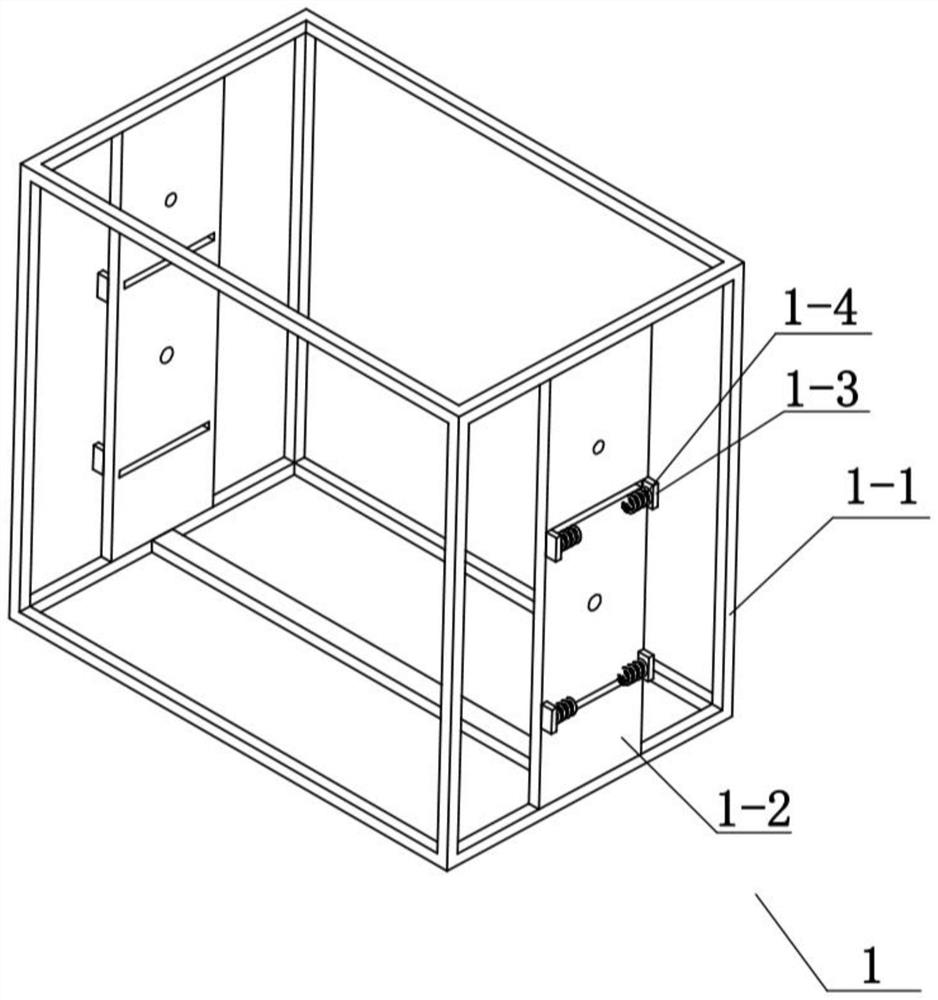

[0036] Combine below Figure 1-11 To illustrate this embodiment, the support assembly 1 includes a support frame 1-1, a side support plate 1-2, a spring plate 1-3 and a return spring 1-4, and the two side support plates 1-2 are respectively fixedly connected to the support frame On the left and right sides of 1-1, two spring plates 1-3 are arranged on the front and rear sides of the two side support plates 1-2, and a plurality of spring plates 1-3 are fixedly connected with reset springs 1-4; A side support plate 1-2 plays a role in supporting and installing the remaining components. After being compressed and stretched by the two opening and closing components 9, when the applied external force disappears, the plurality of return springs will 1-4 play a role in resetting the two opening and closing components 9 .

specific Embodiment approach 3

[0037] Combine below Figure 1-11 To illustrate this embodiment, the screening assembly 2 includes a screening plate 2-1, a screening hole 2-2, a screening shaft 2-3 and a cover 2-4, and the screening plate 2-1 is provided with a plurality of The screening hole 2-2, the left and right sides of the screening plate 2-1 are fixedly connected to the screening shaft 2-3, the cover 2-4 is fixedly connected to the left side support plate 1-2, and the two screens The sub-shafts 2-3 are respectively rotatably connected to the two side support plates 1-2, and the sieving shaft 2-3 on the left side is rotatably connected to the cover 2-4.

[0038] When the sieving plate 2-1 rotates, small particles will pass through multiple sieving holes 2-2 from one side of the sieving plate 2-1 and fall to the other side. The rotation of the sieving plate 2-1 prevents particles Accumulation, resulting in low screening efficiency, this form of rotation will allow small particles to be better separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com