Good and bad screening device after fertilizer production

A screening device, good and bad technology, applied in sieves, solid separation, chemical instruments and methods, etc., can solve the problems of non-plasticity, dust, fertilizer, dust explosion, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

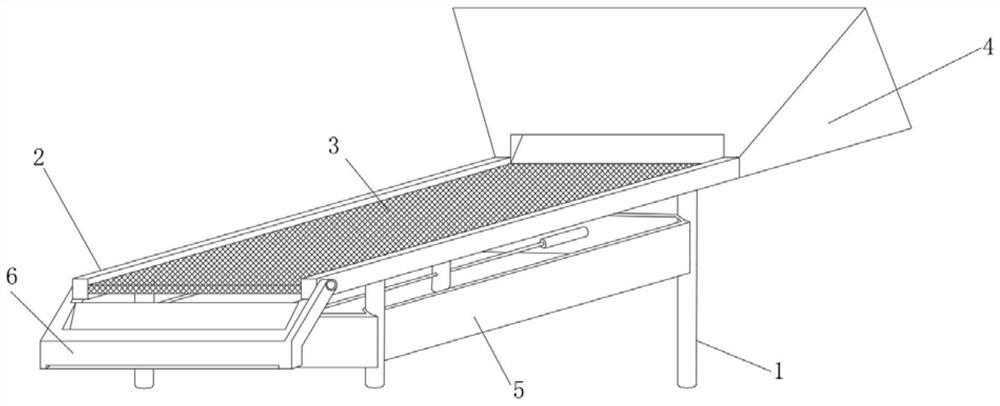

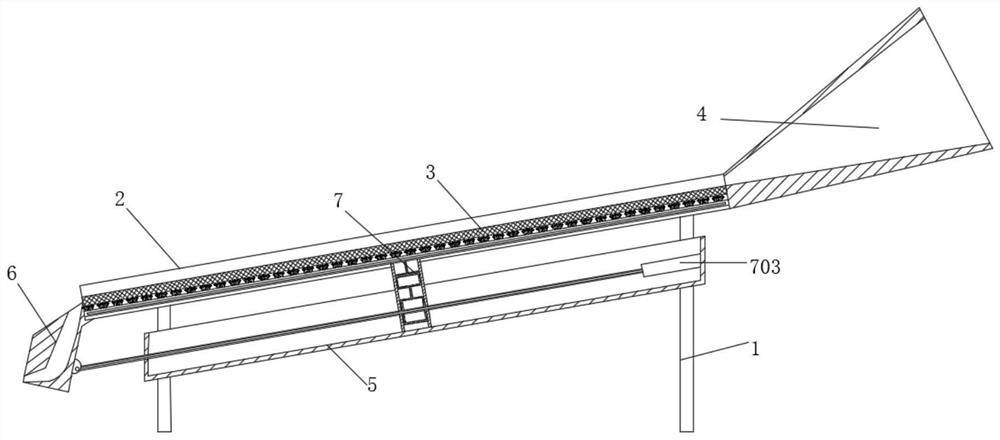

[0020] Such as Figure 1-6 As shown, the present invention provides a technical solution: a fertilizer quality screening device after production, including a support leg 1, the upper end of the support leg 1 is fixedly connected with a fixed frame 2, and the front side of the fixed frame 2 is fixedly connected with a filter screen 3 , the right end of the fixed frame 2 is fixedly connected with the feed hopper 4, the left end of the fixed frame 2 is connected with the hopper 6 through bearing rotation, the outer wall of the support leg 1 is fixedly connected with the ash storage box 5, and the bottom of the filter screen 3 is provided with a transmission mechanism 7;

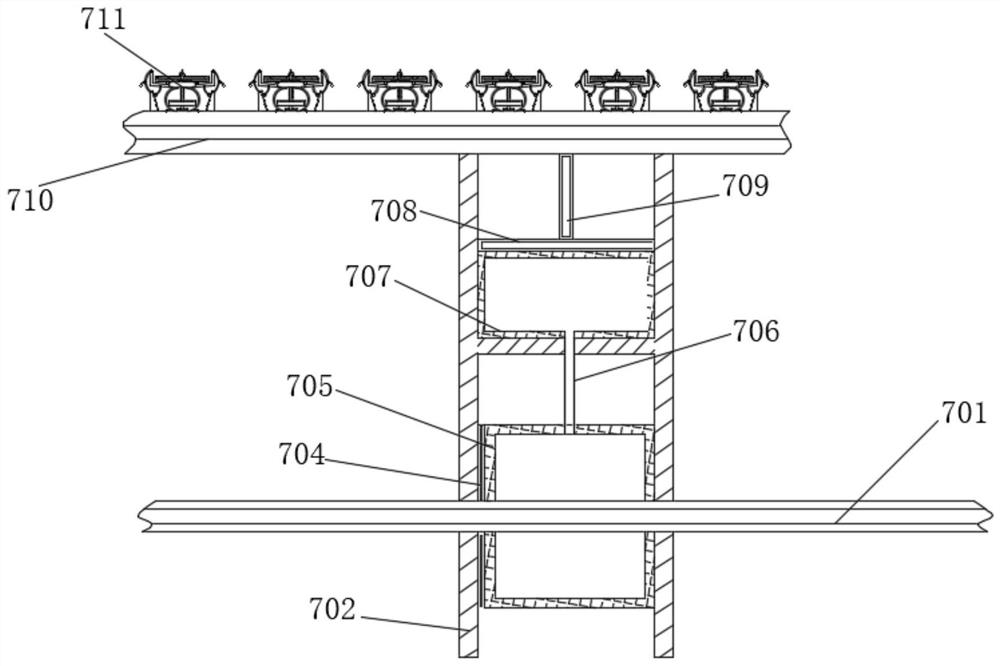

[0021] The transmission mechanism 7 includes a guide rod 701, a fixed shell 702, a sliding cylinder 703, a pressing plate 704, a first air bag 705, an air pipe 706, a second air bag 707, a top plate 708, a push rod 709, a support plate 710, a cleaning mechanism 711, and a guide rod 701 The left end of the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com