A kind of preparation technology of small particle size cerium carbonate

A preparation process, cerium carbonate technology, applied in the preparation/treatment of rare earth metal compounds, rare earth metal carbonates, etc., can solve problems that are not conducive to mass production of cerium carbonate, uneven heat transfer speed, crystal structure of cerium carbonate powder, Problems such as uneven shape, shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

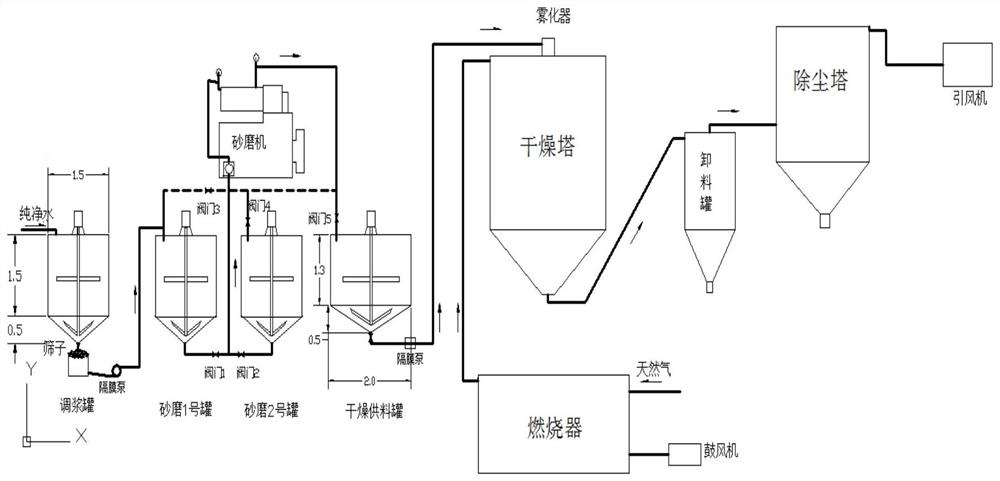

Method used

Image

Examples

Embodiment 1

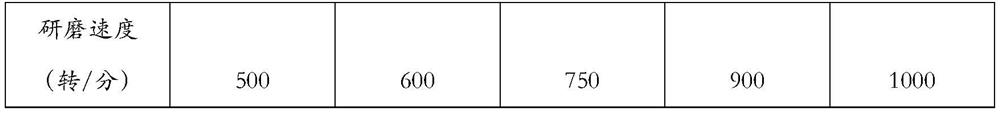

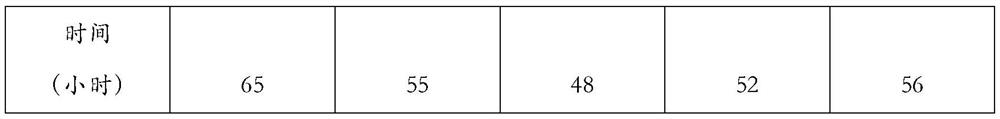

[0043] Add 1 ton of cerium carbonate into the batching tank, add 1.2 cubic meters of water in the batching tank, and stir at a constant speed of 600 rpm for 40 minutes to adjust the slurry. The adjusted cerium carbonate slurry is passed through a 60-mesh sieve and passed through a sand mill for 60 hours, and the sand mill is 750 rpm to uniformly screen the sanded slurry samples for quality inspection. D. 50 2.0 micron, add 5wt% polyethylene glycol, pH value is 8, stir at 750 rpm for 1 hour. The cerium carbonate slurry is spray-dried by an LPG high-speed centrifugal spray dryer, the drying temperature is 100°C, and the drying time is 3 hours to obtain a small particle size cerium carbonate particle size D 50 = 2.5 microns, total amount TREO = 62wt%, purity 99.9%, bulk density 0.6g / cm 3 .

Embodiment 2

[0045]Add 1 ton of cerium carbonate into the batching tank, add 1.5 cubic meters of water in the batching tank, and stir at a constant speed of 600 rpm for 30 minutes to adjust the slurry. The adjusted cerium carbonate slurry was passed through a 60-mesh sieve and passed through a sand mill for 48 hours, and the sand mill was 750 rpm to uniformly screen the sanded slurry samples for quality inspection. D. 50 1.8 micron, add 8wt% polyethylene glycol, pH value is 8, stir at 750 rpm for 2 hours. The cerium carbonate slurry is spray-dried by an LPG high-speed centrifugal spray dryer, the drying temperature is 80°C, and the drying time is 5 hours to obtain a small particle size cerium carbonate particle size D 50 = 2 microns, total amount TREO = 63wt%, purity 99.9%, bulk density 0.56g / cm 3 .

Embodiment 3

[0047] Add 1 ton of cerium carbonate into the batching tank, add 2 cubic meters of water in the batching tank, stir at a constant speed of 600 rpm for 30 minutes to adjust the slurry. The adjusted cerium carbonate slurry was passed through a 60-mesh sieve and passed through a sand mill for 48 hours, and the sand mill was 750 rpm to uniformly screen the sanded slurry samples for quality inspection. D. 50 2.0 μm, add 10% polyethylene glycol, pH value is 10, stir at 750 rpm for 2 hours. The cerium carbonate slurry is spray-dried by an LPG high-speed centrifugal spray dryer, the drying temperature is 80°C, and the drying time is 5 hours to obtain a small particle size cerium carbonate particle size D 50 = 2.1 microns, total amount TREO = 65wt%, purity 99.9%, bulk density 0.5g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com