Low-resistance and efficient fluidization demister device and demisting method thereof

A low-resistance, high-efficiency, mist eliminator technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc. Improve convenience, high demisting efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

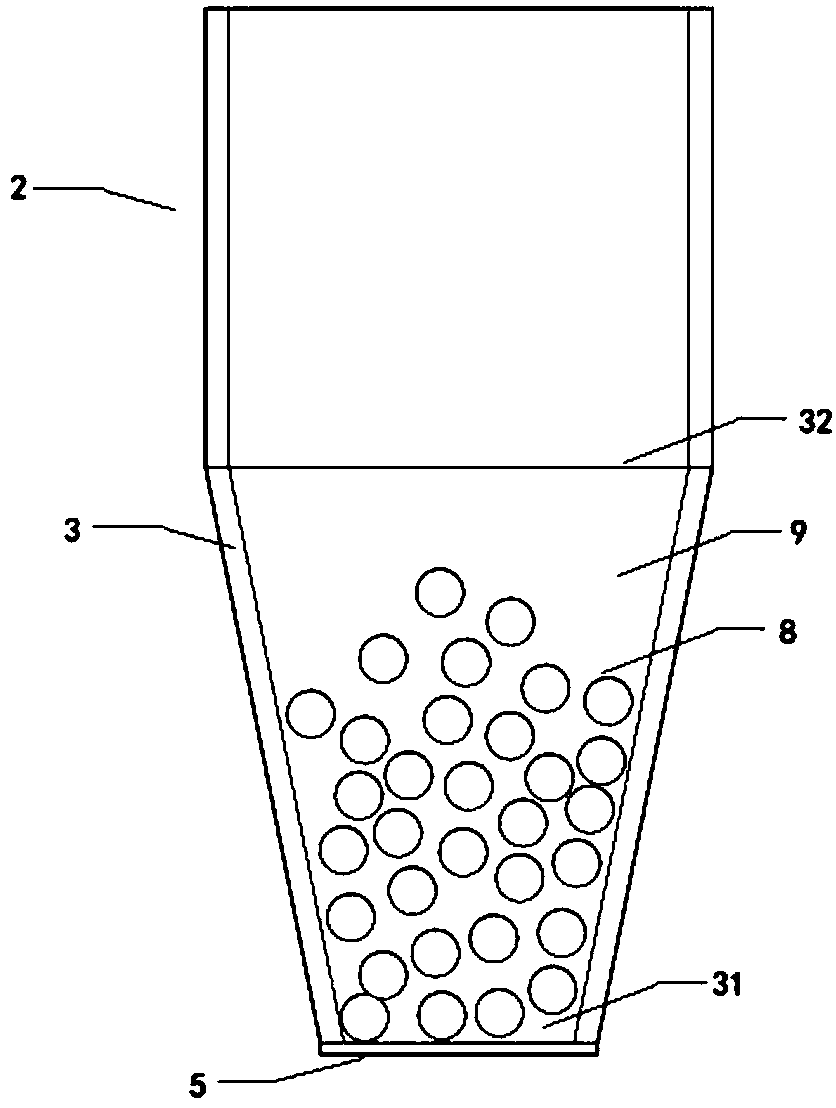

[0038] Example 1 as image 3 As shown, the present invention is a low-resistance and high-efficiency fluidized demister. The gas to be treated is introduced from one end of the vertically installed fluidized demister and discharged from the other end. The fluidized demister includes a variable-diameter pipe 3 , the sieve plate 5 arranged at the bottom of the variable diameter pipeline, the demister chamber 9 enclosed between the sieve plate and the variable diameter pipeline, and the demister medium 8 placed in the demist chamber, the variable diameter pipeline inlet 31 The area is smaller than that of the outlet 32. The inlet of the variable-diameter pipe faces downward for introducing the gas to be treated, and the outlet of the variable-diameter pipe upwards for discharging the purified gas. The gas to be treated contains atomized liquid and / or solid particles.

[0039] The outlet area at the upper end of the variable-diameter pipe is 1.1 to 8 times that of the inlet at the...

Embodiment 2

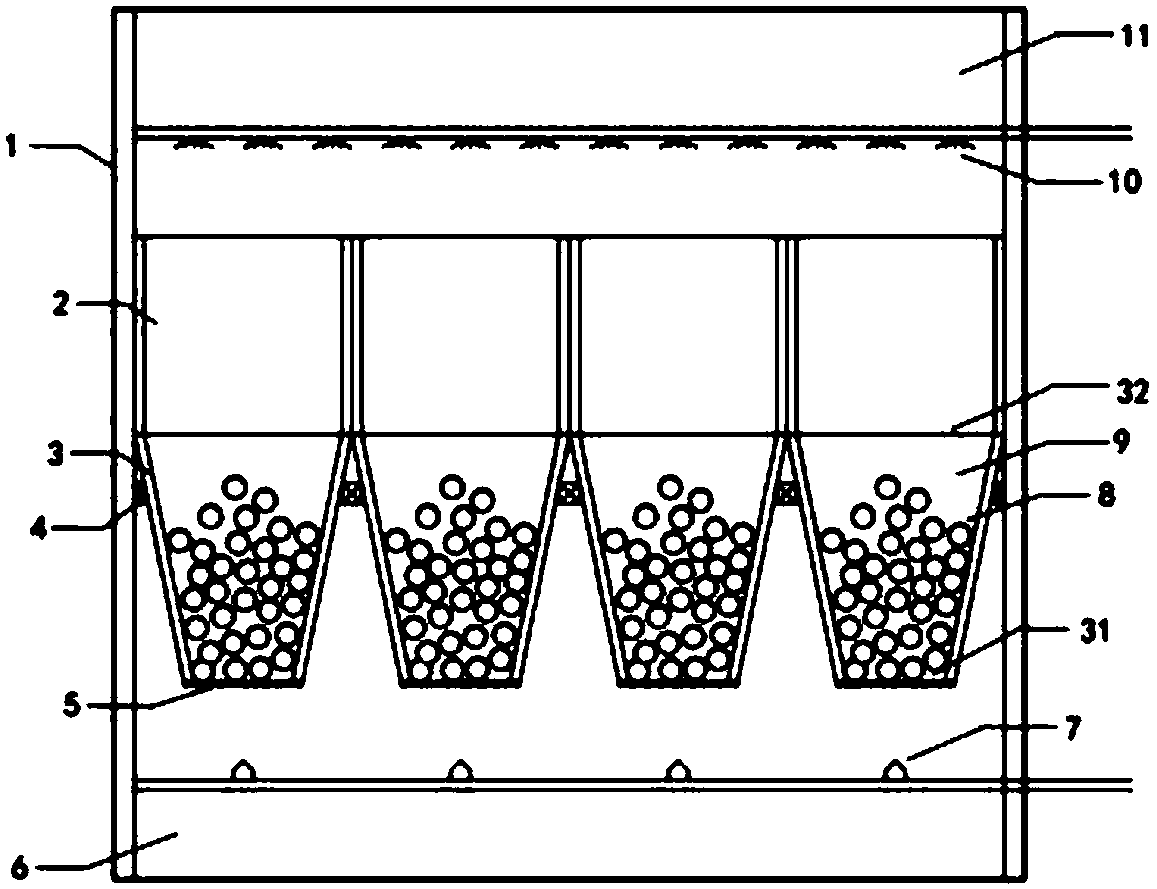

[0046] Example 2, such as figure 1 As shown in the low-resistance and high-efficiency demister of the fluidized demister, at least one of the fluidized demisters is installed in the hole of the flower plate 4 in the confined space 1, and the flower plate is a common one in the bag filter. The partitions with through holes of the same size are distributed, and the fluidized mist eliminator and the flower plate together divide the closed space into a clean air chamber 11 and a mist chamber 6, and the clean air chamber is located above the outlet of each fluidized mist eliminator. Extension cylinder 2, the height of the extension cylinder is greater than the distance that the demisting medium moves upward against gravity, and is used to prevent the demisting medium from running away. The cleaning nozzle 10 connected to the liquid pipe is arranged above the extension cylinder 2 for cleaning the demisting medium In the mist chamber, the gas nozzle 7 connected with the compressed ga...

Embodiment 3

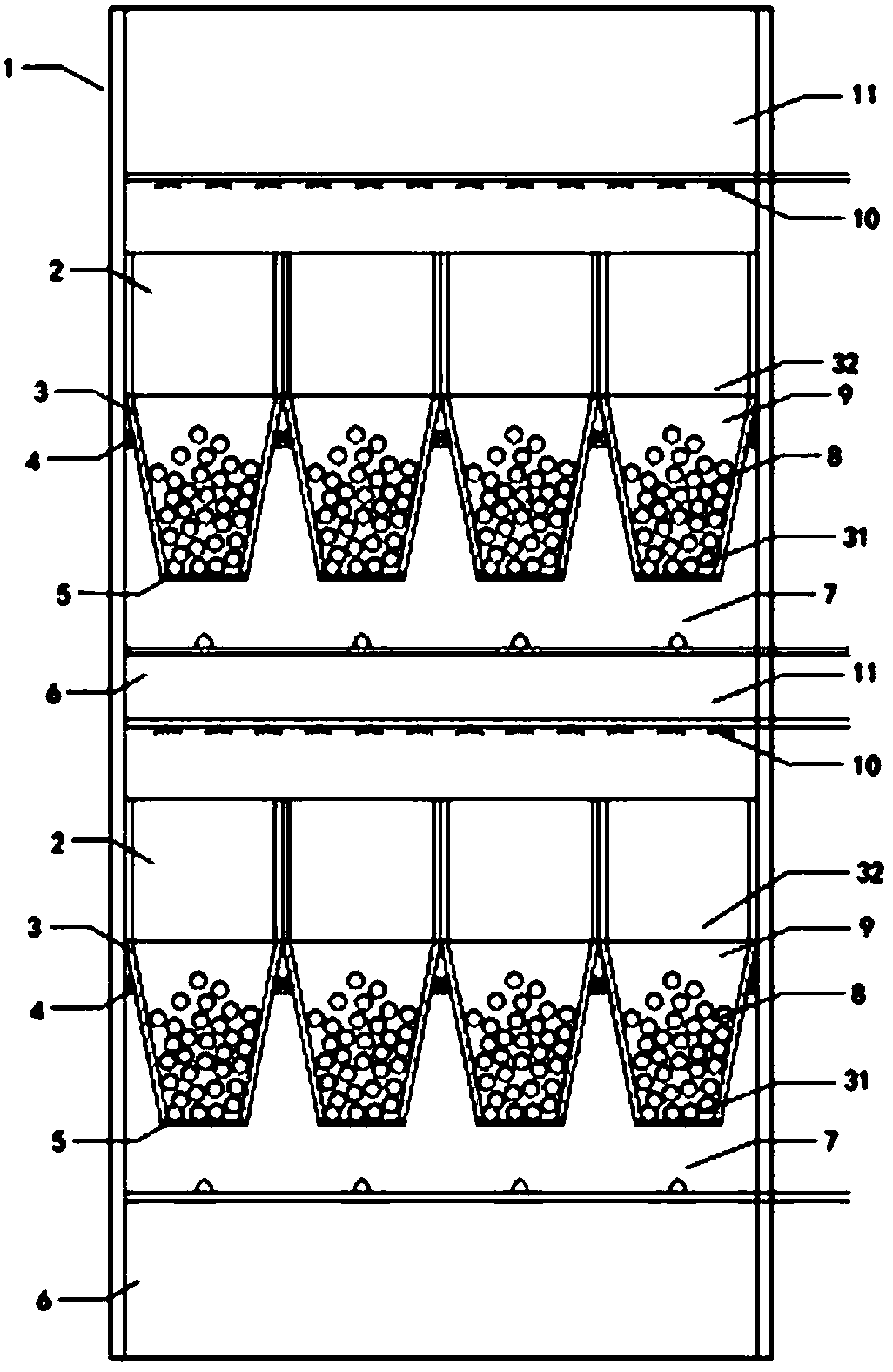

[0058] Example 3, such as figure 2 As shown in the low-resistance and high-efficiency fluidized mist eliminator, at least one of the fluidized mist eliminators is installed in the hole of the flower plate 4 in the enclosed space 1, and the fluidized mist eliminator and the flower plate together make the enclosed space It is divided into a clean air chamber 11 and a mist chamber 6. In the clean air chamber, an extension tube 2 is connected above the outlet of each fluidized demister, and a cleaning nozzle 10 connected to a liquid pipe is arranged above the extension tube 2 for cleaning and demistering. Fog medium: The gas nozzle 7 connected to the compressed gas pipe is arranged below the inlet of each fluidized mist eliminator in the mist chamber for pre-fluidizing the mist eliminator.

[0059] The aforementioned low-resistance and high-efficiency fluidized demister adopts multiple low-resistance and high-efficiency fluidized demisters for demisting in series, and can also us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com