Deep fog and dust removal apparatus

A technology of dust removal device and depth, applied in the direction of combination device, dispersed particle separation, chemical instrument and method, etc., can solve the problems of difficult application, easy blockage and difficult flushing of desulfurization system, so as to reduce the risk of corrosion and blockage, and reduce the amount of waste water. Small, low water consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

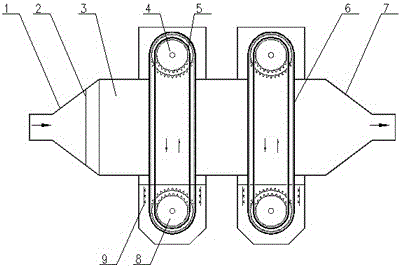

[0023] The deep demist and dust removal device includes: the intake smoke box 1, the rotary filter bed 6 that intercepts and absorbs the mist and smoke in the intake smoke box 1, the gas outlet smoke box 7 that receives the gas passing through the rotary filter bed 6, and is submerged and rotated One end of the filter bed 6 and clean the water cleaning assembly 9 of the rotary filter bed 6 .

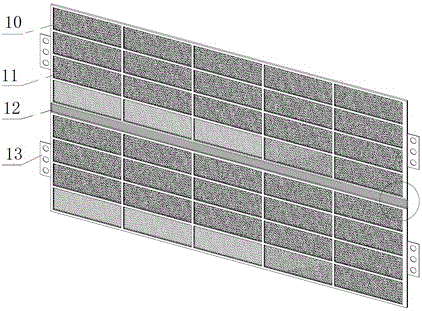

[0024] The rotary filter bed 6 consists of: a shell 3 connected to the intake smoke box 1 and the exhaust smoke box 7, a circulation transmission component placed in the shell 3, and a filter bed 6 wrapping the circulation transmission component. In order to let the flue gas evenly enter the rotary filter bed 6 and improve the filtration efficiency, an airflow uniform distribution plate 2 is provided between the intake smoke box 1 and the rotary fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com