Wave baffle type mist eliminator

A technology of mist eliminators and baffles, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc. Air volume is not the same and other problems, to achieve the effect of improving the overall effect, reducing the pressure drop, and improving the efficiency of demisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

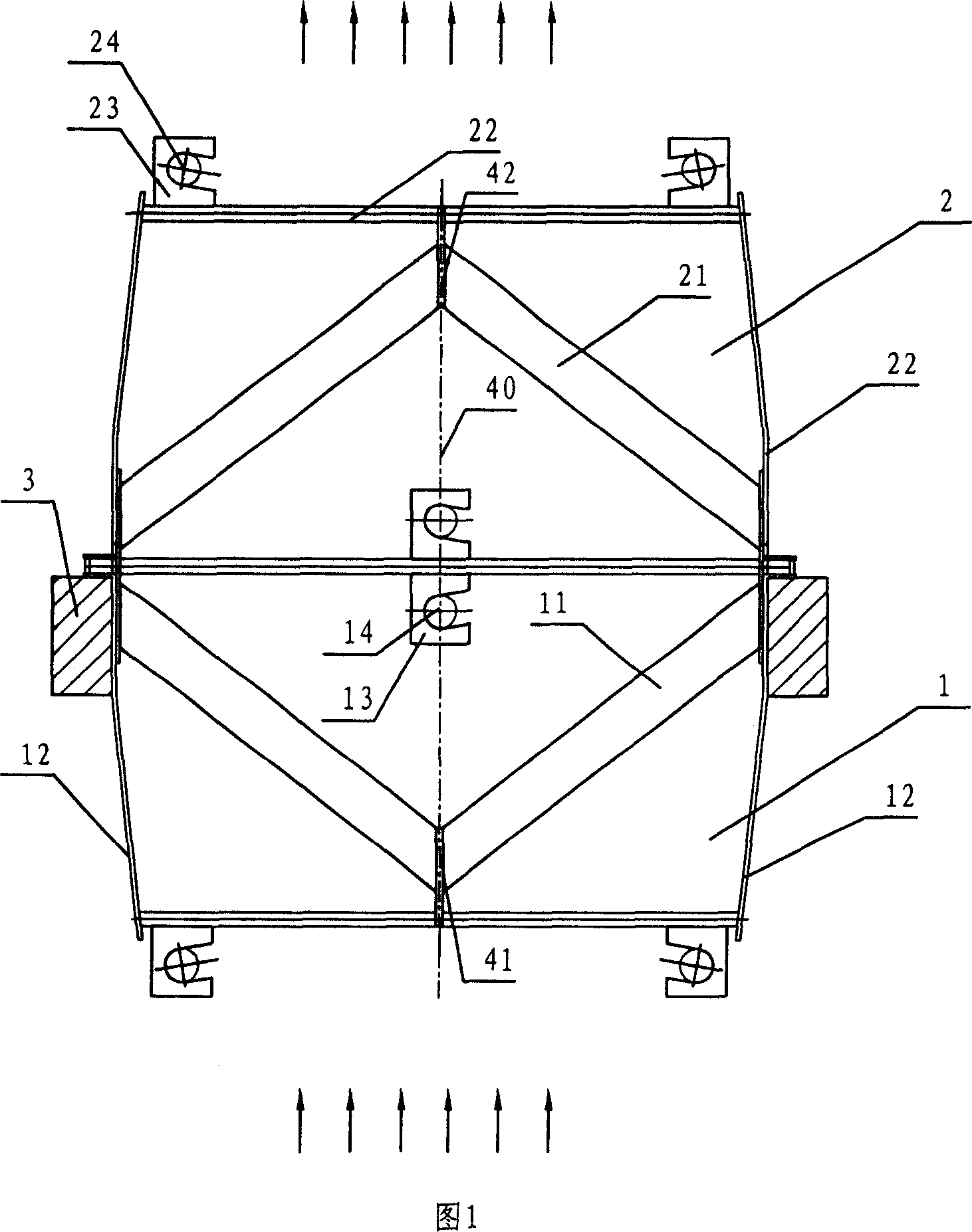

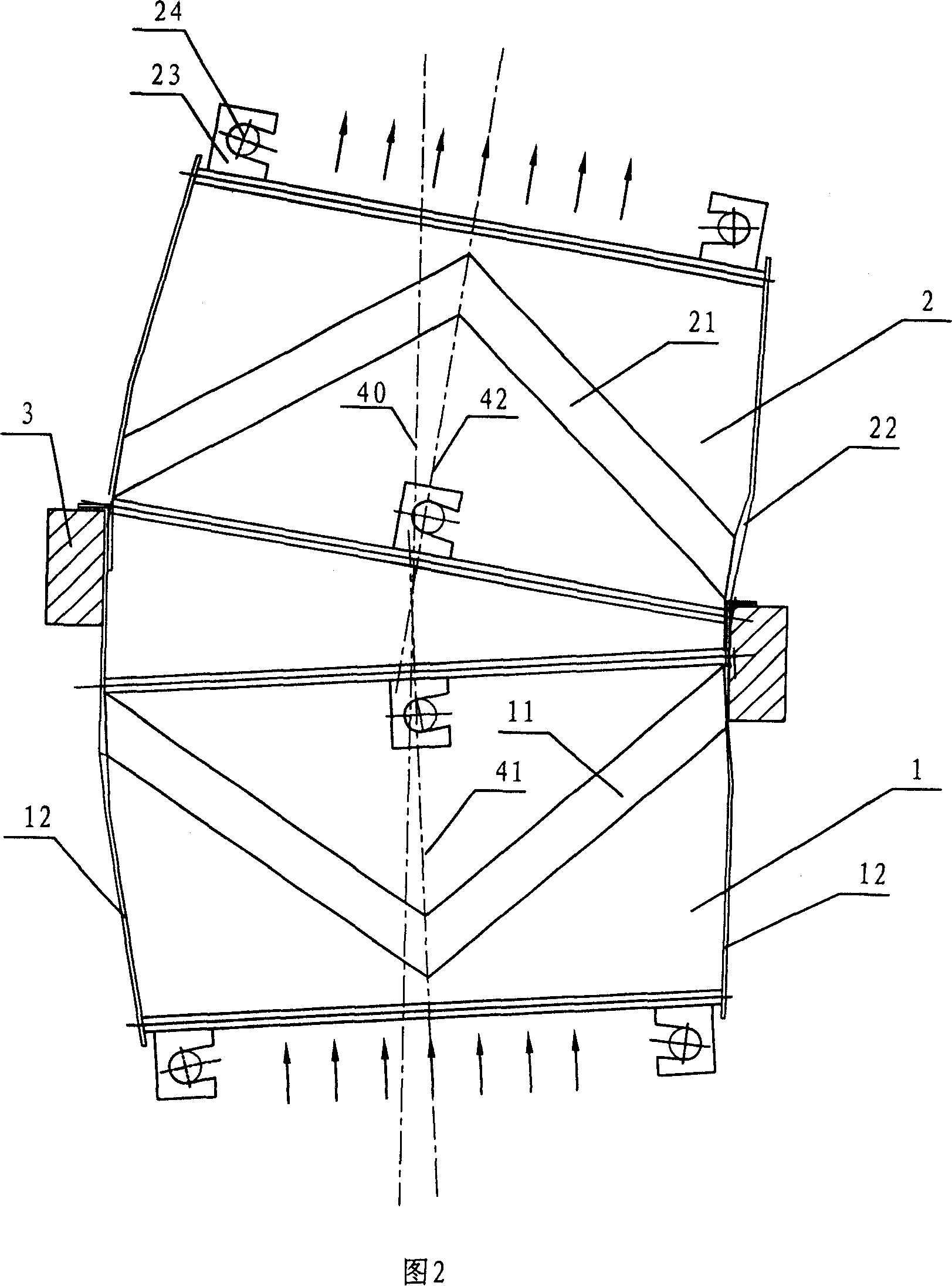

[0031] The relative arrangements of the first-stage mist eliminator assembly and the second-stage mist eliminator assembly can be varied, that is, the cross-sections of the two-stage mist eliminator assemblies can be arranged opposite to each other, or arranged identically to each other. Specifically, there are four typical arrangements as follows. Figure 1 shows the first embodiment of the present invention, that is, the V-shaped opening of the first-stage mist eliminator assembly 11 faces away from the flue gas flow. direction, the V-shaped opening of the section of the second-stage mist eliminator assembly 21 faces the direction of the flue gas flow; Figures 3, 4 and 5 respectively show several other layout forms.

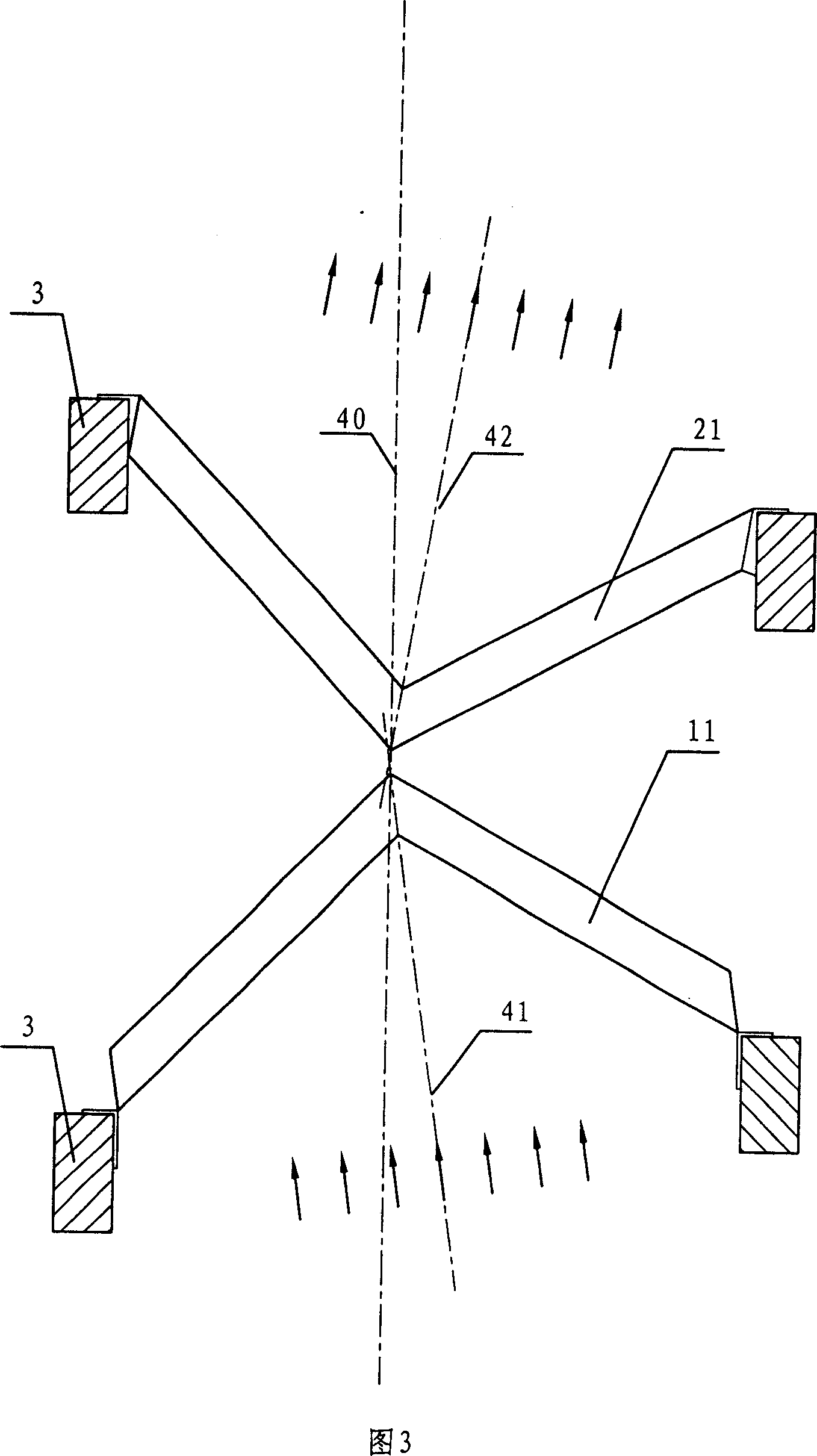

[0032] Fig. 3 is a partial enlarged view of a vertical section of a structure of a two-stage mist eliminator according to a second embodiment of the present invention. The feature of this arrangement is that the cross-section V-shaped opening of the first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com