Vacuum sputtering mixed light-cured resin packaging process for organic electronic device

An organic electronic device, photocurable resin technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of low packaging yield, multiple materials, poor durability and stability, etc., to improve the yield and packaging. performance, the effect of improving the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

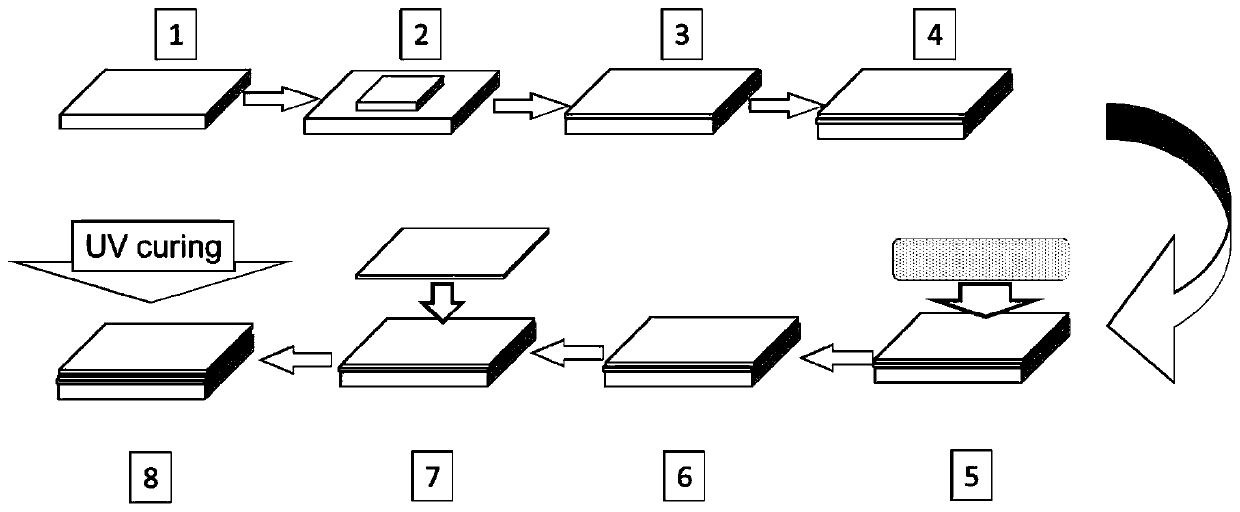

[0051] According to the design and process of the invention, the hybrid packaging structure and steps of vacuum sputtering and photocuring resin are as follows:

[0052] According to the design and process of the invention, its packaging scheme is very simple and practical, and the following steps are adopted:

[0053] In the first step, the ready glass or high-barrier flexible substrate is prepared, and the surface can be cleaned. And put it into a vacuum drying oven to remove more than adsorbed water vapor and oxygen. Putting glass or high-barrier flexible substrates into organic electronic device equipment completes the preparation of organic device OLEDs.

[0054] The third step is to prepare 100nm LiF on the prepared OLED device, or Al 2 o 3 Film protective layer.

[0055] The fourth step is to transfer the sample into a nitrogen glove box with water and oxygen less than 1ppm at 20°C. Apply a layer of UV curable resin by spin coating, hang coating process, about 5-50...

Embodiment 2

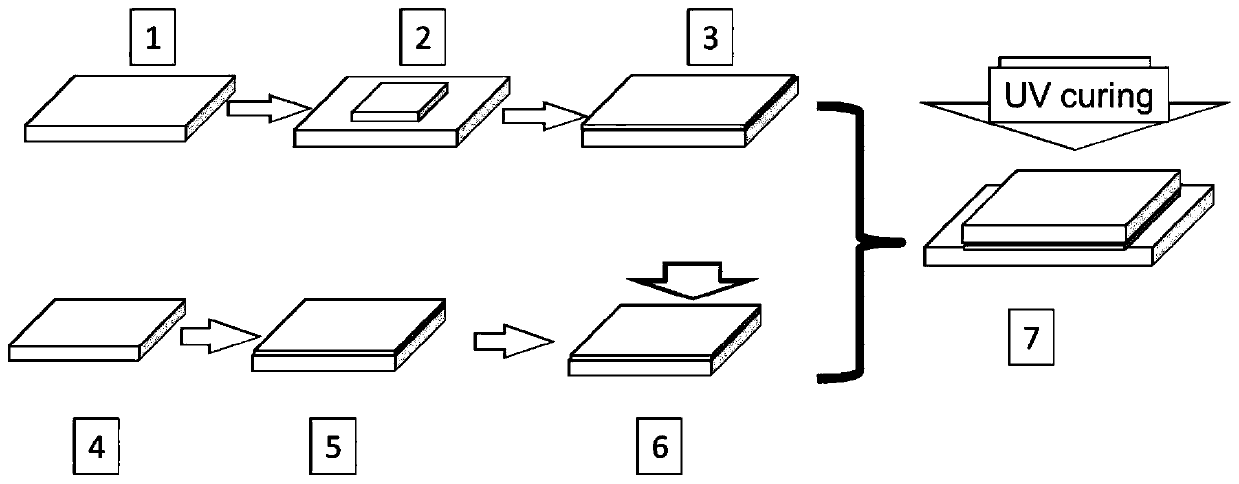

[0061] According to the design and process of the invention, the hybrid packaging structure and steps of vacuum sputtering and photocuring resin are as follows:

[0062] According to the design and process of the invention, its packaging scheme is very simple and practical, and the following steps are adopted:

[0063] In the first step, the ready glass or high-barrier flexible substrate is prepared, and the surface can be cleaned. And put it into a vacuum drying oven to remove more than adsorbed water vapor and oxygen. Putting glass or high-barrier flexible substrates into organic electronic device equipment completes the preparation of organic device OLEDs.

[0064] In the third step, 100nm LiF, Al 2 o 3 Film protective layer.

[0065] In the fourth step, at the same time as the first three steps, the upper packaging glass or film is introduced into a nitrogen glove box at 20°C, water, and oxygen less than 1ppm. Apply a layer of UV curable resin by spin coating, hang co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com